Top Impact Testing Machine in China. Like testing the barriers on a roller coaster, impact testing is one of the oldest methods used to study the behavioral characteristics of materials in science and engineering. It’s impact testing that reveals a material’s absolute strength and its various levels of toughness. This type of testing is especially important is safe designs for bridges, gears, or even armor that is meant to endure heavy impacts. Learning how materials react to being slammed with immense force enables designers to decide whether or not a certain material is reliable or safe to use.

In this article, I take a tour of impact testing and focus mainly on the Charpy and Izod tests, as they are the most popular around the world. Let’s zoom in on their roles, processes, and importance to construction, manufacturing, and beyond. In the end, you’ll have more information about the reliability and safety of common products found in any modern household.

What is an impact test and why is it Important?

An impact test evaluates a material’s capability of sustaining energy and resisting fracture when a shock force is applied to it. Such tests are important in determining a material’s performance endurance under actual real-life scenarios such as impacts, drops, and vibrations. Impact tests check how tough and durable a material is to ensure that it is safe and reliable for construction, automobiles, and manufacturing. Testing impact toughness helps to recognize some weaknesses within certain structures while choosing other materials that aid in the structural reliability in a delicate environment.

Defining the impact test and its Purpose

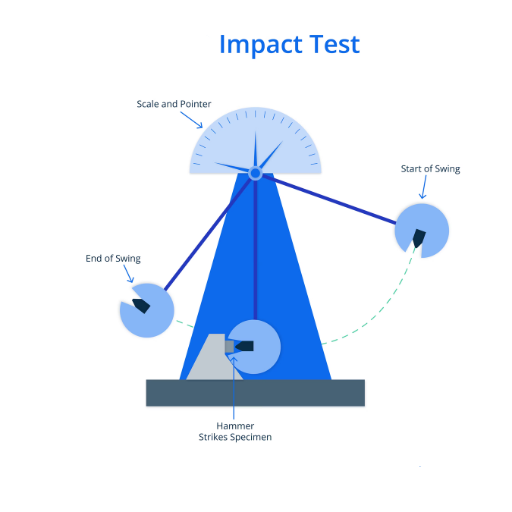

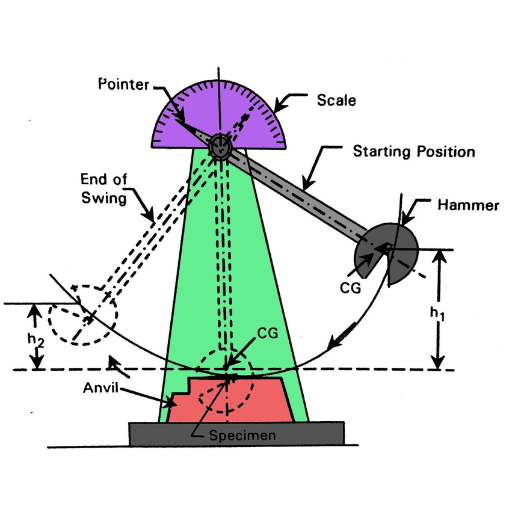

An impact test includes different standardized methods to gauge a material’s ability to withstand sudden forces. The most popular methods of testing are the Charpy impact test and the Izod impact test. While both methods assess energy expelled by the material when struck by a pendulum, they differ in sample orientation and positioning during the tests.

Charpy tests are still the preferred impact test due to their ease of use among professionals in metallurgical and civil engineering industries, especially in testing structural steel. The Joules (J) value obtained from the tests indicates a quantifiable figure for impact resistance. For instance, contemporary structural steels demonstrate an energy absorption capacity surpassing 150 J in the Charpy test, thereby endorsing their considerable toughness and dependability in challenging settings.

Moreover, the application of instrumented impact testing allows the recording of total force and time data during testing, a feature made possible by technological advancements. This method enhances material performance assessments as it provides a deeper understanding of stresses with greater detail, making accuracy more reliable. Such developments are fundamental as industries everywhere are challenged to design materials that weigh less yet require more strength and sustainability globally.

