Instrument And Equipment Wholesale

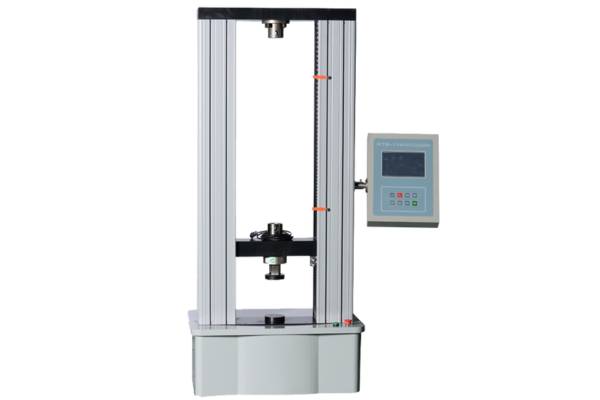

2025 universal testing machine: High-precision automated UTM solution

Introducing our High-Quality Universal Testing Machine, crafted by a leading factory in China renowned for precision engineering and innovative design. This versatile machine performs accurate tensile, compression, and bending tests, ideal for diverse industrial applications. Built with eco-friendly materials and advanced technology, it offers extensive customization options to meet specific needs. Trusted for reliability and superior performance, it’s the top choice for quality control and material testing solutions.

What Is A Universal Testing Machine

-

Applies a controlled force to a material sample to determine its mechanical properties under various stress conditions.

-

Capable of performing tests that determine crucial material characteristics such as tensile strength, compressive strength, flexural modulus, and elongation.

-

Used across diverse industries including manufacturing, construction, aerospace, automotive, and research to evaluate material performance and ensure product reliability.

-

Often integrates with data acquisition systems and software for precise control, real-time monitoring, and comprehensive analysis of test results.

-

Available in various configurations and load capacities to accommodate different sample sizes and testing requirements.

Essential Tests You Can Perform with a Universal Testing Machine

Explore the comprehensive range of material characterization capabilities available with a Universal Testing Machine. This versatile equipment allows for detailed analysis of various materials and components under controlled conditions, providing critical data for research, development, and quality assurance.

Tensile Test

This fundamental test determines a material's behavior under a stretching force. By pulling a sample until it breaks, you can measure key properties like tensile strength, yield strength, elongation, and Young's modulus. Understanding how a material performs under tension is vital for applications where stretching or pulling forces are encountered.

Flexure Test

Also known as a bending test, this measures a material's ability to resist deformation under bending stress. It provides insights into the material's stiffness and its strength before it breaks. This test is particularly important for brittle materials and composites used in beams or structural components.

Compression Test

Evaluate a material's resistance to crushing or squeezing forces with the compression test. This test reveals the compressive strength, yield point, and elastic modulus under compressive loads. It's essential for assessing materials used in load-bearing structures, packaging, and components subjected to compression.

Stress Relaxation Test

Measure how the stress within a material decreases over time while the material is held at a constant deformation (strain). This test is important for understanding the long-term behavior of materials like polymers and elastomers used in seals, gaskets, and components where maintaining a constant force or pressure is critical.

How to Choose the Right Universal Testing Machine?

- Select a machine based on the maximum force required for your tests and ensure it supports all necessary test types (tensile, compression, flexure, etc.)

- Verify that the machine's test space accommodates your sample sizes and that it meets the required accuracy and precision for reliable data acquisition.

- Choose user-friendly and functional software that offers robust data analysis capabilities, allows for customized test methods.

- Ensure the machine complies with relevant industry testing standards (ASTM, ISO, etc.) and opt for a model with robust build quality for durability and long-term performance.

- Consider the manufacturer's after-sales service, technical support, calibration options, maintenance contracts.

What are the uses of Universal Testing Machine?

- Automotive Sector: Tests car components like tires and seat belts for tensile strength and durability, ensuring safety under extreme conditions.

- Aerospace Applications: Assesses aircraft materials for tensile and compressive strength, guaranteeing reliability in high-stress environments.

