Instrument And Equipment Wholesale

Leading Durability Testing Machine Manufacturer in China

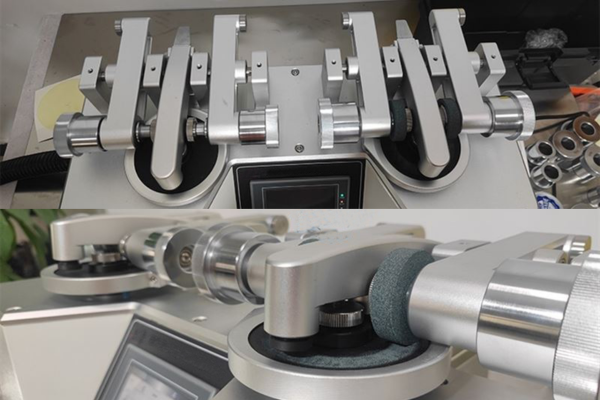

Discover our state-of-the-art Footwear Durability Testing Machine, engineered by a premier factory in China renowned for excellence in material testing technology. Designed for precision, this machine evaluates the wear resistance, flexibility, and structural integrity of footwear under rigorous conditions. Built with high-quality materials, it ensures long-lasting performance and reliable results for quality assurance. Ideal for manufacturers and labs, it offers customizable testing setups to meet specific standards.

What Is A Durability Testing Machine?

-

A Footwear Durability Testing Machine is a precision device used to assess the long-term performance of footwear under stress.

-

It operates by applying controlled forces to footwear samples, measuring wear, fatigue, and resistance over time.

-

The machine provides detailed data on material lifespan, strength, and stability under various conditions.

-

This testing is standardized (e.g., ASTM F1976, ISO 20344) and supports quality control in manufacturing.

-

Equipped with advanced sensors and software, it delivers reliable results for durability analysis and compliance testing.

Main Features of Durability Testing Machine

Durability Testing Machine enables detailed analysis of materials under controlled conditions, providing critical data for research, development, and quality assurance.

Enhanced Wear Resistance Testing

This feature ensures accurate evaluation of footwear materials, measuring their ability to withstand prolonged use.

Superior Fatigue Endurance

Measures footwear’s resistance to fatigue, providing insights into long-term durability under repeated stress.

Improved Flexibility Assessment

Enables precise testing of footwear flexibility, ensuring comfort and performance during dynamic movements.

Reliable Structural Integrity

Evaluates the structural stability of footwear, ensuring safety and quality for diverse applications.

Durability Testing Machine For Sale

WT-6034 Footwear Insulation Against Heat Testing Machine

Test footwear heat insulation with this machine. Uses a 150°C sand bath to measure insole temperature rise, per ISO 20344. Accuracy ±0.5°C, with safety features.

WT-6013 Oil Resistance Testing Machine for Rubber

Evaluate rubber oil resistance with this tester. Immerses samples in oil, measuring swelling and degradation per ASTM D471 standards, ensuring durability in harsh environments.

WT-6067 Microcomputer Leather Cracking Testing Machine

Test leather cracking resistance with this microcomputer-controlled machine. Meets EN 344, with adjustable speed.

WT-6054 TABER Abrasion Resistance Testing Machine

Evaluate material wear with this TABER tester. Uses rotary abrasive wheels, meets ASTM D4060, for plastics, leather, and coatings.

WT-6054B 2 Stations TABER Abrasion Tester

Dual-station TABER tester for simultaneous abrasion tests. Complies with ISO 5470, ideal for textiles, rubber, and coatings.

WT-6010 Top Piece of Leather Shoes Abrasion Device Abrasion Resistance Tester

Test leather shoe top pieces for abrasion resistance. Simulates wear with adjustable cycles, per EN 13521 standards.

WT-6010 Sole Abrasion Tester

Assess shoe sole durability with this tester. Measures abrasion resistance under simulated walking, meets ISO 20344, for rubber and synthetics.

WT-6048 Shoe Lace Abrasion Tester

Test shoelace durability against rubbing. Simulates lace-to-lace abrasion, compliant with SATRA TM154, ensuring long-lasting performance.

WT-6047 Shoe Lace and Eyelets Abrasion Tester

Evaluate shoelace and eyelet wear resistance. Tests lace-to-eyelet abrasion per ISO 22774, with adjustable tension and cycles.

WT-6043 Shoe Heel Lateral Impact Tester

Test shoe heel durability with this machine. Simulates lateral impacts per SATRA TM21, with adjustable energy up to 20J, ensuring compliance for women’s high heels.

WT-6026 Safety Shoe Impact Resistance Tester

Evaluate safety shoe toe cap impact resistance. Delivers 100J or 200J energy per ISO 20344, ensuring protection against falling objects. Ideal for steel-toe testing.

WT-6061 Rub Rotary Friction Fading Color Fastness Testing Machine

Test fabric and leather color fastness with rotary friction. Meets ISO 105-X12, uses adjustable pressure, ideal for dry/wet tests on dyed materials.

WT-6060 IULTCS Leather Reciprocating Friction Color Fastness Testing Machine

Assess leather color fastness with reciprocating friction per ISO 11640. Uses wool felt, suitable for dry/wet tests on dyed leather surfaces.

WT-6060D Shoe Upper Lining Friction Color Fastness Testing Machine

Evaluate shoe upper and lining color fastness. Complies with ISO 11640, features reciprocating friction for dry/wet tests on leather materials.

WT-6059 Manual Leather Friction Fading Testing Machine

Manually test leather color fading with friction. Meets SATRA PM173, uses felt under pressure, ideal for small-scale dry/wet color fastness tests.

WT-6059B Fur Friction Decolorization Testing Machine

Test fur decolorization with friction. Complies with ISO 11640, uses reciprocating motion for dry/wet tests on fur and leather goods.