Performing these examinations not only assesses basic material performance but also aid significantly in the designing steps of product safety. In automotive collision testing, particularly impact resistance data, is used to enhance the sturdiness of vehicle frames and protect passengers. This kind of testing ensures that materials and the end products are adequately tested so that they will fulfill aggressive requirements, lowering the risks of disastrous failures when implemented in real-life scenarios.

How impact testing is used in Material Science

Impact testing is important for any material science work involving forces that are both sudden and extreme. Impact testing allows researchers to study the toughness, strength, and energy absorption of materials by subjecting them to controlled impact forces. This helps in developing safer and more reliable products.

One of the most used methods is the Charpy impact test. Every material has a certain number of fractures it can endure, or a fracture threshold. The amount of energy absorbed during this fracture adds to the material’s toughness. This test greatly aids in determining brittle versus ductile behavior and provides valuable information for the automotive and aerospace industries. For instance, Argonne National Laboratory does Charpy testing for steel to find out if it can be used under extremely harsh conditions without causing catastrophic failure.

Recent innovations in impact testing include the addition of high-speed cameras and digital data acquisition systems to the setup, which allows researchers to capture real-time deformation data with extreme precision. For example, some of these systems captured data that revealed that advanced composites like carbon fiber reinforced polymers absorb more energy than traditional materials, which is significant for next-generation safety applications.

This type of testing is essential for breaking new ground. The better performing alloys and composites that are lighter and more durable require the impact testing engineering process. It can even help with things like combating climate change; materials analyzed for their strength in renewable energy systems, such as wind turbine blades, ensure reliable operation during storms.

The impact testing of materials integrates the best of modern technology with classical methods. As a result, it continues to be a foundation and pillar of progress in material science and works toward balance across many industries – safety, innovation, and efficiency.

Key impact test requirements for Materials

Energy Absorption Capacity

Materials are required to sustain high amounts of energy due to impact. This guarantees that they can survive sudden loads or shocks without breaking. This is frequently measured using the Charpy or Izod impact test, which yields results in Joules (J) or Foot-pounds (ft-lb). For example, in automotive applications, modern composite materials are calculated to have an impact energy absorption ranging from 20-50 J, depending on the thickness and design.

Temperature Sensitivity

The performance of any material at difference temperatures is crucial. Material can become brittle at low temperatures and lose its strength at higher heats. For example, metals such as steel tend to lose their toughness when subjected to sub-zero temperatures, or cryogenic impact testing which is relevant for aerospace and energy industries.

Fracture Toughness

Impact resistance to crack advancement is required to maintain a structure’s level of integrity. Materials designed for advanced high-risk segments, such as in aviation, have to surpass base threshold levels of fracture toughness – values of engineered alloys like titanium are around 50-100 ksi√in (grade dependent).

Strain Rate Sensitivity

Altering the pace at which a material is ruptured or deformed during an impact is said to change its response. Testing for strain rate sensitivity pattern assists in understanding how a material will behave while undergoing dynamic loading, for instance in polymers, there may be evidences showing marked differences in toughness traits where there is quick or gradual loading or unloading.

Fatigue and Dynamic Load Testing

The contemporary industry expectation is that a material is capable of withstanding repeated impacts or undergo high-frequency physical shocks sustained over it without any mechanical failure in the long run. Testing fatigue under dynamic loading assures circadian rhythm durability of the material which entails cycling the component of interest into to several millions of times to reflect the actual conditions.

Environmental Resistance

Equally, fundamental but less rated is the resistance a material poses to environmental factors like moisture, UV radiation or chemical corrosion. As an example, impact testing for marine-grade materials tends to include some form of simulated water ingress or saline conditions to assess the long term resilience to water.

Standardized Testing Protocols

To ensure reproducibility and continutity in utility and safety for all applications, materials need to comply with International standards who’s the body of the national standards dominates the American Society of Testing Material, ISO and European Norms, then internationally standardized Federations. Commonly embraced standards for impact testing are ASTM D256 for plastics and ASTM E23 for metal.

Industries can guarantee materials are safe, dependable, and capable of meeting contemporary engineering challenges by following these requirements alongside advanced testing methodologies.

Exploring Different Types of Impact Testing

Impact testing analyzes the possible challenges presented in sudden force scenarios for materials, such as shocks, and ensures that the material performs reliably under stress or force. The most pertinent types of impact testing comprise:

Charpy impact test: Most widely used for metals, the Charpy test tries to determine the amount of energy that a material can absorb while undergoing fracture. An easy fracture notched sample is struck with a pendulum and the energy absorbed during the break is quantified.

