Manhole cover testing machines and compressive testing machines serve critical yet distinct roles in material testing, often leaving professionals in construction, engineering, and quality assurance curious about their specific applications and comparative functionalities. This article aims to demystify these two advanced testing systems, shedding light on their unique purposes, operational principles, and the key differences that set them apart. Whether you are assessing the durability of infrastructure components or evaluating load-bearing capacities, understanding these machines is essential for making informed decisions in testing and compliance. Read on to explore how each of these machines works, the situations they are best suited for, and how they contribute to maintaining safety and quality standards in their respective domains.

What Is a Test Machine?

A test machine is a device designed to evaluate the physical properties, performance, or durability of materials, components, or products under controlled conditions. These machines simulate real-world stresses such as tension, compression, or torsion to measure characteristics like strength, flexibility, or fatigue resistance. By providing precise and repeatable results, test machines play a critical role in ensuring that materials and products meet safety, quality, and compliance standards across various industries.

Types of Test Machines

Test machines primarily include tensile, compression, fatigue, hardness, impact, and torsion testers.

|

Type |

Purpose |

Key Feature |

Example Use |

Material |

|---|---|---|---|---|

|

Tensile |

Measure tension |

High precision |

Wire testing |

Metals |

|

Compression |

Assess pressure |

Load capacity |

Foam durability |

Polymers |

|

Fatigue |

Test endurance |

Cycle counts |

Machine parts |

Alloys |

|

Hardness |

Measure hardness |

Indentation |

Surface coating |

Ceramics |

|

Impact |

Evaluate shocks |

Energy absorbed |

Vehicle parts |

Composites |

How a Test Machine Works

A testing machine operates by applying controlled force, pressure, or deformation to a material or product to evaluate its structural and mechanical properties under specific conditions. For manhole cover and compression testing machines, the fundamental working principle involves a combination of mechanical, hydraulic, and electronic systems that work together to execute tests with precision and consistency.

Compression testing machines typically utilize hydraulic or servo-controlled systems to apply a predetermined load to a material. Sensors and load cells measure the applied force, while displacement sensors measure deformation. The data is processed through advanced software to provide detailed results such as maximum load capacity, stiffness, and stress-strain curves. These machines are essential for determining a material’s compressive strength and elasticity, ensuring compliance with industry standards like ASTM or ISO specifications.

Manhole cover testing machines function similarly but are designed specifically for testing load-bearing components like manhole covers. These machines must adhere to standards such as EN 124, which specifies the load classes and testing procedures for covers. The test involves applying a gradually increasing load to a sample until it fails or achieves specified parameters. Computerized systems often enhance accuracy by monitoring real-time results and generating automated reports.

Modern advancements include fully automatic systems with programmable controls, allowing for faster and more repeatable processes. Hydraulic systems are now integrated with electronic feedback mechanisms for superior precision. By utilizing these advanced technologies, testing machines deliver reliable data crucial for compliance, safety, and quality assurance in engineering and manufacturing industries.

Applications of Testing Machines

- Material Strength Testing – Used to evaluate the tensile, compressive, and flexural strength of materials such as metals, plastics, composites, and concrete.

- Quality Control – Ensures manufactured products meet predefined specifications and industry standards by assessing their mechanical and physical properties.

- Research and Development – Essential in designing new materials and optimizing existing ones by providing detailed performance data under various simulated conditions.

- Component Durability Testing – Evaluates the lifespan and wear resistance of components subjected to repetitive stress or harsh environmental conditions.

- Failure Analysis – Identifies the root cause of material or product failure by subjecting samples to controlled testing conditions, aiding in design improvements and safety evaluations.

How Does a Manhole Cover Testing Machine Work?

A manhole cover testing machine operates by simulating real-world conditions to evaluate the load-bearing capacity and durability of manhole covers. Typically, the machine applies controlled static or dynamic loads to the cover, replicating stresses it would encounter in situ, such as vehicular traffic or environmental pressure. Sensors integrated into the machine monitor parameters such as force, deformation, and resistance throughout the testing process. Results are analyzed to ensure compliance with industry standards, highlighting any potential weaknesses or failure points. This systematic approach ensures the reliability and safety of manhole covers in practical applications.

Components of a Manhole Cover Testing Machine

A manhole cover testing machine typically consists of the following key components:

1. Load Application System

-

- This system applies compressive or flexural forces to the manhole cover to simulate real-world stresses.

- Technical Parameters:

- Load capacity: Up to 400 kN (customizable based on testing standards).

- Adjustable loading rates ranging from 1 kN/min to 20 kN/min.

