If ceramics or glass is to be tested, then it is mandatory for these processes to be carried out with great accuracy to provide for the durability of the materials and their functional, as well as operational safety. The reason for this is that these materials are often used in harsh conditions such as the very high temperature and other mechanical forces. This post focuses on the subject of ceramics and glass testing and presents detail about the processes and machines that are used to test their toughness, elongation, and resistibility. This book may appeal either to the technician wishing to understand engineering or to anyone who is interested in the growth of fictional settlements cut off from our neighboring planets. This, however, thanks to its use overviews all the functional/appropriate methods required, for example, to surface test these sought after materials, will be a certain help the reader. Please come along as we discuss both the developments and the skills in glass and ceramic industry towards producing the ideal product.

Overview of Ceramics and Glass Testing

The processes referred to as ceramics and glass testing aim to determine such properties of the materials as the ability to not fail under the applied load, the ability to operate in aggressive thermal regimes and resist chemicals. For these purposes various types of mechanical tests, determining mechanical properties such as strength and fracture toughness are used, thermal behavior tests which assess responses of materials subjected to temperature variations and chemical analysis which helps determine the degree of corrosion or degradation of a material are carried out. Such testing is conducted to ascertain whether the ceramics and glass in question adhere to the application expectations of that particular industry or conformations and hence provide comfort and safety for their effective construction or other use where they are supposed to be. Thus, Ceramics & Glass Testing has advanced to a point where it can produce consistently high quality and safe products for different application areas through the manufacture of such products.

Importance of Ceramics Testing in Consumer Products

In consumer quality products ceramics testing has a vital role since it guarantees their safety and long-life as well as compliance with requirements. Direct performance tests are used in mechanical, thermal and chemical testing for the determination of practical designs. It is important in many products in the house for instance, cookware and table wares as well as decorative products that they should characteristically resist shock and temperature , as they may t for customarily use the products and this is tested. Another issue is the leaching ,which is how the materials released when in contact with food, particularly inhibiting substances such as lead and cadmium. This is also constantly utilized for quality control, and helps manufacturers greatly especially with the very stringent environmental and health rules that help in the reduction of the number of cases of product recall and earning more trust from the consumers. In fact, robust ceramics testing methods enhance safety, promote manufacturer’s goals of environmentally safe, high performance consumer goods, and further help prevent crisis management.

Applications of Glass Testing in Various Industries

1.Food and Drinks Bottling – Glass testing assesses the appropriateness of the bottles and jars used to store food and drinks as safe and functional. Reliability of the packaging system in terms of factors such as heat shock resistance, mechanical strength, leaching ability is assessed so that there is no hazard to health and hygiene standards.

2.Pharmaceuticals and Healthcare – Glass containers used for vials, ampoules, or any other type of pharmaceutical containers are evaluated for chemical resistance, ability to withstand sterilization procedures, and biocompatibility so as to ensure medical devices and drugs are both effective and safe.

3.Building and Construction – Considerable testing has been done on architectural glass to assess its mechanical strength, ability to sustain impact and if the constraints of energy saving are met. Very specific tests check aspects such as thermal insulation, ultraviolet insulation and the capacity of this type of glass to withstand structure codes as well as thermal stress.

4.Transport Sector – Clear glass used in car windshields, windows and mirrors has certain optical clarity standards, strength and laminate performance standards. These tests are very key to ensuring that passengers are safe and drivers can see in any condition.

5.Technology Products – In portable devices, display screens or hard covers in cases of smartphones, tablets, televisions and other devices undergo tests for hard layers, scratch resisting, and endurance towards mechanical pressure. These testing procedures help in ensuring that the functioning and the useful life of an electronic device are at a peak.

