Weld testing is a critical process that ensures the structural integrity and performance of welded joints across a variety of industries, from construction to manufacturing. Among the various methods used to evaluate weld quality, bend testing stands out as one of the most reliable and widely applied techniques. This guide dives deep into the world of bend test machines, exploring their functionality, importance, and the role they play in assessing weld strength and flexibility. Whether you’re an industry veteran looking to refine your testing process or a newcomer eager to understand the mechanics of weld evaluation, this article will provide you with a thorough understanding of bend test machines. Get ready to uncover actionable insights, practical tips, and an in-depth breakdown that will help you master the art of weld testing with confidence.

What is a Bend Test and Why is it Important in Weld Testing?

A bend test is a mechanical testing method used to evaluate the ductility and soundness of a weld or material. This test involves bending a specimen to a specific angle or to the point of failure to determine its ability to withstand deformation without cracking. It is important in weld testing because it directly identifies discontinuities, such as fractures or lack of fusion, which may compromise the integrity of the weld. By simulating real-world stresses, bend tests help ensure that a weld meets quality and safety standards in applications where structural reliability is critical.

Understanding the Basics of Bend Tests

Conducting effective bend tests involves applying controlled pressure to a material or weld to assess its ductility and soundness under stress. The process typically evaluates the tensile strength and elasticity by bending a sample around a predetermined radius. Common factors considered during these tests include material thickness, bend radius, and the angle of deformation, which are crucial in identifying potential discontinuities like cracks or incomplete fusion. The results provide critical data to confirm a material’s compliance with industry standards, ensuring the safety and reliability of structures where these materials or welds are utilized.

The Role of Weld Testing in Quality Assurance

- Ensuring Structural Integrity

Weld testing verifies that welds can withstand operational stresses without failure, which is vital in maintaining the overall structural integrity of engineered systems.

- Detecting Defects

Comprehensive weld inspections identify potential defects such as porosity, cracks, or lack of penetration, which could compromise the performance of the material.

- Compliance with Industry Standards

Testing processes ensure that welds meet predefined specifications and regulations, adhering to industry codes such as ASME, AWS, or ISO standards.

- Preventing Catastrophic Failures

By identifying weaknesses in welds early, testing minimizes the risk of failure under load, temperature fluctuations, or environmental conditions, thus avoiding costly accidents.

- Enhancing Longevity and Reliability

Proper testing extends the service life of components by confirming weld quality, reducing maintenance requirements, and improving overall reliability in critical applications.

Common Defects Detected Through Bend Testing

As an integral part of assessing weld integrity, bend testing is instrumental in identifying several common defects:

- Cracks – These can form due to insufficient fusion, rapid cooling, or inherent material weaknesses. Bend tests reveal surface or subsurface cracks that could compromise structural integrity.

- Incomplete Fusion or Penetration – Bend testing highlights areas where the weld hasn’t adequately fused with the base metals, which is critical for ensuring strength.

- Porosity – The presence of small gas pockets or voids caused during the welding process can significantly weaken the weld, and bend testing is effective in making these flaws visible.

By systematically detecting these imperfections, bend testing serves as a reliable method for ensuring the safety and durability of welded components.

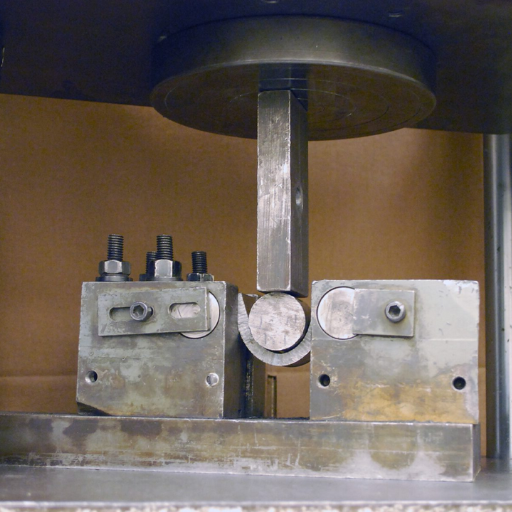

How Does a Weld Bend Tester Work?

A weld bend tester operates by applying controlled force to a welded test sample to assess its ductility and integrity. The tester typically uses a guided bending process, where the sample is placed between a set of rollers or a bending die. Force is then applied to deform the sample into a specific angle or shape. During this process, the sample is closely observed for surface cracks, fractures, or other defects that might compromise the weld’s strength. This method ensures precise evaluation of the weld’s performance under stress conditions.