Izod impact test: Although similar to the Charpy one, the Izod test orthogonally sets and positions the notched sample. It strives to assess how tough or brittle a material is.

Drop weight test: The test describes the level of resistance a material offers against fractures when affected by dynamic conditions using a rigid weight set atop a specific height. Typically, the target materials are metals and polymers.

The performance aspect of the materials which undergo these tests is crucial especially when dealing with safety and durability in the fields of construction or aerospace.

An Overview of types of impact Testing

Impact testing is Type of evaluational test that allows engineers and material scientists to understand the effects of stress, shock or sudden forces on an object. Impact testing identifies data followed by a toughener, handle, deformed or fragile material which will be appropriate for use. Here we discuss few commonly used information metrics (impact tests) and include new information based on new constructions improvements.

Charpy Impact Test: It is one of the oldest has not been bypassed for evaluating the fracture energy absorption by materials charpy impact test. Notch specimens are set on pendulum hammer strikes and energy is calculated for exserved. A lot of development of high-speed recording technology has also been done, including thermometric easy energy analysis measurement, focused, clear examination of material properties with temperature.

Izod Impact Test: Like the Charpy test, the pendulum setup is used to assess the impact resistance of materials, presided by an Izod impact test. The only difference is that the speciman is set stationary and placed vertical. They are the current standard to which ever remaining instruments having the capability to measure physical parameters are subjected for proper testing.

Impact tests have their application in several industries, including testing renewable energy materials and components, aerospace engineering systems, and autonomous vehicles impact simulation. Applying Impact Testing in Materials Research shows how impact testing plays an important role in evaluating materials, while also serving as a research-based impact simulation.

Drop Weight Test: Common in evaluating materials like steel and polymers, the drop weight test has a weighted striker dropped on a specimen from a predetermined height. Automation breakthroughs now pair software with drop weight test machines to monitor fracture start and growth during testing, ensuring precision.

Dynamic Shear Impact Test: This is mostly for use in automotive and aerospace sectors. The test determines the materials exhibiting to shearing force under dynamic forces.

Strain mapping has improved through the use of modern sensors during these tests, which capture stress-strain loadings along the fracture face.

In the aerospace industry, for instance, more than 60% of the material evaluation undergoes the use of Charpy or drop weight tests for endurance and fatigue testing coupled with damage tolerance assessments.

These testing procedures verify that items perform satisfactorily in safety-critical settings. Because of the growing role that digital and automated systems perform in the industry, impact testing is becoming easier for sophisticated R&D activities and more precise at the same time.

Understanding the Charpy impact test

The Charpy impact test, as it is more technically known, is a high-strain energy impact test that quantifies the absorbed energy of an impact-fractured specimen. This energy indicates the degree of toughness a given test material possesses, which is a very important measure of the material’s behavior when subjected to severe impact or strain. In this test, a notched specimen is impacted by a pendulum-type hammer that transfers energy to the material until it fractures. The material is monitored and the results documented in units of energy Joules (J) depending upon the tendency of the material to break or be Ductile.

The recent developments in the field of tools and materials have increased accuracy using the Charpy test. For instance, modern digital displays capture the amount of energy used and the energy after the process (after analyzing the fracture surfaces) instantaneously, which guarantees a higher level of precision. Research has shown that materials that can withstand impacts very well tend to give values lower than 50 J at room temperature, while brittle materials tend to give values lower than 10 J. This test is usually performed in aerospace and automotive industries on the fuselage panels, drive shafts, and structural reinforcements which have to endure a lot of stress to see whether they are reliable or not.

International standards such as ASTM E23 and ISO 148-1 govern the procedures for Charpy impact testing for uniformity cross checking marking their value across laboratories and applications. Besides, there is a growing implementation of sophisticated simulations and high-speed imaging in conjunction with the Charpy test to evaluate microstructural influences and crack propagation more effectively. These advancements broaden the range of the test and also provide a deeper insight into the understanding of materials behavior in demanding settings.

