Polyurethane flexible foam is versatile and is widely found in numerous industries-from furniture and automotive to packaging-and bedding. Its performance and durability stand as elements that guarantee product quality and ultimate consumer satisfaction. Testing processes, therefore, are vital in checking the material’s physical properties, resistance, and standards adherence. This article looks into all aspects related to tests for flexible foam, explaining the processes, parameters, and tools used to measure quality. Whichever position one might occupy in the chain-from manufacturer to design engineer and onward to quality engineer-it would help to grasp these testing fundamentals to focus on performance and the stiff criteria imposed on the industry today.

Introduction to Flexible Foam Testing

Flexible foam testing is the term given to the observations leading to the assessment of physical performance and durability of any foam materials conforming to specifications or certain industrial standards. Testing tests parameters such as density, compression, tensile strength, hardness, or resilience to ensure the foam meets the requirements for safety and functional application. Reliable testing helps one to assess and identify any defect in the material during manufacturing, forecast the performance of the finished product, and verify if the material is suitable for the intended application-life as an element of furniture, automotive seating, or insulation. By following such processes, manufacturers ensure the standard quality of products and meet regulatory requirements.

The Importance of Flexible Foam in Various Industries

Due to flexible foam being adaptable, resistant, and highly efficient, it plays a key role in many industries. Its gargantuan cushioning and shockproof capabilities contrast with its light makeup, while at the same time, it can be customized to suit various application needs.

In the furniture domain, flexible foam finds use in mattresses, sofas, and chairs to give comfort and support and long-term durability to its users. Automotive-makers use flexible foam in their seats, headrests, and armrests, with straight comfort in mind but also complying with safety requirement standards. Construction-wise, because of flexible foams’ insulating characteristics, flexible foams help in thermal and acoustic insulation to conserve energy and reduce noise.

Flexible foam is also used in packaging to cushion sensitive goods during transit and in medical devices where it’s valued for conformability and ease of cleaning. With advances in production techniques and material sciences, flexible foam continues to be one-of-a-kind locomotive for industries, thus providing reliable and effective solutions in response to newer technological and regulatory parameters.

Relevance of ASTM D3574 in Foam Testing

The ASTM D3574 serves as a supreme factor in testing activities and evaluation of flexible cellular materials for polyurethane foams to ascertain quality, performance, and safety on diverse applications. It presents different methods for testing mechanical and physical properties: tensile strength, tear resistance, indentation force deflection (IFD), compression set, and resilience. These ensure a common framework to test all types of applications of foam, so that all products can conform to requirements accepted by the industry, along with those which also test against common conditions during their intended uses. The first developed and still widely accepted ASTM D3574 standards equip manufacturers, regulators, and researchers with the essential benchmarks to develop and assure product quality from a technology standpoint, thereby bringing these products and standards to the global market.

Impact on Product Durability and Customer Satisfaction

The valid application of Standards under ASTM D3574 ensures durability of the products, which in turn increases customer satisfaction; this is afforded to a manufacturer by enabling him to produce foam products which comply with the exact technical requirements. Performance specifications allow for the selection of materials designed to continue functioning for years of service. Furthermore, conformance reduces incidence of interference with quality, thereby enhancing product reliability and consistency. This quality assurance increases the confidence of the customers hence the capacity for fostering greater trust in customer loyalty as the customers will believe in the use of the products that have accepted standards. By providing better and proven solutions with foam, companies will also reduce their risks associated with product failures and grow in further customer satisfaction and retention.

Common Testing Methods and Standards

Common testing methods and standards include tensile strength testing, compression testing, thermal conductivity evaluation, flammability testing, and dimensional stability testing.

|

Method |

Purpose |

Key Parameter |

Explanation |

|---|---|---|---|

|

Tensile Testing |

Measure strength |

Max Load |

Determines maximum stress foam can withstand when being stretched. |

|

Compression Testing |

Assess durability |

Compressive Mod |

Evaluates performance under compression and resistance to deformation. |

|

Thermal Testing |

Heat insulation |

Conductivity |

Measures foam’s ability to resist heat transfer. |

|

Flammability |

Fire safety |

Burn Rate |

Tests foam’s reaction and resistance to fire exposure. |

|

Dimensional Check |

Dimensional accuracy |

Tolerances |

Ensures foam retains accurate form and size under varying conditions. |

Overview of ASTM D3574 and its Applications

Considered globally recognized, ASTM D3574 is considered the reference testing standard for analyzing the performance characteristics of flexible polyurethane foams. It gives an outline of procedures from tensile tests to compressive stress, to tear resistance, and to resilience. Such tests ascertain whether foam materials satisfy certain requirements for quality, durability, and safety in a given industry.

