When it comes to evaluating the mechanical performance and durability of materials, bend and re-bend testing machines are indispensable tools in various industries. These machines provide critical insights into a material’s flexibility, strength, and ability to withstand repeated stress without fracturing. Whether you are involved in construction, manufacturing, or quality assurance, understanding how these machines operate and their key features can help you make informed decisions that ensure compliance with industry standards. This guide is designed to demystify the technical aspects of bend and re-bend testing machines, outline their applications, and explore the best practices for maximizing their performance. By the end of this article, you’ll have a clear understanding of how these testing systems contribute to maintaining product integrity and enhancing overall quality control processes.

What is a Testing Machine for Bend and Re-Bend?

A testing machine for bend and re-bend is a specialized device designed to evaluate the ductility and strength of materials, particularly metals. It performs standardized tests by bending and re-bending material samples at specific angles to assess their ability to withstand deformation without cracking or breaking. Such machines are critical in quality control processes, ensuring that materials meet the required mechanical properties and comply with industry standards. They are widely utilized in construction, manufacturing, and engineering sectors to verify the structural integrity of materials before use.

Understanding the Bend Test

The bend test evaluates the ductility, strength, and flexibility of a material by subjecting it to a controlled bending process. This involves deforming the material to a specific angle or curvature, typically determined by industry standards like ASTM or ISO, to observe its performance under stress. It is not a measure of direct tensile strength but rather a practical way to assess how a material behaves under bending forces and whether it exhibits any deformation, fractures, or surface cracks. Such testing is crucial for ensuring that materials comply with mechanical and structural requirements, thus identifying any potential weaknesses before implementation in critical applications.

Components of a Bending Testing Machine

A bending testing machine is a sophisticated apparatus designed to evaluate the flexural properties of materials under controlled conditions. It typically comprises the following components, each playing a critical role in ensuring accurate and reliable test results:

- Load Frame

The load frame provides the structural foundation of the testing machine. Constructed with high-strength steel or aluminum, it ensures stability and alignment during testing. The frame is designed to accommodate various specimen sizes and load requirements, often equipped with adjustable fixtures for flexibility.

- Force Sensor (Load Cell)

The load cell is a precision instrument that measures the force applied to the specimen. It operates based on piezoelectric or strain gauge technology, ensuring high accuracy, often within ±0.1% of the full-scale range. Force measurement data is essential for calculating the bending stress.

- Crosshead

The crosshead is a movable component that applies force to the specimen. It can be driven by hydraulic, pneumatic, or electric actuators, depending on the machine type. The crosshead speed can typically range between 0.01 mm/min and 500 mm/min, allowing for various testing scenarios in compliance with standards like ASTM D790.

- Support Fixtures

These fixtures secure the test specimen at predefined points to create a three-point or four-point bending configuration. They are made from hardened materials to withstand high loads and are adjustable to test specimens of different lengths and thicknesses. Fixture spacing is often adjustable within a range, such as 50 mm to 500 mm.

- Deflection Measurement System

A deflection measurement system, commonly a linear variable differential transformer (LVDT) or laser displacement sensor, tracks the displacement of the specimen’s midpoint during testing. Measurement precision is often within micrometer levels to ensure detailed strain data.

- Control and Data Acquisition System

The control system manages the test parameters, such as force application and crosshead speed, through a programmable interface. Modern machines are equipped with real-time data acquisition systems to record stress-strain relationships and generate comprehensive test reports. Systems may include software compliant with testing standards to ensure compatibility.

- Specimen Grips and Holders

These components ensure that the specimen remains stable throughout the test. Grips are designed to conform to specific shapes and sizes of materials, often equipped with interchangeable parts for versatility.

Each of these components, working in tandem, ensures that bending tests are performed with precision, repeatability, and adherence to international standards. The collected data helps in material characterization, quality control, and compliance verification.

How Rebending is Performed

Rebending is conducted to evaluate the ductility and behavior of reinforced steel bars under repeated bending stresses. First, the sample bar is bent to a specified angle, often dictated by relevant testing standards, using a standardized mandrel. This process ensures the initial deformation is uniform. After the initial bend, the bar is returned to its original position or a defined angle within a specific time frame to simulate real-world stress conditions. The process is carefully monitored to identify any cracks, fractures, or surface defects. Data collected during rebending helps assess the material’s structural reliability and compliance with international construction standards.

How Does bend rebend testing machine Work?

The bend rebend testing machine operates by applying controlled force to a metal bar or material sample to perform sequential bending and rebending actions. Initially, the machine bends the sample to a specified angle under precise conditions, ensuring uniform stress distribution. It then rebends the sample to its original or another defined position. Throughout the process, the equipment collects real-time data on deformation, fractures, and surface irregularities. This machine is calibrated to adhere to standardized protocols, ensuring accurate assessment of the material’s ductility, strength, and compliance with construction industry requirements.

