Rubber hardness plays a critical role in determining the performance, durability, and suitability of materials across countless industries, from automotive and construction to medical devices and consumer goods. Understanding the science behind rubber hardness and how it is measured is essential for engineers, product designers, and quality control professionals aiming to make informed material choices. This guide explores the intricacies of durometer testing and Shore hardness scales—two standardized methods for quantifying rubber firmness. By the end of this article, you will gain a clear understanding of why rubber hardness matters, how testing methods work, and how to select the right material for your specific application. Whether you are new to material science or an experienced practitioner, this comprehensive guide is designed to answer your questions and provide actionable insights.

What Is Rubber Hardness and How Is It Measured?

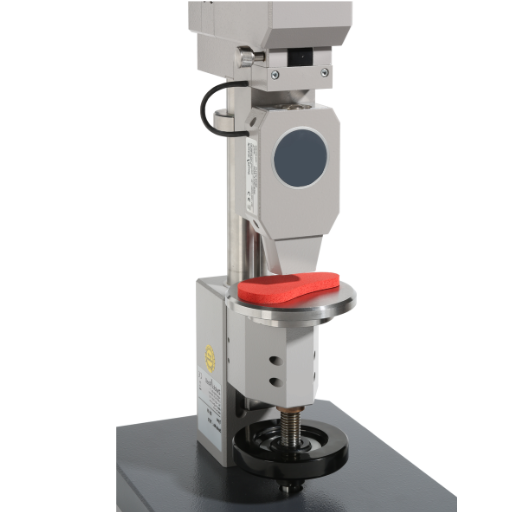

Rubber hardness refers to the material’s resistance to deformation under an applied force. It is a key property that determines how a rubber material will perform in various applications, such as sealing, vibration dampening, or load-bearing. Rubber hardness is commonly measured using a durometer, an instrument that assesses hardness based on the material’s resistance to indentation. The Shore hardness scales, including Shore A for softer rubbers and Shore D for harder materials, are the standard scales used for these measurements. Accurate hardness testing ensures that the selected rubber fits the functional and performance requirements of specific applications.

Understanding the Concept of Hardness in Rubber

Rubber hardness is influenced by several critical factors, each of which directly affects the material’s structural and functional characteristics. The formulation of the rubber compound, including the type and proportion of fillers, plasticizers, and curing agents, plays a major role in determining hardness. For example, adding carbon black as a filler typically increases the hardness while improving tensile strength and abrasion resistance. Temperature also significantly impacts rubber hardness since materials like elastomers become softer at higher temperatures due to reduced intermolecular forces or stiffer in colder conditions when molecular mobility decreases.

Additionally, the method of vulcanization, which involves cross-linking polymer chains, determines the degree of elasticity and rigidity in the material. A higher degree of cross-linking generally results in increased hardness but may reduce flexibility. Understanding these parameters and their interplay is paramount for selecting the appropriate rubber grade for specific industrial applications, whether it’s for vibration damping, sealing, or load-bearing tasks. Combining this technical knowledge with real-world performance metrics ensures optimal material selection aligned with both functionality and durability expectations.

How Does a Durometer Work in Hardness Testing?

A durometer measures the hardness of rubber, elastomers, and soft plastics by quantifying the material’s resistance to indentation. The device typically utilizes a spring-loaded indenter that applies pressure to the material’s surface, and the hardness is recorded as a value on a specified scale, such as Shore A or Shore D. The Shore A scale is used for softer materials, while the Shore D scale measures harder ones. Key technical parameters involved in durometer testing include the indenter geometry, such as the shape and size of the tip, the applied force (e.g., typically 8.05 N for Shore A), and the dwell time during which the force is applied. These factors must align with ISO or ASTM standards (e.g., ASTM D2240) to ensure consistent and reliable results. By adhering to these parameters, durometer testing provides a standardized method for determining material properties crucial for their intended applications.

