Top Material Testing Machine in China. Material testing is exceedingly critical in verifying construction, manufacturing and quality control standards of safety, endurance, performance and longevity for materials used in major projects. And in the absence of dependable testing techniques, the possible consequences resulting from defective and failing materials can be life-threatening, can lower the standards of the project and revenue, and, exponentially increase expenses. This article focuses on the significant types and processes of testing materials and their role in sustaining the balance between quality control, innovation, and effective invention. Be it a professional who wants to get ahead in their career, or someone just interested in the science behind material standards, this explainer will help demystify materials testing and understanding its relevance in industry.

Why is material testing important?

Material testing contributes to ensuring the absolute safety, dependability, and functionality of materials for different usages. By revealing isotropies, flaws, or inconsistencies, it aids in averting failures that may result in accidents or expensive repairs. It also makes sure materials are compliant to the standards in requirements and specifications, thus, capable of performing safely and efficiently for the set purpose. This as a whole improves product quality, minimizes risks, and fosters advancement in industries such as construction, manufacturing, and aerospace.

What material properties are evaluated?

Materials are assessed on several fundamental properties to determine their usefulness in certain applications. Some of the most commonly evaluated properties of a material include:

Mechanical Properties

Mechanical properties evaluate the response of a material to applied force and stress. These include:

Tensile Strength: Indicates the amount of stress a material can withstand when stretching prior to breaking. Structural steel, for instance, has a tensile strength that ranges from 400 to 550 MPa.

Compression Strength: Measures the ability of a material to withstand compressive force. Concrete, for example, is known to have high compressive strength which ranges from 17 MPa for residential buildings to over 100 MPa for specialized application.

Elasticity (Young’s Modulus): Defines the ability of a material to deform when under stress, and the ability to return to its original shape. Aluminum, for example, has an elasticity of about 69 GPa.

Hardness: The ability to resist scratching or surface indentation, measured using Mohs, Vickers or Brinell scales.

Thermal Properties

Those that determine the reaction of materials to a change in temperature are termed thermal properties and these include:

Thermal Conductivity: This shows the ability of the material to conduct heat. Copper is used for wiring because it has high thermal conductivity (about 400 W/m·K).

Coefficient of Thermal Expansion: Indicates the amount of expansion or contraction a material undergoes with the change of temperature. This is necessary for bridge construction, electronics, etc.- Melting Point: Evaluates the temperature needs for a given solid to transform into a liquid. For instance, stainless steel’s melting point is roughly 1,400°C.

Electrical Properties

Electrical properties evaluate a material’s performance in electrical settings:

Conductivity: Evaluates the degree to which a material conducts electricity. The greatest electrical conductivity is held by Silver (62.1 × 10^6 S/m) and is closely followed by Copper.

Resistivity: The opposite of conductivity, which means how much a given material opposes the flow of electricity.

Chemical Properties

Chemical Properties assess a material’s reaction with other elements as well as its lasting endurance:

Corrosion Resistance: Evaluates how well a material holds up against destruction from different environments. Aluminum is well-known for having remarkable rust resistance.

Oxidation Stability: Determines how a material may readily combine with oxygen which is important for automobile or aerospace components.

Physical Properties

Mentioned properties outline the basic physical traits possessed by a material:

Density: Determines the mass per given volume of the material. Lead is an example with a density of 11.3 g/cm³ and lighter substances like balsa wood have lower densities.

Porosity: Determines the space within a material which is essential for soil or filtration systems.

Specific Gravity: Provides the relationship of the material s density within that of water , which can be used in flotation and structural design.

With today’s engineering requirements in mind, advanced techniques like stress testing, thermal analysis, and spectroscopy can be used to systematically evaluate specific properties of different materials and optimize their performance.

How does material testing ensure safety?

Material testing serves to address the reliability and safety associated with products, structures, and systems for various industries. Through controlled environment testing, engineers make sure that the materials do not fail by assessing variables such as strength, durability, and performance limits. As an example, the tensile strength test assesses the resistance offered by materials when they are pulled apart. This test plays an important role in the use of cables in bridges and components of aircraft.

The use of ultrasonic and radiography, which falls under non-destructive testing (NDT) methods, shows the most recent milestone reached in material testing. As described in the 2023 industry report, almost 40% of structural failures in construction and manufacturing are attributed to defects at the molecular level. These non-invasive methods allow detection of hidden internal damages without changing the state of the material, therefore mitigating risk.

