Top Impact Testing Machine in China. Grasping how resilient materials are to instantaneous force is important in many industries, like construction and aerospace. Central to this analysis is the impact test which assesses a material’s toughness and impact resistance. Out of all methods, the Charpy impact test is one of the most prominent and utilized. How does it differ from other forms of impact testing? This blog post will take you through the journey of material testing, exposing the highlights of the Charpy test alongside other methods. Be you professional engineer or a science enthusiast, this article will explain some of the many ways impact testing can help us in the real world.

What is an Impact Test and Why is it Important?

An impact test experiments a material’s effectiveness in resisting rupture and absorbing energy with a sudden force or impact applied to it. This is vital for figuring out how materials will perform in practice, like during impacts and falls . Impact tests assist in ascertaining the dependability and safety of structures, equipment, and products in various industries by figuring out a material’s toughness and brittleness.

Understanding the Impact Test Methods

Impact testing utilizes set procedures for testing the toughness of materials to sudden forces. The most important are the Charpy Impact Test and the Izod Impact Test.

1. Charpy Impact Test

The Charpy Impact Test is one of the most popular tests for quantifying the energy a material is capable of absorbing while fracturing. During the test, a notched specimen is impacted with a pendulum hammer and the energy spent in breaking the specimen is measured. Studies reveal that materials like metals and polymers are tested to wonder their toughness with various temperatures. As a case, some types of steel tend to drop impact resistance at zero degrees and below which is essential for its usage in cold regions.

2. Izod Impact Test

The Izod Impact Test is similar to the Charpy but differs in sample orientation and clamping of the specimen. The material is arranged in a vertical position and the pendulum impacts on the notch face side. This test is specially designed for plastics and helps producers to know if the material can be used for heavy load and strain applications. Advances in research proved that composites with nano-reinforcements have better results in these tests.

New Data and Other Developments

Newer research features the modernized form of impact testing with its instrumentation, in which pieces of fracture data, like force-displacement curves are captured by sensors. This adds to the analysis of materials in comparison to prior techniques. Moreover, newer materials like carbon-fiber-reinforced polymers (CFRPs) have performed better in both Charpy and Izod tests. According to recent publications, these materials are capable of absorbing energy at levels as high as 150 J/cm².

Why Picking the Right Test is Important

The nature of the material and how it will be applied impact the method of the impact test chosen. The level of testing required in the aerospace and automotive industry is much more profound because it is critical to test if the skeletal parts suffer any damage during crash conditions or application of extreme stress. Accurate and no delay data capture methods alongside real-time data integration offer engineers and designers exquisite value on the performance of material honored through the integration of safety and structural durability.

The Role of Impact Testing in Material Testing

Impact testing is a crucial procedure for assessing materials that undergo sudden loads or dynamic stress. Examination of a material’s impact requires this testing method, in which ‘tis measurement of impact measurement defined as toughness, impact resilience, and impact fracture resistance. Charpy and Izod tests are two of the most common impact tests, both measuring the energy a material can withstand during fracture. According to some recent studies, sharp improvements in the precision of these tests due to advanced high-speed data capturing sensors and data collection methods have greatly enhanced the precision of these tests by offering real-time data regarding the most diverse behaviors of materials.

An example can be taken from the automotive sector which, under modern impact testing, calculates core safety components such as airbags and crumple zones and measures them under real-world tests of collisions and crashes. Engineering principles coupled with traditional methods, combined with highly innovative technology such as high mark imaging and AI, allow for more accurate prediction of failure points. 2023 Research also adds to the need to rely on impact tests for 3D printing, especially with the higher material variability that deductively manufactured parts offer against traditional machining. With comprehensive testing methodologies in place, industries can be sure that the materials they use fulfill strict safety and durability demands, which significantly boosts the quality of the end products.

Recent geopolitical shifts globally material testing focus includes sustainable materials such as composites and bio-based polymers. Sustainability does not negate the need for safety and performance prerequisites, which is why impact testing is a prerequisite. Recent data from aerospace applications suggests that modern compacted structures made of composites can indeed soak up 30% more impact energy than metals while maintaining their structural integrity. This substantiates the need for impact testing. It highlights the significance of material impact testing as the cornerstone of advancements in material science, where innovation, safety, functionality, and sustainability are unified.