With ASTM D3574, testing finds other applications in automotive seating, furniture cushioning, mattresses, insulation, and packaging. With such standards in place, manufacturers are able to ensure consistency in how their products perform, adhere to regulatory requirements, and bolster the confidence of the customer. This highly inclusive standard ensures that foam products shall perform reliably in the specified scenarios of expected use.

ISO Standards Relevant to Foam Testing

In an effort to ensure quality and consistency around the globe, ISO standards guide the testing of foam materials. A few important standards include ISO 3386, which centers its focus on the measurement of compression stress-strain behavior of flexible cellular materials; and ISO 1856, which looks at the return of foam after compression. Another worthy mention is ISO 2439, which is concerned with hardness measurements on foam by indentation force deflection (IFD). Such standards are heavily utilized in the automotive, furniture, and packaging industries, where they lend credence to foam test results under prescribed conditions, so manufacturers can effectively meet international quality standards.

Comparative Analysis: ASTM vs. ISO Testing Guidelines

ASTM and ISO testing guidelines differ primarily in focus, methodology, application scope, and regional preferences.

|

Key Point |

ASTM |

ISO |

|---|---|---|

|

Origin |

U.S.-based |

International |

|

Focus |

Material-specific |

Process-based |

|

Scope |

Regional |

Global |

|

Flexibility |

More flexible |

Standardized |

|

Industries |

Varied |

Varied |

|

Parameters |

Broader |

Streamlined |

|

Compliance |

Voluntary |

Often mandatory |

This table highlights the primary distinctions between ASTM and ISO testing frameworks, aiding in understanding their respective roles in standardization based on industrial and organizational requirements.

Emerging Technologies in Foam Testing

Foam-testing technology progresses with greater precision, efficiency, and applicability across industries. Some emerging methods involve the use of machine learning algorithms to treat the mechanical and structural behaviors for improved predictive modeling. There is an increase in the application of NDT technologies such as ultrasonic imaging and optical 3D scanning for the assessment of internal foam properties without compromising the material’s integrity. In addition, the use of automated systems and robotics is changing testing protocols to ensure consistent results while minimizing the risk of operational error. Real-time monitoring methods using IoT sensors are introduced to track foam performance in manufacturing and application. These technologies advanced toward making foam testing more accurate, reliable, and flexible.

Automated Testing Systems and Their Benefits

Automated testing systems provide unmatched advantages in the efficiency and precision of foam testing procedures. At the forefront of these systems are robotic platforms, along with software-controlled systems, which allow for consistent and repeatable test data to be recorded, thus minimizing data variability due to operator competence. Testing speeds increase while accuracy is maintained, rendering higher throughput for the industrial applications. At the same time, these systems can implement multiple protocols for testing concurrently, increasing time and cost efficiency. When connected to data analytics software, automated systems feed back data and actionable insights in near real-time to optimize processes and assure quality control. These benefits free up human resources and promote efficiency, facilitating attainment of strict regulatory requirements, and making automatic foam testing an essential part of the present-day workflows.

Advanced Materials Analysis Tools

Advanced material analysis tools employ an array of technologies to enable an exceedingly precise and accurate evaluation of material properties at a micro and macro level. The tool utilizes spectroscopic techniques, microscopy, and thermal analysis to test parameters such as composition, structure, mechanical performance, and thermal stability. Typically, the modern tool also offers enhanced and swift methods of identifying trends and anomalies by employing machine learning algorithms and artificial intelligence-based means for data analysis. These systems find use in aerospace, automotive, electronics industries, among others, where the information provided from material performance tests directly impacts product reliability and safety. Adopting such testing systems, which adhere to international standards, also promotes compatibility and compliance to regulations in global markets, thus maintaining the industries’ standing in industrial innovation and competitiveness.

Environmental Considerations in Foam Testing Innovations

When it comes to the environmental consideration of foam testing, the adage goes: first, do no harm-never compromise sustainable practices, nor use materials that can hinder the process. According to me, the innovation here would lie in the use of biodegradable or recyclable foam materials that have a minimal impact on the environment. Furthermore, the testing procedures should be made more efficient with regard to waste and energy usage. This will probably involve relying on technology such as simulation models to determine whether some physical tests can be avoided. This offers the opportunity to strike a balance between strict testing criteria and environmental conservation. In this way, by being aware of current trends and compliant with emerging regulations, we have foam testing contribute to building a sustainable industrial ecosystem.

