Bend test machines play a critical role in assessing the durability and flexibility of a wide range of materials, making them indispensable in industries such as manufacturing, construction, and quality assurance. Whether you’re testing metals, plastics, or composite materials, these machines provide precise insights into a material’s performance under stress. This guide is designed to help you navigate the technical landscape of bend test machines, offering an in-depth look at their specifications, key features, and essential accessories. By the end, you’ll be equipped with the knowledge necessary to select the right machine for your application and optimize its usage to meet your operational requirements.

What Is a Bend Test Machine and How Does It Work?

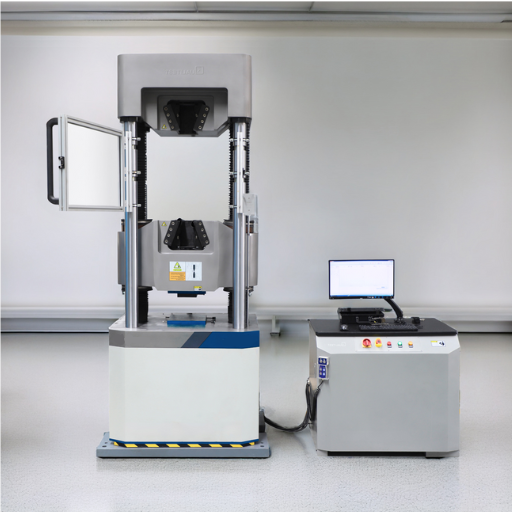

A bend test machine is a specialized device used to evaluate the ductility, strength, and performance of materials when subjected to bending stress. It operates by applying a controlled force to a specimen, typically a metal or composite, to bend it around a fixed radius or between supports. The test measures the material’s ability to withstand deformation without cracking or breaking, providing critical insight into its flexibility and structural integrity. Bend test machines are essential in quality control and research applications, ensuring materials meet specific standards for various industrial uses.

Understanding Bend and Testing Processes

Bend testing is a fundamental mechanical test used to assess material ductility, fracture resistance, and strength. The process involves placing a material under controlled stress using standardized equipment. It is predominantly utilized for metals and composites to determine their behavior under applied force. During the test, parameters such as the radius, span length, and applied force are adjusted to match the material’s specifications and the standards defined by ASTM or ISO for accurate evaluation. Key measures include the angle and degree of the bend, as well as whether cracking or fracturing occurs, directly reflecting the material’s flexibility and load tolerance. This testing method is critical across industries such as construction, aerospace, and automotive, ensuring compliance with structural and safety requirements.

Components of a Bend Test Machine

A bend test machine consists of several key components, each designed to ensure precise and reliable testing of material properties. Below is a detailed breakdown:

- Fixture Supports

These are designed to securely hold the test specimen in place during the application of the bending load. The supports are typically adjustable to accommodate varying specimen dimensions, with spacing determined by the material standards (e.g., ASTM E290 or ISO 7438). For instance, standard testing may require a support span ranging from 10 mm to 200 mm based on the material thickness.

- Plunger (or Bending Die)

The plunger applies the bending load to the material. It is generally shaped to create controlled deformation and is manufactured with high-strength materials like hardened steel to resist wear over repeat tests. The radius of the plunger is critical, often ranging from 1 mm to 20 mm, depending on test specifications.

- Load Cell

A load cell measures the force exerted during the bending process. High-calibration precision is required, with devices capable of capturing force up to 100 kN or more for industrial-grade machines. The responsiveness and repeatability of the load cell ensure accurate data recording.

- Control System

The control system often includes a digital interface with software integration for monitoring and recording test parameters in real time. This system can measure applied force, displacement, and bending angle with high precision, often within ±0.5% of actual values. Data logging and analysis capabilities are essential for compliance reporting and further material study.

- Support Frame

The frame is the structural backbone of the machine, designed to withstand high loads without deformation. Frames are commonly built from steel or alloy composites, ensuring stability and minimizing vibrational impact during testing.

- Displacement Sensors

These sensors track the material’s deflection under load with extreme precision, often down to micrometer levels. This data is critical for determining the ductility and flexibility of the material, as well as for calculating stress-strain relationships.