Prediction of the lifespan of the material when subjected to long sustained stresses is critical, this is where fatigue testing techniques come in handy. Aircraft and automobiles operating under high stress environments greatly benefit from the assurance of material safety. Additionally, thermal analysis techniques can ascertain the behavior of various materials when subjected to different levels of temperature, thus confirming material stability under extreme conditions.

The implementation of modern technologies including machine learning for defect detection and real-time monitoring, have affected testing standards and procedures. These advances in technology, alongside material testing, help to mitigate severe accidents, verify compliance with legal requirements, and enhance public trust in modern engineering products.

What testing standards are followed?

In various industries, material testing is based on several internationally accepted standards that guide their reliability, safety, and quality. Some of the major players defining these standards are ASTM International (formerly: American Society for Testing and Materials), ISO (International Standards Organization), and DIN (Deutsches Institut für Normung). These companies develop holistic standards on different methods of testing and repeatability of assessing material properties.

About metal industry materials, ASTM E8/E8M describes the methods for tension testing of metallic materials, including precise measuring techniques for tensile strength, elongation, and yield strength. ISO also has its standards such as ISO 6892-1, which describes the standards for tensile testing of metal materials at a given temperature and strain rate. In case of some critical equipment for aviation or medical devices, ISO 13485 (regarding quality systems for medical devices) and ASTM F519 (Hydrogen embrittlement testing) become crucial to ensure reliability and endurance.

In addition to traditional methods, new technologies are being integrated into these practices. For example, non-destructive testing (NDT) methods such as ultrasound scanning or X-ray computed tomography have specific standards like ASTM E1444/E1444M for magnetic particle inspection and ISO 16810 for ultrasonic testing. These methods maintain today’s standards for accuracy and effective sample retention.

Compliance with these standards is necessary for regulation and product acceptance since the materials have to demonstrably meet the constraints set for safety and performance.

What are the types of material testing?

For material testing, the various methods and objectives place material testing under different categories, such as:

Destructive Testing – This is testing a material to catasrophic failure to gain information on mechanical properties such as strength, tensile, hardness, and impact resistance. Examples include fatigue tests, hardness tests and tensile tests.

Non-Destructive Testing (NDT) – As the name suggests, this method evaluates the materials properties or identifies flaws without inflicting any damage. Some of the common methods used are visual inspections, radiographic testing, ultrasonic testing as well and magnetic particle testing.

Chemical Testing – This testing is done on a material’s chemical composition so as to ascertain whether or not the material meets the required standards. Examples that extend to spectroscopy and chromatographic methods.

Environmental Testing – This assesses how materials perform under specific conditions, ranging from high temperatures, moisture, or corrosion exposure.

Physical Testing – This encompasses testing for density, conductivity and measuring rate of thermal expansion.

As seen above from the parts discussed, each type of testing has a distinct purpose while at the same time ensuring that materials meet the safety, reliability, and performance standards.

How does mechanical testing work?

Mechanical testing includes the assessment of properties of materials concerning forces and other environmental conditions. It provides insights into the degree of strength, elasticity, ductility, hardness and toughness of the materials. In general, mechanical testing requires the use of special equipment that applies and measures specific stress or strain to a material and quantifies the behavior data it presents.

Some of the most common tests in mechanical testing include:

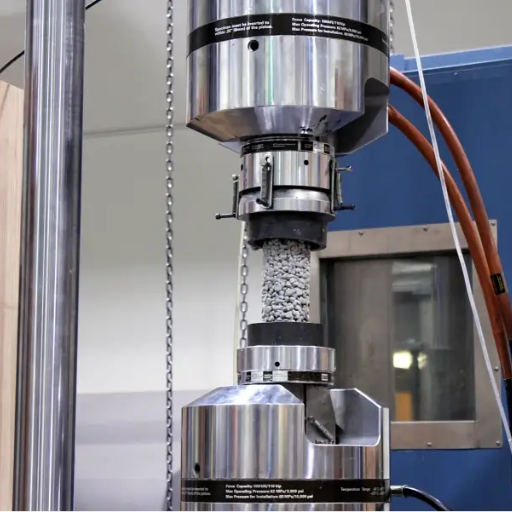

Tensile Testing – This analytical test determines how a specimen responds to a force that tries to pull it apart. In this type of testing, a specimen is placed under tension until it breaks and properties such as ultimate tensile strength, yield strength and elongation at break are determined.

Compression Testing – This is the same as tensile testing but in terms of compressive forces. This form of testing evaluates a material’s response to crushing loads. It is used mostly of straightforward materials like concrete and ceramics.

Impact Testing – This type of test estimates the ability of a given material to withstand pressure. Charpy and Izod impact tests are some of the tests carried out on metals and composite materials for this purpose.