- Construction Field: Validates concrete and steel strength to ensure building safety and compliance with structural regulations.

- Textile Manufacturing: Measures fabric tensile strength and elasticity, supporting quality control for durable clothing and upholstery.

- Medical Device Production: Tests materials for implants and prosthetics, ensuring they meet stringent safety and performance standards.

Universal Testing Machine Operation Demonstration

Components of UTM

Choose from a variety of controller packages, grips, fixtures, chambers, extensometers, and more, all designed to perform thousands of ASTM, ISO, EN, DIN, and JEDEC industry-standard test methods. When you are ready to complete your system, contact us, and an application expert will help you optimize it for your testing requirements and budget.

View our Universal Testing Machine Price

Top universal testing machines tailored for you, our advanced technology provides reliable quality efficiently and professionally.

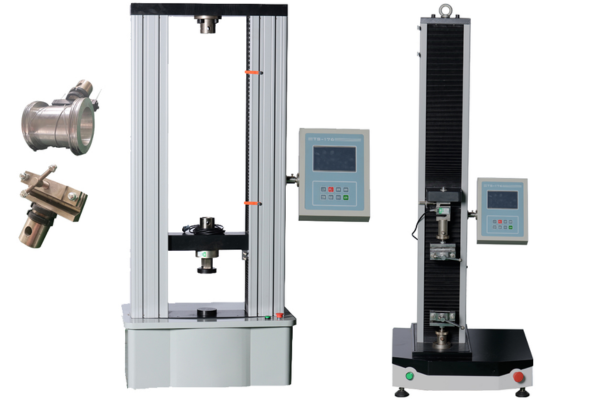

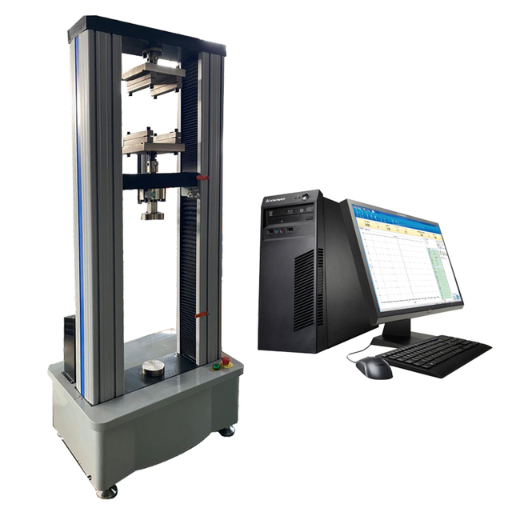

Electronic Universal Testing Machine

Experience precision with our Electronic Universal Testing Machine, powered by servo motors for low-noise, high-accuracy tensile, compression, and bending tests. Ideal for plastics, metals, and textiles.

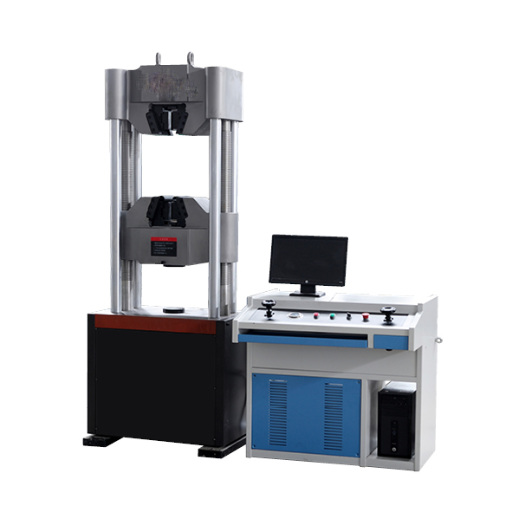

Hydraulic Universal Testing Machine

Our Hydraulic Universal Testing Machine delivers robust testing for high-strength materials like metals and concrete. With capacities up to 2000kN, it excels in tensile, compression, and shear tests, featuring automatic controls and hydraulic grips.