- Data Acquisition System

- Equipped with high-precision sensors to measure parameters such as load, deformation, and strain in real-time.

- Technical Parameters:

- Accuracy of force measurements within ±1%.

- Displacement measurement precision up to 0.01 mm.

- Hydraulic or Mechanical Power Unit

- Provides the necessary force for testing, often through a hydraulic press or servo motor system.

- Technical Parameters:

- Hydraulic pressure range: 0-250 bar.

- Motor power rating: 2-5 kW.

- Control Panel and Software Interface

- Enables technicians to configure test parameters, monitor progress, and generate detailed reports.

- Includes an intuitive interface with options for automated and manual operation modes.

- Test Fixtures and Support Frames

- Sturdy fixtures are designed to securely hold manhole covers in place during testing.

- Technical Parameters:

- Compatibility with standard manhole cover sizes (e.g., 600-800 mm diameter).

- Adjustable supports for uniform loading.

- Safety Mechanisms

- Emergency stop systems, pressure release valves, and protective enclosures ensure operator safety.

- Designed to meet ISO 13849-1 or similar safety standards.

These components work together to provide a comprehensive testing solution, adhering to industry specifications such as EN 124 or ASTM standards.

Steps in Manhole Cover Testing

1. Inspection and Preparation

-

- Visually inspect the manhole cover for any cracks, deformities, or visible defects.

- Clean the surface to remove dirt, rust, or debris to ensure accurate testing.

- Verify that the cover’s dimensions and specifications match testing requirements.

- Equipment Setup

- Install the testing frame and ensure it is securely positioned.

- Calibrate the testing equipment, including load cells and pressure gauges, to ensure precision.

- Configure the test parameters, such as load limits, as per applicable standards (e.g., EN 124).

- Load Application

- Gradually apply the test load to the manhole cover using a hydraulic or pneumatic press.

- Monitor the load application rate and maintain alignment to avoid non-uniform stress distribution.

- Record the load applied until the cover reaches its deflection limit or failure point.

- Deflection Measurement

- Use precision measurement tools, such as dial indicators or laser systems, to capture deflection data.

- Document the maximum deflection observed during the load application process.

- Load Testing

- Conduct standard load tests to simulate real-world stress conditions based on traffic classes (e.g., Class D400 for heavy-duty applications).

- Repeat the process for different load levels if needed for further evaluation or class certification.

- Failure Analysis

- Inspect the manhole cover post-testing for structural failure, including cracks, fractures, or permanent deformation.

- Perform material analysis if necessary to identify potential weaknesses in composition.

- Documentation and Reporting

- Compile detailed test results, including load-deflection curves, maximum load capacity, and observed failure modes.

- Ensure the report aligns with industry standards and includes recommendations for improvement if applicable.

- Compliance Verification

- Compare the test results against relevant standards, such as EN 124 or ASTM standards, to determine compliance.

- Issue certification or provide feedback for redesign if the cover fails to meet the required criteria.

These steps ensure that manhole cover testing is performed systematically, producing reliable and consistent results that meet industry regulations.

Role of Hydraulic Systems in Cover Testing

Hydraulic systems play a critical role in simulating real-world forces during manhole cover testing, ensuring precise and repeatable results. These systems are designed to apply controlled loads, both static and dynamic, to evaluate the structural integrity, deformation, and durability of the cover. Using hydraulic actuators, varying pressure levels can be exerted to replicate conditions such as traffic loads or extreme environmental stresses. Furthermore, hydraulic systems provide consistent force distribution, minimizing testing variability and enhancing the reliability of results. Their advanced control mechanisms allow engineers to fine-tune load parameters in compliance with international standards such as EN 124 and ASTM. This technical accuracy is instrumental in identifying design flaws, improving material performance, and validating compliance for safe, long-term deployment.

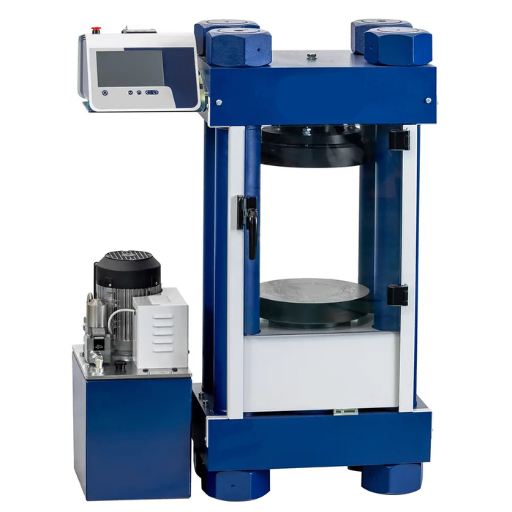

What Is a Compression Testing Machine?