How the Impact Test Helps in Evaluating Material Toughness

The impact test is one of the primary tests used to measure the toughness of a particular material. Toughness, in a broader sense, is a measure of a material’s ability to absorb energy and undergo plastic deformation without fracturing. Since materials are subjected to specific conditions, the impact test assists engineers and scientists in analyzing the failure modes and performance of the material both in laboratory and real-world scenarios.

Materials are subjected to different procedures which include the Charpy or Izod test, where a pendulum hits a notched specimen. These tests quantify the energy needed to break the sample and yield important information about the material’s resistance to dynamic loads. Also, according to a publication in *Materials Today* (2022), modern metallurgical methods significantly enhance material performance by increasing high-toughness steels’ impact energy absorption by 70% more than untreated alloys.

Additionally, development in the testing procedures makes it possible to practically replicate even the most extreme conditions. For example, cryogenic impact testing is gaining popularity, since LNG (liquified natural gas) storage tanks and space vehicles have to operate in very frigid conditions. Recent aerospace reports indicate that the newer alloys of titanium now in use are capable of retaining almost 90% of their impact toughness even at -250°F (-157°C).

The information yielded by impact testing is equally important for the development of advanced sustainable materials. A good case would be bio-composites from natural fibers that undergo stringent testing for quality assurance, certifying them for use in automotive or construction domains. Research shows that some eco-friendly composite materials have dosages of durability on par with some traditional synthetic materials which creates an opportunity for sustainable engineering design.

In conclusion, the impact test remains one of the most useful procedures in material science and provides data for new designs, technologies, and advancements for greater security and sustainability. All thanks to impact tests being efficient when identifying optimal limits of materials.

Exploring the Charpy Impact Test

The Charpy Impact Test quantifies the energy a material absorbs when impacted and fractured. This test is important for analyzing how materials respond to sudden stress because it determines the toughness and brittleness of materials. The specimen is notched and struck with a pendulum hammer, recording the energy needed to break it. The data is important to industries in selecting materials for applications which require durability and resistance to impacts.

What is the Charpy Impact Test?

The Charpy impact test is one of the standardized tests for determining the ductile-brittle transition temperature of metals. Impact tests measure the energy absorbed by a material during fracture. It was designed in the early 20th century, and now it is one of the most commonly used impact test methods because it is crucial in determining the impact toughness of materials used for construction, bridges, and other automotive applications. This test is completed under controlled parameters with a notched sample which is usually a bar, to produce uniform stress outcomes from various materials to make the test stress independent.

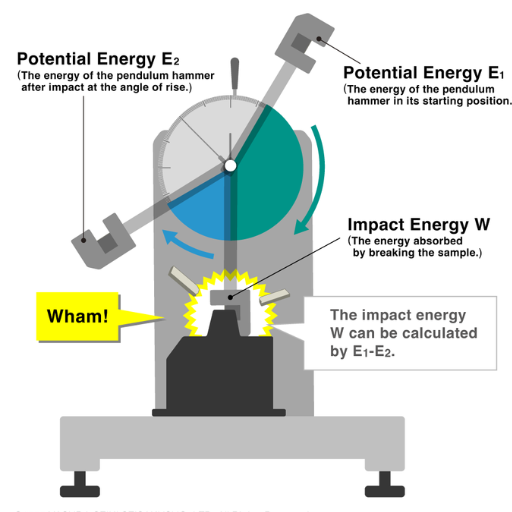

The testing device used for the test is a pendulum impact-testing machine, in which the specimen is placed horizontally and is struck by a pendulum hammer at a certain height. Using the formula for potential energy, the energy absorbed during the strike is measured by calculating the height difference of the pendulum before and after impact. Different materials require different amounts of energy, hence, all materials are measured with a set standard. For temperatures, high-toughness steels require over 100 J while brittle materials like ceramics require lower than 10 J.

With newer technology being produced, better results are able to be achieved using digital measuring systems. Materials must undergo this test if they are being used in rotative machinery, bridges, and other critical structures like automotive components and high-pressure vessels, making them better withstands against extreme environment such as cryogenic or high-temperature scenarios.