Key Differences Between Ceramic and Glass Materials

The key differences between ceramic and glass materials include their atomic structure, thermal resistance, strength, brittleness, and manufacturing processes.

|

Key Parameter |

Ceramic |

Glass |

|---|---|---|

|

Structure |

Crystalline |

Amorphous |

|

Thermal Resist. |

High |

Moderate |

|

Strength |

High |

Lower |

|

Brittleness |

Very High |

Less |

|

Process |

Complex |

Simpler |

|

Transparency |

Opaque/Varies |

Clear |

|

Usage |

Industrial/Tech |

Consumer Optics |

|

Cost |

Higher |

Affordable |

This table provides a concise comparison of the primary attributes and applications of ceramic and glass materials, aiding in material selection based on specific requirements.

Testing Methods for Ceramic and Glass Materials

Various testing methods for ceramic and glass materials include mechanical testing, thermal testing, optical testing, chemical testing, and nondestructive evaluation.

|

Key Point |

Ceramics |

Glass |

|---|---|---|

|

Mech. Strength |

Compression, Flexure |

Tensile, Hardness |

|

Fracture Test |

Fractography |

Fracture Toughness |

|

Thermal Resist. |

Thermal Cycling |

Heat Shock |

|

Optical Test |

Reflectance |

Transparency |

|

Chemical Resist. |

Acid/Base Tests |

Corrosion Testing |

|

Nondestructive |

Ultrasonics |

Acoustic Testing |

|

Density Testing |

Archimedes Method |

Floatation |

|

Dimens. Tolerance |

Metrology Tools |

Profilometry |

|

Microstructure |

Microscopy |

Surface Analysis |

|

Durability Test |

Wear Resistance |

Weathering Test |

This table encapsulates key testing methods and critical evaluation criteria for ceramics and glass, providing a detailed yet concise framework for material assessment.

ASTM Standards for Ceramics Testing

Technical and standard papers of American Society for Testing and Materials (ASTM) on ceramics is a credible reference stating the mechanical, thermal and structural studies of the ceramic materials. These standards give a guarantee that the test results will be consistent, reproducible and reliable for any industry., Examples of such include: ASTM C1161 used for flexural tests, ASTM C373 for wet density and poro or hydrostatic porosity, and ASTM C1327 for specification of Vickers indentation hardness test.

Furthermore, ASTM E837 defines procedures that are related to the analysis of residual stress; while ASTM C1557, applies to the ceramic matrix mixture tensile test. This is why it is very important for the industries to follow these standards to maintain the materials efficiently and of course the process control effectively. These algorithms are important needles to check the adequacy of ceramics in certain areas, including aviation, health care, and higher technologies. Applying such standards in combination with the latest analytical methods makes it possible to achieve a unique level of characterization that corresponds to the current level of technology.

ISO Regulations in Glass Testing

It is important to note that the ISO regulations in glass testing helps in comprehensively assuring all the industries that the glass products are of good quality, safe and performs accordingly. Examples of some of the essential standards and procedures include, ISO 719 concerning evaluating hydrolytic resistance, and ISO 1288 stressing mechanical tests of the glass. These regulations aid the control on the procedures used in subsequent testing, providing a better understanding of properties such as strength, resistance to temperature changes as well as stability against chemical activities. To this effect, meeting the ISO standards is essential in implementing applications such as the buildings, automotive and electronics industries among others where collapse might ensue due to any failure of the glass. Also, the supporting role of ISO standards being fused in lines with modern techniques of testing leads to adherence of international standards enhancing the safety as well as the reliability of the products around the globe.

Common Testing Techniques: Compression, Tensile, and Bend

Compression, tensile, and bend tests are key techniques used to evaluate a material’s strength, flexibility, and resistance under various loads.

