Top Material Testing Machine in China. Material testing machines have a significant impact on innovation since they help verify the performance adequacy of equipment and products relative to the infrastructure and consumer goods, as their strength, durability, and safety are pivotal. Comprehending the functionality of these devices and their goals gives ground for new prospects in both product development and quality control for industries. This outline covers all the material testing machines and their relevance concerning different industries. Engineers, manufacturers, and anyone inquisitive about the science of product consistency will find value in this article on material testing machines that serves as a case study on their potential. Texts will guide one through the machines and the advancements they catalyze which aid modern manufacturing and many other fields, along with exploring the machine performance standards to test their various applications.

What is material testing and why is it important?

In terms of construction safety, quality, and durability, material testing or evaluation safeguards that the specified standards are met. Even as a single machine component, a material needs to begin with a certain level of reliability and performance to satisfy industry specifications. Testing aids in the identification of possible pitfalls, compliance with standards, and assists in the development of dependable and high-performance work devices. Through testing of specific criteria such as strength, flexibility, and even resistance testing, one can assure that the material is fit for purpose construction, thereby preventing failure and improving product quality.

Understanding the basics of material testing

Material testing utilizes a number of methods to assess and analyze the characteristics of a material. In general, these methods fall under two categories; destructive testing techniques and non-destructive testing techniques.

Destructive Testing (DT):

Tensile Testing: Determine how a material undergoes tension until failure by measuring the tensile strength, elongation, and the reduction of area.

Compression Testing: Evaluates how materials under test are expected to be crushed, behave when compressed i.e. their crushing strength.

Impact Testing: Determines how strong under fracture a material is by measuring the energy that can be absorbed during the fracture. Examples include the Charpy and Izod impact tests.

Hardness Testing: The determination of the resistance to indentation or penetration, Brinell, Rockwell, and Vickers hardness tests measure.

Non-Destructive Testing (NDT):

Ultrasonic Testing (UT): The use of sound waves through a material having a frequency above that of audible sound to detect internal flaws like cracks or voids in the material without destroying it.

Radiographic Testing (RT): The examination of an object using X-rays or gamma rays to take pictures of the inside of a material to show defects.

Magnetic Particle Testing (MPT): The determination of surface and near-surface imperfections in a magnetic material like iron or steel.

Eddy Current Testing (ECT): The examination of metallic materials by induction into the material for the detection and estimation of the thickness of flaws in the material.

Recent Advancements in Material Testing

With the integration of technology and data analytics into the field of material testing exercises, they have significantly advanced. The use of Artificial Intelligence (AI) and Machine Learning (ML) for data analysis, material behavior prediction, and precision improvement is becoming the norm. Moreover, 3D scanning, automated testing systems, and other innovations allow for reliable and faster assessments. A recent AI application study claims that analyzing microstructures to predict fracture points reduces testing time by 30%.

The globally expanding material testing market is estimated to grow to USD 8 billion by 2028, owing to the technological innovations and sustainability focus. This claim is endorsed by the increased demand from the aerospace, automotive, and construction industries. The urgency to sustain competitiveness emphasizes sophistication in testing methods and devices.

AI assists in making high, quality, safe, and reliable materials. With the combination of classical tested frameworks alongside emerging techniques, the consistent growth in industry demands is met, ultimately making it possible for manufacturers to offer energy-efficient products.

The role of material testing in quality control

Advanced optimizing corrective action systems is a big hurdle for quality control because testing the materials uses both regulatory benchmarks and performance expectations. It reveals some flaws or defects in raw materials, parts, as well as sub assemblies with the set criteria systems. An industry report in 2023 showed that almost 85 percent of the manufacturing defects were traced back to the material level. This alone shows the need for thorough testing.

So and so has shown that testing of materials has been vital, enabling them to check the level of the material strength, elasticity, and chemical identity to include is electrochemistry B diseng Ono corrosion. For example, tensile testing measures the yield strength of materials some set for constructing safer designs in construction and aerospace. Furthermore, AI-powered image analysis paired with advanced testing systems has increased the efficiency of detecting potential material failures by thirty percent in mass production.

Industries keenness in risk control measures guarantees compliance with set ISO standards that augers with client satisfaction and dependability. The fact remains, material testing does auger with the quality of the product couched along with the esteem of the manufacturer instrumental in the everlasting core semifinished parts market prudently in the competitive market.

Applications of material testing in various industries

Materials testing is essential in safeguarding safety, performance, and quality thresholds across various industries. Some industries that benefit from material testing include:

1. Aerospace Industry.

Due to the nature of their work, the aerospace industry depends on testing materials to ensure all aircraft parts can function safely and reliably. Composite fibers, alloys, and ceramics are put through multiple tests to determine their effectiveness at high altitudes, temperatures, and pressures. For instance, tensile testing and fatigue analysis are vital for checking if turbine blades and fuselage parts will endure long-term stress. As per Statista, the spending on aerospace material testing adhesives is estimated to grow globally at a 6.5% CAGR during 2023-2028. This shows, material testing is increasingly relevant for the aerospace sector.