Benefits of High-Quality Foam Materials

High-quality foam materials offer several crucial advantages across various industries. The durability offered by these foams guarantees long-term usage, hence diminishing replacement and disposal cycles. They possess superior thermal insulation properties suited to energy-efficient applications, which in return, bring down energy consumption and operational costs. On the other hand, advanced foam materials offer highly effective vibration dampening and shock absorption characteristics for the safety and durability of their end products-from automotive to construction applications. Their being lightweight also helps in conserving fuel in various transport applications while still maintaining structural integrity. Therefore, it can be said that high-quality foam materials offer economic and environmental advantages for sustainability and efficiency.

Improved Product Performance and Lifespan

Advanced foams furtherized the durability of products by reducing wear and tear brought about by continuous use or by environmental stresses. They are able to resist water, temperature, and chemicals to an extent whereby the material will not degrade with age. Further modifications can be applied to meet requirements: thermal insulation, soundproofing, and impact resistance, to name some, thereby ensuring optimum use. In extending the product life cycle, these materials reduce the cost of maintenance as well as consuming less resources, and thus, they realize long-term cost-effectiveness and sustainability.

Reducing Product Recalls through Effective Testing

Effective testing reduces product defects and, basically, guarantees a product’s entry into the market without expensive recalls that would harm its reputation. A good testing regime will combine a mixture of functional testing, stress testing, and compliance testing to ensure that products work as they should under a variety of conditions. Exploiting advanced technologies like automated testing systems and simulation software will ensure that it is carried out efficiently, while also pinpointing weak points that may remain undetected through manual means.

Implementing quality assurance measures, such as statistical sampling and failure mode analysis, is equally important to find systemic problems in engineering or manufacturing. Feedback loops of previous recalls can be employed to further enhance testing methods and avoid the repetition of prior faults. By concentrating on rigorous and preemptive testing, companies will be able to reduce recall risks and simultaneously build reputation and stand up to industry standards.

Challenges in Maintaining Foam Quality

Several technical and operational challenges have to be addressed while maintaining foam quality. One fundamental factor that needs consideration is the control of process parameters such as temperature, pressure, and mixing ratios because fluctuations in these aspects would confer defects into the foam in respect to its structure and performance. Controlling raw material selection is also very crucial because variations in material composition tend to perturb some of the physical properties of the foam, for example, density, and resiliency. Certain precautions must be observed to limit contamination during production as this would greatly affect the uniformity and durability of the foam. Testing and exercising quality assurance procedures at the levels are of utmost importance to detect any probable challenges as early as possible and to ensure that the standards are consistently maintained throughout the production life cycle.

Common Quality Control Issues in Foam Production

From my point of view, some of the most important quality control problems in the production of foams include inconsistencies in materials, contamination during production, and issues with the testing procedures. Changes in the composition of raw materials, such as the percentages of polyols or isocyanates, will enhance or degrade physical properties of the foam: sometimes these changes neither increase foam uniformity nor resilience, leading to problems in density or resilience. The introduction of contaminants during production processes either by the working environment or from improper handling of materials contributes to the reduction in uniformity and durability of the foam. Inconsistent or absent quality assurance measures, such as neglecting density tests or compression or tensile strength tests, can also lead to deficiencies going unnoticed, with an adverse impact on product reliability. A systematic method of approaching material selection, rigorously followed production methods, and conscientiously implemented testing standards need to be put into place to remedy these problems.

Adopting Latest Testing Techniques to Overcome Challenges

For product reliability and performance being scrutinized to the utmost, the importance of the latest trends in testing materials cannot be overlooked. For instance, with non-destructive testing (NDT) techniques like ultrasonic, radiographic, and X-ray computed tomography, the internal composition of the material can be studied in great detail without harming or destroying the specimen. Automating testing procedures with AI to analyze data can speed the process as well as quickly pinpoint defects or inconsistencies. And then there is real-time monitoring during production that can catch deviations as they occur and prevent hits on quality. These aspects addressed in conjunction with adherence to updated industry standards, such as ASTM or ISO, deal with the major problems presented by assuring quality and durability so that ample performance is guaranteed even beyond expectations.

