Testing of reinforced concrete is deemed a necessary process, assuring structural integrity, safety, and durability in construction projects. Being at the backbone of modern infrastructural facilities-by-and-large picture tall skyscrapers or intricate networks of bridges-reinforced concrete must be tested by stringent testing procedures. This article provides a route on the best practices and methodologies employed in the evaluation of reinforced concrete, giving engineers and architects and other construction professionals the knowledge to attain the best of quality standards. From testing material properties to observing the response to stresses, this text is prepared to discuss all key testing techniques, innovations, and standards in the industry, to build a safe and enduring structure. The post should, therefore, be a source of knowledge for anyone who is upgrading existing practices or developing new testing procedures.

Introduction to Reinforced Concrete Testing

Reinforced concrete testing is necessary to ascertain the concrete structure’s integrity, durability, and safety against varying load conditions. This testing evaluates crucial factors such as compressive strength, tensile strength, and the bond between concrete and reinforcement. The most common testing techniques of reinforced concrete consist of compressive strength tests on concrete cylinders or cubes, and non-destructive testing methods such as ultrasonic pulse velocity. Tests conforming to a known standard such as one laid out by ASTM or ISO guarantee consistency and dependability in the results; hence, they form an essential step in construction quality control.

Importance of Concrete Testing in Construction

Concrete testing is necessary for ensuring the quality of materials used for structures, their durability, and safety, thus saving expensive failure and complying with design specifications. The tests measure the restrictions imposed on adequate compressive and tensile strengths of materials, which the structure by itself is capable of carrying and withstanding throughout undergoing stress. It also affords an opportunity to detect faults that might do damage to any part of the construction, ` e.g.` voids, inconsistencies, etc.

Standardized tests-and-compressive strength tests on concrete specimens and non-destructive testing methods-are fundamental methods in achieving the necessary control practices. Testing ensures that the concrete conforms to code requirements laid down by organization groups like ASTM or ISO and assist in examining the extendibility of materials such as aggregates or reinforcement. Constant testing while in construction is therefore a foundation to maintain safety regulations but also best materials-use, thereby reducing waste on-site and lasting for a longer time throughout the project life.

Overview of Reinforced Concrete and Its Applications

Reinforced concrete is a composite material that combines the high compressive strength of concrete with the tensile strength of reinforcement material, usually steel. This synergy of materials allows reinforced concrete to withstand various mechanical stresses, and thus it is one of the most widely used construction materials. Its applications range from infrastructure works such as bridges, tunnels, and highways to residential, commercial, and industrial constructions. Reinforced concrete is quite adaptable to be applied in various structural elements, such as beams, columns, slabs, and foundations. Furthermore, reinforced concrete offers benefits such as durability, fire resistance, and ease of forming to meet complex architectural designs, which ultimately speaks about its pressing value in modern construction engineering.

Key Standards and Organizations (ACI, ASTM)

Two major organizations are the American Concrete Institute (ACI) and ASTM International, which set most of the standards and guidelines for construction and materials engineering. ACI provides broad codes, technical resources, and certifications that are equally necessary for the safety and quality assurance of concrete structures. Notably, the ACI 318 Building Code provides the minimum requirements for the design and construction of reinforced concrete.

ASTM International Standards develop consensus-based standards, which differ so much for use by a wide variety of industries. ASTM standards used in construction include standards such as ASTM C150 for portland cement, ASTM C33 for concrete aggregates, and ASTM A615 for reinforcing steel. These standards guarantee uniformity in the physical properties of materials, testing methods, and performance criteria, thus being a very crucial framework for reliably conducting construction practices worldwide. Both ACI and ASTM continuously work to enable innovative advances and maintain stringent standards that address modern engineering needs.

Testing Methods for Reinforced Concrete

Reinforced concrete encompasses a host of testing methods and are tested for strength, durability, and structural integrity. Major tests are as follows:

1.Compressive Strength Tests: When implementing compressive strength, either cylindrical or cubic specimens can be subjected to axial load till failure of the concrete in accordance with ASTM C39.

2.Flexural Strength Tests: To determine the tensile strength of concrete by means of bending tests according to ASTM C78, which is crucial in the assessment of load bearing ability of beams and slabs.