|

Test Type |

Purpose |

Key Metric |

Load Type |

Common Material |

|---|---|---|---|---|

|

Compression |

Strength |

Compressive |

Axial |

Metals, Glass |

|

Tensile |

Stretching |

Tensile Str |

Axial |

Polymers, Steel |

|

Bend |

Flexibility |

Bend Mod |

Bending |

Composites, Wood |

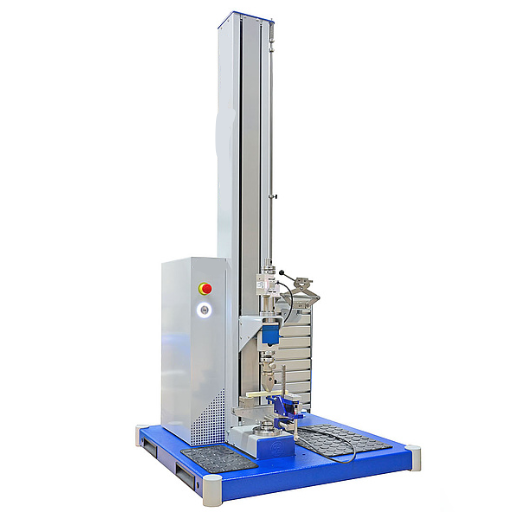

Advanced Testing Machines for Ceramics and Glass

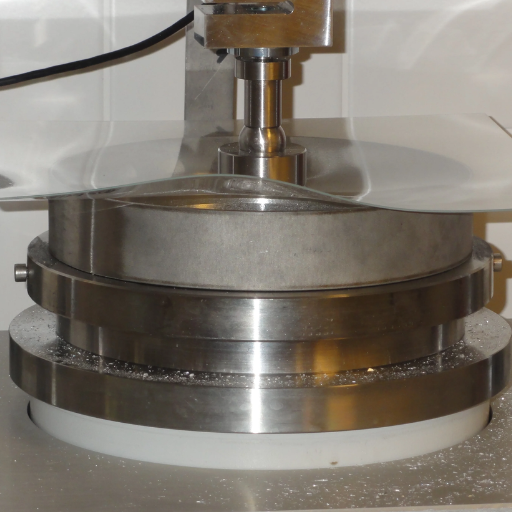

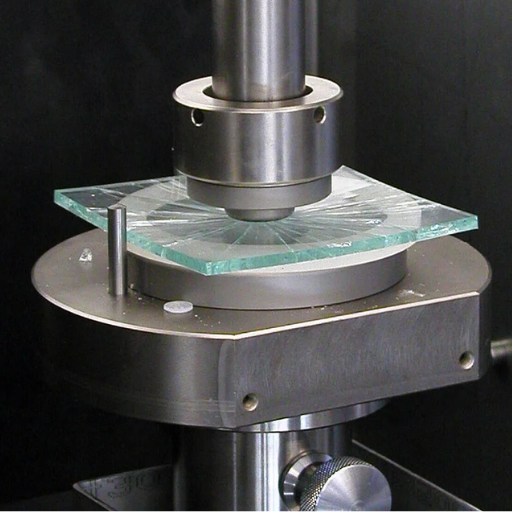

Ceramics & Glass Testing Machines are primarily used for assessing the properties of a material under certain conditions. Such machines are engineered to accurately apply controlled forces – compression, tensile, and bending – to the material being tested with the intent of determining the strength, elasticity, and toughness. In ceramics where the materials easily break, compression tests are particularly important, while in bend testing, the impact of cracks and the quality of the mechanics can be thoroughly assessed. In glass, tensile and bending stress calculations are most utilized since resistance to elongation and versatility are critical in glass mainly for construction or clarity purposes. Components that allow precise loading, high accuracy gauges, and conditions reproducing those in the ambient environment are integrated into such systems to guarantee the achievement of objectives within the obligatory standards and safety.

Overview of Fracture Testing Machines

Fracture testing machines are used to characterize the mechanical properties of materials in terms of the stress/strain behavior and the toughness of the fracture process. These machines are capable of detailed evaluation of how well a material can withstand having internal cracks extended towards the surface and play an important role in quality, durability, reliability, and performance control in critical environments. These machines have accurate systems and can apply accurate loads and displacements which are recorded alongside the calculations of the loads, stress intensity factors, and the crack growths. The latest fracture testing machine models often conform to several requirements for accuracy and reproducibility, such as those contained in ASTM E1820 or ISO 12135 standards. These machines are also brought in for use in such industries as aerospace, building, and power to validate the suitability and safety of the material and manufacturing processes employed in the designs.