How the Charpy Impact Test Measures Energy Absorption

The Charpy Impact Test was developed to quantify the amount of energy a material absorbs during fracture, since it is proportional to the material’s toughness. This test is done on a notched specimen, usually in the form of a rectangular bar, which is hit by a pendulum hammer. The sum of energy absorbed is calculated based on the material breaking energy amount determined by the hammer’s potential energy (before impact) and its energy (after impact).

Digital versions of the test have been developed to increase precision, capture impact velocity, load during the strike, and fracture time using advanced sensors and data software. Results are expressed in joules (J) with tests often conducted at different temperatures to see the effect of toughness on temperature. For example, low temperatures can reveal brittle fracture behavior that is important for assessing safety in cryogenic applications. High-temperature testing evaluates performance in heat-tolerant applications like turbines and pipelines.

Recent studies suggest a large variability in energy absorption values for different materials. For example, certain grades and treatments of steel can absorb 300 J of energy, whereas ceramics typically absorb around 50 J and even lower for brittle materials. In addition, new composite thermoplastic materials are being tested with Charpy to see if they can be used in lightweight and stiff applications. Through the combination of tried and tested methodologies with modern technological advancements in testing, engineers and scientists can fully understand a material’s energy absorption capacity which contributes to the formulation of better and more reliable designs for use in structures and machinery.

Understanding Charpy Test Results and Their Implications

Charpy test results are quoted in terms of energy absorbed in joules (J). This value indicates the material’s toughness, which is important when a material is subjected to impact loads. In most cases, the tougher the material, the greater the amount of energy absorbed which is important in averting sudden failure in construction, transportation, and machinery.

Developments in material science have increased the scope of Charpy test applications. For instance, the toughness of metals such as steel and aluminum alloys differs with treatment (annealing, tempering) and composition. Research has shown that some grades of high-strength structural steel, depending on their geometry and temperature, often fall in the range of 50-200 J of energy absorption.

Moreover, Charpy test results are also influenced by temperature. Most materials undergo ductile to brittle transformation as the surrounding temperature drops. Take, for example, low-alloy steels, they can absorb roughly 20 J at sub-zero temperatures and over 100 J at room temperature. This is problematic when designing materials for use in low temperature regions or cryogenic applications.

Innovations bring additional factors into evaluating Charpy test results. The composite and polymer industry is being tested more extensively. One study noted that some thermoplastic fiber reinforcements absorbed as much as 150 J, demonstrating the requirements for lightweight yet durable materials for use in automotive and aerospace industries. Other researchers attempt to combine these tests with finite element analysis (FEA) simulations, so as to come closer to predicting actual performance.

Furthemore, Charpy impact test results remain one of the most dependable parameters, within given limits of operational load and stress, for determining the usability of materials. The data assists design engineers in setting margins of safety and selecting materials for contemporary, advanced engineering architectures.

Diving into the Izod Impact Test

The ‘Izod Impact Test’ gauges a material’s resistance to impact by striking a pre-notched specimen with a pendulum. In contrast to Charpy, the sample in the Izod test is held vertically with a horizontal notch facing the direction of impact. This test, like others, assists in determining the toughness of a material and its ability to bear sudden forces, particularly when subjected to extreme conditions. The test is common in the automotive and construction industries, where components need to be tested for strength and safety. The results obtained from these tests help to determine the most suitable materials for various applications.

What Makes the Izod Impact Test Unique?

The Izod Impact Test is particularly noteworthy because it can accurately mimic real-life circumstances. Its distinctive characteristic is the inclusion of a notched sample which serves to intensify stress while assessing the tolerable fracture impact of the material. Unlike the Charpy test, the Izod test analyzes the energy loss or damage a material sustains when the structure breaks, providing critical understanding regarding the material behavior under dynamic load.

The Izod test is cited to be extremely accurate for evaluating thermosetting plastics, metals, and composites according to recent data. For instance, modern thermoplastics are said to have impact strengths greater than 80 kJ/m² during an Izod test which makes them suitable for use in automotive bumpers or protective casings that require high durability as per industry statistics.

Moreover, the Izod test has great relevance in predicting the performance of materials under extreme conditions. For example, data collected from materials at varying temperatures ensures reliable performance in cold or high heat conditions. This information supports material selection but most importantly, enhances the reliability of safety in various fields such as aerospace, construction, and electronics.