Every component of a bend test machine is engineered to meet industry-specific requirements, allowing for accurate and repeatable assessments. Advanced machines may also include automated specimen loaders, environmental chambers for temperature-controlled tests, and optical systems for detecting surface cracks in real time.

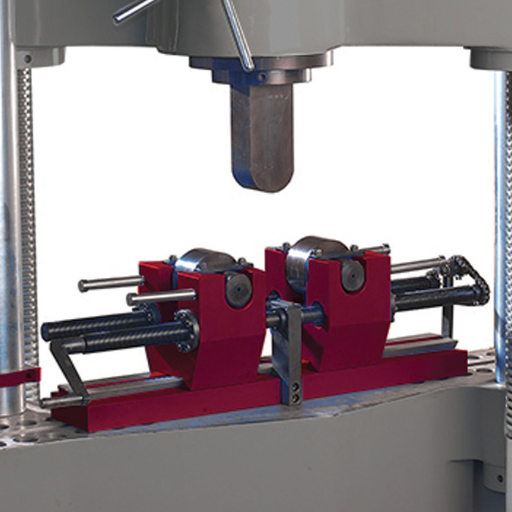

Role of Test Fixtures and Mandrels in Bend Testing

Test fixtures and mandrels play a critical role in ensuring the accuracy, precision, and repeatability of results in bend testing. Test fixtures are designed to securely hold the specimen in place during the testing procedure, maintaining consistent alignment and preventing unwanted lateral movement that could skew results. They are typically constructed from high-strength materials, such as hardened steel or tool-grade alloys, to endure the forces applied during testing without deformation. The design of the test fixture must correspond to the size, shape, and material specifications of the test specimen, as outlined in industry standards such as ASTM E290 or ISO 7438.

Mandrels, on the other hand, are primarily used to apply force and create a uniform bend in the specimen. The diameter of the mandrel is a critical parameter, as it directly influences the bending radius, which is often specified in testing codes. For example, in standard ductility tests, mandrels are selected based on a specific ratio to the thickness of the test specimen, such as 2t, 3t, or higher, where “t” represents the material thickness. This ratio ensures that the induced stress remains within acceptable parameters for the material being evaluated.

Empirical data supports the importance of standardized test fixtures and mandrels in bend testing. For instance, improper alignment in the fixture can lead to measurement deviations of up to 15%, particularly in materials with low yielding strength. Similarly, variations in mandrel diameter outside tolerance limits can induce premature cracking or overly severe stress concentration, producing non-representative data. Studies have demonstrated that utilizing calibrated fixtures and mandrels in controlled conditions improves repeatability by as much as 20%, providing reliable insights for material qualification and quality control purposes.

By integrating precision-engineered test fixtures and mandrels, bend testing laboratories can ensure compliance with stringent international standards and yield dependable data for evaluating material performance.

How to Choose the Right Bend Test Machine for Your Needs

When selecting the appropriate bend test machine, start by determining the specific testing standards and material properties required for your application. Consider the machine’s load capacity, precision, and compatibility with various fixtures to ensure it meets your testing range and accuracy needs. Evaluate the machine’s control software for ease of operation, data acquisition, and analysis functionality. Additionally, prioritize machines that offer structural rigidity and high repeatability to ensure consistent results. Lastly, assess after-sales support, calibration services, and compliance with recognized quality standards to ensure long-term reliability and performance.

Evaluating Specifications and Accessories

When evaluating specifications and accessories, I prioritize equipment that aligns directly with my testing requirements in terms of capacity and precision. I assess whether the machine’s load range and measurement accuracy are sufficient for the intended applications. Additionally, I ensure that the control software is intuitive, offering robust capabilities for data collection and analysis to streamline operations. Structural integrity is another key factor—I look for machines with rigid frames and high repeatability to provide consistent performance over time. I also factor in whether the accessories, such as grips or fixtures, are versatile and compatible with my testing needs. Finally, I carefully review service options like calibration, technical support, and compliance with industry standards to ensure both reliability and long-term sustainability of the equipment.

Selecting a Tester Based on Tensile and Ductility Requirements

When selecting a tester based on tensile and ductility requirements, I prioritize machines that offer precise load control and high-resolution extensometers to accurately measure elongation and yield points. I ensure the tester adheres to ASTM or ISO standards for tensile testing to maintain compliance with industry benchmarks. Additionally, I assess the machine’s force capacity and gauge length adaptability to accommodate various material diameters and properties. Reliability in software analysis and ease of programmability are also critical factors to streamline the testing process and obtain reproducible, accurate results.