Hardness Testing – This type of test determines the hardness of a given material, that is how much they can deform to the point of making permanent indentation. For such tests Brinell, Rockwell, and Vickers hardness tests are conducted.

Fatigue Testing – The goal under this test is to simulate real-world loading patterns by cyclically repeating the loading and unloading incurred on a structure and analyzing the material for deformations over time.

Creep Testing – This test measures the advanced deformation one can expect in a material over time when there is a consistent force acting on it, and is done at higher temperature levels.

Example Data from Real-World Applications:

Tensile Strength of Steel: The tensile strength of structural steel usually ranges from 400 MPa to 550 MPa, depending on the steel’s grade and composition.

Hardness of Aluminum Alloys: Brinell hardness for aluminum alloys is between 35 HB and 150 HB due to certain alloying elements present and heat treatment applied.

Impact Toughness of Polycarbonate: Charpy impact tests on polycarbonate materials show high values of impact resistance, often exceeding 30 kJ/m2, confirming their excellent impact toughness.

This information along with many others gathered from similar experiments aid engineers and material scientists in making informed decisions in regard to materials most suitable for diverse applications while checking compliance with safety and industry standards.

What is dynamic testing?

Dynamic testing is the examination of materials or systems within operational contexts concerning the impact of various environmental factors and loads. It is different from static testing since, in a static specimen, there is no gradual increase or decrease of load or speed, and various input parameters are altered so that the system under test moves. It is done in almost every field of testing, including aerospace, automotive, construction, and electronics for safety, performance, compliance, standards, and material endurance.

Subdivisions of Dynamic Testing

Fatigue Testing

This test determines a material’s toughness while subjected to repeated cyclic loading and unloading over time. There is always a certain amount of stress that can be placed on material, and after a certain number of cycles, the material will break. The vital information obtained from fatigue testing is the fatigue limit as well as S-N (stress vs number of cycles) curves. For example, steel has a fatigue limit of roughly 50% of ultimate tensile strength (UTS), making these materials useful in applications such as construction, where the material has to carry a lot of weight.

Vibration Testing

This kind of testing aids in examining how systems and/or components respond to dynamic mechanical stresses resulting from the operation of machines, as well as externally induced forces like earthquakes. Until recently, vibration tests were restricted to lower ranges of frequencies. More recently, some tests have been able to simulate very high amplitudes such as 2,000 Hz, retrieving data of the amplitude rendered at frequencies that cause the structure to fail(known as mechanical fracture).

Drop Impact Testing

This test applies to polymers and packaging materials, determining their impact resistance capability. For instance, the level of impact resistance polycarbonate plastics possess is often more than 85 kJ/m² when subjected to drop impacts.

High Strain-Rate Testing

Military armor design and crash safety for automobiles heavily rely on materials that undergo high strain-rate testing. Steel alloys optimized for high strain rates are said to have strain-energy absorption capabilities beyond 150 MJ/m³.

Benefits of Dynamic Testing

Capturing the most accurate simulation of operational accuracy enables the detection of failure mechanisms within the dynamic testing environment. The information provided assists in improving design performance alongside durability. Weak areas or points of failure that compromise safety margins when identifying critical design features unlock enhanced safety and reliability.

Latest Trends and Advances

Sophisticated dynamic testing technologies like high-speed camera use, real-time monitoring, AI simulations, and other dynamically tested new materials such as carbon nanotube composites undergoing stress dynamism of 200 GPa lead to precise data compilation. Enhanced repeatability and reduction of human error are accomplished through automation in fatigue and vibration testing. Dynamic testing innovations ensure the creation of reliable and safe materials and systems through optimal stress testing.

The sentence that was provided conveys, with clarity, the significance dynamic testing has on engineers and developers. Further, enabling them to check for problems and enhance system performance, while making sure materials and systems continue to function under harsh conditions.

How is material fatigue assessed?

Material fatigue is evaluated by experimenting with several tests and using analytical methodologies to determine material behavior under cyclic loading. Conventional fatigue tests require stressing or straining specimens repetitively until failure occurs. These tests determine the specimen’s fatigue limit, endurance limit, and the number of cycles to failure.

Current practices use sophisticated technologies like digital image correlation (DIC) and acoustic emission (AE) to track changing fatigue patterns. DIC captures strain and deformation of the material’s surface, and AE identifies sound from damage, aiding in the detection of micro-level cracks and their growth.

Case studies are invaluable for revealing the data about material fatigue. Aerospace alloys, for example, pose as critical case studies where titanium alloys are known to endure stress near the fatigue limit for millions of cycles. Composite materials undergo fatigue testing factoring in moisture, temperature, and other oscillating variables that impact performance.