The Izod Method for Determining Impact Strength

The Izod testing for impact resistance follows the standard procedures put in place a while back. A preset impact is delivered to a notched specimen and the energy registered during fracture is measured. The arrangement of the apparatus is usually a pendulum hammer that impacts the specimen on a designated mounting point, recording the energy required to fracture the sample in joules (J) or foot pounds (ft-lb). This information is critical in evaluating the toughness of the material and determining appropriate uses for the material in situations where it undergoes dynamic loading.

New developments concerning the multidisciplinary cross-section of thermal analysis and mechanical studies have shown how vital testing under different temperatures is for predicting the behavior of the material. For instance, low-temperature Izod tests are routinely used for engineering plastics and polymers which are designed to withstand extremely cold environments in aerospace or outdoor applications. Illustrative material properties suggest that materials like polycarbonate and polypropylene outperform weaker alternatives in sub-zero conditions. On the other hand, materials like nylon are known to demonstrate poor impact properties at elevated temperatures.

Other research shows that the sample geometry such as notch depth and notch angle impacts the outcome of the test. Standards like ASTM D256 and ISO 180 provide global uniformity for testing conditions which aids in the comparison of materials. The results of these tests help engineers construct reliable and safe products like automobile parts or insulating materials for electronic devices.

Interpreting Izod Impact Test Outcomes

The results from the Izod Impact Test are essential for evaluating the material’s toughness and predicting how it would perform in actual conditions. The results, in most cases, are presented based on energy lost (in Joules or foot-pounds) during the fracture of the sample. This energy value greatly impacts the material’s ability to withstand impact, where higher values are capable of withstanding impact fractures.

Modern improvements offer comprehensive analysis tools that provide deep interpretation of the test results. High-speed cameras can now be utilized to monitor the fracture process, permitting engineers to observe failure patterns in real-time. To add, more advanced means of technology can model stress and predict the weak point concentration with the collected data. For thermoplastics used in packaging, Izod values typically range from 1.5–4.0 foot-pounds per inch, while higher values are critical for industrial components. Values above 10 foot-pounds per inch are common in metals used in automotive or aerospace, illustrating their superior toughness.

Recent studies show environmental aspects like temperature have a profound impact on the test results. For example, materials that work well at room temperature could fail in a brittle manner at subzero temperatures. Data collected from low-temperature tests indicate that some polymers, such as polycarbonate, retain toughness significantly better than other materials. Polystyrene with Izod values dropping over 50% doesn’t do as well. Extreme environmental conditions are factors engineers need to account for when designing products.

According to more recent insights, standards like ASTM D256 provide enhanced methodologies for receiving accurate test results and incorporate notch geometry, sample thickness, and even machine calibration. This creates internationally comparable data that is consistent. These modern augmentation tools when incorporated with classical impact testing enable engineers to make more informed material selections. Doing so optimizes the safety and reliability of the engineers’ designs.

Comparing Izod vs Charpy: Key Differences

The two tests differ in specific ways, such as setup and execution, despite being designed to attain the same purpose of measuring a material’s toughness.

Specimen Positioning: In the Izod test, vertical placement of the specimen is performed and the notch is facing the hammer. For the Charpy test, horizontal placement of the specimen is done and the notch is positioned in such a way that it faces away from the hammer.

Point of Impact: About the Izod test, the hammer strikes the notch side of the specimen. In the case of the Charpy test, hammer strikes on the side of the specimen opposite to the notch.

Energy Calculation: Both types of tests uning the galvanometer measure energy absorbed by the specimen during a fracture but the configuration of the test set up varies the materials performance which is why each test is preferable for specific applications.

These pointers dictate how each test is carried out in industries and the type of data material selection and analysis is provided with.

Differences Between Charpy and Izod Explained

Both Charpy and Izod impact tests are integral methods in determining a material’s toughness and energy absorption capacity on breakage. While both tests aim to assess impact strength, there are notable differences in their setups, methods, and uses. Below are more of their differences combined with the latest findings.

Specimen Position and Notch Orientation

Charpy Test: The specimen is held as a beam and is supported horizontally as a simple beam. The notch doesn’t confront the blow’s starting point. The test is done by performing a load on the specimen at the center.