How to Perform Bend Tests Effectively?

To perform bend tests effectively, ensure the material specimen is prepared according to the relevant standards, with precise dimensions and surface quality. Use the appropriate testing equipment, such as a universal testing machine, ensuring it is calibrated and configured for the required load and angle specifications. Align the specimen correctly to avoid unintended stress concentrations, and apply the load gradually to maintain controlled testing conditions. Record the data systematically, focusing on critical parameters like deflection, bending strength, and failure point, while adhering to safety protocols throughout the process.

Preparing the Specimen for Bend Testing

To prepare the specimen for bend testing, I would ensure that the dimensions of the material strictly conform to the standards specified by applicable testing protocols, such as ASTM or ISO guidelines. I would meticulously inspect the specimen for surface defects or irregularities that could influence the outcome of the test. If necessary, I would ensure the specimen is cut and machined to achieve uniformity, carefully removing sharp edges or burrs. Additionally, I would confirm that the specimen’s geometry supports accurate alignment in the testing fixture, preventing skewed results due to asymmetrical loading or misplacement. This thorough preparation ensures that the test results accurately reflect the material’s performance under bending stresses.

Steps for Conducting a Guided Bend Test

- Preparation of the Specimen

Ensure the test specimen adheres to the specified dimensions and geometry, including appropriate thickness and length. Remove any surface irregularities, sharp edges, or burrs to achieve a consistent surface finish.

- Inspection of the Specimen

Visually inspect the specimen for cracks, voids, or other defects that could compromise the test outcome. Record any observations before proceeding with the test.

- Setup of the Testing Fixture

Configure the guided bend test fixture according to the required testing standard. Ensure the die opening, plunger radius, and span are correctly adjusted to match the specimen’s dimensions and the testing standard requirements.

- Alignment and Placement

Place the specimen properly in the fixture, ensuring it is centered and aligned along the axis of bending. Misalignment can lead to non-uniform stresses and invalid results.

- Application of Load

Gradually apply the bending force using the machine’s plunger at a controlled rate. Monitor the load and deflection to avoid abrupt motions or overloading that might lead to premature failure.

- Observation and Monitoring

Continuously monitor the bending process and observe the behavior of the specimen. Pay close attention to any visible signs of cracking or deformation during the application of stress.

- Completion of Bending

Continue the bending process until the specimen reaches the desired angle, typically specified in the testing standard (commonly 90° or 180°). Ensure this is achieved uniformly and without jerking.

- Evaluation of the Specimen

Remove the bent specimen from the fixture and examine it for cracks, surface flaws, or other defects. Record all observations, including the presence and size of cracks, as well as the location of any fractures.

- Documentation of Results

Document the test procedure, observations, and results in detail, ensuring compliance with the applied testing standard. Include photographs or diagrams if necessary for visual reference.

Interpreting Results and Understanding Fracture Behavior

Fracture behavior is a critical indicator of material performance under stress and is influenced by factors such as material composition, microstructure, and loading conditions. When analyzing test results, the presence, size, and location of cracks can indicate whether the material failed through brittle or ductile fracture. Brittle fractures are typically characterized by a clean, sharp break with little plastic deformation, often occurring suddenly and at lower toughness values. Conversely, ductile fractures involve significant plastic deformation prior to failure, often accompanied by visible necking or fibrous surfaces.

Surface flaws, such as voids or inclusions, may act as stress concentrators, reducing material strength and accelerating fracture. It’s essential to correlate these observations with theoretical predictions and testing standards to ensure accuracy. By understanding the fracture behavior, engineers can improve material designs and predict performance under real-world application scenarios.

What Are the Types of Bend Test Machines?