The Future of Foam Testing in a Competitive Market

From my perspective, the future of foam testing lies in further advancements in automation, precision, and data-driven insights. The integration of cutting-edge technologies, such as AI-powered analysis and adaptive testing methods, will enable faster and more efficient testing processes. Besides, with sustainability programs becoming more urgent by the hour, eco-friendly testing methods that reduce waste and energy consumption will become paramount. The race today is far from over, and to stay ahead requires innovation at every turn, investments in advanced technologies, and adherence to the changing regulations in regards to quality, performance, and environmental consciousness.

Reference Sources

-

ASTM D3574 Flexible Foam Testing – ZwickRoell – This source provides details on ASTM D3574, a standard for testing flexible foam properties.

-

The Definitive Guide to ASTM D3574 – Instron – A comprehensive guide to ASTM D3574, covering various tests for characterizing flexible polyurethane foams.

-

Automotive Polyurethane Foam Testing – MGA Research – Focuses on ASTM D3754 and its application in automotive polyurethane foam testing.

-

ASTM D3574 Polyurethane Foam Testing – DDL, Inc. – Discusses standards and methods for testing polyurethane foams, including ASTM D3574.

-

Testing and Quality Assurance for Polyurethane Foams – TCH – Explores the importance of rigorous testing and quality assurance for polyurethane foams in various applications.

Frequently Asked Questions (FAQs)

Q:What is the purpose of flexible foam testing?

A:Flexible foam testing serves to analyze the properties of flexible polyurethane materials. These types of testing enable the manufacturers to assure that the foam products are up to a certain level of performance, from durability and compression resistance to quality. Testing methods are applied under ASTM D3574 and other standards, depending on the nature of the foam’s behavior under testing conditions, to verify the foam meets application testing requirements.

