Instrument And Equipment Wholesale

High Quality Other Rubber Testing Equipment Manufacturer in China

Introducing the Other Rubber Testing Equipment, a sophisticated instrument engineered for precise and versatile material performance testing. This advanced system accurately measures properties such as elasticity, hardness, and fatigue, making it ideal for a wide array of industrial applications.

What Is Other Rubber Testing Equipment

-

Utilizes advanced mechanisms to evaluate rubber properties like hardness, fatigue, and elasticity under controlled conditions.

-

Capable of performing specialized tests such as compression set, heat aging analysis.

-

Widely used in industries like automotive, aerospace, and manufacturing for quality assurance.

-

Equipped with precise sensors and software for accurate data collection and detailed reporting.

-

Available in various configurations to meet specific rubber testing needs and industry standards.

Main Features of Other Rubber Testing Equipment

The Other Rubber Testing Equipment enables precise analysis of diverse materials and components under controlled conditions, delivering essential data for research, development, and quality assurance.

Accurate Performance Analysis

Our Other Rubber Testing Equipment delivers accurate measurements of rubber properties like hardness and fatigue, using advanced sensors to ensure reliable data for quality control.

Advanced Data Processing

Equipped with cutting-edge digital systems, our Other Rubber Testing Equipment captures real-time data with high-precision sensors, enabling detailed analysis for research and development.

Rich Testing Functions

Designed to perform a wide range of tests, our equipment supports hardness, elasticity, fatigue, and compression set analysis, accommodating various rubber types for comprehensive evaluation.

User-Friendly Interface

Integrates intuitive software for seamless test setup, automated execution, and detailed reporting, simplifying complex rubber testing tasks and enhancing efficiency for industrial applications

Other Rubber Testing Equipment For Sale

LX-A Shore Hardness Tester

Measure rubber hardness with the LX-A Shore Hardness Tester, compliant with ASTM D2240, offering precise readings for quality control.

Heat Aging Test Box

Test rubber durability with the Heat Aging Test Box, simulating temperatures up to 200°C per ISO 188, ideal for aging analysis.

Rubber Density Meter

Determine rubber density with this Rubber Density Meter, accurate to 0.001 g/cm³, meeting ASTM D297 standards for material analysis.

Rubber Thickness Measuring Device

Measure rubber thickness with precision using this device, compliant with ISO 23529, ideal for quality assurance in production.

Rubber Elongation Device at Heating Temperature

Test rubber elongation at heated conditions up to 150°C with this device, per ASTM D412, ensuring performance under stress.

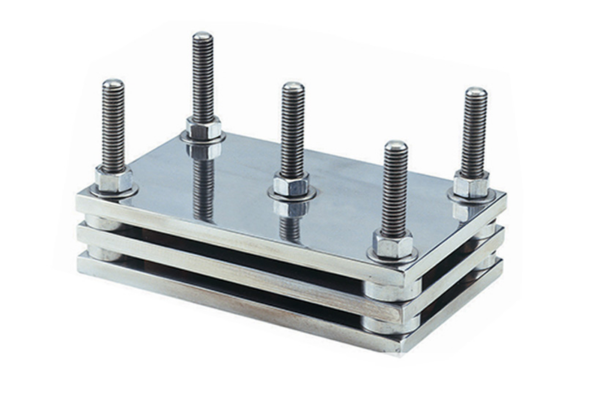

Rubber Compression Permanent Modification Device

Evaluate rubber compression set with this device, meeting ISO 815, testing permanent deformation under controlled pressure.