An Overview of Bend Test Machines

Bend test machines are designed to evaluate the mechanical properties of materials, particularly their flexibility, ductility, and the ability to resist fracture under bending stresses. These machines typically consist of components such as bending dies, support rollers, and loading mechanisms that apply controlled force to deform test specimens. The configuration can vary depending on the testing standard being followed, such as ASTM or ISO guidelines. Modern bend test machines often incorporate digital systems for precise force measurement, real-time monitoring, and automated data acquisition, ensuring accurate and repeatable results. Such systems are used across industries like construction, manufacturing, and aerospace to assess the quality of materials and welded joints under standardized conditions.

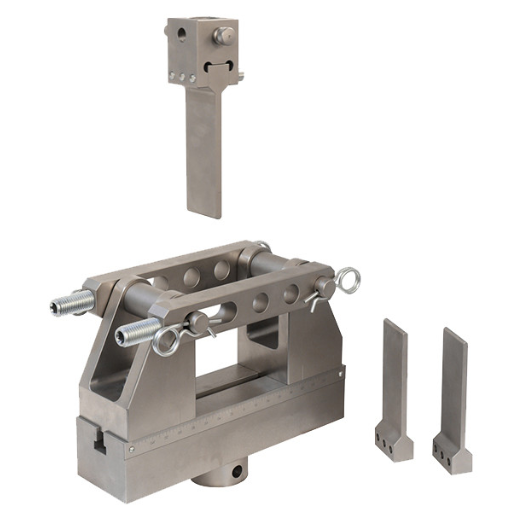

Key Components: Fixture, Plunger, and Jaw

The fixture is the foundational component of the bend test machine, designed to securely hold the test specimen in place during testing. Its structural rigidity ensures proper alignment and stability under applied forces. The plunger is responsible for applying a controlled force or deflection to the specimen. Typically configured as a cylindrical or wedge-shaped component, the plunger’s movement deforms the specimen to evaluate its elasticity, strength, or ductility. The jaw components work in conjunction with the fixture to grip or support the specimen at defined points, ensuring that the loading forces are evenly distributed and aligned with testing standards, such as ASTM or ISO. Together, these elements enable precise and reliable material evaluation.

Setting Up and Operating a Bend Tester

To properly set up and operate a bend tester, I would follow these steps based on widely accepted technical guidelines and practices:

- Preparation of the Specimen

I ensure that the test specimen complies with relevant standards such as ASTM E290 or ISO 7438. The dimensions, material type, and geometry (e.g., flat or round) must meet the specific parameters outlined for the intended bend test. Properly measuring the width, thickness, and length of the specimen is critical for accurate results.

- Fixture Configuration

The bending fixture is selected based on the testing type—three-point or four-point bend tests are most common. I adjust the span length (distance between the supports) to align with standard criteria or the material thickness. For example, in ASTM E290, the span-to-thickness ratio is typically set between 16:1 and 20:1 for ductile materials.

- Machine Calibration

I verify the calibration of the bend tester to ensure precision, including the force application system and displacement measurement. Load cells and deflection meters must be functioning per manufacturer specifications.

- Securing the Specimen

I position the specimen between the supports precisely, ensuring even alignment to avoid off-axis loading. Both ends of the specimen must rest firmly on the supports without external stress prior to initiating the test.

- Execution of the Test

I gradually apply the load through the plunger (or loading nose), following the required loading speed as per the standard being used (e.g., ASTM recommends a strain rate of 0.01–0.03 mm/mm/min for most bend tests). Observations regarding the specimen’s deformation or failure are recorded.

- Data Recording and Analysis

Critical parameters such as maximum load, deflection at failure, and corresponding angles are captured during the test. I cross-check these values against material performance standards for thorough analysis.

By ensuring adherence to these technical steps and parameters, I can achieve accurate and standardized results in material bend testing.

Exploring Different Types of Bend Testing Equipment

Various types of bend testing equipment include three-point bend testers, four-point bend testers, universal testing machines, mandrel bend testers, and strain-controlled bend testers.

|

Equipment |

Purpose |

Key Feature |

Load Type |

Test Mode |

|---|---|---|---|---|

|

3-Point Tester |

Flexural strength |

Single fulcrum |

Static |

Manual/Auto |

|

4-Point Tester |

Precise bending |

Dual fulcrum |

Static |

Manual/Auto |

|

Universal Machine |

Multi-materials |

Versatile |

Dynamic/Static |

Configurable |

|

Mandrel Tester |

Coating testing |

Adjustable rods |

Static |

Manual |

|

Strain Tester |

Controlled strain |

Feedback loop |

Cyclical |

Automated |

Manual vs. Hydraulic Bend Testers

Manual bend testers rely on human operation for testing while hydraulic bend testers use hydraulic pressure for precise, automated processes.