2. Construction and Infrastructure:

To ensure the safety, reliability, and lifespan of structures like buildings, roads, and bridges, strategic standards are put in place for the sole use of concrete, asphalt, and steel. A range of tests has to be executed for accurate regulations to be achieved, such as flexibility and strength testing, in other words, material compliance testing. As an example, ASTM International provides guidelines for trying different construction materials so that collapses do not happen. There are new techniques introduced to non-destructive tests; the newer methods, like ultrasonic and radiography testing help find defects without damaging the asset.

3. Automotive Industry

Material testing is becoming crucial in the automotive sector, especially with the adoption of electric vehicles (EVs) and lightweight designs. Tests check the durability and energy absorption capabilities of the battery, tire, and body materials. For example, crashworthiness tests ensure materials can protect occupants during accidents. Grand View Research reported that the automotive material testing market would surpass $2 billion by 2030 due to new developments in EV parts and automobile safety technologies.

4. Devices, Biomedicals and the Biomedical Sector

The examination of biocompatibility guarantees that the materials in question can endure human contact and resist bodily fluids. In the case of biocompatible implants and surgical prosthetics, precise microwave tissue welding instruments are being manufactured through recent innovations in biomaterials. It is estimated by MarketsandMarkets that the medical device testing industry will expand from $7.6 billion in 2022 to 11 billion in 2027, indicating rapid acceleration.

5. Power and Energy

The power and energy industry incorporates material testing to enhance the efficiency and damage control of critical components such as pipelines, wind turbines, and solar panels. Corrosion testing plays a major role in determining the competency of oil and gas pipelines for extreme weather conditions. Furthermore, fatigue as well as thermal testing prolong the lifespan of materials in renewable energy systems. A project analysis conducted in 2022 predicts an acceleration in the rate of growth for material testing within the components aimed at renewable energy.

6. Electronics and Technology

The electronics industry requires very strict testing of the materials that go into the making of semiconductors, circuit boards, and other components from an environmental as well as a performance standpoint. Thermal conductivity and dielectric strength tests confirm battles with heat dissipation and electrical stability. A “smart technology materials” testing industry report claims that the market value increased by almost 8% in 2023, which is proof that technology breakthroughs are very important.

The rapid rate of development seen in material testing due to the implementation of AI in testing procedures and greater automation, which enhances meeting industry expectations, shows that they are tailored to the level of robotics. Its importance relates to fortifying product portfolios, compliance, and cross-sector innovation.

How do testing machines work?

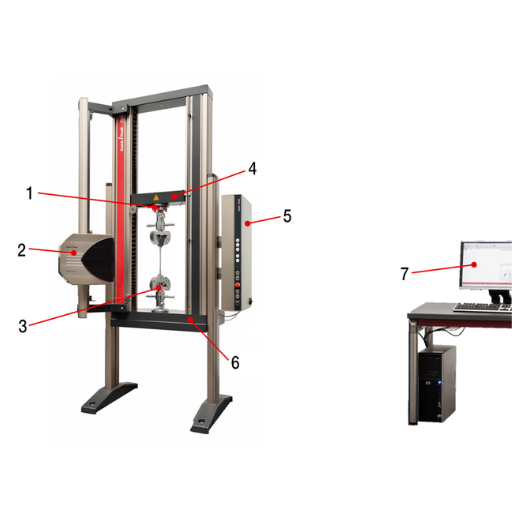

Modern testing machines impose pre-defined actions like force application or a combination of several actions on controlled materials to assess their relevant properties and performance. Such a machine consists of a few critical parts, namely: loading frames, computer control systems, and sensors. After placement of the sample in the machine, the material may undergo one or more forces of tension, impact, or compression. The data captured by the sensors regarding the sample is processed to output the exact values of parameters such as strength, elasticity, or durability. Displaying this data will then enable enhanced analysis. These evaluations yield marked material behavior evaluations presenting the required accuracy under distinct controlled environments.

Components of a testing machine

Loading Frame

The frame as the name suggests, gives shape to the loading structure of the testing machine. It contains the components which apply forces either in the form of tension, compression, or bending on the sample material. Most frames of modern machines are manufactured from aluminum or steel because these materials make the frames durable. Moreover, the frames can withstand a high amount of stress while still being stable and precise.

Actuator and Hydraulic System

An actuator, either hydraulic or electrical, applies a force or displacement that is controlled onto the test specimen. Pumps, valves and reservoirs form the hydraulic system, which controls fluid power. This precision means powerful strokes that can be applied during testing of the specimen. Advanced systems allow for the application of force smoothly and precisely.