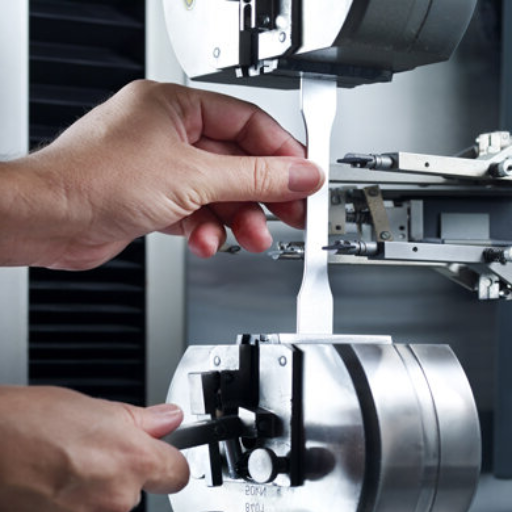

3.Tensile Testing of Rebars: To ascertain tensile properties of the reinforcement steel as per ASTM A615 or equivalent.

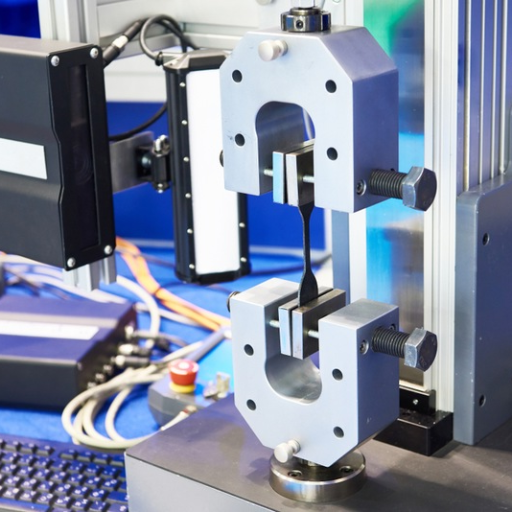

4.NDT Testing: Tests like ultrasonic pulse velocity (ASTM C597) and rebound hammer (ASTM C805) will furnish indications about uniformity and quality of the concrete without inflicting damage.

5.Bond Strength Tests: These tests determine the adhesive strength between steel reinforcement and concrete to ensure stress transfer in a structural system.

Every such test procedure helps in verifying the conformity with design specifications and maintaining the standards concerning safety in construction.

Overview of Concrete Testing Procedures

Concrete testing procedures ensure structural integrity, durability, and adherence to design requirements. These may be destructive or non-destructive, with different uses in the concrete domain. Non-destructive methods, like ultrasonic pulse velocity and rebound hammer tests, will provide information regarding uniformity, density, and surface hardness of a concrete while keeping the structure unharmed in the process. Destructive tests such as those for compressive strength and tensile strength will test the critical capacity of the material under applied stresses of actual load.

Others include slump and workability testing, permeability testing for resistance against water ingress, and chloride ion penetration testing for durability against corrosion of reinforcement. At a higher level, XRD and scanning electron microscopy can be used for microstructure analysis, providing a much more thorough elucidation of performance and potential defects. Together, these procedures form the basis of a quality control scheme, assuring that the concrete suprastructure will meet code criteria provided by ASTM and ACI standards and that the concreting works will stand the test of time.

Types of Testing for Reinforced Concrete

The primary types of testing for reinforced concrete include compressive strength testing, tensile strength testing, flexural testing, ultrasonic pulse velocity (UPV) testing, rebound hammer testing, chloride penetration testing, and carbonation depth testing.

|

Test Type |

Purpose |

Methodology |

Key Parameter |

|---|---|---|---|

|

Compressive Test |

Strength evaluation |

Crushing under load |

Compressive PSI |

|

Tensile Test |

Tensile strength |

Pull until failure |

Tensile PSI |

|

Flexural Test |

Flexural capacity |

Beam bending test |

Flexural PSI |

|

UPV Test |

Material uniformity |

Sound wave velocity |

Wave Speed |

|

Rebound Hammer |

Surface hardness |

Hammer impact |

Rebound Index |

|

Chloride Test |

Corrosion analysis |

Ion penetration |

Cl- Content |

|

Carbonation Test |

Durability check |

Phenolphthalein use |

Depth (mm) |

Non-Destructive Testing Techniques

Non-destructive testing (NDT) refers to a number of methods employed to determine the properties of materials, components, or systems without actually damaging them. In this regard, the previously mentioned methods-compressive testing, tensile testing, and ultrasonic pulse velocity testing-are really important in evaluating mechanical and structural properties, such as strength, homogeneity of the material, and hardness. Such methods ensure that materials are eminently reliable and are subjected to the least amount of downtime, thereby allowing components to be used further. There are other complementary tests like the rebound test for surface hardness and chemical tests like chloride and carbonation tests, aimed at analyzing degradation pathways such as corrosion and durability. Combined, these methods represent an essential set of tools for quality assurance and maintenance in industries.