|

Parameter |

Manual |

Hydraulic |

|---|---|---|

|

Operation |

Manual control |

Automated |

|

Precision |

Moderate |

High |

|

Force Control |

Operator-driven |

Hydraulic |

|

Efficiency |

Lower |

Faster |

|

Cost |

Lower upfront |

Higher upfront |

|

Maintenance |

Minimal |

Regular needed |

|

Versatility |

Limited |

Broad |

|

Automation |

None |

Integrated |

Portable vs. Industrial Solutions

Portable bend testers are compact, cost-effective, and suitable for field use, while industrial models offer superior precision, automation, and are tailored for high-capacity operations.

|

Parameter |

Portable |

Industrial |

|---|---|---|

|

Size |

Compact |

Large |

|

Precision |

Moderate |

High |

|

Portability |

Easy |

Fixed |

|

Cost |

Low |

High |

|

Maintenance |

Low |

Regular |

|

Capacity |

Limited |

High |

|

Automation |

None |

Integrated |

|

Usability |

Field |

Factory |

Choosing the Right Test Machine for Your Needs

When choosing the right test machine, I first assess my specific requirements such as portability, precision, and capacity. If portability is a priority, for example, for on-site testing or fieldwork, I would select a compact and easy-to-carry portable machine, even though it offers moderate precision and limited capacity. However, for high-precision, automated, and high-capacity operations, especially in a factory setting, I would opt for an industrial test machine despite its higher cost and regular maintenance needs. My decision ultimately depends on balancing my operational needs with budget constraints and the level of precision and usability required for the application.

What are the Specifications and Requirements for Bend Test Machines?

Bend test machines must meet specific specifications and requirements to ensure accurate and reliable performance. Key specifications include the ability to apply controlled, uniform force to a test specimen, precision sensors for stress and strain measurement, and compatibility with various material standards (e.g., ASTM, ISO). The machine should offer adjustable bending angles and support different material types, from metals to plastics. Additionally, requirements include durable construction to withstand repetitive testing, user-friendly software for data acquisition and analysis, and compliance with safety standards to protect operators during use.

Industry Standards: ASME and API 1104

The ASME (American Society of Mechanical Engineers) standards provide comprehensive guidelines for the design, fabrication, and testing of pressure vessels, piping systems, and related mechanical components. These standards ensure safety, reliability, and efficiency in industrial applications, with ASME Section VIII often referenced for pressure vessels and Section IX for welding qualifications. Compliance with ASME standards is critical in manufacturing, as it guarantees that equipment can withstand operational stresses under prescribed conditions.

API 1104 (American Petroleum Institute 1104) focuses specifically on welding of pipelines and related facilities. It outlines procedures for qualification of welders, inspection methods, and acceptance criteria for weld quality. This standard is widely used in the oil and gas industry to ensure the integrity of pipeline systems. Key aspects include provisions for nondestructive testing (NDT), welding defect evaluation, and operator qualification. Following API 1104 ensures that pipelines meet safety and operational requirements, minimizing the risk of failure during service.

Both standards serve distinct purposes but are integral to maintaining industry-wide consistency, mechanical integrity, and operator safety in their respective domains.

Understanding Test Requirements and Specifications

Test requirements and specifications define the criteria and parameters necessary to evaluate the functionality, durability, and safety of systems or components. They establish the scope, methodologies, and performance thresholds for testing processes to ensure compliance with industry standards. Key elements typically include detailed procedural guidelines for conducting tests, acceptable tolerance ranges, and required documentation of results to verify conformance. Following defined requirements and specifications is critical to achieving the desired outcomes in both quality assurance and regulatory adherence, thereby reducing operational risks and enhancing overall reliability.

Ensuring Compliance with Weld Testing Standards

To ensure compliance with weld testing standards, I focus on adhering strictly to established industry codes such as those outlined by AWS (American Welding Society), ASME (American Society of Mechanical Engineers), or ISO standards. I consistently verify that all tests—whether non-destructive or destructive—are performed using approved methodologies, calibrated equipment, and specified parameters. Detailed documentation is maintained for each process, including test results and inspection records, to meet regulatory and quality assurance requirements. Regular audits, continuous training, and staying updated on evolving standards further ensure that all welding procedures align with the highest levels of compliance.

How to Analyze Results from a Bend Test?

To analyze results from a bend test, carefully inspect the test specimen for any visible defects, such as cracks, fractures, or surface irregularities, on the tensioned side of the bend. The presence of cracks exceeding the acceptance criteria indicates a failure, while the absence of significant defects confirms compliance with quality standards. Measurements, such as crack length and location, should be documented for record-keeping. Additionally, compare the results against applicable codes or standards (e.g., ASME, AWS) to determine if the weld or material meets the required specifications.