A compression testing machine is a specialized apparatus designed to measure the compressive strength and behavior of materials under applied loads. Predominantly used in industrial, construction, and research fields, these machines evaluate how materials like concrete, metals, plastics, and composites react to compressive forces. Modern compression testing machines are equipped with advanced load cells, precise hydraulic or servo-electric systems, and digital interfaces for high-resolution data collection and analysis. They comply with international standards such as ASTM C39 for concrete and ISO 604 for plastics, ensuring consistent and reliable results. By simulating real-world stress conditions, these machines help engineers and researchers determine critical parameters such as maximum load, elastic limit, and failure points, ultimately guiding material selection and design processes across various industries.

Features of a Compression Testing Machine

- High Precision Load Cells: Equipped with advanced load cells to ensure accurate measurement of force applied during testing.

- Wide Load Capacity Range: Designed to accommodate a diverse range of materials by providing varying load capacities, typically ranging from a few kilonewtons to several thousand kilonewtons.

- Software Integration: Incorporates cutting-edge software for data acquisition, real-time analysis, and comprehensive reporting of results.

- Robust Frame Design: Built with a sturdy, rigid frame to minimize deformation and ensure consistent test results under high loads.

- Versatile Testing Adjustments: Features adjustable platens and attachments to suit different specimen sizes and testing standards.

How to Conduct a Compression Test

- Prepare the Equipment: I ensure the compression testing machine is properly calibrated and configured according to the specimen’s size and testing standards. This includes attaching the appropriate platens and verifying alignment.

- Sample Preparation: I prepare the specimen by ensuring its dimensions and material properties meet the requirements of the applicable testing standard. Any surface irregularities are addressed to ensure accurate and consistent results.

- Position the Specimen: I carefully place the specimen between the platens of the testing machine, ensuring proper alignment to avoid uneven load distribution during the test.

- Set Test Parameters: I configure the machine to the required load application rate and other test-specific parameters as defined by the standard or specific testing objective.

- Conduct the Test: I initiate the test, observing the real-time data displayed by the integrated software. The machine applies a gradually increasing compressive load until the specimen deforms or fails, depending on the purpose of the test.

- Record and Analyze Results: Once the test concludes, I review the data captured by the software, including stress-strain curves, maximum load, and deformation. This information is compiled into a detailed report for further analysis.

By following these steps systematically, I ensure a precise, repeatable compression test that complies with industry standards and provides actionable insights.

Common Uses of Compression Testing Machines

Compression testing machines are essential tools in material science and engineering for assessing the mechanical properties of materials under compressive forces. These machines are widely used in various industries, including construction, manufacturing, and research, to ensure material reliability and structural integrity. Some of the most common applications include:

- Construction Material Testing: Compression testing is critical for evaluating the strength of concrete, cement, and other building materials. It ensures that these materials meet standardized safety and performance requirements.

- Medical Device and Packaging Validation: These machines are employed to analyze the compressive strength and deformation of medical devices, as well as the durability and protective capabilities of packaging materials under load.

- Metal and Alloy Testing: Compression tests are used to confirm the mechanical stability of metals and alloys, particularly in applications where materials are subjected to high pressure, such as automotive or aerospace components.

- Foam and Elastomer Analysis: For softer materials such as foams and elastomers, compression testing determines properties like elasticity, resilience, and load-bearing capacity, which are pivotal for applications like cushioning and sealing.

- Research and Development: Compression testing machines play a fundamental role in R&D, allowing scientists and engineers to design new materials, optimize formulations, and predict how materials will perform in real-world conditions.

By accommodating diverse materials and conditions, compression testing machines ensure that products are safe, compliant, and optimized for their intended applications.

Comparing Manhole Cover Test and Compression Test

- Purpose: The manhole cover test is primarily conducted to evaluate the strength, durability, and load-bearing capacity of manhole covers, ensuring they can withstand vehicular and environmental stresses. Compression tests, on the other hand, are used to measure a material’s behavior under compressive force and determine properties such as compressive strength, elasticity, and deformation limits.

- Test Subjects: Manhole cover tests focus specifically on finished products, i.e., the manhole covers themselves. Compression tests are broader in scope and can be applied to a wide range of materials, including metals, plastics, concrete, and composites, in raw or finished forms.

- Methodology: The manhole cover test involves applying a concentrated load over the cover to simulate real-world usage conditions. Compression tests, however, use standardized testing machines to apply uniform compressive force to the specimen, often following strict ASTM, ISO, or other standards.