Insights into Izod Impact Test Methodology

The Izod impact test is a critical method for measuring the capacity of a material to withstand impact or sudden force. It evaluates the energy loss during a fracture, measuring the material’s toughness and its appropriateness for different applications. Traditionally, the specimen is placed vertically in a clamp, and the notch is struck on the specimen by a pendulum hammer to break it. The energy that is consumed in this activity is measured in joules which indicates the impact strength of the specimen.

Izod testing methodology has recently been enhanced with the addition of high-speed sensors which provide accurate information regarding fracture initiation and propagation detail. These sensors create better measurement accuracy which helps in the material behavior analysis during dynamic loading. Moreover, material test results are now supplemented with computer simulation tools that enable the prediction of material behavior in extreme environments such as low-temperature and high-pressure conditions.

As highlighted in a recent case study, thermoplastic polymers, particularly polycarbonate, exhibited a markedly higher energy absorption compared to brittle materials, accentuating their effectiveness in applications where impacts are central such as in automotive bumpers and protective gear. Furthermore, Iozo’s impact testing data is pertinent for the construction and aerospace industries, which require information regarding materials with high durability for safety purposes.

Integrating classic methods with current technology enables the Izod impact test to develop modern techniques for accomplishing tasks that require meticulous examination of materials. Such advances allow researchers and engineers to select suitable materials for their projects with enhanced certainty.

How the Charpy Impact Test is Conducted

In the Charpy impact test, a notched specimen is placed horizontally on supports within a testing machine. The machine has a pendulum hammer that is released to hit the specimen at the notch, so it fractures and breaks. The energy absorbed in the process of breakage is measured and noted down, which indicates the strength of the material in question. This affects the determination of a material`s impact stress when the material is subjected to sudden shocks and impacts.

Step-by-Step test procedure for Charpy

Sample Preparation

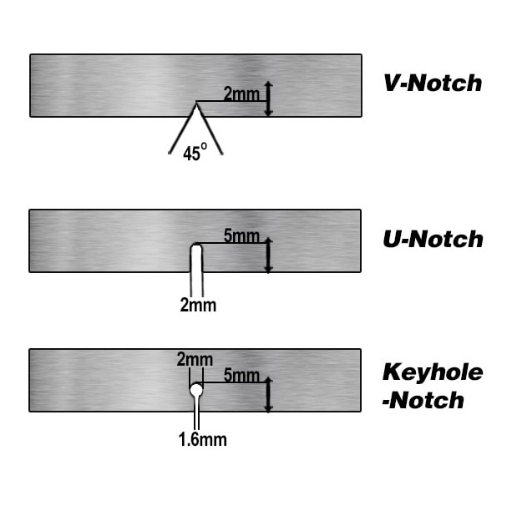

Make sure the specimen meets the standard requirements as indicated in ASTM E23 or ISO 148. Usually, the specimen is rectangular with a central notch (V-notch or U-notch) designed to concentrate stress.

Specimens are usually 10 mm x 10 mm x 55 mm with a 2 mm notch depth, which facilitates precision.

Calibrating the Testing Machine

Check if the Charpy impact testing machine is in calibration and meets the latest verification dates. It is important to check that the pendulum hammer, supports, and scale are accurately functioning.

Check also that the machine’s energy range is adequate for the materials being tested, usually from 0 to 300 Joules, depending on the machine model and the requirements of the tests being conducted.

Setting the Specimen

Place the specimen on the supports in a horizontal position and slip the notch facing the pendulum. The notch’s position guarantees that it is parallel to the strike direction.

Place the specimen on the supports without restricting movement during the test.

Pendulum Release

The pendulum hammer should be raised to the starting position, which has to be consistent for the specimen’s potential energy to be reachable during the impact.

Release the pendulum so that it hits the specimen at the notch, fracturing it into two or more pieces.

Recording the Results

Quantify in Joules (J) the energy consumed during the fracture. The machine automatically records the energy pendulum’s energy drop, which is due to energy transfer to the specimen. This may be done digitally or mechanically.

Optional high-speed cameras or sensors can be used to record the fracture for more sophisticated material assessments.

Analyzing the Data

Evaluate the absorbed energy results. Compare using specified material toughness and brittleness standards.

