Compression testing machines are indispensable tools in the field of material science and engineering, playing a critical role in assessing the mechanical properties of various materials. These machines are designed to measure the strength and durability of materials under compressive loads, providing valuable data for applications ranging from construction and manufacturing to aerospace and automotive industries. This article will explore the fundamental principles behind compression testing machines, their key components, and their diverse applications across industries. By the end, readers will gain a comprehensive understanding of how these machines contribute to quality assurance, product development, and structural integrity, making them an essential asset in modern engineering.

What is a Compression Testing Machine?

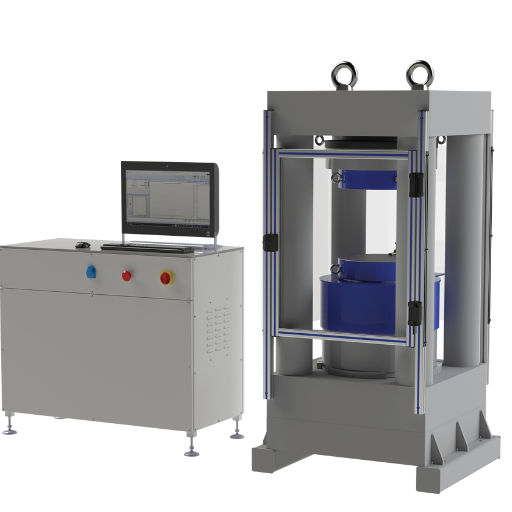

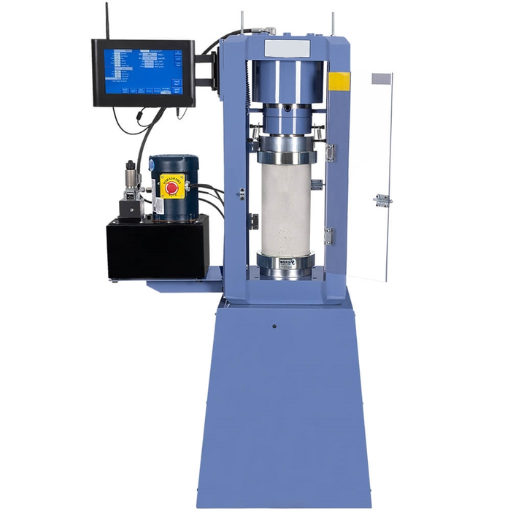

The compression testing machine is generally a technique that measures the response of a material to the applied compressive forces. As foam and compressive materials are such that they do not bend under load, a load is applied to the material until its ultimate compressive strength is exceeded. These machines provide results on several parameters including the compressive strength of the material, deformation structure of the material as well as the elastic range of the material. The essential compression testing machines are used in the quality control processes for civil, structural and other engineering works. Essentially, it comprises a test stand, a control mechanism, and measurement and recording instruments.

How Does a Compression Testing Machine Work?

A compression testing machine operates by applying a controlled compressive force to a test specimen, typically between two rigid platens or plates. The process begins by securely placing the material sample in the machine’s testing area. Once positioned, the machine’s hydraulic or mechanical system generates a steadily increasing load, compressing the sample. Sensors within the machine measure the force applied and any resulting deformation, converting the data into precise metrics. Modern machines utilize advanced control systems and software to analyze material behavior, producing charts for parameters such as stress, strain, and elastic limit. This detailed information is critical for assessing material properties and ensuring compliance with engineering standards.

What Are the Main Components of a Compression Machine?

- Load Frame

The primary structural element that houses and supports all other components, ensuring stability during operation.

- Hydraulic System

Provides the force required for compressing the test specimen, typically consisting of a hydraulic pump, pistons, and oil reservoir.

- Compression Platens

Flat, rigid surfaces between which the test specimen is placed and compressed.

- Load Cell

A sensor that accurately measures the force applied during compression testing.

- Displacement Sensor

Tracks the movement of the platens or the deformation of the specimen, providing critical data for analysis.

- Control System

Includes both hardware and software that regulate the machine’s operation, such as setting parameters, controlling load applications, and monitoring performance.

- User Interface

A digital interface or control panel for inputting test parameters, viewing real-time data, and accessing results.

- Data Acquisition System

Captures, processes, and stores measurement data for detailed material analysis.

- Safety Mechanisms

Includes guards, emergency stop buttons, and overload protection to ensure safe operation.