Tensile Testing Machine

A tensile testing machine measures material strength and deformation by applying pulling force until fracture, used in industries like manufacturing and research for quality control. It features load cells, grips, and software for data analysis.

Universal Testing Machine 2025 Data Overview

| Parameter | Details |

|---|---|

| Load Capacity Range | Ranges from 0.0005 N for micro-testing to 2000 kN for heavy-duty applications. |

| Testing Versatility | Supports tensile, compression, bending, shear, torsion, and peel tests. |

| Accuracy and Precision | Features high-precision load cells with ±1% accuracy and digital controls. |

| Environmental Conditions | Operates from -160 °C to 1000 °C and 5% to 95% RH for real-life simulations. |

| Software and Automation | Includes user-friendly software with AI-driven data analysis and automation. |

| Speed Range | Adjustable from 1 mm/min to 1000 mm/min for precise control of loading rates. |

| Crosshead Travel | Offers up to ±4500 μm displacement for versatile specimen testing. |

| Extensometer Integration | Supports integrated or external extensometers for accurate strain measurement. |

| Power Supply Options | Compatible with 220V/50Hz or 440V/60Hz, depending on regional requirements. |

| Safety Features | Equipped with overload limits, safety valves, and emergency stop functions. |

Performance Comparison: Electronic vs. Hydraulic Universal Testing Machines

| Feature | Electronic UTM | Hydraulic UTM |

|---|---|---|

| Force Capacity | Up to 500 kN | Up to 2000 kN |

| Precision | High (±0.5% accuracy) | Moderate (±1% accuracy) |

| Test Speed | Adjustable (0.001–1500 mm/min) | Limited (10–500 mm/min) |

| Applications | Lightweight materials (plastics, etc.) | Heavy-duty materials (metals, concrete) |

| Noise Level | Low | High |

| Cost | $5,000–$20,000 | $20,000–$100,000 |

| Maintenance | Minimal | Requires regular hydraulic servicing |

Why Choose Our Universal Testing Machine Manufacturers

We are committed to providing top-tier Universal Testing Machines with unmatched precision and reliability. Whether you need advanced testing equipment for industrial applications or research purposes, we offer solutions tailored to your specific requirements.

We specialize as expert UTM manufacturers, leveraging years of experience to deliver high-performance machines. Our designs ensure accurate results for tensile, compression, and bending tests, while prioritizing durability with robust materials and advanced technology.

What Our Client Says

Understand from our clients what they say about doing business with us and the unique value addition we provide.

Expert Insights on Universal Testing Machine

What does a UTM machine do?

A Universal Testing Machine (UTM) measures the mechanical properties of materials by performing tensile, compression, and bending tests, providing data on strength, elasticity, and durability.

What are the standards of UTM machine?

UTMs adhere to standards like ASTM E8, ISO 6892-1, and ASTM E9, ensuring consistent and reliable testing results across industries.

What are the advantages of universal testing machine?

UTMs offer high accuracy, versatility across test types, customizable setups, robust durability, and efficient data analysis for quality control.

How to calibrate a universal testing machine?

Calibrate a UTM by using certified load cells and standards, adjusting with manufacturer guidelines, and verifying with regular checks by trained technicians.

What test is UTM used for?

UTM is used for tensile, compression, bending, shear, torsion, and peel tests to evaluate material performance under various conditions.

What is the maximum length of UTM?

The maximum length varies by model, typically ranging up to 4,500 mm (crosshead travel), depending on the design and application needs.

Summary from Tensile Strength Article

The importance of tensile properties to a materials framework has stood the test of time. It has dominated its overtures not only in the aviation and automobile industries but also in civil engineering as well.

Modern universal testing machines (UTMs) are designed in such a way to deal with nanotechnology and artificial intelligence operations likewise extensive tensile strength evaluations. Thanks to research, more specifically, the creation of composites with graphene, whose mechanical properties such as tensile strength may achieve 130 Gpa and more, material scientists have altered current adjectives of “improving” concerning materials in their possessive and objective cases. And these changes are nor only complicated but also reasonable in natiare in each respect.