The Role of Rebar in Bend and Re-Bend

- Reinforcement of Structural Integrity: Rebar provides critical reinforcement to concrete structures, enabling them to withstand tensile stresses during bending and re-bending processes.

- Testing for Ductility: The bend and re-bend test assesses the ductility of rebar, ensuring its ability to undergo deformation without fracturing, which is vital for its application in seismic zones.

- Assessment of Material Durability: By subjecting rebar to repeated bending, these tests help evaluate its long-term durability and resistance against fatigue in dynamic load conditions.

- Compliance with Industry Standards: Rebar used in construction must adhere to stringent quality standards. This testing confirms the material meets or exceeds regulatory and design requirements.

- Uniform Stress Distribution: Rebar’s proper performance during bending ensures a uniform stress distribution within the concrete, preventing weak points that could compromise structural safety.

Steps in the Re-bend Testing Process

1.Specimen making: Retaining such shape consistency, fiber rebars are fabricated reproducing the standard sample dimensions in all volumes so as to give reliable and stable results. It mainly depends on how long the rebar will be and cleansing of the surface to take away any dirt.

2.Primary bend: The bar reinforcement is intentionally allowed to bend up to a degree of 90 degrees or more usually in compliance with the industry-standard bending radius and the

3.specified angle. This step is important as it replicates acyual situations of deflection which may occur with the reinforcing steel skeletal members.

4.Enviromental Treatment: The sample of bent bars is put into certain conditions such as boiling in water or aging in higher temperature for a certain period of time. This allows evaluation of such factors as stress relaxation or impact toughness of the material.

5.Re-bend: It is then the opposite motion of bend on the reinforcement after some years of use, but often lesserosive. Drill and overbend back rings. aimed at present the steel capability of withstanding urge load and deflection cycles and hoping to identify the hard cracked zones.

6.Examination and Inspection: The reinforcement is checked for any obvious deformation, cracks or fails coming from bending in cases of extreme conditions. These types of analyses undergo analyses for the shearing materials characteristic in all the bending and incubation stages.

7.Documentation and Interpretation: Annotated observations and precise measurements are made and assessed in compliance with the relevant standards. These findings help to establish if the performance and safety requirements of the rebar have been achieved.

Standards and Compliance: ASTM and ISO

Rebar testing and compliance are guided by globally recognized standards, primarily ASTM (American Society for Testing and Materials) and ISO (International Organization for Standardization). ASTM standards, such as ASTM A615 and ASTM A706, specify the material properties, mechanical performance, and requirements for reinforcing steel in construction. These include criteria for tensile strength, yield strength, elongation, and bend testing. Similarly, ISO standards, including ISO 6935-2, define global benchmarks for steel reinforcement properties, ensuring consistency in quality and structural reliability. Both standards prioritize safety, uniformity, and functionality, providing essential frameworks for assessing and certifying rebar used in infrastructure projects worldwide.

What are the Applications of Steel Rebar Bending?

Steel rebar bending is crucial in construction to achieve the shape, angles, and configurations required for various structural designs. Its applications include forming reinforcement for beams, columns, slabs, and footings, ensuring precise alignment with architectural plans. Additionally, bent rebar is used in the construction of complex structures such as bridges, tunnels, and curved walls, where customized reinforcement shapes are necessary for stability and strength. This process enhances the load-bearing capacity and structural integrity of reinforced concrete, adapting to diverse engineering demands efficiently.

Testing Steel Bars for Strength

Testing the strength of steel bars is an essential procedure in construction to ensure compliance with safety standards and performance requirements. The primary tests performed include:

- Tensile Strength Test – This test evaluates the maximum stress that a steel bar can withstand while being stretched or pulled before failing. It provides data on the bar’s yield strength, ultimate tensile strength, and elongation.

- Bend Test – A bend test assesses the ductility and flexibility of steel bars by bending them at specific angles. This test determines whether the steel can withstand deformation without cracking or fracturing.

- Rebend Test – Commonly used for bars subjected to bending during construction, this test measures the steel’s ability to endure reverse bending, which is critical in reinforcement processes.

- Chemical Composition Analysis – This test ensures the steel bar’s composition adheres to prescribed standards, such as appropriate carbon and manganese levels, which influence strength and weldability.

These tests safeguard construction quality by verifying the mechanical and chemical properties of steel bars, helping engineers choose materials that meet the structural demands of a project.