Grips and Fixtures

Different types of grips and fixtures are available to keep the sample material stationary during the time framing it. For instance, there are tensile grips used to pull the material, and compression platens used for crushing the material. Different forms of adjustable grips also add greater versatility, allowing many specifications to be accommodated.

Sensors and Transducers

Critical parameters such as force, displacement, or even strain whiles the testing is being done is measured by these Sensors and Transducers. Most of these components are equipped with load cells which help in force measurement, extensometers to measure strain, and transducers to measure distance. In thorough analysis, the aim is to collect data, precisely sensitive collect data, therefore these sensors need to be highly sensitive.

Control System

The control system covers all functions of the testing machine including force application, timing, and data collection. Most modern machines incorporate computer-based control systems which have user-friendly software. Users can design sophisticated test procedures, analyze real-time data, as well as save data for later analysis.

Data Analysis and Acquisition Software

Modern Sophisticated testing machines come with data acquisition systems that capture data from the sensors and process it for presentation. The software is capable of stress, strain, elasticity, and breaking point analyses and generates informative reports alongside advanced engineering graphical data for engineers and researchers.

Safety Features

The new models of testing machines incorporate overload protection systems, emergency stop buttons, and protective enclosures regarding user and equipment safety, making the whole system far safer than previous iterations.

With these advanced components incorporated into modern testing machines, reliability, precision, and adaptability are ensured in the construction, manufacturing, and research industries.

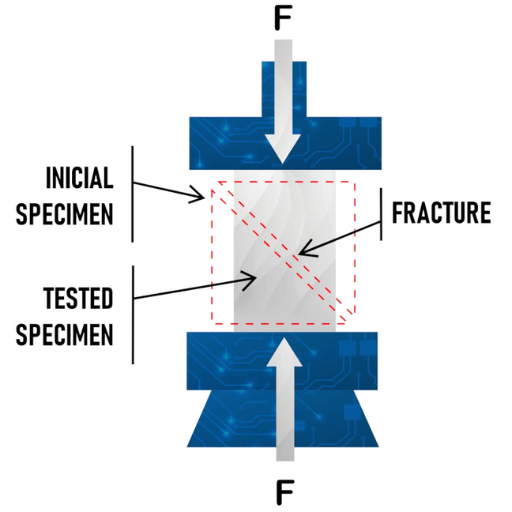

The process of tensile testing

Tensile testing is one of the primary techniques employed in assessing the tensile mechanical attributes of a material. This procedure is critical as it captures important factors of a material, such as its strength, elasticity, ductility, and helps evaluate if the material can be used in practical applications.

Step 1: Specimen Preparation

The preparation of the specimen involves choosing the proper material sample. A specimen must be tailored to certain standard technological measurements, like ISO 6892 or ASTM E8 dictates. These standards give a set protocol on the dimensions and design of the specimen so that uniformity and precision are achieved.

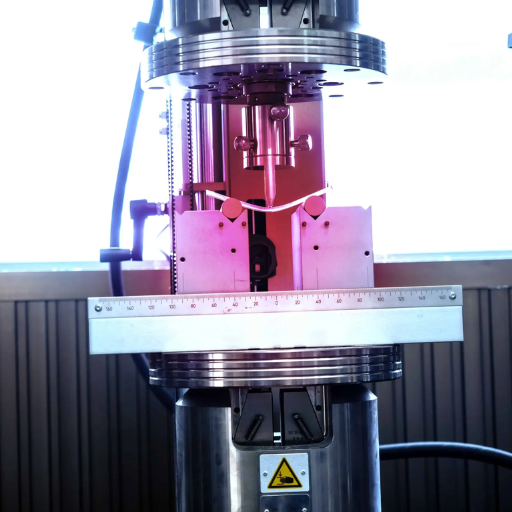

Step 2: Mounting the Specimen

Mounting refers to placing the specimen in a tensile testing machine, which consists of two halves called grips. The apparatus used for the test or the machine has to fix the material from both its edges so that the force will be applied along the longitudinal axis uniformly.

Step 3: Applying Tensile Force

The machine applies the given force in a controlled manner, that enhances the chance of success without damaging or breaking the material. The standards for testing will define how the specimen should be pulled. During the process, sensors capture the force being applied with great accuracy along with strain.

Step 4: Data Collection

The equipment measures stress and strain for the duration of the experiment and constructs a stress-strain curve. The stress-strain curve reveals fundamental properties of the material, including:

Ultimate Tensile Strength (UTS): The stress at failure for the material.

Yield Strength: The value of stress where there’s a permanent change in shape.

Elastic Modulus: The value obtained from the ratio of stress to strain within the linear portion of the curve which defines the stiffness of the material.

Elongation at Break: A measure of ductility that defines the degree of elongation that a material can achieve before breaking.