Higher energy absorption is indicative of toughness and the ductile nature of the material. Lower energy absorption suggests brittleness.

Environmental Condition Considerations

For materials under extreme conditions, such as subzero temperatures, repeat the test in a controlled temperature chamber to assess performance variation. Many metals exhibit vastly different properties in colder environments.

This approach, commonly applied in aerospace, construction, and automotive engineering, produces dependable results concerning material toughness. The Charpy impact test remains indispensable in material science, providing vital insights to engineers for informed decisions in selecting and applying materials.

Role of the Charpy V-notch in Testing

The Charpy V-notch is widely recognized for its added accuracy in impact testing because it precisely notches the specimen being tested. This notch serves as a focal point for stress that is expected to be present in a material during operation, simulating realistic material defects like gaps or fractures. Its design guarantees uniform stress distribution around the point of impact, providing consistent and reproducible results regarding a specimen’s notch sensitivity and toughness.

Underappreciated, this test is tailored to assess the behavior of the material when there is an unforeseen application of force, which is critical where resistance to impact is important. Take the aerospace industry as an example: materials used in this industry are subjected to immense loads and must maintain their shape and structure without breaking. There is some evidence to suggest that the toughest materials, tested using the Charpy method, are better able to withstand these conditions.

The use of digital devices for capturing testing results has become commonplace, enabling precise measurements of energy absorption in joules. For example, as a rule, steel grades with higher impact toughness, like S355 or A516, tend to demonstrate energy absorption values exceeding 50J when the required temperature conditions are room temperature. Furthermore, by varying laboratory temperature conditions, engineers determine the ductile-to-brittle transition temperature of the material. This is important for the design of Arctic pipelines because sudden structural failures at very low temperatures can be disastrous.

This test, used alongside sophisticated data capture and monitoring systems, is an essential component of material selection and monitoring systems aimed at making complex industrial operations safer and more reliable while improving durability.

Analyzing impact test data and Results

As I’ve noted earlier, Impact test data is ever important for measuring a material’s response to cryogenic and severe loading conditions. While studying this data, absorbed energy, ductility, and even fracture surface features are analyzed. Impact tests such as Charpy V-notch tests are commonly accompanied by a graph depicting the transition ductile-brittle region as a function of temperature; these materials are usually described as a metallurgical “soup”. It is appreciated that materials with high impact energies in these tests tend to have more fractures in these tests, more impact they prove to possess higher toughness fractures in low temperature regions.

However, as some of the newest reports to Industrial test companies point out, the most recent changes in machinery technology make use of precision sensors and data acquisition systems, with impact testing having showcased remarkable effectiveness in modernizing complexity throughput alongside improving accuracy. These systems are now capable of capturing Impact Testing data of much finer resolutions which enable thermographs to better define the transition temperatures, snapshot rate tomogram mode. Sublots of material/actions defined may be noticed enhanced analytics coming from these data to simply designed for space travel and automotive.

One of the most notable findings from recent research is the assessment of microstructural features in conjunction with impact tests. Engineers are utilizing high-speed video imaging and microscopic inspection after the tests to gain insights into the pathways of crack propagation. These details are critical for forecasting performance over time—particularly in harsh conditions—by not just assessing strength, but the enduring capability of materials in changing conditions.

Incorporating these new practices helps create accurate estimates regarding material properties and drastically lowers the chances of structural failures for important applications.

Significance of Charpy V-Notch Test in Material Evaluation

The Charpy V-Notch test is important when measuring the toughness of materials in terms of their ability to absorb energy under impact because the test reveals critical information regarding the material in question under sudden loading circumstances. The material is tested to reveal whether it is brittle or ductile. The results provide information that is relevant for deciding whether a certain material is suitable or applicable for construction and industrial design structures that need to be impact-resistant, safe, and reliable.

Why the V-Notch Test is Critical

The Charpy V-Notch test is significant in modern material science and engineering because it accurately describes the measurement of a material’s impact resistance. As per recent studies, the V-notch shape guarantees that the stresses are bound at a specific point, thus enabling accurate quantification of energy utilized during fracture. This data holds considerable importance in the aerospace, automotive, and construction domains where materials face severe and unanticipated forces.