The types of bend test machines include three-point bend test machines, four-point bend test machines, guided bend test machines, and wrap bend test machines.

|

Type |

Description |

Application |

Key Feature |

|---|---|---|---|

|

3-Point |

Applies force at center |

Flexural tests |

Simple setup |

|

4-Point |

Distributes force evenly |

Precise testing |

Reduced stress |

|

Guided |

Uses guides for accuracy |

Welds, plates |

High control |

|

Wrap |

Wraps material manually |

Ductility tests |

Flexible use |

Hydraulic Vs. Universal Testing Machines

Hydraulic testing machines use fluid pressure for high-capacity testing, while universal testing machines are versatile and support a wide range of mechanical tests.

|

Parameter |

Hydraulic |

Universal |

|---|---|---|

|

Mechanism |

Fluid pressure |

Mechanical drive |

|

Capacity |

High load |

Variable |

|

Testing Range |

Limited types |

Broad types |

|

Precision |

Moderate |

High |

|

Speed Control |

Limited |

Accurate |

|

Maintenance |

High |

Moderate |

|

Energy Use |

More |

Less |

|

Application |

Heavy industries |

Labs & industries |

|

Cost |

Higher |

Variable |

|

Versatility |

Low |

High |

Portable Vs. Stationary Test Equipment

Portable and stationary test equipment can be categorized based on mobility, power needs, application suitability, and precision level.

|

Parameter |

Portable |

Stationary |

|---|---|---|

|

Mobility |

High |

Limited |

|

Power Source |

Battery |

Fixed supply |

|

Suitability |

Field use |

Lab testing |

|

Precision |

Moderate |

High |

|

Setup |

Quick |

Complex |

|

Durability |

Lower |

Robust |

|

Weight |

Lightweight |

Heavy |

Specialized Test Machines for Different Materials

When considering specialized test machines for different materials, the choice depends heavily on the material characteristics, application requirements, and testing precision. Based on a review of the top resources available, I can provide a concise overview:

- For metals

Testing machines such as Universal Testing Machines (UTMs) or hardness testers are commonly used. These machines measure tensile strength, compressive strength, and elasticity. Key parameters include:

– Force capacity (e.g., up to 1000 kN for industrial testing)

– Precision (accuracy often within ±0.5% of applied load)

– Durability (robust build for handling high loads)

- For polymers and plastics

Specialized machines like melt flow indexers or dynamic mechanical analyzers (DMAs) assess properties like flexibility, thermal behavior, and viscosity. Technical parameters to note:

– Temperature range (e.g., -150°C to 600°C for thermal testing)

– Deformation rate control (critical for viscoelastic analysis)

– Mobility (portable options available for field labs)

- For composites

Dedicated machines perform interlaminar shear strength and fatigue tests. These require precision to account for the heterogeneous nature of composites. Relevant parameters:

– Load type (e.g., axial, torsional, or combined)

– Data acquisition speed (high-speed systems for capturing transient responses)

– Setup complexity (test rigs are typically complex due to material layering)

Testing machine selection must correlate directly with the requirements of the material and the scope of work, ensuring data accuracy and repeatability.

What Accessories Enhance the Performance of a Bend Test Machine?

- Precision Fixtures – High-quality bending fixtures ensure uniform load application and accurate stress distribution.

- Advanced Load Cells – These provide precise measurement of force, improving data reliability.

- Digital Extensometers – Used to monitor deformation accurately across the bending surface.

- High-Speed Data Acquisition Systems – Capture real-time data for dynamic testing scenarios.

- Temperature Chambers – Allow testing under controlled environmental conditions to evaluate material performance in variable temperatures.

- Protective Shields – Ensure operator safety during high-stress tests.

Selecting the appropriate accessories depends on the specific requirements of the test and the properties of the material under evaluation.

Using Clamps and Grips for Secure Testing

Clamps and grips play a pivotal role in securing test specimens during material testing to ensure accurate and repeatable results. They are designed to firmly hold samples in place without causing damage, which is crucial for maintaining the material’s integrity throughout the test. The selection of a proper grip type depends on the sample’s material, dimensions, and the type of test being conducted, such as tension, compression, or shear testing. Adjustable clamping mechanisms and specialized grips, like wedge or pneumatic grips, enhance adaptability and precision, accommodating a wide range of materials and test configurations. This ensures reliable data collection and minimizes slippage or misalignment during high-stress testing scenarios.

Importance of Adjustable and Portable Test Equipment

Adjustable and portable test equipment plays a critical role in ensuring accurate data collection while maximizing efficiency across various testing scenarios. The adaptability provided by adjustable components allows the equipment to accommodate different material types, dimensions, and testing conditions. For instance, tensile tests require settings that can handle elongation without compromising clamping force, while compression tests demand high rigidity to prevent deformation of the test setup.