Strength Testing of Reinforced Concrete

Various testing methods are used to determine reinforced concrete strength, load-bearing capacity, and durability properties. Conventional strength tests are those that generally rely on compression by using concrete cylinders or concrete cubes to find the maximum load that the material may sustain before failure. Its flexural strength test measures how much bending load it can take; the tensile strength test measures the ability of the reinforcement to take in pulling forces. Non-destructive methods, such as ultrasonic pulse velocity (UPV) and rebound hammer tests, are used to test the properties of the material for quality and uniformity without damage. These methods ensure the enforcement of structural design codes and improve the durability of concrete structures.

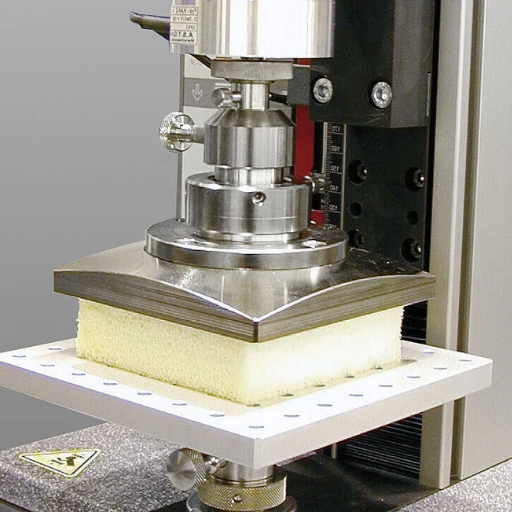

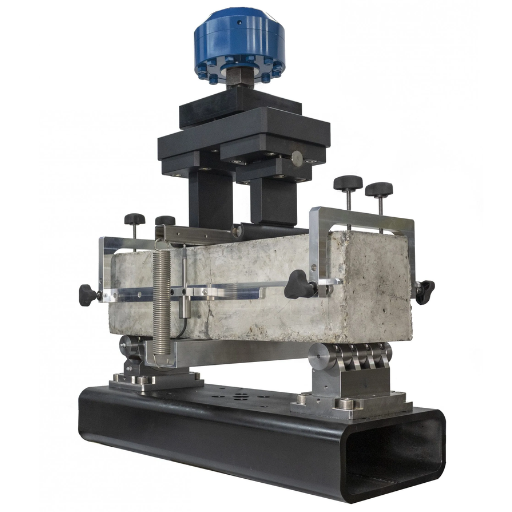

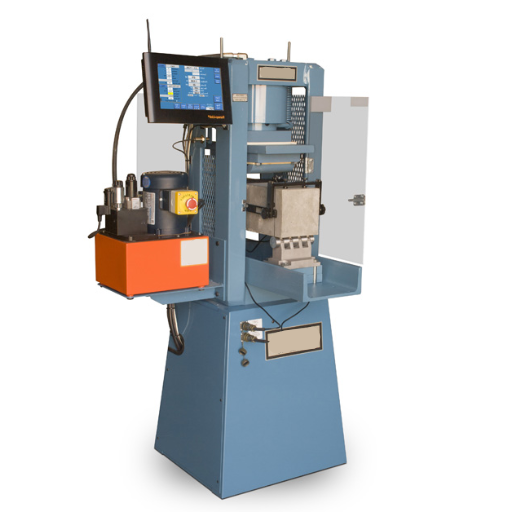

Compressive Strength Testing

This test is usually the first and most important factor in establishing whether concrete will resist axial loads applied to compress a material or structural element. The preparation of samples, testing of cylinder or cube specimens, and subsequent application of controlled loads in a hydraulically operated press until failure are basically how the tests are carried out. This assessment is important in determining whether the concrete will meet the strength requirements imposed upon it for a particular application.

From modern development and recent Google search metadata analysis, it can be inferred that there is a trend towards precision and automation concerning compressive strength testing. Automated compression machines with digital controllers improve accuracy, reduce operator-dependent errors, and provide real-time data recording. Furthermore, through the employment of machine learning techniques in predictive modeling, engineers have proven more capable at estimating compressive strength by analyzing huge amounts of historical test data and material properties. Such advancements serve to improve decision-making and quality control processes and keep abreast of the standards that are evolving within the industry.