Recently, more focus has been put on the impact of Charpy testing about defining transition temperatures, which are the points a material shifts from ductile to brittle behavior. For instance, steel used in bridge construction has to undergo a rigorous testing process to ensure that there is a lower transition temperature to enable safe use during extreme cold. Data from refiners is clear; materials utilized in critical infrastructure, like pipelines and pressure vessels, undergo consistent volumetric testing at different temperature ranges to check if they endure stringent safety and performance benchmarks.

In addition, these testing standards are relied on by global standards bodies such as ASTM and ISO. Analysis of data gathered through these tests has been proved essential not only in the designing of more efficient and safe engineering systems, but also in alleviating engineering risks related with structural failure, saving countless lives and financial resources.

Comparing charpy and izod Specimen Configurations

Both processes assess the impact strength of materials through the Charpy and Izod tests, but differences arise in specimen configuration, specimen orientation, and procedure. It is important to understand these differences to apply the right test for the specific industrial purposes.

Notch and Specimen Orientation

Charpy Test: The specimen is placed in horizontal position with the notch away from the striker side. Notches on the specimen can be U-shaped or V-shaped depending on the material being used or standards of the test. 55mm in length, the Charpy specimen notched rectangular bar has a 10mm x 10mm cross section.

Izod Test: The specimen is fixed in a vertical position, and the notch is facing the striker side. Notches for the Izod test are also notched at the same angle as the Charpy test. However, Izod specimens have a standard overall length of about 75mm and cross sectional area of 10mm x 10mm in the notch area.

Impact Direction

Charpy test: The hammer in a Charpy test strikes the midpoint of the specimen, causing a bending force. Transverse load resistance is then evaluated, such as the ability to withstand fracturing propagation in a material.

Izod Test: A hammer will hit the vertically-clamped specimen at the location opposite to the notch, which tends to be the most impact resistant as far as the longitudinal axis force is concerned.

Energy Absorption Measurement

Both tests aim to capture the fracture energy, but different orientations and configurations yield differing results. The Charpy test typically gives results in joules (J) or foot pounds (ft-lb). Izod, however, uses the same units but pays more attention to material behavior under sharp impact conditions.

Covered Here

Applications

Charpy has found a place in constructed pipelines and many other industries that benefit from understanding material behavior under dynamic loads.

Izod tends to be used more for plastics and polymers where the impact resistance under control is assessed as a measure of toughness of material.

Key Data and Standards

Charpy, or Isoed, tests are rigidly defined to ensure accuracy within the current standards (eg. ASTM E23 and ISO 148 for Charpy, and ASTM D256 for Isoed). The most recent research emphasizes Charpy tests are better suited for larger structures ocularly and logically, while Izod tests are most effective for small molded materials, thereby creating a balance for material evaluation.

Through these methods, engineers and researchers are able to combine results with unique environments and make decisions tailored to the material and it’s location.

Evaluating the toughness of a material through Testing

Material toughness is one of the main properties that indicates how well a material can sustain and dissipate stress energy before fracturing. It is a dynamic field that is driven by the need for greater accuracy and deeper insights into how testing is done.

Charpy Impact Test Details:

The Charpy impact test is one of the most popular ways of checking toughness for larger structural materials. In this test, a notched specimen is struck with a pendulum hammer and the amount of energy absorbed after fracturing is determined. Recent data underscores the fact that the average energy absorbed by structural steel is between 100 Joules and 300 Joules, depending on the grade, with structural steels showing much more toughness even at sub-zero temperatures, having higher grades.

Izod Impact Test Details:

The Izod test is also conducted similarly except that the pendulum impact test is done on a specimen held vertically and fixed at the bottom. Focusing on polymer materials, current standards indicate that impact strength of polycarbonate is around 900 J/m, exhibiting extraordinary toughness for demanding applications, while standard PVC is rated about 50 J/m, indicating moderate energy absorbing capability.

Shifts In The Analyzation Procedures:

New technologies, for example, high-speed cameras and digital image correlation (DIC), are often used in sucle for impact tests. These devices allow visualization in real time of fracture mechanics and stress distribution, assisting researchers to better understand the behavior of materials in their functions. Various industries, especially automotive and aerospace, use these methods to check the reliability and safety of materials in their critical working environments.