Exploring the Shore Hardness Scale

The Shore Hardness Scale is divided into several categories, each designed to measure materials of differing hardness ranges. The most common scales are Shore A and Shore D, which are frequently used in industries such as rubber, plastics, and elastomers. Shore A measures softer materials, while Shore D is suited for harder substances.

Key Parameters and Standards:

1. Shore A Scale:

-

- Applications: Rubber, elastomers, and materials with a softer composition like flexible plastics.

- Indenter Geometry: Truncated cone with a rounded tip.

- Applied Force: 8.05 N (approx.).

- Standards Used: ASTM D2240-15, ISO 7619-1.

- Shore D Scale:

- Applications: Harder plastics, thermoplastic resins, and rigid polymers.

- Indenter Geometry: Sharp pointed cone for enhanced penetration.

- Applied Force: Typically 44.5 N.

- Standards Used: ASTM D2240-15, ISO 868.

Methodology:

To measure Shore hardness accurately, specific procedures must be followed. First, the material surface should be prepared to be smooth and flat to avoid inconsistencies. The durometer is then pressed perpendicular to the material under the specified force, and the indentation depth determines the hardness value. The measurement should be conducted at room temperature (23°C ± 2°C) to reduce deviations caused by thermal influence.

By employing the correct durometer scale and adhering to standardized methodologies, the Shore Hardness Scale ensures repeatable, reliable measurements essential for material evaluation and quality control processes.

Why Use the Shore A Hardness Scale for Measuring Rubber?

The Shore A Hardness Scale is specifically designed to evaluate the hardness of flexible materials, including rubber, making it an ideal choice for such applications. Its ability to measure the resistance of rubber to indentation ensures accurate characterization of properties like elasticity, durability, and wear resistance. Additionally, the Shore A scale is widely recognized in industry standards, allowing for consistency and comparability across tests and materials. This makes it a reliable tool for quality control, product development, and compliance with technical specifications.

Benefits of Using the Shore A Durometer

- Precision in Measurement: The Shore A durometer provides highly accurate readings of rubber hardness, enabling precise assessment of material properties required for various applications.

- Standardized Testing: Its adherence to industry standards ensures consistency and repeatability in measurements, facilitating reliable comparisons between different materials and test conditions.

- Versatility: The Shore A durometer can be used on a wide range of elastomer and polymer materials, making it suitable for diverse industries such as automotive, construction, and consumer goods.

- Ease of Use: The device is designed for straightforward operation, allowing both experts and non-experts to conduct hardness tests efficiently and with minimal training.

- Application in Quality Control: By enabling consistent evaluation of material hardness, the Shore A durometer is an invaluable tool for maintaining product quality and meeting strict technical and regulatory requirements.

Comparing Shore A with Other Shore Scales

The Shore scales commonly include Shore A, Shore D, Shore 00, Shore B, Shore C, and Shore O, utilized for measuring the hardness of materials with varying degrees of softness and rigidity.

|

Scale |

Material |

Hardness Range |

Application |

Example |

|---|---|---|---|---|

|

Shore A |

Soft Plastics |

Medium |

Flexibility |

Rubber, Tires |

|

Shore D |

Hard Plastics |

High |

Rigidity |

Hard Polymers |

|

Shore 00 |

Gels/Foams |

Low |

Softness |

Foam Cushions |

|

Shore B |

Semi-Rigid |

Medium-High |

Durability |

Shoe Soles |

|

Shore C |

Elastic Materials |

Medium |

Elasticity |

Soft Polymers |

|

Shore O |

Thermoplastics |

Medium |

Versatility |

Industrial Films |

Determining Rubber Hardness Using Shore A

Rubber hardness, as measured by the Shore A scale, is a critical parameter in selecting materials for specific applications. Shore A evaluates the resistance of a rubber sample to indentation under standardized testing conditions, offering insights into its flexibility and durability. Materials with lower Shore A values are softer and more pliable, such as those used in tires or seals, while higher values indicate increased hardness and rigidity. This measurement is essential for ensuring that the rubber component meets operational requirements like load resistance, wear tolerance, and structural integrity.

How is the ASTM D2240 Standard Applied in Hardness Testing?