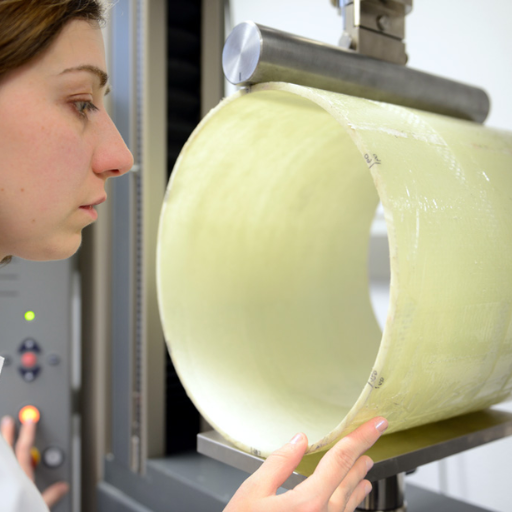

Tensile and Flexural Strength Tests

The tensile and flexural strength tests are important in ascertaining the material behavior under stress. The tensile strength testing determines the magnitude of tensile (pulling) force a material can withstand before it separates. This is important for ascertaining the durability and reliability of components for structural or mechanical application. The flexural strength tests determine the capability of the material to resist deformation or fracture under bending. These tests are most appropriate for materials such as concrete, polymers, or metals, whose flexibility and resistance to load are the prime factors. When combined, these tests supply an extensive insight into the mechanical properties of the materials in question so that the materials could meet the specified parameters and carry out their functions effectively in real life.

ASTM Standards for Strength Testing

ASTM has developed set operational test procedures assessing strength properties of different materials. Representative cases of these are:

1.ASTM C39 – It provides test procedures for axial compressive strength of cylindrical concrete specimens. Sites under construction use the term “site work” to refer to all operations, observations, and tests performed to ascertain the structural integrity of materials and assemblies.

2.ASTM D790- Testing for flexural strength of plastics to measure resist bending forces.

3.ASTM E8/E8M- Test for tensile strength of metals, thus compiling uniformity in testing methods and assurance of materials.

The standards give a clear set of criteria for specifying and the tests, while repetition thereof ensures regardless of whom performs the tests, or in which industry, for safety and performance checks.

Developing a Comprehensive Testing Plan

Every testing plan must have a comprehensive consideration of the material properties, industry standards applicable, and requirements specific to its use case. The process begins with the definition of objectives: whether to validate performance, comply with safety requirements, or ascertain quality control. Subsequently, the identification of standards such as ASTM, ISO, or others, including local regulations, makes the testing process trustworthy and reliable. Choosing testing methods from tensile, flexural, fatigue testing, etc., becomes critical in tandem with stresses foreseen to be inflicted on the material. Next, control over testing conditions coupled with repeatability tests will further promote accuracy of generated data. Documentation of the procedure and results will contribute to the validation of findings and be beneficial in the long run, either through audits or further product developments.

Key Components of a Testing Plan

1.Objective Definition– This should be a clear outline of the testing process’ purpose and of the particular goals that are to be attained.

2.Material Selection– Selection of materials or components to be tested should be done based on their correspondence with project requirements.

3.Testing Methods– Choose the testing methods to be used for instance, mechanical, thermal, or chemical tests, depending on the material properties and expected performance.

4.Environmental Conditions– This will specify the environment under which testing is to take place; parameters such as temperature, humidity, or exposure to different chemicals.

5.Equipment and Calibration– This is the provision of details regarding the used testing equipment and tools while maintaining calibration standards for accuracy.

6.Sample Preparation– Elucidate on techniques involved in the preparation of test samples, dimensions, surface finishes, pretreatment if any.

7.Protocols and Standards– Give details about any industry or regulatory standards that should be applied with the objective of compliance and consistency.

8.Data Collection Procedures– This procedure is on how to collect all data, at what measurement intervals, and from what tools to the accepted data storage format.

9.Repeatability and Reproducibility- Provide means by which the test can be repeated for results verification with minimized errors.

10.Safety Measures– Safety issues to be observed for the protection of personnel and for ensuring a secure testing environment are usually mentioned.

11.Documentation Requirements- Testing procedures, observations, and results should be well documented for future reference and audits.

12.Analysis and Interpretation– Describing the criteria of analyzing the test results, including determination for passing or failing the test.