Recent updates also involve fatigue life predictions based on big data associated with previous tests using machine learning algorithms. A research publication from the year 2023 indicated that AI-based predictive algorithms surpassed the 90% accuracy threshold for estimating fatigue failures across multiple conditions. Such tools enable engineers to refine design processes and prolong material service life in construction, automotive, and energy sectors.

Through a combination of classical testing techniques and modern innovations, contemporary fatigue assessment reinforces the safety, reliability, and endurance of materials against environmental challenges.

How to choose the right material testing method?

The following key factors should be kept in mind for choosing the most suitable material testing technique:

Material Type: Different materials have specific testing methods, such as metals which often use tensile or hardness testing and polymers, which may need impact or creep testing.

Application Requirements: Determine what the material’s performance expectations are. For structural applications, fatigue and stress testing may be crucial, while in high temperature environments, thermal analysis might be vital.

Standards and Regulations: Comply with safety and performance requirements as per industry standards (ASTM or ISO).

Testing Environment: Choose the methods that best mimic actual working conditions of the material, including temperature, pressure, and chemical or moisture exposure.

Resource Availability: Availability of equipment, budget, and expertise for the materials in question should be accounted for.

Following the aforementioned factors will enable you to achieve accuracy and reliability in testing results.

What factors determine the test method?

All methods of testing a particular sample or unit require accuracy and precision, preventing conflicts whatsoever. Here are some insightful details like the ones above for better understanding, with the latest information from the data provided:

Kind of Material: Characteristics like the physical and chemical aspects of the sample influences choice of testing. Examples include tensile testing which is performed on metals in order to evaluate their strength and ductility. Thermal analysis is also frequently used on polymers to evaluate their behavior when exposed to temperature changes.

Purpose of Testing: The aim of the test whether the goal is to assess durability, ensure safety, verify compliance or evaluate function, dictates the selection of the most appropriate methods. For example, environmental testing for materials designed for application in renewable energy technologies such as solar panels, has to be done because of extreme conditions in which they are expected to function optimally as per the ASTM standards of 2023.

Global and Locals Standards and Policies: There is a newish Global requirement that specifies the need (these blanket policies have already been recommended) like ISO, ASTM, and DIN. This guides all players for one unrestricted standard. Also under ISO 10993 exercising policy, biocompatibility testing of medical devices these other frameworks also fall under.

Conditions of Use: Testing for simulation must replicate real-life scenarios to retain accuracy. For electronics testing, that might mean simulating high levels of humidity or UV exposure for outdoor materials. Recent research highlights the attention on performance during extreme weather due to climate change in recent years.

Innovation in Testing Techniques: Advanced methods such as NDT (non-destructive testing) using ultrasound or infrared thermography are being adopted at a rapid pace. According to a March 2023 market report, the non-destructive testing market is expected to grow from $17 billion in 2023 to $23 billion in 2026, which shows a reliance on advanced and streamlined practices.

Budget and Resources: Maintaining cost-effectiveness as a practical concern. High-precision automated test equipment tends to offer higher accuracy but requires a greater initial expenditure. Reviewing some industry reports shows that businesses tend to quickly adopt and implement resource-conservative approaches when operating under new budget limitations.

Taking these factors into account, along with the use of modern technology and international standards, organizations can determine the best testing strategies that fulfill their requirements and enhance dependability.

How to select the appropriate test machine?

Choosing the appropriate test machine is very important for maintaining a balance between accuracy, cost efficiency, cost effectiveness, and operational efficacy. Here are the important factors to use when determining the balance for a test machine as per the most recent industry information:

Evaluate the Specifications of Your Test Equipment

Outline the particulars about the scope and application of testing to achieve a better end. Which parameters would you like to evaluate? For instance, environmental testing requires machines that can control temperature and humidity, while tensile testing requires measuring force and displacement. More than 65% of organizations cited compatibility with existing functionalities as a key driver in machine selection, according to a 2023 market report.

Accuracy and Precision

Confirm that the indexing servos of the provided machine are within the boundaries of controllable industry standards of measurements. Adhere to at least ISO or ASTM standards. In a study by testingequipmentnews.com, it was established that machines equipped with sophisticated calibration systems claim improved accuracy levels of close to 20%, which lessens reporting errors.

Expandability and Multi-functionality

Make sure to obtain machines that can scale to higher capacities or can accommodate many types of tests. For example, universal testing machines are used by 45% of manufacturing firms because they can perform nearly all tests including, tension, compression, and flexural testing.