Step 5: Failure Point Analysis

The test will not stop until the specimen fails; this can either be by necking (localized reduction in cross-section) or complete fracture. With the aid of engineering tools, the failure mode of the specimen is studied to assess material behavior under tension.

Example Data

Below is an example dataset from a tensile test performed on a specimen.

Material Tested: Aluminum Alloy 6061

Specimen Diameter: 12 mm

Gauge Length: 50 mm

Ultimate Tensile Strength (UTS): 310 MPa

Yield Strength: 276Mpa

Elastic Modulus: 69 GPa

Elongation at Break: 12%

This data suggests that Aluminum Alloy 6061 possesses a satisfactory level of strength and ductility, which is appropriate for use in structures in the aerospace industry and construction engineering.

Tensile testing, in general, assists in understanding the behavior of a material, enabling the design of safer and efficient engineering structures.

Calibration and maintenance of testing equipment

For dependably accurate results, reliable calibration and upkeep of tensile testing equipment is mandatory. Standardized check components, such as ISO or ASTM provide set guidelines for testing machines, whose frameworks need to be met. The testing process guarantees that key elements such as load cells or extensometers are functioning accurately.

Outline for Calibration Procedures:

Defined Routine: Machines must be calibrated within specified ranges put forward by the manufacturers or standards. Often, this depends on the level of usage the machine receives on a yearly or semi-annual basis.

Certified Standards Compliance: Calibrations must be undertaken using scrutinized marks that fall within the weight structure of an international standard.

Verification of Load Accuracy: Perform a full check on the machine’s load range, ensuring consistency within accepted tolerable limits (usually within a 1% margin of the tolerable load displayed).

Best Practices for Maintenance:

To assure longevity and unimpeded function, apply grease on mechanics supremes such as lead screws.

Evaluate electrical components regularly for any apparent corrosion and damage.

Dust, moisture, and various environmental pollutants can negatively impact sensors and alter, hence need to be avoided as much as practicable.

Significance of contemporary software integration:

The functionality of modern testing tools usually includes sophisticated software for monitoring and real-time calibration. This type of software integration minimizes human error and expedites calibration procedures. According to recent studies, about 80% of laboratories now utilize equipment that features sensor technologies capable of ensuring data traceability and efficiency.

As a result of consistently applying maintenance schedules, supported by advanced technologies, the reliability of material testing in laboratories can be enhanced, leading to safer and more precise engineering works.

What are the different types of tensile testing machines?

Each testing application has its setting with the following types of tensile testing machines designed accordingly:

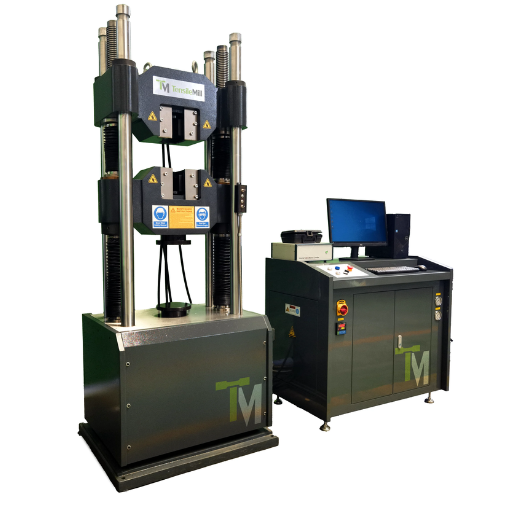

Universal Testing Machines (UTM)– They include Multifunctional Machines capable of Performing tensile, compression, and bending tests on a wide range of materials, from metals to plastics and even composite materials.

Single-Column Testing Machines– These are lightweight testers for small specimens and serve a limited range of functions. They are great compact machines for low force testing applications.

Dual-Column Testing Machines– Precise and stable, these can withstand significant amounts of force and larger specimens during high-force testing. These offer greater stability and precision when dealing with larger specimens.

Horizontal Tensile Testing Machines– These specialize in testing longer samples like cables, ropes and wires. They allow horizontal placement for ease of measurement which is ideal for these longer samples.

Servo-Hydraulic Testing Machines– Great for dynamic testing, these have high load capacity and are commonly used for studying complex material behaviors.

Dependable throughout the industry, these types of machines, with their different complex capabilities, assure reliability with each particular testing requirement that a given industry presents.

Exploring universal testing machines

Universal testing machines, or UTMs, are incredibly flexible devices used for testing the mechanical properties of materials, from their strength to their elasticity, under a wide range of conditions. These machines perform multiple tests, such as tensile, compression, bending, and shear tests, on materials like metals, plastics, rubbers, and composites. They are essential in the construction, aerospace, automotive, and manufacturing industries for material testing and quality control processes.