- Measurement Output: A manhole cover test typically yields data related to total load capacity and structural integrity under stress. Compression tests produce detailed metrics, such as stress-strain curves, modulus of elasticity, and point of failure for a material.

- Applications: While the manhole cover test is a safety and durability assessment specific to public infrastructure, compression testing serves a broader purpose across multiple industries, such as construction, manufacturing, and material development.

By examining these aspects, it becomes evident that while both tests assess strength under pressure, their scope, applications, and methodologies differ significantly depending on their end goals.

Key Differences Between Compressive Testing Machine and Manhole Cover Testing Machine

The key differences between a compressive testing machine and a manhole cover testing machine lie in their function, application, structure, pressure limits, and testing materials.

|

Parameter |

Compressive Testing Machine |

Manhole Cover Testing Machine |

|---|---|---|

|

Function |

Strength assessment |

Load-bearing test |

|

Application |

Diverse industries |

Public infrastructure |

|

Structure |

General-purpose design |

Specific to manhole covers |

|

Pressure Limits |

Highly variable |

Predefined load ranges |

|

Testing Material |

Multiple materials |

Manhole covers only |

Understanding Specifications and Standards

To address the comparison of the compressive testing machine and the manhole cover testing machine, it’s essential to understand their specifications and applicable standards:

1. Function

-

- The compressive testing machine is designed for evaluating the compressive strength of various materials, adhering to standards such as ASTM E9 or ISO 7500-1, which define requirements for mechanical testing machines.

- The manhole cover testing machine, however, is specifically utilized for load-bearing tests on manhole covers, often following EN 124 standards, which regulate testing conditions and loads for access covers and gratings.

- Application

- Compressive testing machines are versatile and applicable across industries, including construction, metallurgy, and composite materials.

- Manhole cover testing machines are tailored for public infrastructure and ensure that manhole covers meet safety and performance criteria under specific load classes.

- Structure

- A general-purpose compressive testing machine features a robust frame, crosshead, and platens to adapt to sample geometry with customizable configurations.

- The manhole cover testing machine is engineered with a specific test rig and plates designed to replicate load conditions directly impacting manhole covers.

- Pressure Limits

- Compressive testing machines have variable pressure ranges, typically up to 3,000 kN, depending on model and purpose.

- Manhole cover testing machines operate within predefined load classes such as 125 kN, 250 kN, or higher, based on EN 124 classifications.

- Testing Material

- Compressive testing machines accommodate metals, plastics, concrete, and ceramics.

- Manhole cover testing machines focus exclusively on manhole cover materials like ductile iron, concrete, or composite products.

By aligning these specifications with appropriate technical standards, these machines ensure precise and reliable testing outcomes tailored to their respective fields.

Choosing the Right Testing Equipment

When selecting the right testing equipment, I focus on aligning the machine’s capabilities with the specific materials and standards required for my application. For instance, compressive testing machines are ideal for versatile material testing, whereas specialized manhole cover testing machines are essential for evaluating ductile iron, concrete, or composite covers under EN 124 classifications. I prioritize equipment with accurate calibration, robust construction, and compliance with relevant technical standards to ensure consistent and precise testing outcomes.

What Are the Specifications and Standards for Manhole Cover Compression Testing Machine?

A manhole cover compression testing machine must adhere to stringent specifications and standards to guarantee accurate and reliable performance. Key specifications include a high load capacity, typically ranging from 100 kN to 300 kN or more, and precise load measurement systems with minimal deviation. The machine should support robust hydraulic or electromechanical operation to deliver uniform force application. Compliance with EN 124 standards is critical, ensuring the machine can evaluate performance across all load classes (A15 to F900). Additionally, it must feature advanced data acquisition systems for real-time monitoring and reporting and be calibrated to recognized international standards, such as ISO 7500-1, for consistent measurement accuracy.

Industry Specifications for Well Cover Testing

From my research, industry specifications for well cover testing emphasize adherence to standardized guidelines like EN 124, which defines load classes and ensures safety and reliability under varied conditions. The testing equipment should incorporate cutting-edge features such as precise load measurement systems and robust structural integrity to handle class-specific requirements (A15 through F900). Additionally, calibration to ISO 7500-1 standards is mandatory, ensuring consistent and repeatable performance validation while maintaining data accuracy through advanced monitoring and reporting systems.

Importance of Computer Control in Testing Machines

Computer control in testing machines plays a critical role in improving the accuracy, efficiency, and consistency of testing processes. Advanced computer control systems enable precise load application, real-time data acquisition, and automated control loops, which are integral for obtaining reproducible results and reducing human error. These systems facilitate the customization of testing protocols to meet specific standards and material characteristics, ensuring compliance with international benchmarks like ISO 7500-1.