- Calibration System

Ensures the accuracy and precision of measurements by regularly calibrating the machine’s components.

Why Use a Compression Test for Materials?

Compression testing is essential for understanding the mechanical properties of materials under load. From my research, this test helps determine a material’s compressive strength, deformation behavior, and elasticity, which are critical for ensuring its suitability in structural and load-bearing applications. It provides reliable data to predict how materials will perform under applied stress, ultimately contributing to safety, durability, and performance optimization in practical designs. Additionally, compression testing helps identify failure points and verify compliance with industry standards, making it a crucial step in material evaluation and quality control.

How to Perform a Compression Test?

To perform a compression test, start by preparing the material sample to meet the required specifications, including proper dimensions and surface finishes. Place the sample in a calibrated compression testing machine between the loading plates. Gradually apply a compressive force or displacement at a controlled rate while monitoring the load and deformation. Capture data on force and strain to evaluate material behavior. Continue the test until the material fails, or the desired parameters are reached. Analyze the results to determine strength, elasticity, and other relevant properties. Ensure proper calibration and adherence to testing standards for accurate and reliable results.

What Is the Procedure for a Compression Test?

The procedure for a compression test is designed to measure the mechanical properties of materials under compressive load. Below are the detailed steps:

- Specimen Preparation: Select and prepare the test specimen according to the relevant standards (e.g., ASTM, ISO). The specimen’s dimensions and shape must conform to standard requirements to ensure reliable results.

- Equipment Calibration: Ensure that the compression testing machine is properly calibrated. Accuracy in load and displacement measurements is critical for reliable data.

- Fixture Setup: Secure the test specimen between the platens of the testing machine. Ensure correct alignment to prevent eccentric loading, which can affect the accuracy of the results.

- Test Initialization: Program the testing machine with the required test parameters, such as the rate of load application or displacement. Compliance with guidelines like ASTM E9 or ISO 604 is essential.

- Loading: Begin applying a compressive force or displacement at a controlled rate. Consistent loading prevents sudden material failure and provides accurate stress-strain data.

- Data Acquisition: Continuously monitor and record the applied load, displacement, and deformation. Note critical points like the proportional limit, yield strength, and maximum compressive strength.

- Termination: Conclude the test after the material fails (fracture, buckling, or deformation beyond usability) or when the desired parameters are reached.

- Data Analysis: Process the recorded data to evaluate key properties such as compressive strength, modulus of elasticity, and strain behavior. Use graphical representation, such as stress-strain curves, for better insight into material performance.

- Standard Compliance and Reporting: Ensure all procedures are in alignment with the respective testing standards and compile a detailed test report. Include specimen details, testing conditions, raw data, and analyzed results for full documentation.

By integrating precision equipment and standardized methodologies, the compression test provides accurate insights into a material’s ability to withstand compressive forces, which is crucial for applications in construction, manufacturing, and materials engineering.

How to Prepare a Specimen for Testing?

To prepare a specimen for testing, I ensure it meets the required dimensions and specifications outlined by the relevant testing standard. First, I gather and verify the material to confirm it aligns with test requirements, including type and quality. Then, I cut or shape the specimen using precise machining tools to achieve uniformity and avoid surface defects that could skew results. Additionally, I clean the specimen to remove contaminants such as oil, dust, or moisture, which could affect measurement accuracy. Finally, I label the specimen for traceability and document its dimensions, preparation method, and any observations before proceeding with the test.

What Are the Common Testing Standards like Astm and Iso?

Common testing standards like ASTM (American Society for Testing and Materials) and ISO (International Organization for Standardization) are globally recognized frameworks designed to ensure consistency, reliability, and quality in testing processes. ASTM develops technical standards for a wide range of materials, products, and systems across industries such as construction, aerospace, and energy. ISO, on the other hand, establishes international standards that promote global trade by defining quality and technical performance benchmarks. Both organizations emphasize rigorous procedures, standardization of methods, and reproducibility of results, making them essential for achieving uniformity in scientific and industrial practices.