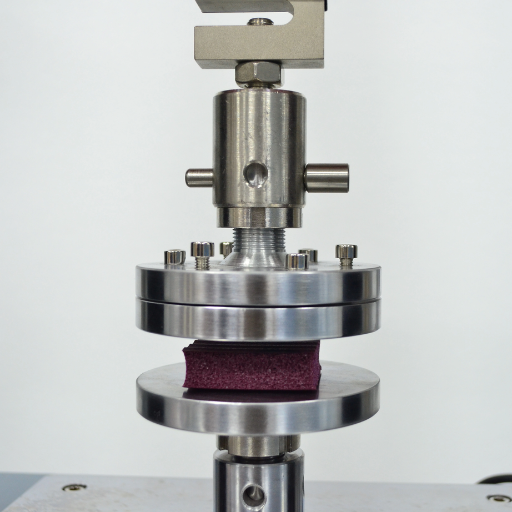

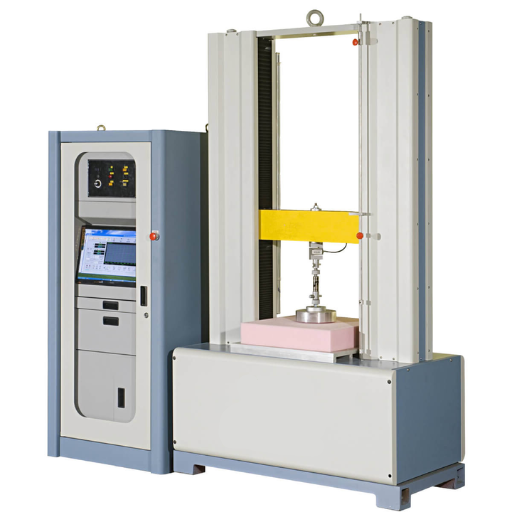

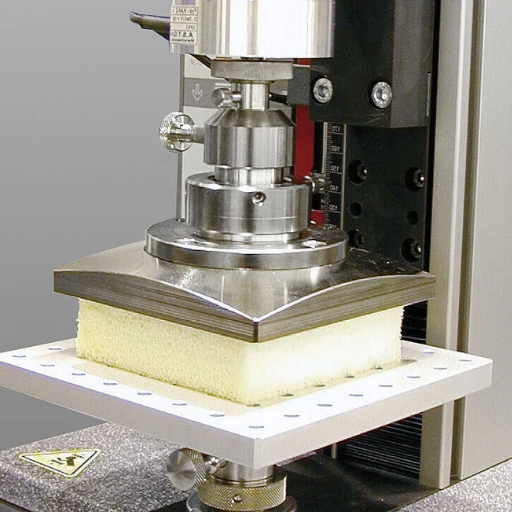

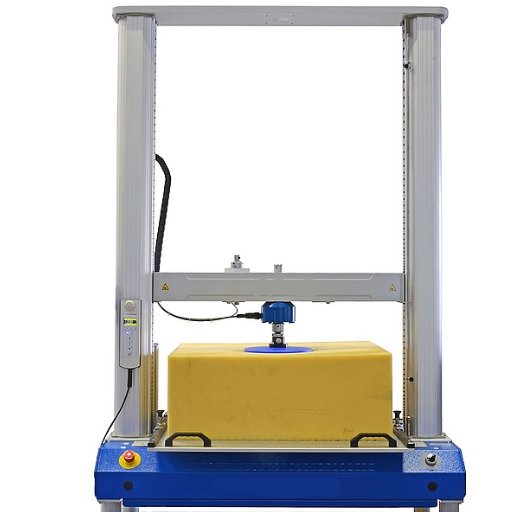

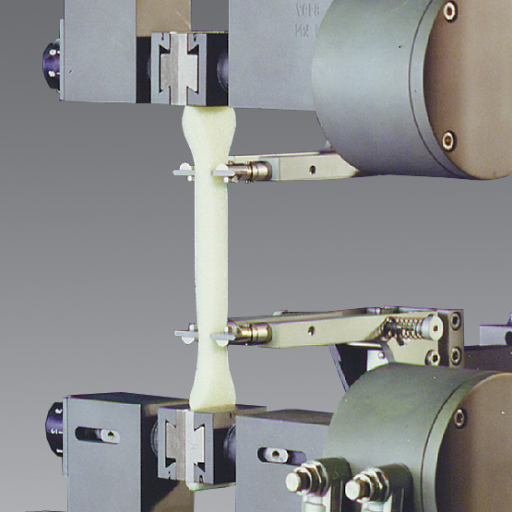

Q:How do test machines evaluate flexible foam?

A:There are numerous ways test machines measure the main properties of flexible foam, namely compression force deflection and indentation hardness. They apply specific forces to the foam samples and thereby deduce their mechanical properties. A universal testing machine often undertakes this role and offers precision and repeatability in results.

Q:What is the ASTM D3574 Test C?

A:ASTM D3574 Test C is a standard test method specially designed for flexible foam materials. It measures the compression force deflection (IFD) of foam samples by compressing the foam at a specified rate and recording the force needed to achieve prescribed deflection levels. This test is integral in determining the load-bearing capacity of polyurethane foam and its performance characteristics.

Q:What are the testing applications of a foam test machine?

A:Within its aptitude, the foam test machine conducts compression, tensile, and fatigue tests. The machine is fitted with sophisticated software that offers precise control over various test sequences and data interpretation. When persuaded by specific fixtures, the machinery accommodates different foam specimens, thus evaluating foam durability across the board.

Q:What is the significance of the IFD test in foam testing?

A:The Indentation Force Deflection (IFD) test studies how flexible foam materiel behaves in terms of firmness and compressibility. This test is very important for uses whereby foam materials will be subjected to variable loads, such as automotive seating or mattress applications. Therefore, knowing the IFD values can help foam manufacturers steer their foam mix toward the particular application of interest.

Q:How is tear strength tested in flexible polyurethane foam?

A:Tear strength testing evaluates the resistance of a material to a tearing or tensile load. This test is quite essential to determine the strength of foam components, such as cushions and automotive interiors, to withstand everyday use without deterioration.”

Q:Which flexible foam testing methods are described within ASTM D3574?

A:ASTM-D3574 provides the guidelines for several standardized testing methods of flexible foams, of which B1 and C are among the methods dealing with compression and force deflection. These methods describe detailed processes for measuring the mechanical properties of foam samples, thereby allowing manufacturers to measure foam quality and performance consistently. Manufacturers can expect credible results that conform to the industry’s standard only when they strictly adhere to the described methods.

Q:Why is compression force deflection important in foam testing?

A:Compression force deflection is an important property to determine how a foam material will behave under applied loads. Knowing this property enables the manufacturers to design foams that give optimum support and comfort in various applications like automotive seating and bedding. By measuring compression force deflection, manufacturers can customize their products to suit the needs and preferences of their consumers.