From a technical perspective, key parameters to consider include clamping force (e.g., up to 50 kN or more for tensile tests with high-strength materials), grip compliance for sensitive specimens (e.g., ±0.01 mm tolerance for alignment), and equipment weight for portability (commonly below 10–15 kg for field-specific applications). Portability ensures that testing equipment can be deployed in remote or constrained environments, enabling on-site data acquisition that is often impractical with stationary systems. Additionally, modular designs allow quick adjustments to meet diverse industry standards, such as ASTM D638 for tensile properties or ISO 604 for compression testing of plastics, ensuring compliance and reliability. This combination of precision, versatility, and mobility enhances the utility and effectiveness of modern test systems.

AdvaAdvanced Side Bend and Flexural Strength Fixtures

Advanced side bend and flexural strength fixtures are specialized tools used in material testing to evaluate mechanical properties under bending stresses. These fixtures are designed to meet stringent standards such as ASTM and ISO requirements and are used to assess characteristics like ductility, flexibility, and structural integrity. Their high precision allows for accurate measurement of deformation and fracture behavior during testing, ensuring reliable data for applications in industries like aerospace, automotive, and construction. Furthermore, modular configurations enable compatibility with a wide range of testing machines and sample geometries, improving efficiency and versatility in material characterization workflows.

Reference Sources

-

TestResources – Bend Test Machines: A comprehensive resource for universal test machines and bend test equipment.

-

Instron – Bend and Flexural Testing: Offers detailed insights into bend tests performed on universal testing machines.

-

PASCO – Bending Accessory: Focuses on accessories for three-point bending tests.

-

CONTROLS – Bend and Re-Bend Test Accessory: Provides information on essential attachments for steel testing.

-

Top Bending Testing Machine in China

Frequently Asked Questions (FAQs)

Q: What is a bend test machine and what is it used for?

A: A bend test machine is an apparatus used to evaluate the flexure and fracture strength of materials, particularly in destructive weld testing and the examination of joints. It helps determine the resistance to fracture and deformation by applying a force to the material.

Q: How does a bend test machine assess weld joints?

A: The machine applies a static load to a welded joint to evaluate its mechanical properties, such as fracture strength and resistance to fracture. This qualitative analysis helps in understanding the durability and quality of the weld.

Q: What are the common accessories for bend test machines?

A: Common accessories comprise bend test fixtures, various types of deflectometers, and an assortment of grips and platens for differing shapes and coatings of raw materials. All of these accessories are used to boost the machine’s testing capabilities.

Q: Why is cold bend testing important in material analysis?

A: This test is important for analyzing the response of mechanical stress on materials, in particular brittle materials and ceramics, at low temperatures. This is important for evaluating the materials… fracture mechanics alongside their durability under extreme conditions.

Q: What role does friction play in bend testing?

A: Friction between the test specimen and the machine’s components can affect the accuracy of the results. Manufacturers strive to minimize friction to ensure that the maximum force applied is accurately measured, providing reliable data on the material’s properties.

Q: How do manufacturers ensure their bend test machines meet standards?

A: Manufacturers design bend test machines in accordance with international standards like API to ensure quality and reliability. They also perform rigorous testing to certify the machines’ accuracy and performance.

Q: What is the significance of using a deflectometer in bend tests?

A: A deflectometer measures the displacement of a material during testing, providing precise data on its deformation and flexure. This is essential for understanding the material’s behavior under stress and its fracture mechanics.

Q: Can bend test machines be used for coatings and ceramics?

A: Yes, bend test machines are versatile and can be used to evaluate the fracture strength and resistance to fracture of coatings and ceramics. These tests help in determining the suitability of these materials for various applications.

Q: What does a tester perform in a typical bend test?

A: The tester performs a controlled application of force to a material to measure its flexure, fracture strength, and resistance to fracture. This involves setting up the bend test fixture, applying the load, and recording the material’s response.

Q: How do bend test machines contribute to quality control?

A: Bend test machines provide qualitative data on the structural integrity of materials and joints, helping manufacturers ensure their products meet necessary safety and performance standards before reaching the market.