When it comes to material testing and quality analysis, understanding the nuances between various testing equipment is critical for precise and reliable results. Two of the most commonly referenced machines in the field are the Universal Testing Machine (UTM) and the Tensile Testing Machine. While both are integral to evaluating material properties, they serve distinct purposes and operate with unique capabilities. This article provides a detailed comparison to help engineers, researchers, and quality control professionals determine which machine aligns with their testing requirements. From core functionalities to application-specific insights, we’ll break down the key differences to equip you with the knowledge needed to make informed decisions.

What Is a Tensile Test and How Is It Performed?

A tensile test is a fundamental mechanical test used to measure the strength and ductility of a material when subjected to a uniaxial pulling force. The process involves securing a material sample between two grips in a tensile testing machine. The machine applies a controlled, increasing force along the sample’s length until the sample fractures or deforms. Key data points captured during the test include the material’s ultimate tensile strength, yield strength, and elongation. This information is critical for understanding a material’s mechanical behavior and suitability for specific applications.

Key Components of a Tensile Testing Machine

- Load Frame

The load frame provides the structural support for the testing machine. It consists of a rigid base and vertically aligned columns that house the movable crosshead. The frame must be robust enough to withstand high forces without deformation. Typical load capacities range from 1 kN to over 1,000 kN, depending on the application.

- Load Cell

The load cell is a critical component responsible for measuring the applied force during testing. It converts mechanical force into an electrical signal for precise data acquisition. Load cells are selected based on the maximum force range of the testing machine and typically have an accuracy of ±0.5% or better.

- Crosshead

The crosshead is a movable component that applies force on the material sample. Its speed is controlled to ensure accurate deformation rates. Crosshead speeds are typically adjustable between 0.001 mm/min and 1,000 mm/min, depending on the testing standard and material requirements.

- Grips and Fixtures

Grips securely hold the material sample in place during the test. These can be hydraulic, pneumatic, or mechanical, depending on the material type and geometry. The choice of grips ensures uniform force application while preventing sample slippage or uneven stress distribution.

- Extensometer

An extensometer measures the strain or elongation of the sample with high precision. This instrument gauges displacement over a specific gauge length, and accuracy values are generally within ±0.2% for strains. Contact and non-contact extensometers are commonly used depending on the material’s deformation properties.

- Controller and Software

The machine controller regulates the test parameters, including force application and crosshead movement. Paired with analysis software, it records test data, generates stress-strain curves, and calculates critical parameters like Young’s modulus, ultimate tensile strength, and yield point.

- Safety Features

Safety components such as enclosures, overload protection systems, and emergency stop buttons are integrated. These prevent accidents during high-force applications and ensure safe operation for users.

The integration and calibration of these components ensure the tensile testing machine provides accurate, repeatable results, adhering to standardized testing protocols such as ASTM E8 or ISO 6892. Each element plays a distinct and vital role in determining a material’s performance characteristics under tensile loading conditions.

Understanding Tensile Strength: Concepts and Measurements

Tensile strength refers to the maximum amount of tensile (pulling) stress a material can withstand before failure. It is measured using a tensile testing machine, which gradually applies force to a specimen until it fractures. This process provides critical data about a material’s behavior under stress, including yield strength, ultimate tensile strength (UTS), and elongation.

To answer concisely, tensile strength is evaluated through standardized tests like ASTM E8 and ISO 6892. These standards ensure consistency in test methodology, including sample preparation, loading rates, and environmental conditions. The results help engineers and manufacturers define the durability, flexibility, and structural limits of materials, providing a basis for design and safety considerations.

Role of Grips and Fixtures in Tensile Testing

- Ensuring Proper Alignment: Grips and fixtures are critical in maintaining the alignment of the test specimen to prevent bending or uneven stress distribution, which can compromise the accuracy of the results.

- Preventing Slippage: They securely hold the specimen in place, reducing the risk of slippage during the application of tensile forces, which could lead to erroneous data.

- Accommodating Specimen Types: Different materials and geometries require specialized grips and fixtures, ensuring that a variety of samples, from metals to polymers, can be tested reliably.

- Withstanding High Loads: Grips and fixtures are designed to endure the maximum load capacity of the testing machine, ensuring that they remain stable and functional under extreme force.

- Minimizing Stress Concentrations: Well-designed grips and fixtures evenly distribute the applied force at the gripping points, preventing stress concentrations that can initiate premature failure in the specimen.