Common Uses of Bend Resistance

Bend resistance in steel bars is primarily utilized to ensure the durability and strength of critical structural elements. It plays an essential role in reinforced concrete construction, where steel bars must withstand bending stresses in beams, slabs, and columns to prevent structural failure. Additionally, it is crucial in infrastructure projects such as bridges, dams, and tunnels, where high load-bearing capacity and resistance to deformation are required. Bend resistance also supports the longevity of structures by maintaining stability under dynamic loads, seismic activity, and other environmental stresses. These applications demonstrate the importance of bend resistance in achieving structural integrity across diverse engineering projects.

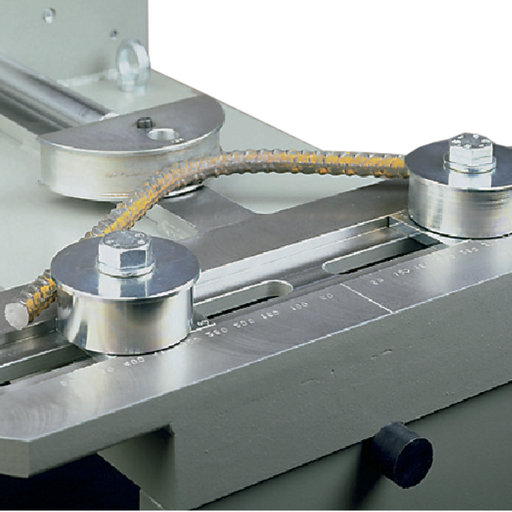

What are the Key Features of Rebending Testing Machines?

Rebending testing machines are designed to evaluate the ductility and bend resistance of reinforcement bars under predefined conditions. Key features include a robust frame for handling high forces, precision-controlled bending mechanisms for consistent test results, and advanced digital interfaces for accurate data acquisition and analysis. These machines often incorporate standardized testing parameters and ensure compliance with international material testing standards, making them essential tools in quality control and material certification processes.

Advancements in Rebending Testing Machines

Recent innovations in rebending testing machines reflect significant technological progress designed to enhance precision, efficiency, and compliance with industry standards. These advancements include the integration of highly accurate load sensors and advanced servo-control systems, enabling improved real-time monitoring and precise force application during testing. Automated sample handling mechanisms and digital user interfaces have also been introduced, streamlining the operation process while reducing human intervention and potential errors.

Additionally, many modern machines now support cloud-based data storage and connectivity, allowing seamless integration with laboratory information management systems (LIMS). This facilitates better data analysis, sharing, and traceability, aligned with rigorous testing workflows. The latest designs emphasize energy efficiency, featuring optimized motors and components that reduce power consumption while maintaining operational performance.

Furthermore, compliance with updated international standards, such as ISO and ASTM, ensures that these machines meet strict material testing requirements across various industries. These improvements not only advance material testing capabilities but also highlight the shift towards smarter, more autonomous testing equipment in quality assurance processes.

Choosing the Right Bend and Re-bend Testing Machine

When choosing the right bend and re-bend testing machine, I prioritize several critical factors to ensure optimal performance and compliance with standards. First, I evaluate the machine’s conformity to international standards such as ISO 7438 and ASTM E290, as this guarantees precise and reliable test results that meet industry requirements. Next, I consider the machine’s capacity and versatility—particularly its ability to handle various material dimensions and grades—since this directly impacts its utility across different applications.

Another essential aspect is the machine’s operational efficiency, including features like automated controls, ease of setup, and accurate data acquisition systems that streamline testing processes. Furthermore, I assess the build quality and durability to ensure long-term functionality under demanding conditions. Finally, I review the availability of technical support and after-sales service from the manufacturer, as this is critical for maintenance and ensuring consistent performance over the machine’s lifespan.

Advanced Hydraulic Systems in Testing

Advanced hydraulic systems have become integral to modern testing equipment, providing precise control, high power density, and versatility. These systems integrate cutting-edge technologies such as proportional valves, servo controls, and digital feedback loops to ensure accurate and repeatable results during testing processes. Additionally, they boast enhanced energy efficiency, leveraging variable displacement pumps and energy recovery systems. With robust build quality, advanced hydraulics are designed to handle high-pressure operations while minimizing wear and tear. Many leading manufacturers also offer comprehensive support, including diagnostic tools, flexible customization options, and compatibility with IoT-enabled monitoring systems for real-time performance analysis. This combination of sophistication and reliability makes hydraulic systems essential for a wide range of industrial testing applications.

Why is Reverse Bend Important in Rebar Testing?

Reverse bend testing is critical in rebar testing as it evaluates the ductility and flexibility of the material under repeated bending stresses. This test ensures that the rebar can withstand deformation during construction without fracturing, maintaining structural integrity in demanding environments. By replicating stress conditions, reverse bend testing verifies compliance with industry standards and confirms the material’s reliability for safe application in reinforced concrete structures.