The combination of the old and the new assesses material toughness more sophisticated, exact, and reliable, thus enabling the engineers to design durable and resilient structures.

The Role of Impact Testing Machine in Material Testing

When it comes to testing a material’s ability to endure impact forces, impact testing machines offer unparalleled support value. By testing materials, these machines gauge the reliability, safety, and credibility of the materials in withstanding the shocks. Such profound data provided through impact testing machines enables progressive constructions, the automotive industry, and the aerospace industry. Devices engineered through the aid of these machines do not fail in critical environments where assessing materials under stress is crucial, preventing a downside impact in these high-performance industries.

Components of an impact testing machine

An impact resistance testing machine comprises several elements that interact and function jointly to measure the impact resistance of a particular material. Elucidated below are the constituents of the machine:

Frame Structure

The burden frame acts as the main support structure that encloses the whole system. Generally, this part of the machine is made out of high-strength materials such as steel to withstand the large forces exerted during the tests. It guarantees constancy as well as accuracy of the measurements.

Hammer

This part creates an impact to the specimen and can, therefore, be termed as a strike hammer with pendulum movement. The pendulum has weight and shape according to the testing standards, which is ASTM or ISO. Adjustments can be made to the speed, energy and angle of the pendulum according to test requirements.

Anvil

This component securely grips the specimen In order to not allow it to move from the desired position during testing. The designed clamp prevents the specimen from rotating about the tool axis in the case of impact. It may vary in design depending on the shape and size of the specimen being tested.

Energy scale or Digital Display

The impact energy can be viewed on the analog scale or through the digital interface. The latest impact testing devices are equipped with advanced resolution and clear, user-friendly interfaces, which make it easy for a user to read through the data displayed. The measure of energy absorbed by the specimen is provided in joules.

Release Mechanism

The release mechanism enables the pendulum to be striked in a particular motion while providing consistent energy application. This contributes to reliable outcomes. This can be operated manually or automated in some advanced machines.

Safety Enclosure

Most machines include a safety enclosure that prevents the operator from being exposed to debris or unwanted movement during the test. This is especially vital for high-speed or high-energy testing scenarios.

Instrumentation and Sensors

Integrated sensors used for real time tracking of force, velocity, and displacement are available in advanced impact monitoring machines. These sensors undergo connection with data gathering systems to provide thorough analysis of material behavior.

Control System

Newer models of impact testers incorporate electronic or software control systems. Such systems enable the user to change parameters such as the required impact velocity, test angle, and temperature, if thermal testing is involved.

Data from Modern Conservation Systems

Today’s impact testing machines incorporate modern technology for improved precision and range of efficiency. For example, several devices utilize fast fracture capture employing high-speed cameras. Post-test examination is automated; modern software provides in-depth analysis alongside the relevant charts and graphs for energy absorption, fracture mechanism, stress-strain characteristics, and other nuanced parameters. Small-scale machines have energy capacities ranging from 5 Joules while industrial-grade test machines typically exceed 750 Joules. Moreover, modern machines also observe international standards such as ASTM E23 for the Charpy and Izod tests, ensuring that datasets are dependable nationally and internationally.

How a pendulum impact test is performed

To determine a given material’s toughness, a pendulum impact test can be done which analyzes the energy used in fracturing the material. The procedure starts with mounting the specimen onto the machine, often at a designed notch to simplify alignment. Notches serve as fundamental features because they aid in stress concentration as well as providing reliable fracture surfaces to sustain consistent results. For Charpy tests, the specimen is positioned horizontally, with the notch facing the pendulum, while in Izod tests, the specimen is placed vertically.

A specific height is set for the pendulum to be lifted, and this corresponds to the potential energy that can be computed using the height and mass of the pendulum arm. Subsequently, the pendulum is released and allowed to swing towards the specimen mounted on the machine. With each swing, a certain calibrated force is applied. This force gradually separates the specimen while the pendulum moves further upwards, consuming energy.

In this case, the energy absorbed by the specimen corresponds to the loss in kinetic energy of the pendulum, which is recorded by the machine. Digital systems have all but replaced analog, capturing accurate datasets automatically, such as an alloy’s energy Joules value, highlighting its absorption potential. High-strength alloys, for example, might show absorption values around 200 Joules, while brittle materials like ceramics may only achieve values lower than 20 Joules. These measurements are essential in aerospace, construction, automotive, and other industries where material toughness influences safety and performance.