13.Review and Reporting- Functions to review the findings, prepare detailed reports, and communicate the results to stakeholders.

14.Contingency Planning- Consider the probable remedial measures when deviations occur, the equipment fails, or there is an undesirable test outcome.

Best Practices for Testing Reinforced Concrete

I consider the test under reinforced concrete under the ASTM or B.S. codes, which encompass complete guidelines for accuracy and repeatability. Sample preparation and curing will be prepared to represent the field conditions accurately. Temperature and relative humidity during testing are also controlled to ensure that the results are free from variability. Another aspect that assures me of the accuracy and reliability of results is the regular calibration of advanced testing equipment. Also, I systematically keep a transparent record of all the processes and results to effectively communicate these to all parties concerned.

Field Testing vs. Laboratory Testing

Field testing and laboratory testing for reinforced concrete differ in terms of portability, precision, environment, and available equipment.

|

Parameter |

Field Testing |

Laboratory Testing |

|---|---|---|

|

Portability |

High |

Low |

|

Precision |

Moderate |

High |

|

Environment |

Variable |

Controlled |

|

Equipment |

Basic |

Advanced |

|

Speed |

Fast |

Slow |

|

Cost |

Lower |

Higher |

|

Accuracy |

Adequate |

Optimal |

|

Versatility |

Limited |

Extensive |

|

Logistics |

Simple |

Complex |

|

Sample Size |

Small |

Large |

Innovations in Concrete Testing

The recent development in concrete testing was aimed at bridging the gap between field and laboratory testing. Paramount considerations included portability, efficiency, and precision; all the three factors were considered alongside reliability. New technologies such as portable compressive strength testers; handheld UPV devices; and NDE methods, in effect, equip field-based testing with scaling and enhanced precision without loss of portability and good speed.

On the other hand, automated laboratory testing equipment coupled with AI-driven analysis systems are rewriting the controlled test environment, ensuring rapid data processing and extraction of insights from large sample sizes. Newly developed techniques such as lifetime monitoring with embedded sensors and employing a digital twin model further expand the scope and precision of concrete performance evaluations. These innovations are reducing logistical complexity, optimizing costs associated with the process, thereby making concrete testing more efficient and reliable under variable conditions.

Emerging Technologies in Concrete Testing

Emerging technologies in concrete testing are revolutionizing traditional methods with a focus on precision, efficiencies, and sustainability. One such innovation is the integration of NDT methods such as ground penetrating radar and ultrasonic pulse velocity to assess a structure without impairing the integrity of the material. Moreover, advanced imaging methods such as X-ray computed tomography (X-ray CT) allow detailed internal analysis of concrete microstructures. Real-time data acquisition capabilities are enhanced even further by embedding IoT (Internet of Things) sensors that monitor temperature, humidity, strain, etc., thus providing endless insights throughout an entire life cycle of a structure. All of these innovations go towards fruitful maintenance of durability and ultimately contributing to an engineering solution which is much more data-driven.

Case Studies of Successful Reinforced Concrete Testing

1.Bridge Condition Assessment in Germany

The Bavarian reinforced concrete highway bridge was subjected to a detailed case study involving embedded fiber optic sensors that kept track, day and night, of strain, crack propagation, and temperature changes over a period of five years. Real-time data proved supervisory personnel capable of pointing out faults and failures before they grew to critical status, thereby significantly enhancing the service life of the structure by implementing focused maintenance activities.

2.Earthquake-Resistant Design for Reinforced Concrete in Japan

In Tokyo, advanced seismic testing was performed on reinforced concrete buildings using large-scale shake table simulations. The tests were carried out with the use of high-strength materials and novel rebar configurations to further dissipate energy and enhance flexibility of the structure. The outcome confirmed better performance under cyclic loads-unfolding as standards for the erection of earthquake-resilient infrastructure in seismic-prone regions.

3.Durability Study under Marine Environment in Australia

A port facility in Queensland was used as a proving ground for reinforced concrete in aggressive marine environments. Advanced chloride ion penetration testing was conducted alongside sensor-based corrosion monitoring. The study brought to light that supplementary cementitious materials like fly ash and slag reduce corrosion rates, thus opening ways toward very durable concrete for coastal infrastructure.