Additionally, computer control provides enhanced data management capabilities, including real-time monitoring, comprehensive reporting, and integration with external software for advanced analysis. The ability to store and retrieve testing data digitally improves traceability and simplifies compliance auditing. This approach significantly reduces the time and manual intervention required for testing, thereby promoting operational efficiency while ensuring adherence to rigorous quality standards.

Advancements in Automatic and Hydraulic Systems

- Integration of IoT (Internet of Things) Technology

Modern automatic and hydraulic systems are increasingly incorporating IoT capabilities to enable remote monitoring, predictive maintenance, and enhanced diagnostics. This integration improves overall system performance and reduces downtime.

- Enhanced Energy Efficiency

Advancements in energy-efficient components, such as variable frequency drives and energy recuperation mechanisms, have enabled hydraulic systems to operate with reduced energy consumption, meeting stricter environmental regulations.

- Digital Control Systems

The adoption of sophisticated digital control systems allows for precise management of pressure, flow, and force in hydraulic systems. These controls enable better responsiveness and accuracy, particularly in highly automated industrial applications.

- Smart Sensors and Feedback Mechanisms

The development of smart sensors provides real-time data on parameters like temperature, pressure, and fluid levels. These feedback mechanisms improve system reliability and allow for immediate adjustments to optimize performance.

- Innovative Materials and Designs

The use of advanced materials, such as lightweight alloys and high-strength polymers, has improved the durability and efficiency of hydraulic components. Innovative designs have also led to more compact systems, enabling their implementation in diverse and constrained environments.

Reference Sources

- TBTWC-1000A Compression Testing Machine – Details on a specific compression testing machine used for manhole covers.

- Manhole Cover Compression Testing Machine by Rushi Test – Information on a microcomputer-controlled manhole cover compression testing machine.

- JYAW Series Manhole Cover Compression Testing Machine – Specifications and details of the JYAW series testing machine.

- Compression Testing: Machine & Test | Strength & Tension – General information on compression testing machines and their components.

- Top Manhole Cover Testing Machine in China

Frequently Asked Questions (FAQs)

Q: What is a manhole cover testing machine used for?

A: A manhole cover testing machine is used to test the bearing capacity and residual deformation of materials like fiber reinforced concrete well covers, water grate covers, and steel fiber reinforced concrete well covers. These machines often use a hydraulic cylinder and a hydraulic pump for applying load.

Q: How does a compressive testing machine differ from a manhole cover testing machine?

A: A compressive testing machine is primarily used for assessing the cement compressive strength of materials like concrete cylinders. In contrast, a manhole cover testing machine is specialized for testing the load-bearing capabilities of well covers and grates.

Q: What role does a manufacturer play in the supply of testing machines?

A: A manufacturer is responsible for designing, producing, and ensuring the quality and reliability of testing machines. They often work closely with suppliers to distribute their products to various industries that require precision and standardization in testing.

Q: Can you explain the term “computer control manhole cover” in testing machines?

A: “Computer control manhole cover” refers to testing machines that use microcomputer control systems to manage the loading and unloading processes. This technology enhances drive precision and allows for automatic control during testing.

Q: Why is concrete testing important in construction?

A: Concrete testing is crucial to ensure that construction materials meet safety and performance standards. It helps in verifying the compressive strength, durability, and overall quality of concrete used in structures like pavements and buildings.

Q: What is the significance of using an electro-hydraulic servo system in testing machines?

A: An electro-hydraulic servo system in a testing machine offers precise control over the application of test force. This system allows for accurate and repeatable test results, making it ideal for high-pressure testing scenarios.

Q: How do suppliers contribute to the availability of testing machines?

A: Suppliers are vital in marketing concrete testing machines and other related equipment to various sectors. They act as middle links to industries, ensuring that they have the appropriate apparatus to undertake diverse tests including concrete testing and cement compressive strength assessments.

Q: What are the advantages of using a hydraulic cylinder in testing machines?

A: Using hydraulic actuators within testing machines permits the application of remarkable effective uniform force. This is important for carrying out tests which require very high pressures and accurate loading sequences such as those performed with cast iron and composite materials.

Q: What materials are typically tested using a compressive testing machine?

A: Compressive testing machines are commonly used to test materials like concrete cylinders and other cementitious composites. These tests determine the materials’ ability to withstand loads without failing.

Q: How do testing machines ensure the standardization of test procedures?

A: Testing machines ensure standardization by adhering to industry standards and guidelines. They utilize technologies like microcomputer control and automatic control systems to maintain consistency and accuracy in test results.