Importance of Testing Machine Calibration

Testing machine calibration is crucial for maintaining the accuracy, reliability, and repeatability of material toughness evaluation calculations. Consistently providing accurate measurements, properly calibrated machines form the baseline for the development of materials designed to conform to safety standards set by relevant industries. Recent findings suggest that a machine out of calibration could produce deviations of 15–20 percent in the measured energy absorption values, hence drawing false conclusions regarding the performance of the material.

Cited industry benchmarks, such as ISO 148 and ASTM E23 for impact testing with Charpy devices, have retrospectively stressed the need for stringent calibration controls aimed at sustaining compliance. These guidelines propose set intervals of recalibration employing Standard Reference Materials (SRM) of definite and established values to confirm machine correctness. Data from a NIST study conducted in 2023 emphasizes calibration errors in laboratory calibration efforts, stressing the importance of these errors for rejection of good materials and approval of bad ones, illustrating the importance of precision-calibrated equipment in effective quality control.

In addition, today’s Integrated Software Testing Systems (ISTS) come with the option for automated calibration checks which eliminate human error and ensure accuracy. This is consistent with the movement toward more sophisticated information technology-based manufacturing in fields such as automotives and aerospace, where even the slightest inaccuracies can pose serious risks to safety and operation. Compliant and regular calibration of the test systems increases trust in the testing process, promoting material development, innovation, and trust in the system.

Reference Sources

- Impact Testing – Purdue University

Provides the reasons for planning impact tests, for example, measuring energy absorption when a material breaks.

- Impact Tests – Mechanical Testing Instructional Laboratory, University of Illinois

Discusses the methods used in impact tests which reproduce very harsh environments to evaluate the performance of a material that is highly stressed.

- The History and Importance of Impact Testing – NIST

Explains the importance of impact testing with a special focus on Charpy impact testing for the stability of safety-related, fracture-critical structures.

Frequently Asked Questions (FAQs)

Q: Why is an impact test required for a material?

A: An impact test is required to determine the toughness and impact resistance of a material. It measures the energy absorbed by a material during an impact event, which helps in assessing its durability and suitability for specific applications.

Q: What is the purpose of testing composite materials?

A: Testing of composite materials is crucial to understand their impact properties and ensure they can withstand impact loads. It helps in evaluating their performance under dynamic conditions and tailoring them for specific engineering needs.

Q: How does the Charpy test measure impact resistance?

A: The Charpy test is a standard test method that measures the energy absorbed by a test piece when it is broken under an impact load. This helps in determining the material’s toughness and impact resistance.

Q: What is the difference between an Izod impact test and a Charpy test?

A: The Izod impact test differs from the Charpy test in terms of specimen positioning and the way the test measures the energy absorbed. While both tests evaluate impact properties, the test specimen in an Izod test is positioned vertically and clamped at one end, whereas in a Charpy test, it is supported at both ends horizontally.

Q: What types of impact test specimens are there?

A: Impact test specimen types include notched and unnotched specimens. The notched specimens are commonly used in tests like the Charpy and Izod to concentrate stress and simulate real-world conditions where notches or cracks may exist.

Q: What does the dynamic tear test evaluate?

A: The dynamic tear test evaluates the material’s ability to resist tearing under dynamic or rapid loading conditions. It is similar to other impact tests and provides insights into the material’s toughness and impact resistance.

Q: How does impact testing help in material selection?

A: Impact testing helps in material selection by providing data on the energy absorbed and the material’s ability to withstand impact events. This information is crucial for selecting materials for safety-critical applications where impact resistance is a key requirement.

Q: Can impact testing be applied to all materials?

A: While most materials can undergo impact testing, the specific test method and apparatus might vary based on the material type, such as metals, polymers, or composite materials. Each material may require a tailored approach to accurately assess its impact properties.

Q: What is the role of a testing apparatus in impact testing?

A: The testing apparatus in impact testing is crucial for accurately measuring the energy absorbed by the test specimen. It ensures that the test is conducted under controlled conditions, providing reliable and consistent impact test results.