Latest Blog Posts

Maintain Inventiveness by Following The Blog for the Latest Best Practices, Techniques, Innovations, and Insights in the Field.

Enforcement testing is an indispensable process that helps to ascertain the functional correctness of engineering, quality assurance, and product manufacturing […]

When one dwells on the concepts surrounding forces, one will find them integral to many industries: from aerospace engineering to […]

The mechanical properties of materials are sometimes essential knowledge for engineers, designers, and researchers from different industries; amongst these properties, […]

Friction acts as an essential variable in the mixing of numerous applications, industrial processes, and everyday activities. Usually, it was […]

Testing the friction coefficient is one of the most important parts of getting to know how materials interact with each […]

This blog delves into stress relaxation, a phenomenon going into what goes on with materials when they undergo a constant […]

2025 Trends in UTM supplier China: Servo-Hydraulic Precision and AI-Driven Insights

In the context of the Univeral Testing Machine industry in 2025, two recent waves of the development of such devices come to pass: the introduction of servo-hydraulic systems, and the enhancement of Data Analysis processes as governed by Artificial Intelligence.

For instance, Servo-hydraulic UTMs deliver exceptional force control that allows extreme precision in their application especially in the testing of hard and strong materials such as those used in aerospace composite building and automotive components. Such machines on their own, and coupled with AI-based algorithms bring forth features like real time data analysis, immediate notification to the users on the next service expected date (predictive maintenance), and finally increased testing accuracy. Servo UTM prices have also gradually stabilized.

This is even truer for the aerospace and automotive industries where the concern is focused additional material resistant to catastrophic failure. In this direction, AI makes it possible for manufacturers to design and choose the most suitable materials for their components, who work to the highest levels of safety and operational criteria.

Get a Quote for Your Universal Testing Machine Today

Looking for a reliable, high-precision Universal Testing Machine? Partner with a leading manufacturer trusted by global industries for superior quality and innovative technology. Whether you need robust testing for materials or advanced customization, we provide the perfect solution. Contact us now for a tailored quote!

Frequently Ask Questions

Q: What is a hydraulic universal testing machine?

A: A hydraulic universal testing machine uses hydraulic power to apply high forces, ideal for heavy-duty testing like tensile and compression on metals and concrete, offering robust performance for industrial applications.

Q: Where can I find a universal testing machine sketch?

A: A universal testing machine sketch typically illustrates key components like the load frame, crosshead, and grips. You can find detailed sketches in manufacturer manuals or technical datasheets online, such as on ZwickRoell or Instron websites.

Q: How does a bending test in universal testing machine work?

A: A bending test in a universal testing machine applies force to a specimen via a three-point or four-point setup, measuring flexural strength and stiffness. The machine records the load and deflection to assess material durability.

Q: What should I consider when buying a universal testing machine?

A: When buying a universal testing machine, check its calibration, load capacity, and condition of universal testing machine parts like load cells and grips. Ensure it meets current standards.

Q: What are the key features of universal testing machine design?

A: Universal testing machine design includes a sturdy load frame, precise load cells, and adjustable crossheads. Modern designs, like the electromechanical universal testing machine, often feature digital controls and software integration for accurate testing.

Q: Where can I find a universal testing machine manual?

A: A universal testing machine manual is typically provided by the manufacturer, such as Instron or MTS, detailing operation, maintenance, and safety. Digital versions are often available on the manufacturer’s website or through customer support.

Q: What types of tests can a universal testing machine (UTM) perform?

A: A universal testing machine (UTM), also called a universal material testing machine, performs tests like the universal testing machine tensile test, compression, bending, shear, and torsion, making it versatile for various materials.

Q: What is the difference between an electronic universal testing machine and a universal tensile testing machine?

A: An electronic universal testing machine uses digital controls for precision across multiple tests, while a universal tensile testing machine focuses specifically on tensile strength, often as a subset of broader UTM capabilities.