Izod Test: In this case, the specimen is vertically positioned and is cantilevered on one side. The notch, during the impact of the hammer, is directly facing the material and placed on axis of maximum stress concentration.

Application-Specific Preferences:

From industries which for advanced impact-resistance testing, it has become understandable that there is a need for the test best suitable to their needs. Charpy for instance, is extensively used in structural applications to evaluate materials like steel and in pipeline industries. As for the Izod, this test is popular when testing plastic since it simulates best to concentrated impact scenarios.

Energy Absorption Data:

Both tests try to determine the energy absorbed during fracture, in this case, using Joules (J). As noted in previous studies that combine modern analytical techniques with these tests, it seems the Charpy test reports higher energy absorption than the Izod test for comparable materials. This is due to different notch shapes and the method of energy’s Grashof’s law distribution.

Standardized Specifications:

Charpy test enjoys international recognition as ISO 148 or ASTM E23, while the Izod test adheres to industry norms such as ASTM D256. Based on the type of material, its fabrication requirements, and intended application, professionals from the industry choose the relevant test based on these standards.

Recent Findings and Industry Trends:

As noted in recent materials science studies, sophisticated data analysis techniques enable engineers to simulate Charpy and Izod tests virtually, as noted in recent research. Such simulation methods help in minimizing wastage as well as understanding the behavior of materials under different environmental or loading conditions. Comparative datasets indicate that there is a shift from actual testing towards these hybridized simulation models.

These material differences showcase the usefulness of the Charpy and Izod tests even in today’s world of material science. By knowing the differences between the two methods, engineers and researchers can choose the right test for their materials and design.

When to Use Charpy or Izod Tests

The selection of the Charpy or Izod test impact depends on the specific use case, material of concern, and testing needs. Both tests provide a different insight into the toughness of the material, and with that, both of them are useful in different tests because of their differences.

Charpy Test

The Charpy impact test is meant for testing the type of impact a specimen would experience if it were to rest horizontally. It is very common in the construction, automotive, and structural engineering industries. This test is particularly useful for materials like metals and composites, providing critical information about their behavior under sudden loading conditions. For materials with parts that can get exposed to extreme temperature conditions, Charpy data supports the reliable assessment of their performance.

Several recent studies point out that in quality assessment of manufacturing processes, charpy test is still regarded as one of the charpy is considered one of the main tests boom benchmarks. Some data states that more than 50% of assessments made on steels used in construction frameworks incorporated a charpy cylinder primarily because he charpy test faithfully replicates conditions but for real-world operational impacts.

Izod Test

Particularly in the case of smaller components, the specimen is vertical and clamped at one end, which is most appropriate for the Izod impact test. This method is very often used in the plastic industry for ascertaining the impact strength of polymers. With the aid of the Izod test, manufacturers are able to design lightweight materials which are also strong enough to withstand the stress…and this is why the test aids advances in consumer goods and packing materials.

New tests being done on polymers show that there is more and more reliance with Izod testing in conjunction with 3D printing. This means that there is a continued development of strong, high-performance thermoplastics intended for custom manufacturing parts or other pieces.

Key Differences and Application Scenarios

Notch Orientation: The cutting of specimens also differs where Charpy specimens are notched on the side, while Izod specimens are notched at the front. Depending on the anticipated real-life applied stresses, this difference might motivate the choice of test to differ.

Industries and Standards: Unlike for the Charpy tests which are done under some standards like ASTM E23, there are others for Izod testing which include the ASTM D256 for plastics.

Temperature Sensitivity: anner in which the tests are done, The Charpy test is generally done for studies that are temperature dependant, for instance determining ductile to brittle changeover temperatures in metals.

Merging these tests with modern simulation techniques allows researchers to predict the behavior of materials with higher accuracy, minimizing the number of physical trials needed. Knowing when to implement Charpy or Izod tests makes it possible for various industries to ensure that materials comply with safety and durability requirements.

Choosing the Right Test for Your Material Testing Needs

It is often recommended that a subset of requirements concerning a material and its application be examined when choosing between Charpy and Izod impact tests. Both techniques assess how tough a substance is, along with its capacity to absorb energy when high-speed impact is applied, but each has specific configurations and results regarding the scope of testing.