The ASTM D2240 standard is applied in hardness testing by specifying the methods and equipment required to measure the hardness of rubber and elastomeric materials. Using a durometer device, the material is tested under specific conditions, including defined force and time parameters, to ensure consistency and reproducibility of results. The standard includes different Shore hardness scales, such as Shore A and Shore D, tailored to materials with varying degrees of hardness. This ensures that the test method is appropriate for the material being evaluated, providing reliable data for quality control and performance assessments.

Overview of the ASTM D2240 Test Method

Key Components of the ASTM D2240 Test Method

The ASTM D2240 test method is designed to measure the hardness of elastomers, polymers, and similar materials using a durometer device. This standardized procedure ensures precise evaluation of material properties pertinent to durability, flexibility, and performance under specific conditions. The test involves the application of a calibrated force by the durometer’s indenter onto the material’s surface, with the depth of indentation being measured according to specific Shore scales.

The method provides multiple Shore scales, including Shore A for softer materials like rubbers and Shore D for harder plastics, enabling flexibility in testing diverse ranges of hardness. Factors such as environmental conditions, preparation of the material sample, and consistent application of force play a critical role in ensuring the accuracy and repeatability of results. ASTM D2240 is widely used in quality control processes and engineering applications to classify materials, predict their behavior under stress, and validate their conformity to industry standards.

This method is recognized for its reliability, having established its relevance across sectors such as automotive, aerospace, and manufacturing, where precise material specifications are critical to performance.

Implementing ASTM Standards in Rubber Hardness Testing

ASTM standards, particularly ASTM D2240, play a pivotal role in rubber hardness testing by providing a uniform methodology to measure material hardness using durometer scales such as Shore A or Shore D. These standards outline comprehensive guidelines on test equipment calibration, operational procedures, and environmental conditions to ensure consistent and repeatable results. For instance, the test involves pressing an indenter of specified geometry into the rubber surface under controlled force and duration, with the resulting hardness value determined by the material’s resistance to deformation.

The versatility of ASTM D2240 allows it to accommodate diverse rubber types and hardness ranges, making it an essential tool for evaluating materials used in automotive parts, seals, tires, and industrial components. Adhering to these standards minimizes variability in testing outcomes, ensuring results meet performance and safety requirements. Furthermore, ASTM compliance supports global material specifications, facilitating the seamless integration of products into international supply chains. By leveraging the detailed procedural framework of ASTM standards, industries can maintain rigorous quality control, optimize material performance for specific applications, and ensure adherence to regulatory benchmarks.

Interpreting Hardness Values According to ASTM D2240

ASTM D2240 provides a standardized methodology for measuring the hardness of elastomers, plastics, and similar materials using durometers. The hardness value obtained is a dimensionless number ranging from 0 to 100, where higher values indicate harder materials with less indentation under defined testing conditions. The standard specifies multiple durometer scales (e.g., Shore A, Shore D) that are chosen based on the material’s characteristics, such as flexibility and thickness. For example, softer materials like rubber typically utilize the Shore A scale, whereas harder polymers or thermoplastics are measured with the Shore D scale.

When interpreting hardness values, it is crucial to consider the testing conditions, such as sample thickness, temperature, and dwell time, as these factors can significantly influence results. Consistency across testing parameters ensures reliable and comparable measurements. Additionally, hardness values should not be used in isolation but should complement other material properties, such as tensile strength and elongation, to provide a comprehensive understanding of performance. Accurate reporting requires clear documentation of the durometer scale, specific test conditions, and any modifications from the ASTM D2240 procedure to maintain alignment with industry standards.

What Are the Challenges in Measuring the Hardness of Elastomers?

Measuring the hardness of elastomers presents several challenges due to their inherent material properties and testing conditions. Elastomers exhibit time-dependent behavior, such as viscoelasticity, which can result in varying hardness measurements based on the rate of indentation and dwell time during testing. Additionally, surface conditions, like texture or contamination, can introduce inconsistencies in results. The geometry of the test specimen, including thickness and uniformity, further influences the accuracy of the measurement, as non-standard sample dimensions may lead to deviations from expected outcomes. Ensuring consistent environmental conditions, such as temperature, is also critical, as elastomers’ mechanical properties are highly sensitive to thermal variations.