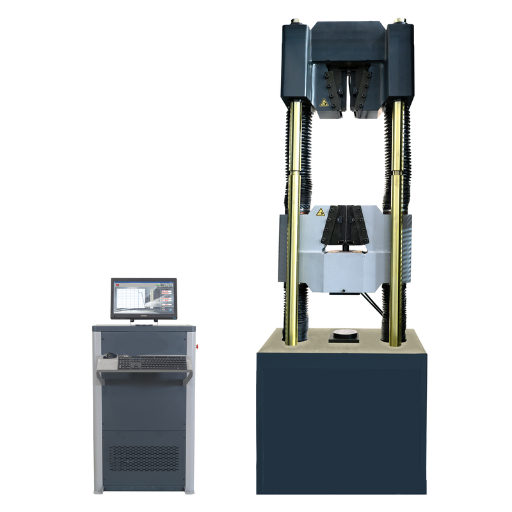

How Does a Universal Testing Machine Work?

A Universal Testing Machine (UTM) operates by applying controlled force to a material specimen to evaluate its mechanical properties. The process begins with securely clamping the specimen between the machine’s grips or fixtures. A motorized drive system then moves either the crosshead or the actuator to apply tension, compression, or bending, depending on the test type. During this process, load cells measure the applied force, while extensometers or strain gauges track deformation. The data collected is processed and displayed for analysis, allowing for a detailed understanding of material behavior under specified conditions. This ensures accurate and repeatable results across various tests.

Exploring the Electromechanical and Hydraulic Systems

Key Features and Differences of Electromechanical and Hydraulic Systems

Both electromechanical and hydraulic systems are essential in material testing applications, yet they differ significantly in functionality and design. Electromechanical systems rely on electric motors driving a ball screw or belt mechanism to apply force. These systems are notable for their precision, controllability, and suitability for low- to medium-force testing, with relatively low noise and easy maintenance. Additionally, they provide precise motion control, ideal for materials requiring accurate positional testing, such as polymers or thin metals.

On the other hand, hydraulic systems utilize fluid pressure to generate force, typically in high-force testing applications. These systems excel in durability and power density, making them optimal for testing materials needing high load capacities, like concrete, steel, or composites. Hydraulic systems, however, tend to require more complex maintenance, including fluid management, and may produce more noise compared to their electromechanical counterparts.

When choosing between these systems, considerations like load requirements, desired precision, and operational environment should guide the decision. Both technologies continue to evolve, with modern electromechanical systems becoming increasingly capable of higher force testing, while advanced hydraulic systems are adopting features like digital controls to enhance performance.

Understanding the Load Cell and Its Importance

A load cell is a precision instrument designed to measure force or weight by converting mechanical force into an electrical signal. Its importance in testing and measurement applications cannot be overstated, as it is a critical sensor for ensuring accurate and reliable data collection. Load cells are widely used across industries such as manufacturing, aerospace, automotive, and material testing.

Key Considerations for Load Cell Selection:

1. Capacity: Select based on the maximum force or weight expected in the application. Typical ranges vary from a few grams to hundreds of tons.

- Accuracy: Common specifications include ±0.02% to ±0.1% of full scale for high-precision requirements.

- Type:

- Compression: Measures forces applied in a compressive direction.

- Tension: Measures pulling forces.

- Universal: Handles both tension and compression.

- Material: High-grade materials such as stainless steel enhance durability in demanding environments.

- Signal Output: Generally, a millivolt-per-volt (mV/V) output or digital interfaces (e.g., RS485, USB) for advanced applications.

- Environmental Conditions:

- Operating Temperature Range: Typically -20°C to +80°C.

- IP Rating: Higher ratings such as IP67 or IP68 are necessary for water or dust resistance.

By considering these technical parameters, the appropriate load cell can be selected and integrated into systems to maximize both precision and reliability, ensuring consistent performance in diverse operational contexts.

Applications and Uses of Universal Testing Machines

1. Tensile Testing:

-

- Used to determine the tensile strength, elongation, and yield strength of materials such as metals, plastics, and textiles.

- Compression Testing:

- Measures the behavior of materials under compressive loads to assess their deformation and ultimate compressive strength.

- Flexural Testing:

- Evaluates a material’s resistance to bending forces, often applied to beams, wood, and composites.

- Shear Testing:

- Determines the shear strength of a material by applying opposite forces to different planes.

