Instrument And Equipment Wholesale

Premium Other Plastic Testing Equipment Manufacturer in China

In addition to universal testing capabilities, a range of specialized instruments is vital for comprehensive plastic characterization. This includes equipment like the dumbbell-type sample-making machine, WTB-401A aging test chamber, Melt flow rate meter. Thermal properties are measured by the Thermal deformation Vicat softening point temperature measuring instrument. Precise notches are created using a Manual notch sample cutter for impact testing. High-temperature applications or sample preparation may utilize a box type resistance furnace muffle furnace, while an Electric constant temperature drying oven handles controlled drying or heating.

What Is A Other Plastic Testing Equipment

-

Other plastic testing equipment includes specialized instruments designed to measure specific properties beyond basic tensile or compression tests performed by universal testers.

-

These machines focus on properties like melt flow rate, impact resistance, hardness, thermal deformation, density, and environmental aging behavior of plastic materials.

-

They are crucial for evaluating characteristics that affect processing, durability, and performance under various environmental conditions or specific stresses.

-

Examples include Melt Flow Indexers, Impact Testers (Izod/Charpy), Thermal Testers (HDT/Vicat), Hardness Testers, Density Meters, and Weathering Chambers.

-

This diverse range of equipment allows for comprehensive material characterization necessary for quality control, research, and compliance with specialized standards.

Main Features of Other Plastic Testing Equipment

Other Plastic Testing Equipment provides focused solutions for analyzing specific characteristics of plastic materials and products, offering critical data beyond general mechanical tests.

Focused Property Evaluation

These instruments are specifically designed to isolate and accurately measure individual properties like melt flow rate, impact strength, hardness, or thermal behavior, ensuring highly relevant data for material selection and processing control.

Optimized Testing Efficiency

Unlike versatile machines requiring frequent setup changes, dedicated equipment is often quicker and simpler to operate for specific, repetitive tests, streamlining workflow and increasing throughput for routine quality checks.

Compliance with Standards

Dedicated testers are built to conform strictly to specific industry standards (ASTM, ISO, etc.) for particular tests, guaranteeing reliable and comparable results essential for quality assurance and market acceptance.

Specialized Measurement Capability

Engineered with specialized fixtures, sensors, and control systems, these machines provide precise and repeatable measurement of unique material responses (e.g., energy absorbed during impact, material flow under heat and load) crucial for detailed characterization.

Other Plastic Testing Equipment For Sale

Dumbbell Type Sample Making Machine

Precisely cuts standardized dumbbell samples for plastic tensile testing. Ensures consistent geometry and quality for accurate mechanical property evaluation.

WTB-401A Aging Test Chamber

Simulates UV light, temp, humidity for plastic aging tests. Evaluates long-term durability & degradation resistance. Essential for weathering assessment.

Melt Flow Rate Meter

Measures melt flow rate (MFI/MVR) of thermoplastics under heat and load. Crucial for quality control, material identification, and processing optimization.

Thermal Deformation Vicat Softening Point Temperature Measuring Instrument

Determines heat resistance by measuring thermal deformation (HDT) or softening point (Vicat) of plastics under load. Essential for high-temp applications.

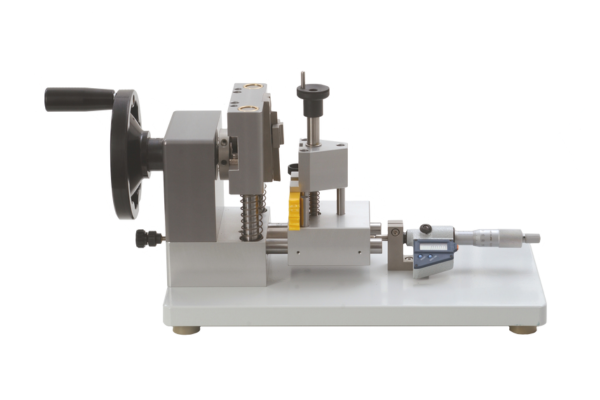

Manual Notch Sample Cutter

Creates precise, standardized notches on plastic impact test samples (Izod/Charpy). Ensures accurate and repeatable impact strength measurements per standards.

Box Type Resistance Furnace Muffle Furnace

High-temperature furnace for plastic sample preparation like ashing or ignition loss determination. Reaches high temperatures for material analysis and testing.

Electric Constant Temperature Drying Oven

Provides controlled temperature for drying, conditioning, or low-temp heat aging of plastic samples. Ensures proper sample preparation and consistent testing environments.