The test of Charpy is acceptable for metals and other materials with considerable changes in structure over periodic temperatures. It measures the amount of energy needed to break a specimen by paying a horizontally positioned sample which is struck by a pendulum. Charpy test is widely used for ductile to brittle transition temperatures, especially in aerospace, construction and manufacturing industries which experience severe temperature changes. Recent research indicates that Charpy tests reliably predict impacts on materials at low temperatures, such as -40°F, which is critical for arctic pipelines.

The Izod test employs a vertically clamped sample which is positioned to receive a pendulum blow. It utilizes such configuration for polymers and plastics to determine their impact resistance. With the speed at which research is performed nowadays, Izod testing methods have also had a revised accuracy expectation for composites used in automotive parts which require lightweight and durable materials to increase fuel efficiency.

Both tests may be augmented with Finite Element Modeling (FEM) to simulate stress and strain distributions for contemporary engineering requirements. Google Scholar cites works where the fusion of experimental data from these tests and FEM simulations resulted in decreased prototyping periods by up to 30%. In addition, many testing laboratories now incorporate DIC technology into Charpy and Izod setups, providing real-time monitoring of micro-level deformation and failure mechanisms analysis.

Engineers and researchers can ensure materials adequately fulfill safety, performance, and sustainability standards while integrating traditional methods with cutting-edge innovations, making informed decisions by leveraging multifaceted modern tools.

The Role of Impact Testers in Charpy and Izod Impact Testing

A material’s ability to absorb energy during fracture impacts is measured by impact testers using Charpy and Izod impact measuring systems. Impact washers are critical for test precision and uniformity as they control load application on the test specimens, recording vital data like energy absorbed, fracturing patterns, and failure modes. This data is crucial in determining the value of material toughness and highlighting areas of expected weakness, while also assessing if these materials are useful for given applications. Impact testers aid in providing accurate and reproducible results which determine materials’ selection and quality standards.

How an Impact Tester Functions

An impact tester measures the reaction of a material sample in the middle of a controlled and sudden force. The impact material tester measures the physical and elastic properties of different materials. The impact tester starts with placing the test specimen securely in a specialized fixture. An impact tester has impact pendulums or a drop weight mechanism that strike and hits the material at a predefined speed. While putting the pendulum or drop weight down, the tester notes down important factors differentiating energy absorbed during fracture and behavior of material.

Modern impact testers hold advanced sensors and software that aid in analyzing data accurately. Two conventional methods of impact testing is Charpy test and Izod test, that use the energy put to break a notched sample to evaluate toughness of the material. One of the pieces of data needed is impact energy which is noted in Joules measured lateral expansion, and shear appearance.

Each of the materials in any industry has its performance indicators, features such as sample handling and equipment used. Revised measuring devices improved with digital handling enable faster data grabs on impact events alongside real-time display of results and illustrations of the outcomes. These improvements allow for measuring the repeatability of the device while measuring performance indicators in terms of safety, where construction, as well as automotive and aerospace industries, have high requirements.

Industry white papers and Google Scholar cite that the use of AI in devising experimental protocols adds even more refinement to their predictive modeling and consistency. Because of this, advanced impact testers are essential for both research and industrial applications.

Types of Impact Test Machines and Their Uses

All impact testing machines have their peculiarities and designs depending on the practical application and requirements of a specific machine. The primary testing machines include Charpy impact testers, Izod Impact testers, and drop-weight impact testers. Different industries use them to ensure materials are safe to use and perform as intended.

Charpy testers are meant for calculating the energy loss of materials during fracture, through pendulum mechanisms. These machines hit a notched metal sample and determine its capability to endure sudden impact. Charpy tests are used for assessing the brittleness and toughness of materials in industries like aerospace and automotive. Recent developments testify that modern Charpy machines are equipped with AI-based data analysis, which increases accuracy and simplifies the testing process. Industry sources say that their usage guarantees compliance with the requirements of ASTM E23 and ISO 148 standards.

Impact Testing of Izod Machine

Similar to Charpy testers, Izod machines use pendulums to break notched samples, however, the sample’s position varies. Primarily associated with plastics and polymers, Izod tests aid in evaluating the impact resistance of materials. A report from 2023 states that recent advances in Izod testing machines now enable the real-time collection of data through smart sensors, ensuring more dependable results for R&D work in material science.