Digital Integration and Software Compatibility

Some modern test machines have accompanying software that provides real-time telemetry data, automated reporting, and integration with other data management platforms. Recent data indicates that 70% of firms moving to digital management systems prefer IoT-enabled test machines for easy integration.

Cost Efficiency and Budget Alignment

The latest test machines are more costly but they are usually more durable, consume less energy, and require less maintenance, which leads to savings in the long term. Businesses that invested in energy efficient models reported-operational cost reductions between 15-25% according to a 2023 survey.

Supplier and Manufacturer Support

Analyze the supplier’s customer support, including warranty, training, and maintenance services. They often get extended warranties and help on-site during downtimes and other equipment issues, making leading manufacturers much more appealing as a primary source.

Case Studies and Peer Recommendations

Insights can be gained from examining relevant case studies within the industry alongside getting feedback from peers, particularly on how machines perform in practice. For example, a 2022 review showed that companies relying on machinery validated by peer testing reported 30% fewer implementation issues compared to companies that did not.

Considering all these factors in combination with the most recent technological developments enables industries to choose test machines that satisfy contemporary requirements and improve future testing processes. Consulting with industry experts or carrying out pilot studies relevant to your use case is recommended to help you arrive at an informed decision.

Why is understanding the type of material crucial?

Comprehending the type of material is relevant because it affects the efficiency and accuracy of test procedures. Every material has unique properties which include: tensile strength, hardness, elasticity, and thermal conductivity, which all affect performance under certain conditions. For instance, metals require an understanding of ductility and stress resistance, but polymers require flexibility and temperature sensitivity.

As stated recently, selecting the right material optimizes product design, minimizes waste, and reduces production costs. A MarketsandMarkets report shows that the global materials testing market is expected to grow from $6.4 billion in 2022 to $8.2 billion by 2027. This growth reflects how industries depend more on effective methods of material characterization for innovation in aerospace, automotive, and construction.

Also, advanced specialized tests promote safety and product durability while preventing failure of materials. For example, the National Institute of Standards and Technology stresses the need for constant monitoring of materials’ behavior under extremely high temperatures or highly corrosive environments to develop reliable products for critical infrastructure technology and protect them. Furthermore, understanding material helps industries ensure regulatory compliance and improve product performance.

What are the test methods used in material testing?

The determination and assessment of materials is often done using different techniques which may include, but are not limited to, subjecting them to particular conditions.” The most popular methods include the following:

Tensile Testing – Analyzes the limit of strength as well as the resistance towards pull-apart forces by straining until rupture.

Hardness Testing – Measures the capability of a material to withstand permanently-shallow cut or surface-damage. It can be done via Brinell test, Rockwell test, or Vickers test.

Impact Testing – Evaluates the strength of a material and the durability it sustains when a force is suddenly imposed, in most cases capitally using Charpy or Izod tests.

Fatigue Testing – Checks the reliability of the materials regarding their cyclic stress over extended periods.

Corrosion Testing – Testing the invasive environmental influences like humidity, chemicals, and salt spray, focuses on the durability of the material.

Non-Destructive Testing (NDT) — The detection of defects and inconsistencies without modifying or damaging the material itself, like Ultrasonic Testing of Radiography or Visual Testing. Overall, they are required not only for the purpose of ensuring safety, but also for trust and quality in various industries.

What is the purpose of a tensile test?

A tensile test measures the mechanical characteristics of a sample material, based on the material’s uniaxial tensile loading, which provides essential information regarding the material’s strength, ductility, and elasticity. The test highlights the fundamental issues regarding a material’s response to stretching or pulling which is important for material selection in engineering and manufacturing processes.

A specimen is usually mounted in a machine that applies tensile force incrementally to a given point where the material will deform or break. The following ranges represent the more common key parameters measured:

Ultimate tensile Strength (UTS). This is perhaps the most fundamental parameter that indicates the uniaxial stress of a material before finally breaking. UTS values are quite beneficial say to engineers who design components exposed to specific loads or try to specify the amount of steel, an alloy composed dominantly of iron, might have around 400-550MPa UTS circa.

Yield Strength. This parameter indicates the stress of a material which the deformation of a given sample initiates throughout. This confirms the condition when the force will be removed and the sample does not return to its shape, as seen in the case of study of aluminum alloys the yield strength might fluctuate around 200-400 MPa, depending also on the qualitative grade of the sample.

Elongation at Break: The specimen’s increase in length prior to fracture expressed in percentage, which shows ductility of the specimen. Ductile materials like some polymers probably have break elongation above five hundred percent, whereas brittle ceramics will probably fracture at values less than one percent.