Exploring Different Test Types in Compression Testing

Compression testing involves multiple test types, including uniaxial, biaxial, triaxial, cyclic, fatigue, and creep tests.

|

Test Type |

Purpose |

Key Points |

Common Use |

|---|---|---|---|

|

Uniaxial |

Assess strength |

Single axis |

Materials testing |

|

Biaxial |

Measure 2-axis |

Dual stress |

Thin materials |

|

Triaxial |

Analyze 3D stress |

Multi-axis |

Geotechnical study |

|

Cyclic |

Repeated loads |

Load cycles |

Fatigue analysis |

|

Fatigue |

Failure by cycles |

Lifecycle |

Aerospace, metals |

|

Creep |

Long-term stress |

Time effect |

High-temp parts |

What Are the Various Test Types Available?

Various test types include uniaxial, biaxial, triaxial, cyclic, fatigue, creep, tensile, compression, shear, and torsion.

|

Test Type |

Purpose |

Key Points |

Common Use |

|---|---|---|---|

|

Uniaxial |

Strength test |

Single axis |

Materials testing |

|

Biaxial |

Dual stress |

Two axes |

Thin materials |

|

Triaxial |

3D stress |

Multi-axis |

Geotechnical soil |

|

Cyclic |

Load cycles |

Repeated loads |

Fatigue analysis |

|

Fatigue |

Lifecycle |

Failure cycles |

Aerospace, metals |

|

Creep |

Time stress |

Long-term load |

High-temp parts |

|

Tensile |

Stretch test |

Axial tension |

Fiber materials |

|

Compression |

Crush test |

Axial force |

Structural parts |

|

Shear |

Shear force |

Parallel load |

Joint testing |

|

Torsion |

Twist stress |

Rotational |

Springs, shafts |

How Does a Universal Testing Machine Differ from Others?

A universal testing machine (UTM) differs from other testing machines in its versatility to perform multiple types of material tests, including tensile, compression, bending, and shear, under a single system setup.

|

Aspect |

UTM |

Other Machines |

|---|---|---|

|

Purpose |

Multi-testing |

Specific testing |

|

Tests Types |

Tensile, shear |

Single type focus |

|

Flexibility |

Adjustable load |

Fixed load setup |

|

Materials |

Wide range |

Limited range |

|

Cost |

Higher upfront |

Variable |

|

Efficiency |

Multi-purpose |

Specialized |

Understanding the Controller in Compression Testing Machines

The controller in compression testing machines serves as the central system for regulating and monitoring test operations. It governs load application, displacement rate, and data acquisition with precision. Modern controllers are equipped with user-friendly interfaces, allowing operators to input test parameters, observe real-time results, and ensure compliance with testing standards. Additionally, advanced controllers often feature automation capabilities, data logging, and integration with analysis software, enhancing accuracy and reducing operational complexity. This pivotal component directly affects testing repeatability, accuracy, and overall efficiency.

What Role Does a Controller Play in Testing?

A controller serves as the central component in a testing system, managing and coordinating test procedures to ensure accuracy and consistency. It regulates key parameters such as load, speed, or environmental conditions, ensuring they adhere to predefined testing protocols. Advanced controllers enable the automation of complex procedures, minimizing human error and improving repeatability. Furthermore, they often integrate with data acquisition systems to monitor performance metrics in real-time, store critical data, and facilitate precise analysis. By providing a standardized framework for operation, controllers play an indispensable role in achieving reliable and reproducible test results.

How to Calibrate a Compression Testing Machine?

To calibrate a compression testing machine, I would follow these precise steps to ensure accuracy and compliance with standards. First, I would inspect the machine thoroughly, checking for any visible wear or damage that could impact its performance. Next, I would ensure the calibration environment meets required conditions, including a stable temperature and vibration-free setup. Using certified calibration equipment, I would apply known loads to the machine and compare the output readings against these reference values. If discrepancies are detected, I would adjust the machine’s settings as per the manufacturer’s guidelines. Finally, I would document all calibration processes and results to maintain traceability and confirm adherence to relevant standards like ASTM or ISO. This ensures the machine produces reliable and consistent test results.

The Importance of 3000kn Capacity in Compression Machines

A 3000kn capacity in compression machines is critical for testing materials with high compressive strength, such as concrete used in large-scale infrastructure projects. This capacity ensures the machine can accurately apply the necessary force without risk of overloading or mechanical failure, thus maintaining test precision and reliability. Additionally, it allows for adherence to international testing standards like ASTM C39 and ISO 4012, which often require higher load capacities for standardized material evaluations. The 3000kn capability also provides versatility, enabling the machine to handle a wide range of test specimens, making it indispensable in industries where high-strength materials are commonly utilized.