Other Plastic Testing Equipment Technical Specifications

| Parameter | Details |

|---|---|

| Test Function | Clearly defines the specific type of test the equipment performs (e.g., Melt Flow Rate, Impact Strength, HDT, Vicat Softening Point, Aging). |

| Measurement Range | Specifies the range of values the instrument is capable of accurately measuring for the tested property (e.g., 0.1 to 2000 g/10min , 0.5 to 25 J impact energy). |

| Temperature Range & Control | Indicates the operational temperature limits and the precision with which temperature can be maintained or ramped during testing cycles. |

| Applicable Standards | Lists the relevant international and national testing standards (e.g., ISO, ASTM, DIN) that the equipment complies with for the test method. |

| Sample Type and Size | Describes the physical form, required dimensions, or volume of plastic samples that the equipment is designed to accommodate for testing. |

| Accuracy and Repeatability | Provides specifications on the measurement precision and the consistency of results obtained from repeated tests on the same material under identical conditions. |

| Environmental Simulation (if applicable) | Details the specific environmental factors (like UV intensity, humidity range, temp cycling) the chamber can simulate for aging or weathering tests. |

| Data Output & Software | Explains how test results are presented, capabilities for data logging, analysis features, and software interface for test control and reporting. |

| Heating/Cooling Rate (if applicable) | Specifies the rate at which the temperature can be increased or decreased during thermal tests, crucial for controlled testing procedures. |

| Power Requirements | Lists the electrical power supply specifications (voltage, frequency, phase) needed for the equipment to operate correctly and safely. |

Application Industries of Other Plastic Testing Equipment

Plastic Production: Characterizing raw polymer resins and compound formulations for properties like melt flow index, density, and thermal stability.

Automotive: Testing specific plastic parts for impact strength, heat resistance (HDT/Vicat), weathering (aging chambers), and material identification.

Construction: Assessing plastic pipes, fittings, window profiles, and insulation for thermal deformation, impact resistance, and long-term aging characteristics.

Consumer Electronics: Testing plastic housings, connectors, and internal components for hardness, impact resistance, flammability, and environmental stability.

Medical Devices: Ensuring the biocompatibility, sterility resistance, and physical durability of plastic components through specific property testing.

Aerospace: Evaluating lightweight plastic and composite components for thermal limits, impact tolerance, and resistance to environmental extremes.

Request Information on Specialized Plastic Testing Equipment!

Seeking precise testing for specific plastic properties like melt flow, impact strength, or thermal limits? Discover our specialized Plastic Testing Equipment. Engineered for accuracy and standard compliance, these machines provide crucial data for quality control, processing optimization, and material development. See how our dedicated solutions can meet your unique testing needs. Contact us today for details and a custom consultation!

Frequently Ask Questions

Q: What property does a Melt Flow Rate (MFR) or Melt Volume Rate (MVR) tester measure, and why is it important?

A: It measures the ease of flow of molten thermoplastic polymers under standard conditions. This indicates processing characteristics, helps differentiate material grades, and is crucial for quality control in injection molding or extrusion.

Q: What is the difference between Izod and Charpy impact testing, and what do these tests tell you about a plastic material?

A: Both measure impact strength (toughness), but differ in how the sample is held and notched. They determine the energy absorbed by a material when fractured by a pendulum, indicating its resistance to brittle failure under sudden force.

Q: What properties are measured by HDT (Heat Deflection Temperature) and Vicat Softening Point testers?

A: HDT measures the temperature at which a plastic sample deforms under a specific load, while Vicat measures the temperature at which a standard indenter penetrates the surface under a specific load. Both assess a plastic’s ability to withstand heat under stress.

Q: Why are environmental aging chambers (like UV or Weathering testers) important for plastic testing?

A: These chambers simulate long-term exposure to conditions like UV radiation, temperature changes, and humidity to evaluate how plastics degrade over time, predicting their outdoor or service life durability.

Q: What kind of hardness tests are commonly performed on plastics, and what do they measure?

A: Common tests include Shore Hardness (Shore A, Shore D) and Rockwell Hardness. They measure a material’s resistance to indentation or penetration, indicating its surface hardness and sometimes overall rigidity.

Q: Why is sample preparation equipment like notch cutters or sample presses necessary for plastic testing?

A: Many tests, especially impact testing, require samples with precise dimensions and geometry (like a specific notch). Sample preparation equipment ensures that samples meet the required standards, leading to accurate and repeatable test results.

Q: What does a Density Tester for plastics measure, and how is this property useful?

A: Density measures the mass per unit volume of a plastic. It’s a fundamental property used for material identification, quality control (checking for variations or voids), and calculating part weight.

Q: Are specific calibration procedures required for specialized plastic testers?

A: Yes, like all testing equipment, specialized plastic testers require regular calibration using certified standards to ensure the accuracy and reliability of their measurements, adhering to relevant testing standards.