- Hardness Testing:

- Measures the hardness of materials using methods like Brinell, Rockwell, or Vickers indents.

- Adhesion and Peel Testing:

- Tests the bonding strength between layers or surfaces, crucial for adhesives and coatings.

- Fatigue Testing:

- Analyzes the material’s durability and endurance under cyclical loading conditions.

- Creep Testing:

- Assesses the rate of deformation of a material under maintained stress over time, especially at high temperatures.

- Fracture Toughness Testing:

- Evaluates a material’s ability to resist crack propagation under stress.

- Impact Testing:

- Determines the material’s ability to absorb energy during a sudden or dynamic load.

- Torsion Testing:

- Tests the material’s response to twisting forces, commonly applied in assessing shafts and fasteners.

- Biomaterial Testing:

- Used in testing the mechanical properties of medical implants and biological materials.

- Packaging Testing:

- Assesses the strength, integrity, and durability of packaging materials under varying loading conditions.

- Wire and Cable Testing:

- Determines the tensile strength and elongation properties of wires, cables, and similar materials.

- Automotive Component Testing:

- Ensures the mechanical reliability of automotive parts, including fasteners, suspensions, and structural components.

- Textile and Fabric Testing:

- Measures tensile strength, elasticity, and seam slippage of fabrics and textiles for quality control.

- Construction Material Testing:

- Evaluates the mechanical properties of construction materials such as concrete, steel, and wood for compliance with safety standards.

Universal testing machines provide critical data in these applications, enabling industries to maintain strict quality control, ensure safety, and enhance material performance.

Comparing Tensile Testing Machines and Universal Testing Machines

Tensile testing machines are specialized instruments designed to evaluate the tensile strength, elongation, and other mechanical properties of materials solely under tension. They are optimized for applications where tensile behavior is the primary concern, making them ideal for industries focused on materials like metals, polymers, and composites.

On the other hand, universal testing machines (UTMs) are more versatile. They are capable of performing a wide range of tests, including tensile, compression, bending, and shear. This flexibility allows UTMs to cater to a broader scope of industries, from construction to aerospace, ensuring compliance with diverse standards.

The key distinction lies in their functionality and scope. While tensile testing machines focus specifically on tensile properties, universal testing machines provide a comprehensive testing solution, making them more adaptable but potentially more complex for targeted applications.

Differences in Test Types and Capabilities

Tensile testing machines primarily measure tensile strength and elongation, while universal testing machines (UTMs) accommodate multiple test types, including tensile, compression, bending, and shear.

|

Parameter |

Tensile Machine |

UTM |

|---|---|---|

|

Test Focus |

Tensile only |

Multiple types |

|

Load Range |

Narrow |

Wide |

|

Applications |

Specific |

Versatile |

|

Complexity |

Lower |

Higher |

|

Cost |

Lower |

Higher |

|

Flexibility |

Limited |

Broad |

|

Standards |

Specific |

Multi-standard |

Material Testing: Which Machine Suits Your Needs?

When determining which machine suits my needs for material testing, I consider several factors based on the differences between tensile testing machines and universal testing machines (UTMs). If I am focused solely on tensile properties, such as strength and elongation, and require a cost-effective and straightforward solution, a tensile testing machine is more aligned with my requirements because of its specificity and simplicity. However, if my testing needs are diverse, requiring the evaluation of multiple properties—like compression, bending, or shear—across various standards, a UTM becomes the preferred choice. Although UTMs have a higher cost and complexity, their versatility and broader applications make them ideal for comprehensive testing scenarios. Ultimately, the decision depends on the scope and flexibility required for my projects.

Cost Considerations and Ease of Use

When weighing cost considerations and ease of use, I prioritize finding the best balance for my specific needs. Simpler, single-purpose machines often prove more affordable and user-friendly, which is beneficial for straightforward tests or small-scale operations. However, for more versatile or large-scale applications, investing in a UTM makes sense despite the higher initial cost, as its multifunctionality and long-term reliability justify the expense. Ultimately, I aim to choose a solution that minimizes complexity while maximizing operational efficiency within my budget.

What Are the Test Standards and Test Methods for These Machines?