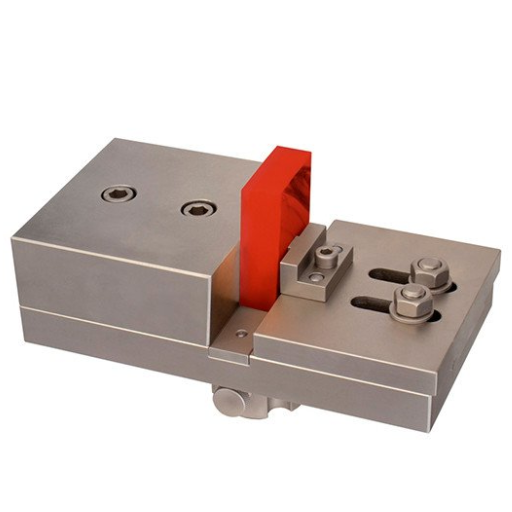

Shear and Biaxial Testing Equipment

Shear testing and biaxial testing systems are used to experiment with materials under intra-complex stresses that simulate pragmatic conditions. Shear testing seeks to measure the behavior of a material to a pulling force applied parallel to the surface tested or aims at determining such a material’s properties as shear stress and shear modulus. However, biaxial testing is usually done in areas where the sample would be stressed along two opposite directions and the content of emphasis is on the behavior of two perpendicular to each other forces, as it is practical in applications such as usage of bladders, flexible screens, and reinforcement fabrics. The aforementioned equipments are fitted with sophisticated Servo-Hydraulic or Servo-Electro-Mechanical controllers; therefore, providing accurate application of loads, as well as data logging. In that case, there are such standards as ASTM D4255 and ISO 6602 that help maintain the procedures uniform and effective, improving performance of these machines, mainly in the areas of aerospace, automotive engineering and civil engineering.

Adhesion Testing in Ceramic Foodware

Sticking such as surface coating adhesion testing in the case of ceramic food ware refers to the evaluation of such sticks as for instance a glazed or decorative layer adhesion under conditions that have been created. Developed tests aim to assure high performance as well as member coefficients of friction consistent with the design standards especially in regards to food-safe ceramic treatment. These include techniques such as cross-hatch adhesion testing made for meeting standards in pull-off testing like ASTM D3359. Such a process ensures that there is no psychological shock to the consumer due to wear, washing, or heating processes where the coatings do not peel off in the way it is not supposed to very good and well designed as is required by laws and regulation. The importance of this testing can never be underscored in any manufacturing operation and most importantly’fda-compliant ceramics.

Mechanical Properties Assessment

The term assessment of mechanical performance and properties of materials includes evaluation of strength, hardness, elasticity and the ability to resist form change when force is applied. Some of these properties are measured through tests such as the tensile test, the Vickers or Brinell hardness tests and the impact testing. Processes are established to standardize the procedures involved, such as the ASTM E8 for testing tensile specimens. Such evaluation is very important to ensure that the materials are able to perform to the required standards through various applications, especially in cases where the materials would be suffering severe conditions such as structural and thermal loading.

Tensile Testing for Ceramics

Ceramic tensile testing is fraught with problems due to the high brittleness that is characteristic of such materials. Unlike in the case of metals, ceramics do not exhibit a substantial amount of plastic deformation before they fracture, thus particular care and attention is required while handling and testing such materials. In most cases, conventional tensile test methods often cause premature failure at the grip section, which leads to a false value. To solve such a problem, alternative approaches are used such as use of appropriate grips or high strength adhesives to hold the specimen; and testing samples with dumbbell sectioned specimens so as to uniformly load the specimen.

The widespread use of techniques such as diametral compression (also known as Brazilian test), and flexural testing has contributed to the understanding of the tensile strength of brittle ceramics without exposing them to high axial forces. Thus, alternative approaches include the use of digital image correlation systems for a high accuracy of strain distribution determination within the bulk of the ceramic materials.

Even so, the tensile testing for ceramics is also necessary as the ability to withstand tensile stress is a structural property of ceramics especially those used in aerospace industry, biomedical applications and electronics industries among others. Following the standardized testing tasks, such as those stated in ASTM C1273, allows for obtaining repeatable and accurate results in such work.