Future Trends in Concrete Testing

In the emerging age for the construction industries, these developments in concrete testing are going to be construed-as improvements in accuracy, efficiencies, and sustainability. From being non-destructive, the NDT techniques have to evolve into becoming more sophisticated, allowing better diagnosis with respect to the concrete structure conditions without inflicting any damage. The analysis of concrete performance, including predictive maintenance and risk assessment, is being facilitated by AI and machine learning while being embedded in real-time monitoring. Smart sensors and IoT infrastructures also offer a more advanced level of continuous monitoring for parameters such as temperature, moisture content, and chloride ion concentration, enabling an immediate reaction to structural weaknesses. These new developments stand alongside the growing consciousness of materials and methods favorable to the environment, marking a trend in the concrete testing paradigm-in moving toward meeting infrastructure development needs worldwide.

Reference Sources

-

Strength assessment in reinforced concrete structures: from research to improved practices – Discusses nondestructive techniques and general rules of good practice.

-

Fundamentals of durable reinforced concrete – Covers testing and guidance for durability in reinforced concrete.

-

Principles of reinforced concrete – Explores the behaviors and mechanisms of reinforced concrete in engineering practice.

-

Non-destructive evaluation of reinforced concrete structures: Non-destructive testing methods – Focuses on the latest non-destructive testing methods and innovations.

-

Non-destructive testing of concrete: A review of methods – Reviews various non-destructive testing methods, including standards like ASTM C 805.

Frequently Asked Questions (FAQs)

Q:What is reinforced concrete testing, and why is it considered significant?

A:Reinforced concrete testing is an essential part of analyzing the strength and durability of concrete structures. Testing is conducted to ascertain that the concrete used meets the minimum set of requirements for strength, durability, and resistance to various forms of degradation. The engineers test the materials used in the structure from different perspectives to ensure that the concrete will bear various loads and environmental conditions imposed on it throughout time.

Q:What kinds of tests are carried out on reinforced concrete?

A:Many tests are carried out on reinforced concrete, include testing for compressive strength, flexural strength, and abrasion resistance, among many others. These tests determine the concrete’s behavior under different circumstances and ensure that it responds as anticipated, given the design of the reinforcement concrete structures.

Q:How does one determine the concrete strength?

A:Concrete strength is determined by means of various standardized test methods commonly referred to as compressive strength testing, wherein concrete samples, also known as test specimens, are loaded under pressure until the sample fails. This test helps engineers understand the ultimate load applied before breaking concrete; hence, it imparts an intuition into that concrete’s capacity to bear loads.

Q:What role do materials test and testing guidelines take in reinforced concrete testing?

A:Materials testing and testing guidelines make an evaluated reinforced concrete test accurate and reliable. They provide a framework that governs the conduction of tests by appropriately qualified persons, assuring that the methodology and procedures involved are up to industry standards. The resulting interpretation of tests is crucial in deciding the structural integrity of the concrete element.

Q:What is Fiber Reinforced Concrete and how is it tested?

A:FRC works by introducing fibers to improve its performance with respect to ductility and flexural toughness. Testing of the fiber-reinforced concrete usually involves tests for flexural performance and impact resistance, which apply to situations where the concrete will be subjected to dynamic loading.

Q:How does testing work in the design of reinforced concrete structures?

A:Testing in designing reinforced concrete structures concerns the evaluation of materials used in the structure to ascertain that they satisfy the necessary performance criteria: It includes testing the yield strength of rebar, testing fresh concrete properties, and carrying out structural testing to verify that the design criteria are satisfied and that the structure will perform as anticipated under practical conditions.

Q:What are the methods and procedures for testing concrete?

A:Methods and procedures for testing concrete consist of standard tests such as slump tests for workability, compressive strength tests, and non-destructive testing. These methods are used to test specific properties of hardened concrete to check if they meet the required performance criteria for a given construction use.

Q:What factors can affect the performance of reinforced concrete?

A:Several factors do affect the performance of reinforced concrete: the quality of materials used, the mixing procedure, and curing conditions, all can influence the concrete performance. Yet, the environmental factors may corrode the rebars; lowered performance concrete due to moisture exposure, and chemicals act over time. Performing regular tests might help find the problems before they affect the structural integrity of concrete.

Q:Why should tests be performed by suitably qualified personnel?

A:Testing by qualified personnel is the key to ensuring that the testing process is not only conducted according to accepted standards but also that it produces credible results. Those professionals must be sufficiently skilled to grasp the subtleties of concrete testing, including the preparation of test specimens, actually carrying out testing procedures, and the correct interpretation of test results. Their ability to make sound judgments is, in fact, crucial to the evaluation of concrete structures concerning their safety and performance.