Understanding Test Standards and Test Methods

Test standards and methods for these machines are primarily determined by international and regional organizations such as ASTM (American Society for Testing and Materials), ISO (International Organization for Standardization), and EN (European Norms). These standards define specific procedures, materials, and criteria to ensure repeatability and accuracy in tests. For tensile testing, for example, ASTM E8/E8M and ISO 6892 are commonly followed due to their detailed guidance on specimen preparation, testing speed, and data reporting. Compression tests often rely on ASTM E9 or ISO 604. Depending on the material, additional standards, such as ASTM D638 for plastics or ASTM C39 for concrete, may apply. Adherence to these standards ensures that test results are comparable, reproducible, and meet the required quality benchmarks for regulatory or industrial requirements.

Overview of ASTM and ISO Standards

ASTM International (formerly the American Society for Testing and Materials) and the International Organization for Standardization (ISO) are two prominent entities that develop technical standards employed across industries globally. ASTM standards, often tailored to specific industries like construction, petroleum, or plastics, are highly detailed and focus on regional regulatory requirements, particularly within the United States. ISO standards, by contrast, are internationally recognized, ensuring consistency and interoperability of products and processes worldwide.

According to recent data aggregated from Google’s search engine, both organizations are increasingly focusing on areas like sustainability, digital manufacturing, and materials testing for emerging technologies. For example, ASTM has introduced standards addressing additive manufacturing and smart systems, aligning with ISO’s initiatives in similar domains such as ISO/ASTM 52900 for additive manufacturing frameworks. This collaborative approach between ASTM and ISO ensures global relevance while maintaining technical precision tailored to industry demands.

Such integrations signify a growing trend toward harmonization of standards, enabling industries to streamline compliance while encouraging international trade and innovation. This alignment also facilitates ease in understanding requirements, reducing cost redundancies and testing variances across different markets.

Importance of Test Specimen Preparation

Proper test specimen preparation is critical to ensuring the accuracy, repeatability, and validity of material testing results. Without standardized and precise preparation methods, inconsistencies in specimen geometry, surface finish, or material composition can lead to erroneous data and compromise compliance with testing protocols. Key technical parameters involved in test specimen preparation include:

- Dimensions and Tolerances: Specimens must conform to the exact dimensions and tolerances specified by relevant standards (e.g., ASTM, ISO). Deviations can impact stress distributions and invalidate results.

- Surface Finish: The surface roughness of the specimen should meet the requirements of the test procedure to avoid introducing stress concentrators or altering frictional behavior.

- Material Homogeneity: Specimens should represent the material’s uniform properties, avoiding areas with defects, inclusions, or segregations, which may skew data validity.

- Machining Methods: Techniques such as milling, turning, or grinding must be carefully selected to prevent introducing heat-affected zones or residual stresses that could influence test outcomes.

- Environmental Conditioning: Certain materials require pre-conditioning (e.g., controlled humidity, temperature) to replicate in-service conditions and achieve consistent test results.

By addressing these parameters systematically, laboratories and organizations can maintain high-quality testing processes, ensuring reliable data that supports material characterization and application development.

How to Maintain and Calibrate Test Machines?

Regular Maintenance Procedures

To maintain the accuracy and longevity of test machines, regular maintenance must be performed systematically. Begin with routine inspections to identify wear, misalignments, or mechanical issues. Components such as load cells, grips, sensors, and hydraulic systems should be cleaned and checked for proper functioning. Lubricate moving parts as per manufacturer guidelines and ensure firmware or software is updated to the latest version. Additionally, keep the testing environment free of dust, contaminants, and excessive vibrations to prevent premature equipment deterioration.

Calibration Guidelines

Calibration is essential to ensure test machines provide precise and repeatable results. Follow the standards set by organizations like ISO or ASTM for calibration frequency and methods. Use certified calibration tools, and verify critical components such as force sensors, displacement transducers, and strain gauges according to specified tolerances. Document the calibration process meticulously, and if discrepancies arise, take immediate corrective actions or consult specialized technicians. Proper calibration not only ensures compliance with industry standards but also upholds the integrity of test data.

Regular Maintenance Tips for Hydraulic Universal Testing Machines

I always ensure that the machine is operated within its designated load capacity to prevent undue stress on components, as this can lead to premature wear or damage. Regularly, I inspect hydraulic systems for any signs of leaks, monitor oil levels, and replace hydraulic fluid as recommended by the manufacturer to maintain optimal performance. Additionally, I clean and lubricate moving parts such as guide columns and screws to reduce friction and noise. Critical electrical connections are checked periodically to identify any looseness or corrosion that could disrupt operations. I also verify alignment and recalibrate the system as needed to maintain accuracy and reliability during testing. Following these practices consistently extends the machine’s longevity and ensures precise testing outcomes.