Interpreting Test Coupons and Fracture Patterns

When analyzing test coupons and fracture patterns, I evaluate the material’s performance based on the observed characteristics, ensuring these align with the specified mechanical standards. I focus on identifying crack propagation, fracture modes (e.g., ductile or brittle), and any irregularities in the weld or base metal. By documenting the crack lengths, angles, and locations, I compare these findings directly to the acceptance criteria outlined in relevant codes such as ASME or AWS. If the fracture indicates ductile behavior, it often suggests adequate toughness, while brittle patterns may highlight potential material weaknesses or improper welding techniques. Through systematic analysis, I can determine conclusively whether the material complies with required standards or necessitates further rework.

Identifying Defects and Ensuring Quality

Identifying defects and ensuring quality involves a multi-step process grounded in adherence to industry standards and effective diagnostic techniques. Inspection methods such as visual testing (VT), ultrasonic testing (UT), and radiographic testing (RT) are routinely employed to detect surface and subsurface flaws. Common defects include porosity, cracks, inclusions, and lack of fusion, each of which requires precise classification and evaluation as per standards like ASME Section V or AWS D1.1. Advanced nondestructive testing (NDT) techniques and detailed root cause analyses provide actionable insights, allowing engineers to address these defects effectively, optimize processes, and maintain compliance with stringent quality assurance frameworks.

Improving Weld Quality Through Testing Feedback

Enhancing weld quality requires the integration of systematic testing feedback into the fabrication process. Key strategies include leveraging advanced nondestructive testing (NDT) methods such as ultrasonic testing (UT), radiographic testing (RT), and phased array ultrasonic testing (PAUT) to detect and classify defects accurately. Analysis of real-time data from these tests provides critical insights into weld consistency, enabling engineers to identify root causes of issues like porosity, cracks, or lack of fusion. Implementing closed-loop feedback systems ensures that test results are not only collected but actively used to refine welding techniques, adjust parameters, and enhance procedural adherence.

Additionally, adopting predictive analytics and machine learning algorithms can help recognize defect patterns and anticipate problematic areas before welding begins. Collaboration among stakeholders—welders, inspectors, and engineers—ensures that lessons learned from testing are effectively translated into practical improvements. Complying with established welding standards like ASME Section IX or ISO 3834 further enforces a culture of quality and consistency. Ultimately, integrating comprehensive feedback mechanisms fosters continual improvement and aligns both production efficiency and compliance standards.

Reference Sources

- Weld Quality Testing Guide – PrimeWeld

- Accurate Weld Testing: Ensuring Quality Control and Certification – WH Labs

- Bend Testing Equipment Guide – ADMET

- Bend Testing – TestResources

- Bend and Flexural Testing: An Introduction – Instron

Frequently Asked Questions (FAQs)

Q: What is a bend test machine and why is it important in weld testing?

A: A bend test machine is a device used to evaluate the ductility and soundness of welded joints by bending specimens to a specific angle. It is important in weld testing because it helps identify potential defects and ensures that the weld meets the required specifications for safety and performance.

Q: How does a tensile tester differ from a bend test machine?

A: A tensile tester measures the strength and elongation of a material by pulling it apart, while a bend test machine evaluates ductility and weld integrity by bending it. Both are essential in assessing different mechanical properties of welded joints.

Q: What role does a 55 ton bend and tensile tester play in welding labs?

A: A 55 ton bend and tensile tester is used in welding labs to perform both bending and tensile tests on weld specimens. It is crucial for qualifying welds, ensuring they meet industry standards, and verifying the quality of the welding process.

Q: Can you explain the importance of a bend test fixture in weld testing?

A: A bend test fixture is an accessory used to hold and support the specimen during the bend test. It ensures accurate testing by maintaining proper alignment and minimizing external influences that could affect the test results.

Q: What are die and plunger sets, and how are they used in bend test machines?

A: Die and plunger sets are components used in bend test machines to apply force to the specimen. The die supports the specimen, while the plunger applies pressure to bend it. They are essential for conducting precise and effective bend tests.

Q: How does filler metal impact the results of bend and tensile tests?

A: Filler metal plays a significant role in the overall quality and strength of a weld. In bend and tensile tests, the filler metal must be compatible with the base metal to ensure accurate results. Poorly chosen filler metal can lead to failures or discrepancies in test outcomes.

Q: Why is specimen preparation crucial before conducting a weld test?

A: Specimen preparation is crucial because improper preparation can lead to inaccurate test results. It involves cutting, machining, and sometimes polishing the specimen to ensure it meets the required dimensions and surface conditions specified for the test.

Q: What are the advantages of using a pneumatic bending machine in destructive weld testing?

A: A pneumatic bending machine offers consistent force application and ease of use, making it ideal for destructive weld testing. It allows for quick and efficient testing, which is particularly beneficial for contractors and labs with high testing volumes.

Q: How do you select the right bender for different welding applications?

A: Selecting the right bender involves considering the material type, thickness, diameter, and the specific requirements of the weld test. It is important to match the bender’s capacity and features to the specifications and standards applicable to the welding project.