Young’s Modulus (Elastic Modulus): An example of stiffness of a material by determinable value, which is defined as the ratio of stress to strain in the stage of elasticity. More rigid materials like titanium tend to have a higher modulus value, unlike softer materials like plastics which have lower values.

In the aerospace and automotive industry, construction, and materials research, tensile testing is helpful. Appropriate selection of materials for critical applications augment safety, endurance, and performance.

How is a compression test conducted?

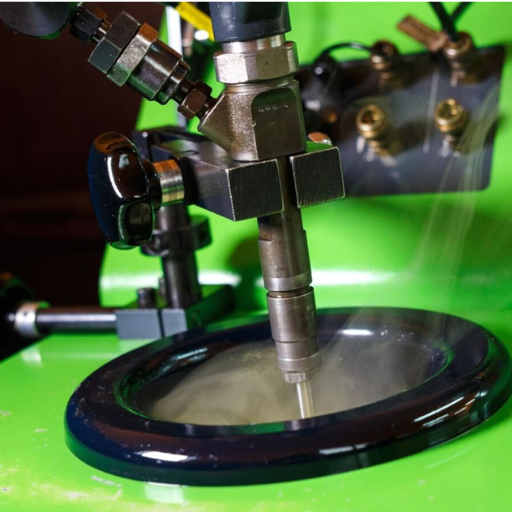

A compression test determines the capacity of a material to resist enclosure yields whilst measuring how a test specimen behaves under crushing loads. It consists of placing a specimen, which is usually a cylinder, cube, or prism, between two compression plates. These plates subsequently apply an increasing load until the specimen bends or breaks. The test is commonly performed in a universal testing machine fitted with compression fixtures. It provides fundamental data like compression strength, compressive modulus of elasticity, yield strength, and the strain properties of the material.

The procedure starts with the specimen being fastened to the machine. The deformation of the material and the force that is applied to the machine is captured by high-precision sensors. Up-to-the-minute testing systems use real-time software to create stress-strain curves which are critical for understanding the functioning of the material during compression exercises. The speed with which the load is applied, specimen dimensions, and certain external conditions, such as temperature, depend on the compression material being tested to replicate practicable conditions.

The recent developments in the field of compression testing focus on employing high-precision strain gauges and digital image correlation systems for the assessment of small granular patterns of deformation. Take construction, for instance, testing the concrete compression strength is vital for verifying that the material suffices for bearing structural loads. As with other engineering materials, concrete is governed by standards like ASTM C39 for concrete or ASTM D695 for plastics, which stipulate that resultant values from testing must be benchmarks against requisite safety and design compliance indicators.

Al-in-all, normal concrete has compressive strength ranging from three thousand to five thousand PSI, with high-performance concrete surpassing this figure, attaining an impressive twenty thousand PSI. Also, alloys like aluminum, and steel, are known to have widely differing values in compressive strength based on their intended use in aerospace or automotive engineering parts.

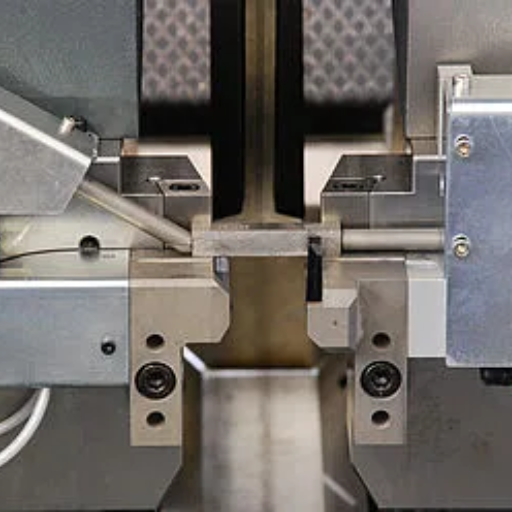

What does a hardness test measure?

Surface hardness is defined as a material’s capability to withstand deformation, such as scratches and indentations caused by forceful actions. This attribute has great significance when analyzing the product’s durability, resistance to wear, and general efficiency. Different branches of industry use hardness tests for determination of metals, plastic, ceramics and even coatings to check for specific engineering requirements or safety standards.

Each method of testing hardness is unique in its own terms as it is tailored to a specific region of material or property. For example, the Brinell Hardness Test (BHN) is mostly employed on metals and utilizes a steel or tungsten carbide ball that compresses into the material at a prescribed load, calculating hardness by measuring the indentation’s diameter. The fundamental value ranges from 10 HB for soft materials such as lead to greater than 600 HB for hardened steels.