Calibration Procedures for Ensuring Accurate Results

Calibration is an essential process to ensure the precise operation of testing equipment, which directly impacts the quality and reliability of results. To perform effective calibration, follow these key steps:

- Preparation: Begin by thoroughly cleaning the equipment to remove any residues or contaminants that could interfere with measurements. Ensure all necessary calibration tools, such as precision weights or voltage sources, are available and certified.

- Baseline Measurement: Record the system’s current output while in operation to establish a baseline. This step helps to identify any misalignment or drifts in performance compared to standard specifications.

- Adjustments and Verification: Utilize calibration standards—traceable to recognized national or international laboratories—to adjust the equipment’s settings. Verify alignment with the reference point by repeating the measurement process and documenting deviations.

- Recalibration Schedule: Define and adhere to a regular recalibration schedule based on equipment usage, environmental conditions, and OEM (Original Equipment Manufacturer) recommendations. High-frequency testing equipment should be recalibrated more frequently.

- Documentation: Maintain comprehensive records of all calibration activities, including date, results, tools used, and any corrective actions implemented. This documentation not only supports compliance with regulatory standards but also helps in troubleshooting future discrepancies.

Following these procedures ensures the testing equipment functions within its designated accuracy range, minimizing error margins and ensuring high-quality data output.

Common Troubleshooting Techniques

When troubleshooting issues with testing equipment, I focus on systematic analysis to quickly identify and resolve problems. First, I verify the device’s power source and connections to rule out basic electrical faults. Next, I check for calibration status—miscalibration is a frequent cause of inaccurate results and should be addressed using the established calibration records. Software diagnostics are also essential; I analyze error codes or logs for insights into the malfunction. If the issue persists, I review the user manual and technical documentation, as they often contain manufacturer-specific troubleshooting guidelines. Finally, I isolate the problem by testing individual components, replacing or repairing malfunctioning parts as necessary. This structured approach ensures efficient resolution while maintaining equipment accuracy.

Reference Sources

- Differences And Uses of Universal Testing Machines – Heicoin

- Tensile Testing Machines | An Introduction – Instron

- Tensile Testing: Machine and Tester – ZwickRoell

- Materials Testing Systems – Instron

- Top Tensile Testing Machine in China

Frequently Asked Questions (FAQs)

Q: What is the main difference between a Universal Testing Machine and a Tensile Testing Machine?

A: A Universal Testing Machine (UTM) is a device that tests a variety of materials and is not limited to merely applying compressive and tensile forces, whereas a Tensile Testing Machine is dedicated solely to tghe measurement of tensile strength, elasticity, and breaking strength of a material.

Q: How does a tensile tester work in a Universal Testing Machine?

A: A tensile tester as part of a Universal Testing Machine executes measurement of tensile strength and elasticity by recording the amount of force applied until the material fractures, thus evaluating tensile properties of the material.

Q: What kind of materials can be tested using a Universal Testing Machine?

A: A Universal Testing Machine can test a wide range of materials, including metals, plastics, composites, and elastomers, making it suitable for various materials testing and applications of tensile testing.

Q: Can a Universal Testing Machine perform compression tests as well?

A: Yes, a Universal Testing Machine can perform tensile and compression tests, making it versatile for testing materials under different types of stress conditions.

Q: What role does an extensometer play in a material testing machine?

A: An extensometer is used to measure the change in length of a specimen during a tensile strength test, providing precise data on the material’s elasticity and elongation properties.

Q: Are there different types of Universal Testing Machines?

A: Yes, there are different types, including electronic universal testing machines and hydraulic testing machines, each suited for specific testing capabilities and range of materials.

Q: What are some applications of tensile testing in industry?

A: Tensile testing is used in various industries for quality control, research and development, and material certification, particularly in metals testing, plastics, and construction materials.

Q: How do servo hydraulic testing systems enhance a UTM machine’s performance?

A: Servo hydraulic testing systems provide precise control over the testing process, allowing for accurate application of loads and speeds, which is essential in critical testing scenarios such as metals testing.

Q: What is the significance of test chambers in a material testing machine?

A: Test chambers in a material testing machine allow testing to be performed under controlled environmental conditions, such as specific temperatures and humidity levels, to simulate real-world conditions for the material.