Compression Testing in Glass Materials

Compressive testing is one of the most useful techniques utilized in understanding the behavior of glass materials. This technique is applied in determining the compressive strength, stress-strain response and mode of failure under axial loading. Glass is one such example of a material that is amorphous in nature and has better compressive strength than tensile strength. Specimens are usually regular cylinders or parallelepipeds, and are carefully compressed to failure, during compression analyses. In more sophisticated instruments, these deformations and stresses distribution are monitored and assessed for the material.

As such, ASTM C1424 is commonly adhered to, in order to achieve accuracy and precision. Such tests are especially significant in cases of glasses used for construction purposes as in such cases, it is the compressive stresses that dominate working stress conditions. The findings from compression tests aid in the evaluation of the behavior of glass for serving purposes in areas of high performance.

Shear and Bending Tests for Ceramic Products

Shear and bending test-principles are very important in determining the mechanical features of the ceramic materials in conditions of abuse which occur, as a rule, in the course of their practical application. Such tests focus on the response of the ceramic materials to the strains which lead to deformations or fracture of ceramic bodies, thereby providing useful information about their stiffness, strength and shear brittleness amongst others. However, shear strength or flexural strength of a material is measured by three- or four-point bending tests, and shear test is carried out using a suitable fixture. This information is crucial especially where development of ceramic products is expected such as for components that must withstand high mechanical but also temperature stresses like in structural or electronic applications. Measures are taken, and usually ASTM C1161 is well-known to produce a reasonable and comparative result.

Specific Applications of Testing in Ceramic Tiles and Glass Products

The testing of ceramic tiles includes the assurance of properties such as strength, resistance to wearing and load settling, essential in any floor in most homes, offices or industries. However, within glass products, checks include thermal shock resistance, transparency, impact strength, which are vital in applications like windows, car windscreens, and solar constructs. These reports are helpful when improving the function of materials or ensuring it fits within a certain threshold of completeness.

Testing Procedures for Ceramic Tiles

In our examinations of ceramic tiles, the attention is given to all the considered health and safety requirements within the intended use of the tiles. Such are the procedures aside of designing specifically the weight, height and grade of the material within the aims of providing very high quality products for the market. The modulus of rupture and strain in bending tests are other types of tests conducted to determine the gap before the tiles are cracked merged or other such bodily loading is followed by collapse. Each of the concrete floors and certain low-rise buildings is physically compacted when they are built. This also involves polymer use very long time ago, but it refers to mostly evaluation of the shock absorption that is simulated within the real walls and steps of a building. These procedures are in conformance with not only silicon gel Tel is mentioned above but also the ISO 10545 restrictions as well as ASTM practices, that warrant that it does not fall short on quality control of ceramic tiles through their performance.

Evaluation of Glass Durability and Performance

For performance and glass durability assessment, I would take into account mechanical strength, thermal strength, external irritants among others, following standards such as ASTM C1499 and EN 12150. In order for this to be achieved, impact and bending strength tests are carried out to determine the ability for forces, rapid temperature changes thanks to thermal shock tests, apply as well as evaluate surface hardness for scratches and wear. Furthermore, chemical assay of the resistance of glass in assessing the performance in such aggressive environments is paramount. For risk assessing and normal use of the glass, it is vital that non-functional use of glass is restricted to its users or the environment wherein it is employed achieves the requisite free level of functionality.

omposite Materials: Testing Challenges and Solutions

The challenges that arise include the inability to easily perform tests on composites, as these materials are heterogeneous and anisotropic as opposed to conventional materials. Composite materials consist of more than one component such as fibres and matrix systems and they affect one another to produce a certain result. For this reason, developing unique test strategies becomes imperative.

More to it is that even properties inherited within the composite structure vary. Properties such as bone orientation, mosaic space, and also production errors will tend to create variances. In order to confront this issue, non-destructive tests like ultrasonography and X-ray computed tomography are used so that internal structure of the composite can be visualized and analyzed.