A more straightforward and simpler method known as the Rockwell Hardness Test (HR), measures with ultrasonic equipment the depth of indentation under a specified load. The obtained results are measured in terms of different scales (HRC and HRB). An estimate of 60 HRC is obtained from high-carbon steel, while aluminum alloys measure 25-30 HRB.

Vickers Hardness Test (HV): This is the most common test for small or thin samples. It employs a diamond-shaped indenter that is pressed into the material using a specific load, and results are dependent upon measuring the indentation’s area. The Vickers test is flexible; it can be applied to materials from a few HV for soft metals to well over 1,000 HV for ceramics.

Mohs Scale: Most often referenced for minerals, it quantifies the scratch resistance of a material within a range of 1 to 10, with talc ranked as 1 and diamond as 10.

In engineering and manufacturing, hardness testing, whether for quality checks or measuring a material’s appropriateness for a specific function, is indispensable when predicting how a material will react to stress. In the automotive industry, for example, the steel used in the gears is tested for hardness because this determines its wear resistance and life span. Bolt-on tools, such as cutting tools, are also coated with hard materials to test for hardness to guarantee their efficiency in machining operations at elevated temperatures.

Such tests provide additional information alongside other mechanical tests like tensile and compressive strength measurement, to give a holistic view of a material’s mechanical properties.

How does raw material impact testing results?

Raw materials are among the most important elements that affect the results of the tests; factors such as purity, consistency, or composition greatly impact performance. Differences in the quality of raw materials may result in discrepancies across various outcomes, including, but not limited to, measurements of hardness, strength, or ductility. Homogeneous quality of raw materials guarantees the reliability of the test results, while variation and premar any irregularities compromise the result, thus affecting the strength or function of the structure engineered. The selection of raw materials greatly impacts the overall reliability and reproducibility of testing results.

Why is the quality of raw material important?

Accurately said, the quality of the raw materials supplied influences the outcome’s productivity, reliability, and usability across differing sectors. Poor construction also caused damage from a plummeting aircraft crash, resulting in billions. In a 2023 survey, it was noted that ferrous alloys used in construction accounted for approximately twenty percent of all structure collapses in the world. In the manufacturing sector, the presence of certain refining impurities deteriorates raw materials’ mechanical attributes such as tautness and stiffness which results in increased defective output and wastage.

On the other side, industries like pharmaceuticals require high levels of purity and uniformity of raw materials for the product’s effectiveness and safeness. As an example, WHO report issued in 2022 pointed out that ten percent of recalls of some pharmaceutical forms stemmed out of the contamination of raw materials which further drives the importance of quality control.

Using high quality upgrades adds to the sustainability to a seeping extent. Raw material standards streamline energy use, and waste material in the course of producing the parts which is in accordance to worldwide initiatives aimed at lowering emissions on the environment. Raising the standards of raw materials improves output quality while also ensuring compliance with objectives set by legislation and customer satisfaction.

How does raw material composition affect outcomes?

The raw materials used in the manufacturing or production processes directly determine the quality, efficiency, performance, and effectiveness of the end product. For example, the amount of carbon in raw steel determines its ductility and hardness. An increase in carbon content leads to an increase in hardness but a subsequent decrease in malleability; hence, a balance has to be struck. Another industry that is affected by the same factors is pharmaceuticals. Weighing the evidence indicates that the purity of raw chemical compounds can strongly affect the safety and efficacy of the resultant medications.

Maintaining fixed limits on the composition of raw materials also poses a significant challenge for the manufacturing industry. For example in 2023, a report released by the Materials Research Society claimed that fluctuations in the purity of raw materials significantly contribute to 25% of the production defects in advanced manufacturing industries. It has also been noted that firms focusing on advanced technologies for material testing and refinement, tend to report waste reduction of nearly 30% during other production processes.

These days, advanced analytical techniques, such as spectroscopy and chromatography, are commonly used to examine the chemical and physical properties of materials. These methods, as discussed, ensure precision, fidelity, and reproducibility while supporting sustainable approaches by lessening rework, expending energy and resources, and reducing consumption overall. Industries are now able to manage enhanced quality assurance while minimizing expenditures by optimizing raw materials, along with meeting high standards of environmental policies.

What are common material failures due to poor quality?

Quality issues can result in material failures which can pose a threat to safety as well as result in huge financial losses. Some industry-specific issues can be identified as:

Fatigue Failures

Repeatedly applied loads and stress on components results in diminished fatigue life. This is especially prominent on lesser quality materials used in gears, metals and other critical components in automotive and aerospace industries. Metals of lesser quality have the chances of yielding, cracking thereby leading to the breakdown of the structural frame of these important industries.