Today’s UTMs make use of the latest technology which includes digital controls, sensors, and automated data collection systems, which all contribute to heightened accuracy and efficiency. Such machines can measure critical parameters such as ultimate tensile strength, yield strength, modulus of elasticity, and elongation at break. The value of data helps to know the performance of the material against various loads, fulfilling the requirements from regulatory bodies like ASTM and ISO.

For instance, the most recent models incorporate software interfaces integrated with AI-powered analytics for interpretation in real time and data access through the cloud. These models also provide high-capacity load frames with a wide range of testing force capabilities from several Newtons to hundreds of kilonewtons. This range accommodates lightweight and heavy-duty materials. With these advancements, UTMs have become dependable to accurately perform tests, but also to cater to the changing requirements of contemporary businesses.

By integrating powerful hardware components and the latest technological advancements in software, universal testing machines continue to be essential in material testing, delivering unmatched value for research and product development endeavors.

Features of an electromechanical tester

High Precision Load Cells

With remarkable accuracy, the load cells in electromechanical testers measure the forces applied in precision testing. This guarantees the precision of data when testing many types of materials.

Wide Range of Test Speeds

These machines can operate between a very low and to very high test speed, enabling applications from slow tensile testing of materials to high speed compression tests.

User-Friendly Software Interface

Integrated software provides a user-friendly interface, allowing easy configuration of tests, data collection, and analysis of the results. It also provides advanced reporting capabilities along with real-time graphing for better visualization.

Customizable Grips and Fixtures

A broad range of grips and fixtures is provided with the electromechanical testers to fit various shapes and sizes of materials thus ensuring the versatility of the instruments across many testing conditions.

Durable and Compact Design

Testers have Compact and sturdy construction which ensures the economical use of laboratory space while remaining durable.Due to the design, the instruments are withstanding long-term high frequency use,without effecting operational performance.

The benefits of a hydraulic testing system

The precision and power offered by hydraulic testing systems are unmatched, making them perfect for wide-ranging applications. These systems utilize hydraulic force to test materials and components under various conditions, which offers the following advantages :

High Load Capacity

Due to their ability to generate extremely high forces, these systems are suitable for testing heavy-duty materials and components. They provide precise force control and have with load capacity of several hundred tons, depending on the specific model.

Consistent Performance

With evolutionary controls of fluid regulation, machines are capable of performing dynamic tests consistently and reliably. This is important in severe conditions like prolonged testing durations and environmental changes.

Versatile Across Material Types

Hydraulic testing systems are capable of testing metals as well as polymers and composites. They are especially effective in tensile, compression, bending, and fatigue testing.

Integration with Modern Technology

Real-time data acquisition and analysis is a possibility with modern state-of-the-art software which is integrated in most hydraulic testing systems. Advanced data logging enables pinpointing the exact moment where stress-strain transitions occur with great precision. Supplementary control systems also contribute to a more streamlined and efficient testing procedure.

Improvements to Energy Efficiency

The latest developments in eco-friendly hydraulic systems have resulted in the greatest reduction of energy use to date. New designs include optimization of hydraulic circuits and pumps, which results in less energy waste and reduced heat generation.

Longevity and Durability

Hydraulic systems are built for longevity, and tend to have reinforced frames and parts that endure high frequency and extreme stress use. In turn, this durability lowers the overall burden of ownership through increased operational uptime and less maintenance, repair, and replacement needs.

Data Insights:

In the past 5 years, there has been a 15% adoption surge for hydraulic testing systems across industries due to their unparalleled load capacity and adaptability within aerospace, automotive, and construction sectors. Additionally, advancements in the devices’ energy efficiency have broadened their appeal across industries due to compliance with eco-friendly mandates.

How does compression testing differ from other tests?

Unlike other types of tests, the compression test uniquely evaluates a material or product’s ability to withstand compressive forces. While tensile testing analyzes the response of materials under tension or pulling forces, compression testing deals with the performance of materials when being pushed or squeezed. This test is often employed to evaluate the compressive strength, elasticity, and deformation under load due to its importance in structural materials and packaging integrity. In comparison to more dynamic tests, compression testing is relatively static and simple, providing accurate information on a material’s robustness and ability to endure loads.

Understanding compression versus tensile testing

Both tensile testing and compression testing are principal methods employed in the field of material science for evaluation of a material’s mechanical properties while subjecting it to different forms of stress. Both methods evaluate strength and performance; however, the methodology and application of each has much divergence from the other.

Compression Testing: This type of testing determines how a material responds to being pushed together or to compressive force. And like any other method, this has specific goals, including measuring compressive strength, modulus of elasticity, deformation, etc. This type of testing is very important for materials such as concrete, foam, and structural metal,s where compressive loads are expected. For instance, according to some ASTM standards (ASTM D695), the compressive strength of high-strength concrete ranges from 6000 psi to over twenty thousand psi, dependent upon the mix design that is used and the curing process conducted.