WT-6058F JIS Friction Dyeing Firmness Testing Machine

Evaluate dyeing firmness on fabrics per JIS L0849. Features rotary friction, suitable for dry/wet tests on textiles and leather.

WT-6058D Scott Rubbing Friction Testing Machine

Test fabric rubbing resistance with Scott method. Meets ASTM D2054, uses reciprocating motion for dry/wet color fastness on textiles.

WT-6058A Electric Friction Fading Testing Machine

Electric tester for fabric color fading. Complies with AATCC 8, offers adjustable speed and pressure for dry/wet friction tests.

WT-6058B Leather Electric Friction Fading Testing Machine

Test leather color fastness electrically. Meets ISO 11640, features reciprocating friction for dry/wet tests on dyed leather surfaces.

WT-6056 Leather Breaking Strength Testing Machine

Test leather tensile strength with this machine. Measures breaking force up to 10 kN, compliant with ISO 3376, ideal for quality control in footwear production.

WT-6056A Automatic Leather Rupture Strength Testing Machine

Automate leather rupture testing with this device. Handles up to 20 kN, meets EN ISO 3377-1, with auto data logging for precise strength analysis.

WT-6031B Manual Shoe Peeling Strength Testing Machine

Manually test shoe peeling strength. Applies up to 5 kN, compliant with SATRA TM401, suitable for sole-upper adhesion checks in small-scale production.

WT-6031A Whole Shoe Peeling Strength Testing Machine

Evaluate whole shoe peeling strength. Supports up to 10 kN, meets ISO 20344, designed for comprehensive adhesion testing in footwear manufacturing.

WT-6027 Shoe Compression and Sole Penetration Resistance Testing Machine

Test safety shoe toecap compression and sole penetration resistance. Applies 20 kN or 50 kN loads per ISO 20344, with microcomputer control for precise results. Ideal for durability and safety testing.

WT-6045A Footwear Shank Fatigue Testing Machine

Test steel shank fatigue resistance in footwear. Simulates repeated bending per ISO 18895, with adjustable cycles up to 240 cpm, ensuring durability in high-heeled shoes.

WT-6044 Shoe Heel Fatigue Testing Machine

Evaluate heel fatigue resistance with this machine. Applies repeated impacts per SATRA TM21, suitable for slender heels, ensuring performance under normal walking conditions.

Durability Testing Machine Technical Specifications

| Parameter | Details |

|---|---|

| Applicable Materials | Suitable for testing leather, rubber, synthetic fabrics, and soles. |

| Standards Compliance | Designed to meet global standards (e.g., ASTM F1976, ISO 20344, EN 13521). |

| Load Application | Features adjustable force application from 0.05 kN to 50 kN for testing. |

| Test Speed & Control | Includes precise speed settings from 10 mm/min to 300 mm/min for accuracy. |

| Measurement Method | Allows evaluation of wear resistance, flexibility, and tensile strength. |

| Sample Compatibility | Accommodates various footwear sample sizes and shapes per testing needs. |

| Automation Features | Offers programmable test cycles and automatic data logging for ease. |

| Data Output | Provides detailed reports on durability, stress, and performance metrics. |

| Safety Features | Includes overload protection, emergency stop, and safety interlocks. |

| Environmental Range | Operates in temperatures from -10°C to 50°C and 20% to 90% humidity levels. |

Application Industries of Durability Testing Machine

- Footwear Manufacturing: Quality control and assurance for raw materials (leathers, synthetics), in-process checks, and final product testing to meet specifications and standards.

- Sporting Goods Industry: Testing footwear components like soles, laces, and uppers for strength, wear resistance, flexibility, and environmental factors.

- Retail and Distribution: Assessing the mechanical properties (tensile strength, tear resistance), comfort, and durability of footwear for various market segments.

- Consumer Safety: Evaluating the physical and mechanical properties of footwear used in daily wear, safety gear, and outdoor products to ensure safety and performance.

- Research and Development: Characterizing the properties of new footwear materials, blends, and designs to understand their behavior under various conditions and develop innovative products.

Ensure Footwear Excellence with Our Durability Testing Machine!

Elevate your footwear production with our Footwear Durability Testing Machine. Designed for precision, it tests wear resistance, flexibility, and strength per ASTM F1976 and ISO 20344 standards. With robust materials and advanced tech. Ideal for manufacturers and labs, it ensures quality and safety.

Frequently Ask Questions

Q: How does a Footwear Durability Testing Machine work?

A: It applies forces to footwear samples, simulating real-world wear, and measures resistance to abrasion, flexing, and fatigue, providing data on material durability.

Q: What materials can be tested with this machine?

A: It tests leather, rubber, synthetic fabrics, and soles, assessing their performance in footwear applications under various mechanical and environmental stresses.

Q: What standards does the machine comply with?

A: The machine meets global standards like ASTM F1976, ISO 20344, and EN 13521, ensuring consistent and reliable testing for footwear durability.

Q: What tests can be performed with this machine?

A: It conducts abrasion resistance, flexing endurance, tensile strength, and impact tests to evaluate footwear durability and performance under stress.

Q: Who uses Footwear Durability Testing Machines?

A: Footwear manufacturers, sporting goods companies, retailers, and research labs use it for quality control, product development, and safety compliance.

Q: What are the key features of this machine?

A: It includes adjustable load settings, automated data logging, environmental simulation, and safety features like overload protection for reliable testing.

Q: Can the machine test different footwear sizes?

A: Yes, it accommodates various footwear sizes and shapes, with adjustable fixtures to ensure accurate testing across different designs and styles.

Q: How does it benefit footwear manufacturers?

A: It ensures product quality, reduces returns by identifying weaknesses, and supports compliance with safety standards, enhancing brand reliability.