Corrosion

Mechanically inferior materials have a lesser ability to counter corrosion and serve the purpose of checking environmental degradation. For instance, poorly manufactured steel materials or some finishing materials used in construction components corrode easily when they come into contact with oxygen and moisture, causing damage to the structures.

Brittle Fracture

Some materials made up of glass or porcelain used in specific medical equipment or facilities lack dedicated ductility ,leading these components to fracture with integrated brittle formation. These may not be strong enough to withstand built-up stress. As a result ,such materials tend to shatter with the collapse of pressure leading to damaging fractures.

Wear and Tear

Rubberized parts yield high friction leading to the increased fracturing of lesser grade materials. These undergo faster attrition especially if it occurs in high-friction areas. Poor gauge metal components in Machinery units like gearboxes, and bearings swift lead to machinery collapse resulting in needless serves and damage.

Dimensional Instability

Due to improper fabrication or substandard raw materials, parts are prone to expansion, contraction, or deformation from Dimensional Instability. As an example, low-grade polymers used in plastic fabrication could lead to malfitting constituents due to excessive temperatures.

Supporting Data

As reported by MarketsandMarkets in 2023, the automotive industry faced global deficits in billions due to material quality failures. Attributed to them were fatigue and corrosion for 55 percent of the failures.

Engineering News-Record reported that close to 25 percent of construction structural failures stemmed from misselected low-grade materials.

A study conducted by The Journal of Materials Science claimed that traditional metals can be replaced by corrosion resistant alloys prolonging constituent replacement cycles by 40 percent, thus boosting mid to long term maintenance planning.

Choosing the right materials alongside quality control helps to eliminate so many failures ensuring safe and economical production and efficient operation.

Reference Sources

1. CE 431-001: Construction Materials Laboratory

This document outlines specific requirements and procedures pertaining to material testing, within the scope of construction materials and processes.

2. CE 431-106: Construction Materials Laboratory

From the same institution, this material emphasizes designing procedures for construction material tests and reporting the findings of the research conducted.

3. How to prepare better multiple-choice test items: Guidelines for university faculty

Though this document largely discusses testing strategies, it provides sample guidelines on how to design and assess testing methodologies relevant to the material.

Frequently Asked Questions (FAQs)

Q: What is material testing and why is it important?

A: Material testing is a process used to evaluate the mechanical properties and behavior of materials under various conditions. It is important because it helps determine a material’s suitability for specific applications, ensuring safety and reliability in engineering and manufacturing processes.

Q: What are the different types of material testing?

A: The types of material testing include tensile test, compression test, hardness test, fatigue testing, shear test, creep testing, and dynamic testing. Each test method evaluates different mechanical properties of the material.

Q: How do you choose the right material testing method?

A: Choosing the right material testing method depends on the type of material being tested and the specific mechanical properties you need to evaluate. Consider the application, environmental conditions, and material specifications when selecting an appropriate test method.

Q: What is a tensile test and what does it measure?

A: A tensile test measures a material’s strength and ductility by applying a controlled force to a material specimen until it fails. It helps determine how much stress a material can withstand before deformation or failure.

Q: What equipment is used in material testing?

A: Material testing equipment includes universal testing machines, hardness testers, impact testers, and specialized equipment for dynamic and fatigue testing. These machines are designed to apply controlled forces and measure material response accurately.

Q: What is a compression test and why is it performed?

A: A compression test evaluates a material’s ability to withstand compressive forces. It is performed to determine the compressive strength and deformation characteristics of materials like metals, plastics, and composites.

Q: Why is dynamic testing important in material testing?

A: Dynamic testing is crucial because it assesses a material’s performance under conditions of varying loads or impacts over time. It helps predict material behavior in real-world applications where dynamic forces are present.

Q: How does material testing ensure material quality?

A: Material testing ensures material quality by verifying that the properties of materials meet specified standards and requirements. It helps identify defects and inconsistencies, ensuring that materials and components perform as expected in their intended applications.

Q: What role does material testing play in preventing material failure?

A: Material testing helps prevent material failure by identifying potential weaknesses and ensuring that materials can withstand expected stresses and conditions. It aids in the design and selection of materials to avoid costly failures and ensure safety.

Q: How does the testing of raw material differ from the testing of finished products?

A: Testing raw materials focuses on evaluating the fundamental mechanical properties and quality before processing, while testing finished products assesses the overall performance and suitability of the final product. Both are essential to ensure the integrity and reliability of the materials and products used.