Another significant dislocation is found in the products of stress tests, in how the forces in simulated environments under testing conditions are recreated. Modifications come even most mechanical tests of composites concerning tensile strength, flexure and interlaminar shear tests usually have to get modified in order to clinch the characterization of the composite under the states of use. Where available these advanced computational models are made actual to increase the dependability of the tests as well.

Also, in addition to the technological factors, there are many environmental factors, which cause concern. Performing accelerated performance tests allowing to assess the chemical resistance properties, temperatures fluctuations, sunlight and heat is extremely important for knowing the actual service capability of manufactured items. In order to resolve these preoccupations to be able to meet performance and safety criteria regarding the use of composite materials, improving tests apparatus by incorporating new technologies and methods at times helps to abate these conflicts.

Reference Sources

-

Ceramics & Glass Testing – TestResources: This source provides an overview of ceramics testing processes and their importance in ensuring material quality.

-

Top 20 Ceramic Testing Methods – InfinitaLab: A detailed guide on various ceramic testing methods, covering traditional and advanced ceramics.

-

Testing of Glass and Ceramics – ZwickRoell: This source discusses flexure tests and other quality control methods for glass and ceramics.

-

Ceramic & Advanced Material Testing – Stable Micro Systems: Information on testing physical properties of ceramics and advanced materials using a Texture Analyser.

-

Importance of Glass & Ceramics Testing – Presto Group: Highlights the significance of testing methods like the Pendulum Impact test for assessing the strength and quality of glass and ceramics.

Frequently Asked Questions (FAQs)

Q:What are advanced ceramics and their testing methods?

A:Advanced ceramics are high-performance materials that exhibit superior mechanical properties and thermal stability. Testing methods for these ceramics often include bending strength tests, measurement of viscosity of glass, and thermal analysis techniques to assess their behavior under elevated temperatures.

Q:How is the bending strength of ceramic composites measured?

A:The bending strength of ceramic composites can be evaluated using a 3-point bending test, where a sample is subjected to a load until it fractures. This method helps determine the material’s durability and suitability for various applications, including building materials and electrical and electronic insulators.

Q:What is the standard test method for measurement of viscosity of glass?

A:The standard test method for measurement of viscosity of glass involves heating the glass to a specific temperature and assessing its flow characteristics. This is crucial for understanding the glass’s softening point and annealing range, which affects its processing and final application.

Q:What role does carbide play in ceramics and glass testing?

A:Carbide materials are often used as fixtures in testing setups due to their exceptional hardness and wear resistance. They can be utilized for cutting or machining ceramic substrates and composites, ensuring precise measurements during various testing processes.

Q:How is the softening point and annealing range determined for glass between softening point?

A:The softening point and annealing range for glass are determined through thermal analysis, where the temperature at which the glass begins to deform under load is measured. This process is essential for ensuring the glass can withstand operational conditions without compromising its integrity.

Q:What are ceramic coatings and their significance in testing?

A:Ceramic coatings are protective layers applied to materials to enhance their resistance to wear, corrosion, and high temperatures. Testing these coatings involves evaluating their adhesion, thickness, and performance under cyclic loading conditions to ensure they meet industry standards.

Q:How do researchers use microscopes in ceramics and glass testing?

A:Researchers employ microscopes to analyze the microstructure of ceramics and glass, examining features such as grain size, porosity, and cross-section. This detailed examination aids in understanding the material properties and informs adjustments to improve performance in various applications.

Q:What is the significance of the liquidus temperature in ceramics and glass?

A:The liquidus temperature is critical in ceramics and glass testing as it indicates the temperature above which the material is completely molten. Understanding this temperature is vital for processes like melting, molding, and forming, ensuring that the materials are processed correctly for optimal performance.

Q:What testing methods are used for measuring elongation in ceramic materials?

A:Testing elongation in ceramic materials often involves tensile tests where samples are pulled until failure. The elongation percentage is calculated based on the change in length relative to the original length, providing insights into the material’s ductility and potential performance in real-world applications.