Understanding Cold Bend Techniques

Cold bend techniques involve the mechanical deformation of materials, typically reinforcement bars (rebars), without the application of heat. This process is essential for shaping rebars to meet specific geometric requirements in construction projects. The technique ensures accuracy and precision in bending while minimizing the risk of compromising the material’s structural properties. Key factors in cold bending include adherence to minimum bend radius specifications to prevent microcracking and ensuring the material retains its mechanical integrity. Additionally, specialized machinery, such as rebar benders, is often employed to maintain consistency and compliance with engineering standards. By controlling stress distribution during bending, cold bend techniques contribute significantly to the durability and safety of reinforced concrete structures.

Reverse Bend vs. Traditional Bend Tests

Reverse bend and traditional bend tests differ in purpose, methodology, stress distribution, and application requirements.

|

Key Point |

Reverse Bend |

Traditional Bend |

|---|---|---|

|

Purpose |

Test fatigue |

Test ductility |

|

Methodology |

Reversing bend |

Single direction |

|

Stress Type |

Reverse stress |

Compressive stress |

|

Application |

Dynamic parts |

Static structures |

|

Equipment |

Specialized |

Standard tools |

|

Material Focus |

Fatigue-prone |

Ductile materials |

Impact on Steel Rebar Quality

The quality of steel rebar is significantly influenced by the testing methodology employed. Reverse bend tests are often utilized to evaluate rebar’s performance under repeated stress conditions, which is critical for applications in dynamic structures subject to cyclic loading. Conversely, traditional bend tests focus on assessing the rebar’s ductility and ability to withstand permanent deformation without failure, a key attribute for static structures. Utilizing appropriate tests ensures that the steel rebar meets specified tensile strength, fatigue resistance, and durability requirements, thereby enhancing overall structural integrity and compliance with industry standards.

Reference Sources

- Essential Guide to Bend Testing: Evaluating Material Strength – A comprehensive overview of bending tests and their applications.

- BEND AND FLEXURAL TESTING An Introduction – Detailed insights into bend and flexural testing methods.

- Rebar Bend & Re-bend Testing Machine – BENTEK 300 – A video demonstration of a rebar bend and re-bend testing machine.

- 55 Ton Tensile Tester | Destructive Weld Testing – Information on equipment for bend and tensile testing.

- 30 Bending Test Companies in 2025 – A list of manufacturers and companies specializing in bend testing equipment.

Frequently Asked Questions (FAQs)

Q: What is a bend and rebend testing machine?

A: A bend and rebend testing machine is specialized testing equipment used to assess the bend and rebend performance of materials such as reinforced rolling steel bars and deformed and plain carbon-steel bars. It helps ensure compliance with standards like BS 4449 and ASTM A615M.

Q: How does a bend and rebend test work?

A: A bend and rebend test evaluates the ductility and strength of materials by bending them to a specified angle and then rebending them to the original position or another specified angle. This process tests the material’s resistance to deformation, crucial for concrete reinforcement and steel testing.

Q: Why is the bend and rebend test important for concrete reinforcement?

A: The bend and rebend test is vital for concrete reinforcement because it ensures that the steel bars used in construction can withstand the stresses and strains encountered during use. This testing ensures the reliability and safety of building materials, contributing to the durability of structures.

Q: What standards are applicable for bend and rebend testing?

A: Bend and rebend testing must comply with various standards such as ISO 15630-1, BS 4449, EN 10080, DIN 488-2, and ASTM A615M. These standards ensure consistent testing procedures and reliable results for the reinforcement of concrete.

Q: What are the key features of a bend and rebend testing machine?

A: Key features of a bend and rebend testing machine include low noise operation, a compact structure, and easy operation. These features make the machine user-friendly and efficient for steel bending and plane rebend tests.

Q: How does electromechanical testing benefit bend and rebend testing?

A: Electromechanical testing provides precise control and accuracy in bend and rebend tests. It ensures consistent application of force and speed, leading to reliable and repeatable testing results essential for evaluating the quality of building materials.

Q: What materials are typically tested using a re-bend testing machine?

A: A re-bend testing machine is specially used for testing materials such as reinforced rolling steel bars, deformed and plain carbon-steel bars, and other materials used in the reinforcement of concrete. It assesses their ability to withstand bending and rebending stress.

Q: Can bend and rebend testing machines be used for evaluating API 5L pipes?

A: While bend and rebend testing machines are primarily designed for steel bars used in concrete reinforcement, they can be adapted for testing other materials like API 5L pipes, provided the machine specifications align with the testing requirements for these materials.

Q: What is the significance of low noise in bend and rebend testing machines?

A: Low noise in bend and rebend testing machines is significant because it enhances the working environment by reducing noise pollution and making the testing process more comfortable for operators, especially in facilities where multiple machines operate simultaneously.