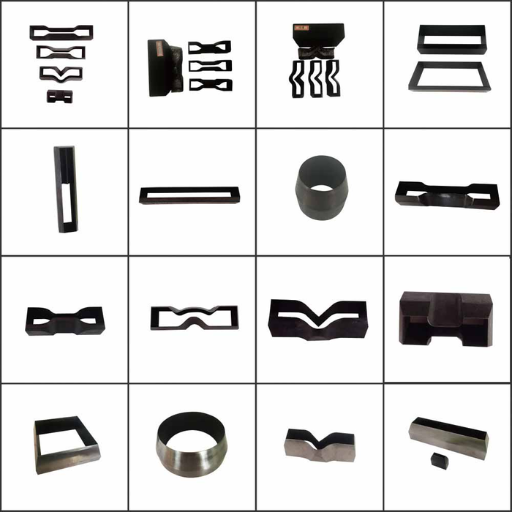

Dumbbell and Sheet Specimen Cutter for Tensile Test

Cut precise dumbbell and sheet specimens with this cutter, compliant with ASTM D638, perfect for tensile testing preparation.

Other Rubber Testing Equipment Technical Specifications

| Parameter | Details |

|---|---|

| Load Capacity Range | Ranges from 0.1 N to 20 kN for light to heavy-duty rubber testing. |

| Testing Versatility | Supports hardness, fatigue, elasticity, and compression set tests. |

| Accuracy and Precision | Features high-precision sensors with ±1% accuracy and digital controls. |

| Temperature Range | Operates from -40°C to 200°C for heat aging and low-temp testing. |

| Software and Automation | Includes intuitive software with automated data logging capabilities. |

| Speed Range | Adjustable from 1 mm/min to 500 mm/min for precise test control. |

| Crosshead Travel | Offers up to ±150 mm displacement for versatile specimen testing. |

| Extensometer Integration | Supports external extensometers for accurate strain measurement. |

| Power Supply Options | Compatible with 110V/60Hz or 220V/50Hz, depending on regional needs. |

| Safety Features | Equipped with overload protection, safety sensors, and emergency stop. |

Application Industries of Other Rubber Testing Equipment

- Automotive: Testing rubber seals, gaskets, and hoses for resilience and durability.

- Aerospace: Evaluating rubber components for fatigue and heat resistance.

- Manufacturing: Assessing rubber hardness and elasticity for industrial use.

- Medical Devices: Ensuring rubber in gloves and tubing meets quality standards.

- Research & Development: Analyzing new rubber formulations for performance.

- Construction: Testing rubber expansion joints for compression set resistance.

- Sports Equipment: Measuring rubber durability in grips and padding materials.

- Consumer Goods: Assessing rubber in toys and household items for safety.

Request Information on Other Rubber Testing Solutions!

Seeking precise and versatile testing equipment? Discover our advanced Other Rubber Testing Equipment, engineered for reliable material performance evaluation. Ideal for diverse needs like hardness and fatigue testing, it offers accurate measurements and robust performance, aligning with standards like ASTM D2240. Learn how this sophisticated equipment can enhance your quality control and R&D capabilities, especially for industries like medical devices and aerospace.

Frequently Ask Questions

Q: What is Other Rubber Testing Equipment used for?

A: It evaluates rubber properties like hardness, fatigue, elasticity, and compression set, ensuring material performance for various industrial applications.

Q: What specific tests can Other Rubber Testing Equipment perform?

A: It conducts hardness tests, fatigue analysis, elasticity measurements, and compression set evaluations to assess rubber durability and functionality.

Q: What standards does Other Rubber Testing Equipment comply with?

A: It aligns with standards such as ASTM D2240 for hardness, ISO 815 for compression set, and ASTM D412 for tensile properties, ensuring reliability.

Q: How does Other Rubber Testing Equipment operate?

A: It uses controlled mechanisms like durometers or compression devices, with sensors and software to measure and analyze rubber responses accurately.

Q: Which industries benefit from Other Rubber Testing Equipment?

A: Industries like medical devices, aerospace, automotive, and manufacturing use it to test rubber components for quality and performance.

Q: Can Other Rubber Testing Equipment be customized?

A: Yes, it offers adjustable settings for load, temperature, and test types, allowing customization to meet specific rubber testing needs.

Q: How accurate is Other Rubber Testing Equipment?

A: Equipped with high-precision sensors, it provides accuracy within ±1%, delivering dependable data for quality control and research.

Q: How often should Other Rubber Testing Equipment be maintained?

A: Maintenance, including calibration every 6-12 months and sensor checks, is recommended to ensure consistent and accurate performance.