Factors Affecting Hardness Measurement Accuracy

- Surface Condition of the Material: Irregularities on the surface, such as scratches, dust, or residual contaminants, can interfere with the indentation process, leading to inaccurate hardness readings.

- Sample Dimensions and Geometry: Variations in thickness, uneven surfaces, or non-standard shapes can cause discrepancies in hardness measurement, as standardized testing equipment may not properly account for these deviations.

- Environmental Temperature: Temperature fluctuations can significantly affect the mechanical properties of materials, particularly elastomers, altering their hardness and resulting in inconsistent results if not controlled.

- Application of Testing Force: Variability in the applied load, including inconsistencies in the speed or duration of force application, can affect the depth of indentation and, consequently, the hardness measurement.

- Type and Calibration of Testing Instruments: The accuracy and calibration status of the testing device play a crucial role, as outdated or improperly calibrated equipment may produce erroneous or unreliable results.

Addressing Indentation Issues in Elastomer Testing

To address variability in the applied load, I ensure that testing procedures follow standardized protocols, such as maintaining consistent force application rates and durations as outlined in ASTM or ISO standards. Adopting automated systems can help minimize human error in this regard. Regarding the material’s composition, I carefully analyze the specific formulation and manufacturing history of the elastomer, since changes in fillers, plasticizers, or curing conditions significantly influence its response to indentation.

When it comes to ensuring reliable instrumentation, I prioritize regular calibration and maintenance of testing devices. This includes adhering to a periodic verification schedule using certified reference materials to validate accuracy. Additionally, I ensure that testing instruments are appropriately selected for the material being tested, avoiding the use of equipment beyond its intended specifications, which could lead to flawed results.

Choosing the Right Durometer for Elastomers

When selecting the right durometer for elastomers, I focus on the Shore hardness scale most suited to the material’s intended application, such as Shore A for softer elastomers and Shore D for harder variants. I ensure the durometer meets ASTM D2240 or equivalent standards to achieve reliable measurements. Additionally, I account for material thickness and geometry, adjusting the testing technique if necessary to prevent inaccuracies. Proper environmental conditions, such as temperature control, are also critical to maintain consistent and valid results.

How Does Hardness Testing of Plastics Differ from Rubber?

Hardness testing for plastics and rubber varies primarily due to their distinct material properties. Plastics, being more rigid, often require tests like Rockwell or Ball Indentation to measure their resistance to deformation under static loads. On the other hand, rubber, known for its higher elasticity, is typically tested using methods such as Shore A or Shore D, emphasizing the material’s surface resilience and flexibility. Additionally, the deformation and recovery characteristics of rubber demand shorter test durations to avoid permanent indentation, unlike plastics which can sustain longer testing periods without altering the results. These differences ensure that the testing approach aligns with the specific mechanical behavior of each material type.

Differences Between Rubber and Plastic Hardness Testing

Rubber and plastic hardness testing differs primarily in testing methods, deformation characteristics, test duration considerations, and material-specific requirements.

|

Parameter |

Rubber |

Plastic |

|---|---|---|

|

Testing Method |

Shore A, Shore D |

Shore D, Rockwell |

|

Surface Resilience |

High |

Moderate |

|

Test Duration |

Short |

Long |

|

Deformation |

Reversible |

Partial/Irreversible |

|

Indentation |

Avoid Permanent |

Sustain Longer |

|

Flexibility |

High |

Moderate to Low |

Using Shore D Scale for Plastics

When using the Shore D scale for plastics, I focus on its suitability for harder polymers that typically require higher durometer testing. This method ensures more precise measurement of the material’s resistance to indentation under standardized conditions. Shore D is particularly advantageous for assessing plastics with moderate to high hardness, such as thermoplastics and certain reinforced composites. I also ensure that the testing setup adheres strictly to ASTM D2240 standards to guarantee accuracy and repeatability. By employing this scale, I can evaluate the mechanical properties reliably, enabling better material selection and performance analysis for specific applications.