What Does 3000kn Signify in Compression Testing?

The term 3000kn in compression testing refers to the maximum load or force that a testing machine can apply to a material under test. It is equivalent to 3000 kilonewtons (kN), a unit of force in the International System of Units (SI). This capacity determines the machine’s suitability for testing high-strength materials such as concrete, steel, and other engineering materials, where substantial forces are required to induce failure. The 3000kn capacity ensures compliance with industry standards and facilitates accurate and reliable analysis of material properties under compressive loads.

What Are the Benefits of Higher Kn Capacity Machines?

- Enhanced Testing Range: Machines with higher kN capacity can accommodate and accurately test materials with greater strength and load-bearing capabilities, enabling a wider range of applications.

- Improved Accuracy in High-Load Scenarios: Higher capacity ensures precision when testing materials that require substantial force to reach failure points, reducing the risk of measurement errors.

- Compliance with Advanced Standards: Many industries require testing equipment that meets stringent guidelines for high-strength materials, and higher kN capacity machines are designed to fulfill these rigorous standards.

- Versatility in Material Testing: These machines can assess various materials, from standard construction materials like concrete and steel to advanced composites and alloys, providing broader analytical capabilities.

- Durability and Operational Efficiency: Machines with higher capacity are generally built to handle prolonged usage under heavy loads, resulting in reduced downtime and maintenance costs over time.

Reference Sources

-

Instron: What is Compression Testing? – A detailed resource on compression testing methods and equipment.

-

ZwickRoell: Compression Testing Machines – Comprehensive insights into the components and applications of compression testing machines.

-

Heicoin: Compression Testing Machine Types and Benefits – A blog discussing the types, applications, and importance of compression testing machines.

-

ATA Scientific: Material Science Instruments – A resource for material science testing equipment and technologies.

-

ResearchGate: Design and Fabrication of a Compression Strength Testing Machine – A research paper on designing and fabricating compression strength testing machines.

Frequently Asked Questions (FAQs)

Q: What is a compression testing machine?

A: A compression testing machine is a device used to test the compressive strength and stiffness of materials, such as concrete, ceramics, and plastics. It applies a controlled force to a material to assess how it responds under pressure.

Q: How does an automatic compression testing machine differ from a manual one?

A: An automatic compression testing machine, often referred to as a fully automatic tester, uses advanced technology and testing software to control the testing process, offering greater precision and efficiency compared to machines that are manually operated.

Q: What are the applications of compression testing in construction?

A: In construction, compression testing is crucial for the endurance testing of concrete beams and other materials. It helps determine the tensile strength and deflection characteristics of concrete beams used in construction projects, ensuring structural integrity.

Q: Why is it important to test brittle materials such as concrete?

A: Testing brittle materials such as concrete is important to assess their strength and durability. Since these materials can fail suddenly without much deformation, understanding their compressive limits is crucial for safe construction practices.

Q: What role does elasticity and Poisson’s ratio play in compression testing?

A: Elasticity and Poisson’s ratio are critical parameters in materials testing. They help in understanding how a material will deform under a compressive load and its ability to return to its original shape, which is essential for assessing the modulus of elasticity and Poisson’s of the material.

Q: How is flexural testing related to compression testing?

A: Flexural testing is related to compression testing as both assess the mechanical properties of materials. While compression testing focuses on compressive strength, flexural testing evaluates the material’s behavior under bending, which is important for materials like concrete beams used in construction.

Q: What is the significance of test data in compression testing?

A: Test data in compression testing provides detailed insights into a material’s performance under stress. This data is crucial for determining whether a material meets required standards and specifications for its intended use, especially in critical applications like construction.

Q: Can compression testing machines test a wide variety of materials?

A: Yes, compression testing machines can test a wide variety of materials, including plastics, ceramics, and metals. They are versatile tools used in various industries to ensure material strength and reliability.

Q: What is box compression testing?

A: Box compression testing is a specific type of compression test used to evaluate the strength and durability of packaging materials. It measures the maximum load a box can withstand before failing, ensuring that packaging can protect its contents during transportation and storage.

Q: What advancements have been made in electromechanical compression testing machines?

A: Advancements in electromechanical compression testing machines include enhanced precision, automated data collection, and integration with testing software. These improvements allow for more accurate and efficient testing processes, reducing human error and increasing reliability.