Drop Weight Impact Testing Machines

With drop weight machines, the impact resistance of a material is evaluated by dropping a specific weight from a precise height onto a sample. This type of configuration mimics actual impacts that a material would face under shipping or construction. The drop weight impact testers are paramount in testing the composite materials and polymers in the packaging and transportation industries. As stated in a recent publication of Materials Engineering Advances, these machines have been enhanced with AI and IoT (Internet of Things) technologies that utilize sophisticated algorithms to monitor subtle changes in sample deformation, providing unprecedented understanding of the sample’s material responses.

New Developments in Testing Machine Technology

New smart impact test machines allow for complete automation alongside digital analysis. The results of a raw test are now analyzed using an AI algorithm, minimizing human error and improving forecasting capabilities. Over 70% of new impact testing machines are now equipped with dedicated cloud storage and remote access monitoring systems according to a TechInsights survey, ensuring compliance and operational efficiency across different facilities around the world.

With these high standards set by the advanced machines, industries are now able to safely drive innovation. The combination of traditional parameters of testing and modern technology is helping to advance the science of materials.

Reference Sources

- Impact Testing – Purdue University

Divulges information relating to impact testing in general, as well as the Charpy test as a standardized test for defining energy absorption during the fracture of a material.

- Charpy Impact – California State University, Northridge

Discusses the Charpy test as a particular form of impact test aimed at determining the toughness of material.

- Instrumental Setup (Charpy Mode) – Iowa State University

Explains the setup of the Charpy test and other differences between Charpy and other forms of impact testing such as the Izod test.

Frequently Asked Questions (FAQs)

Q: What is the main difference between a Charpy impact test and an Izod impact test?

A: The main difference lies in the positioning and support of the specimen. In a Charpy impact test, the specimen is placed horizontally and supported at both ends, whereas in an Izod impact test, the specimen is positioned vertically and clamped at one end. Additionally, the notch is on the side facing the pendulum in the Charpy test and on the opposite side in the Izod test.

Q: How does the Charpy impact test work?

A: The Charpy impact test involves striking a notched specimen with a pendulum to measure the amount of energy absorbed during fracture. This test helps determine the toughness or brittleness of a material under sudden impact conditions.

Q: What materials are typically tested using Charpy and Izod impact tests?

A: Both Charpy and Izod impact tests are commonly used to evaluate the toughness of metals and plastics. They are particularly useful for assessing materials that may exhibit brittle behavior, such as certain metals and plastic composites.

Q: Why is the notch important in impact testing?

A: The notch in impact testing is crucial as it serves as a point of stress concentration, promoting fracture. This allows the test to reliably measure the material’s ability to absorb energy during fracture. The notch type and orientation can significantly influence test results.

Q: What does the term ‘impact energy’ mean in the context of impact tests?

A: Impact energy refers to the energy absorbed by the specimen during fracture when struck by the pendulum in an impact test. It is a measure of the material’s toughness and ability to withstand sudden impact without breaking.

Q: How do Charpy and Izod impact tests determine material toughness?

A: Both tests determine material toughness by measuring the energy absorbed by the specimen when fractured by a pendulum. The higher the energy absorbed, the tougher the material is considered to be, indicating better impact resistance.

Q: What is an impact tester, and how is it used in these tests?

A: An impact tester is a machine designed to conduct impact tests such as Charpy and Izod. It typically includes a pendulum that strikes the specimen and measures the energy absorbed during the test, thereby determining the material’s impact strength.

Q: What are some of the differences between the Charpy and Izod test methods?

A: The differences include the orientation of the specimen, the position of the notch, and the support method. In a Charpy test, the specimen is horizontal with supports at both ends, while in an Izod test, it is vertical and clamped at one end. These differences can affect the energy absorption measurement and the interpretation of results.

Q: Can Charpy and Izod tests be used interchangeably for all materials?

A: While both tests measure impact resistance, they are not always interchangeable due to differences in specimen orientation and notch placement. The suitability of each test may depend on the specific material properties and testing needs.

Q: What role does ASTM play in Charpy and Izod impact testing?

A: The ASTM (American Society for Testing and Materials) provides standardized methods and guidelines for conducting Charpy and Izod impact tests. These standards ensure consistency, reliability, and comparability of test results across different laboratories and applications.