Tensile Testing: This is contrary to tensile testing because this method will evaluate a material’s response to pulling force or tension. It also provides critical data such as tensile strength, yield strength, elongation, and Young’s modulus which is essential for steel, aluminum and even polymers that have certain components that are subjected to stretching forces. Standards like ASTM E8 prescribe methods for metallic materials which include structural steel with tensile strengths that range from fifty thousand psi to around a hundred thousand, depending on grade and alloy composition.

Analysis Functions: The primary distinction between the two tests centers on the kind of stress applied. Compression testing is usually associated with thick and brittle materials like concrete, and tensile testing applies to ductile materials. Both results are integrated by the engineer to design appropriate structures that consider compressive and tensile forces. For example, concrete in a bridge takes up compressive force and the steel reinforcement exerts tensile force.

Advanced testing equipment such as universal testing machines and digital data acquisition systems have made it possible for today’s engineers to perform unparalleled analysis of material behaviors. This understanding allows the engineering professional to ensure materials will perform safely and efficiently when subjected to actual service conditions.

Key factors in compression testing

Like any other test, compression testing has numerous considerations to take into account to obtain precise outcomes while evaluating the reliability of a material under compressive mechanical loads:

Loading Face and Specimen Configuration

Loading face and specimen preparation greatly influence the outcome of any given test. Specimens must be provided with smooth parallel faces to ensure uniform load application. Cubes, cylinders and prisms are some of the most common geometries, further defined by ASTM C39 and ISO 604 for Concrete or metal and polymer frameworks.

Calibration of the Testing Machine

The precision of a compression test greatly depends on how accurate the testing machine is. Universal testing machines have to be calibrated regularly based on the set standards, e.g. ASTM E4. It is necessary to adhere to the standards if there is any hope of uniformly accurate load measurement. Use of modern digital machines with advanced sensors who provide real time analytical data during the test tend to make the entire process hassle free.

Application of Load

Loading must be gradual and equally distributed among other specimens of the specimen. Preterm breakdown or unexpected readings caused by the introduction of force need to be avoided. Standards such as ASTM D695 test for thermoplastic materials, while ISO 7500-1 does the same for metals, use prescribed constant rate of loading policies to ensure everything is in order.

Environmental factors

One factor which affects the performance of a given material during any testing procedure is temperature and humidity. For example, polymers might respond in a different way in relation to temperature increase, likewise moisture is likely to impact the compressive strength of concrete. Such conditions can also be created in the environmental chambers for accurate assessment.

Material behavior and stress-strain curve

Focus on stress-strain curve can provide great assistance in understanding the behavior of the material. The performance such as the proportional limit, yield strength and ultimate compressive strength posesses are important for engineering application and the materials used to construct them or in machinery.

Data gathering and interpretation

The contemporary digital systems for data acquisition allows the storage of data of high resolution concerning the load and deformation that occurs. These systems facilitate monitoring during the process and after completion of the test which aid the engineers in developing a better understanding on failure methods, deformation and materials limits considerably clearer.

Examples of Concrete Testing in the Industry and Their Data

In recent research, it was noted that the high-performance concrete has a compressive strength of 40 MPa and can even exceed it up to 100 MPa. The strength and durability of the concrete have increased significantly with the introduction of advanced additives and exact mixture designs.

Compressing metal strength

It is known that the aluminum alloy compressing metal strength ranges between 200 MPa and 600 MPa while other structural steel tends to have even higher resistance. The aforementioned figures are acquired upon the completion of compression tests which are conducted under realistic loading scenarios.

Polymers

Studies about compressive testing of polymers mostly involve examining their viscoelastic properties. For instance, some thermoplastics are said to possess compressive strengths in the range of 50 MPa to 150 MPa, and this performance is dictated by molecular configuration and environmental factors.

The application of compression testing, in conjunction with established procedures and emerging technologies, remains instrumental in the innovation and enhancement of materials across engineering disciplines. Such accuracy allows structures and components to outperform the expectations of contemporary usage while ensuring safety and efficiency across multiple sectors.

Applications of compression testing in industry

Compression testing is of utmost importance in quality control and material assessment in several sectors. It guarantees that components and products undergo thorough safety checks as well as performance checks to provide precise data regarding a material’s mechanical properties while under pressure. Here is a summary of some of the industries and applications where compression testing holds utmost importance:

1. Construction and Civil Engineering

Testing the compressive strength of construction materials such as concrete and cement requires compression testing. High-performance concrete undergoes standardized tests in attempts to guarantee that its claimed load-bearing value is not a hollow peak. According to new research, the average compressive strength of high-performance concrete can exceed 100 MPa, facilitating its utility in constructing high-rise buildings and bridges; Compression testing is beneficial to engineers because it enhances their ability to design safe structures as well as provide accurate data to help ascertain whether the structure will be durable and how long it will last.