Understanding the Role of Material Hardness in Application

- Wear Resistance: Harder materials exhibit higher resistance to wear and abrasion, making them suitable for applications where surfaces face constant friction or contact, such as gears, bearings, and cutting tools.

- Load-Bearing Capacity: Materials with higher hardness can withstand significant mechanical stresses without deformation, making them ideal for structural components and heavy-duty machinery.

- Impact Resistance: The hardness of a material directly influences its ability to resist impacts and surface indentations, which is vital for protective coatings and automotive parts.

- Dimensional Stability: Hardness contributes to a material’s ability to retain its shape and size under various environmental conditions, ensuring long-term reliability in precision components like molds and dies.

- Surface Finish and Aesthetic Appeal: Harder materials often maintain their surface quality longer, resisting scratches and dents, which is crucial for consumer goods, decorative applications, and high-end electronics.

Reference Sources

- Understand Durometer and Shore Hardness Scales – Mi Conveyance Solutions

- Durometer Shore Hardness Scale – Smooth-On

- Shore Hardness / Durometer Hardness: ASTM D2240 – ZwickRoell

- Shore Hardness Guide – Techsil

- Top Rubber Testing Equipment in China

Frequently Asked Questions (FAQs)

Q: What is the hardness of rubber and why is it important?

A: The hardness of rubber refers to its resistance to indentation and deformation. It is crucial for determining the suitability of rubber materials for specific applications. Measuring the hardness helps in assessing the durability and performance of rubber products in various environments.

Q: How is the hardness of rubber measured?

A: The hardness of rubber is measured using a device known as a durometer. This instrument applies a specific force to the rubber surface and measures the depth of indentation. The hardness value is determined on a scale, with different shore scales used for different materials and applications.

Q: What is a shore durometer and how does it work?

A: A shore durometer is a type of hardness tester used to measure the hardness of materials like rubber and plastics. It consists of a calibrated spring and an indenter that presses into the material, providing an empirical hardness value on the shore scale.

Q: What are the different shore scales and their applications?

A: Different shore scales, such as Shore A and Shore D, are used to measure different hardness levels of materials. The Shore A scale is typically used for softer materials like natural rubber, while the Shore D scale is used for harder plastics and elastomers.

Q: How does the shore durometer hardness test differ from other hardness test methods?

A: The shore durometer hardness test specifically measures the indentation hardness of elastomers and plastics, providing a quick and non-destructive assessment. In contrast, methods like Rockwell hardness and Vickers hardness tests involve different principles and are often used for metals.

Q: What is the importance of the international rubber hardness degrees (IRHD)?

A: The international rubber hardness degrees (IRHD) provide a standardized method for measuring the hardness of elastomers. This scale measures the hardness of the material by applying a specific force and assessing the indentation depth, ensuring consistency across international testing practices.

Q: Why might different hardness values be important in rubber products?

A: Different hardness values are critical because they determine the material’s suitability for various applications. For instance, softer rubbers may be preferred for flexibility and cushioning, while harder rubbers are used where durability and resistance to wear are essential.

Q: Can hardness testing be used for materials other than rubber?

A: Yes, hardness testing can be applied to various materials, including plastics, metals, and elastomers. While shore hardness testing is often used for rubber and plastics, other methods like Rockwell and Vickers are more suitable for metals.

Q: What factors can affect the results of a shore hardness test?

A: Factors such as temperature, testing angle, and material thickness can affect the results of a shore hardness test. Consistency in testing conditions is essential to ensure accurate and reliable hardness values.

Q: How can understanding rubber hardness benefit product development?

A: Understanding rubber hardness allows engineers and designers to select appropriate materials for specific applications, ensuring optimal performance and longevity. This knowledge can lead to better product quality and customer satisfaction by using the shore hardness to match material properties with functional requirements.