2. Automotive and Aerospace

Suspension springs, composite panels and structural supports require specific strength and reliability validation within the automotive and aerospace industries. Compression testing is widely used to address such issues. For example, the carbon fiber composites used in aircraft undergo extensive compression testing to ensure safety factors in dire conditions. Reports from Industrial composite materials manufacturers claim that these materials can sustain compressive strengths over 600 MPa, designed for lighter and more fuel-efficient vehicles and aircraft.

3. Packaging and Consumer Goods

Foam packaging, corrugated boxes, and cardboard are all considered to be packaging materials that are manufactured. These manufacturers utilize testing procedures such as compression testing on their products to determine the durability and load-bearing capabilities of their products. The ability to withstand compressive forces on a package becomes very important during the safe transportation and storage of goods. According to most studies, the compressive strength of standard corrugated boxes is accepted to vary between 40 to 100 PSI for optimum quality gauges 4. The Use of Medical Devices Along With Prostheses

Testing materials that are used in the making of prostheses and implants is very important, as each one must be evaluated comprehensively to ensure reliability. Different materials such as titanium, steel, polymers, etc, are tested for compressive strength to simulate the body’s forces. This is especially important in cases of spinal components and joint implants which must undergo sustained physical stress – it should counteract failure.

5. Renewable Resources With Energy

Renewable energy represents an area of utmost importance. As such, new areas of testing such as using compressive strength on materials bound for use in wind turbines, solar panels, and solar energy storage systems, are essential. For example, the bombastic impact of lifespan and efficacy of renewable energy systems is attributable to the compressive strength of reinforced polymer composites used in wind turbine blades.

In the case of hydrocarbons, the use of traditional methods of testing these materials alongside newer technologies like digital image correlation and artificial intelligence results in increased efficiency and accuracy of compressive testing. All in all, those advanced materials are ensured to serve the purpose, which allows the freedom to innovate, but with strong precautions on safety and reliability in major industrial areas.

What are the latest advancements in material testing technology?

Digital Image Correlation (DIC): This sophisticated optical technique provides comprehensive contactless monitoring and measuring of strain and deformation within materials.

Artificial Intelligence (AI) Integration: The application of machine learning directs greater focus on the analysis of data, forecasting the performance of the material, and fine-tuning the steps involved in testing them, thus enhancing efficiency and speed.

Non-Destructive Testing (NDT): Methods like ultrasonic testing, x-ray examination, and magnetic particle inspection enable testing for evaluation of material properties without damage to the test specimen, thus maintaining the structural integrity of the component.

Additive Manufacturing Testing: There is ongoing development of protocols and tools aimed at evaluating industrial relevance of 3D printed materials.

Advancements in these areas stimulate increased effort in the innovation of materials testing, automation, and meeting industrial requirements.

The impact of testing software on accuracy and efficiency

With the integration of modern technologies, material testing has seen a tremendous transformation, with software troubleshooting elevating the accuracy, effectiveness, and repeatability of tasks performed in both industrial and research settings. Advanced software products that come with testing hardware now allow for greater automation of data collection through sophisticated data handling and deliver results with accuracy. Reports indicate that automated methods, in contrast to manual methods, have the capability of lowering error margins by as much as 20%. Reliable data sourced from such automated methods is invaluable during decision-making phases of essential processes.

The application of advanced software goes beyond artificial intelligence-powered algorithmic testing; it also amplifies effectiveness by lessening the time needed for carrying out testing cycles. Companies using AI testing software, for example, claim they no longer have to spend as much as 30% on analyzing and preparing for testing in comparison to non-users. Furthermore, engineers are provided with capabilities to conduct thorough monitoring, gain foresight into future event sequences, detailed performance visuals, and corrective action execution which can significantly lower turn-around times. Such developments are vital for the aerospace, automobile, and medical industries, where the functioning and reliability of materials determine safety.

Also, remote testing platforms are allowing teams to collaborate globally by providing access to results and updates in real time. This easier access enhances innovation and efficiency. Thus, the incorporation of advanced testing tools becomes not an option to improve operations, but an urgent requirement to keep pace with ever-increasing industry expectations and technological developments.

Innovations in material tester designs

The design of modern material testers has been greatly streamlined, increasing performance, versatility, and precision. Testing machines now include AI and IoT integration, allowing for real-time monitoring and predictive maintenance, therefore reducing downtime while consistently adapting testing procedures ensuring accuracy.

Of great significance is the automated functionality designed into universal testing machines (UTMs). These machines incorporate robotic arms for specimen manipulation which minimizes human error through optimized efficiency. In addition, thermal chambers have been incorporated in material testers for accurate testing under extreme temperatures to simulate real-world conditions.

Material testing equipment are set to attain an $8.5 billion market value by 2030 at a CAGR of 5.5%, as mentioned in a 2023 report by Allied Market Research. This can be attributed to most recent automated testing systems and an increase in demand for quality assurance in the aerospace, automotive, and construction industries.

Moreover, new eco-friendly designs have been created for the materials and processes used in the construction of the testing machines. S testers have been shown to improve energy efficiency as well as enhance recycling capabilities within the system therefore prioritizing sustainability.

Such innovations fulfill the high standards set by contemporary industries and guarantee that material testers continue to lead technological development and quality control of mass production internationally.

The future of testing applications in materials science

The rapid evolution of artificial intelligence (AI), automation, and even machine learning is transforming the world of testing applications in materials science. These new tools provide enhanced precision and speed for analyses, tremendously improving the accuracy of material testing. As reported recently, the global market for material testing is expected to grow to USD 9.6 billion by 2027; this growth anticipates the demand for innovative solutions in various sectors, such as construction, aerospace, and automotive manufacturing.

One notable advancement that comes with the use of AI is employing AI algorithms that analyze large datasets and identify certain material properties and even predict performance under different conditions. This speeds up the testing processes, lessens the chances of making errors, and even cuts down on resources. Moreover, automated testing is becoming a favorite because of the ease with which non-destructive testing (NDT) can be conducted. This allows for the material being tested to be examined without being damaged.

Emerging trends in sustainability are also having an impact on the field, like eco-friendly testing designed to minimize waste and energy consumption. For instance, companies are trying to develop processes for testing materials that are biodegradable or bustos for the environment. Other innovations that are making an impact on material testing are 3D printers that allow for rapid prototype creation which can then undergo stress and durability tests.

Partnerships between academia and industry are important in advancing these efforts. Funding is anticipated to further propel development of material testing technologies in order to keep pace with the needs of emerging sectors such as renewables and modern electronics.

Reference Sources

The document analyzes the design and operation of material testing machines with particular attention to tensile testing and its relevance in the assessment of material attributes.

- MECH 237-010: Strength of Materials

The course’s syllabus within the catalog analyzes the strength of materials and how testing machines are utilized in teaching laboratories.

- Applicability of Existing Materials Testing Standards for Additive Manufacturing Materials

The report issued by NIST discusses the application of material testing machines and their relevance in the context of additive manufacturing materials, especially about checking materials and standards.

Frequently Asked Questions (FAQs)

Q: What is the purpose of a material testing machine?

A: A material testing machine is used to evaluate the mechanical properties of materials such as tensile strength, elasticity, and hardness. It helps in determining how materials will behave under various types of forces and conditions, ensuring they meet quality standards for their intended use.

Q: How does a tensile testing machine work?

A: A tensile testing machine works by applying a controlled tension force to a test specimen until it reaches its breaking point. This process measures various material properties, including ultimate tensile strength, yield strength, and elongation, providing crucial data for material testing needs.

Q: What are the different types of material testing machines?

A: There are several types of material testing machines, including tensile testing machines, compression testers, and universal testing machines. Each type is designed to evaluate different mechanical properties such as tensile strength, compressive strength, and flexural strength, depending on the testing application.

Q: Why is calibration important for material testing machines?

A: Calibration ensures that material testing machines provide accurate and reliable results. Regular calibration against standards like ASTM and ISO verifies that the testing equipment is functioning correctly, maintaining the integrity and precision of tests conducted for materials and products.

Q: What is the role of a universal testing machine?

A: A universal testing machine is a versatile piece of testing equipment that can perform a wide range of tests, including tensile, compression, and flexural testing. It is used across various industries to assess the mechanical properties of materials, making it an essential tool in quality control and materials science.

Q: How is hardness measured in material testing?

A: Hardness in material testing is measured using a tester that applies a specific force to a specimen and records the resistance to indentation. This test method provides insight into the material’s resistance to deformation and wear, which is critical for applications where durability is important.

Q: What is the significance of using an environmental chamber in material testing?

A: An environmental chamber is used in material testing to simulate different environmental conditions such as temperature and humidity. This allows for the assessment of material properties under various conditions, ensuring materials will perform reliably in their intended environments.

Q: What are extensometers used for in tensile testing?

A: Extensometers are devices used in tensile testing to measure the elongation and deformation of a test specimen. They provide precise data on how materials stretch under tension, contributing to a comprehensive understanding of their mechanical properties.

Q: How does fatigue testing contribute to material testing?

A: Fatigue testing evaluates a material’s ability to withstand repeated stress cycles over time. This type of testing is crucial for understanding how materials behave under long-term use, helping to predict potential failure points and ensuring the safety and reliability of materials such as metals and polymers.

Q: What is the importance of using testing software in material testing?

A: Testing software is vital in material testing as it automates data collection and analysis, enhances accuracy, and provides detailed reports on the material’s mechanical properties. It streamlines the testing process, making it more efficient and reliable for various testing applications.