The peel adhesion property testing of pressure-sensitive tapes is ASTM D3330. This test method is essential for friction measurement of adhesive strength of the tape to be placed for high-demand applications. This method can be implemented in the force of manufacturing or for medical devices, involving mostly the adhesive coatings used on backing materials. Whether you are a quality inspector or a materials engineer, or even if you would like some general technical insight into how tapes adhere, this article will walk you through ASTM D3330 and its importance. We will take you through the actual test procedure, the theory behind it, and how it relates to practical application, thus giving you all-around knowledge on the essential standard.

Introduction to ASTM D3330

ASTM D3330 is a standardized test method established for determining peel adhesion strength of pressure-sensitive tapes. This method is concerned with measuring the force required to peel a tape off at controlled angle and speed against a specified surface, to produce uniform and reliable data. The peel adhesion test for pressure-sensitive tape is very much relevant for various industrial fields who use it for conforming tape performance, comparing adhesive property, and testing their products for quality. Results from ASTM D3330 tests allow manufacturers to design and engineer materials suited for applications of differing requirements in adhesion.

What is ASTM D3330?

Standardized by ASTM International, ASTM D3330 test procedures measure peel adhesion of pressure-sensitive tapes. This test method includes quantifying the force necessary to peel a tape from a standard surface under controlled conditions, usually at 180 degrees and with a standard speed of removal. The test is pertinent for measuring the adhesion performance of pressure-sensitive tape in applications ranging from packaging to automotive, medical, to electronics. By assuring that the testing parameters remain standardized, ASTM D3330 results provide a basis for comparing different adhesive materials used by manufacturers, facilitating quality control, and supporting the refinement of product design. The method determines the reliability of tape adhesion to a particular surface under operational working conditions, so it is essential for validating performance data in product design.

History and Development of ASTM D3330

ASTM D3330 was initially developed as a testing standard by the ASTM organization with the intent to satisfy increasing demands for a consistent and reliable method to evaluate pressure-sensitive adhesive tapes. After development by numerous experts, the method experienced a series of improvements to continually adjust to the technical requirements of sectors such as automotive, aerospace, and electronics. It details measures that will ensure test-to-test repeatability of adhesion strength in varying applications. ASTM D3330 was periodically reviewed and corrected to suit the advancements in material science and evolving needs of short and long-term manufacturing and quality assurance. To assure the sanctity and relevance of the test, every revision was found suitable by the committees, rendering the test one of the most established benchmarks worldwide for performance evaluation of adhesives.

Relevance in Adhesive Testing Across Industries

ASTM D3330 is an important tool in the world of adhesive testing by virtue of its standardized method of evaluating the peel adhesion of pressure-sensitive tapes. This standard is utilized across industries ranging from automotive, aerospace, electronics, and packaging to ensure that materials meet performance and durability requirements. For example, in automotive applications, adhesives must withstand environmental stimuli such as varying temperature and humidity, while in the electronics industry such standards are the guarantee for precision and reliability in assembling components. ASTM D3330, by delivering repeatable and consistent test protocols, assists manufacturers in verifying adhesive performance, ensuring product quality, and enforcing compliance with regulations.

Key Testing Methods in ASTM D3330

ASTM D3330 recognizes six separate testing methods (Methods A through F) to determine the peel adhesion of pressure-sensitive tapes. Each one is suited to testing a defined case or operating condition:

1.Method A measures peel adhesion of single-coated tapes onto a standard steel plate using a 180-degree peel angle.

2.Method B measures the adhesion of single-coated tape directly bonded onto a backing material.

3.Method C measures the adhesive strength of double coatings onto the material backing in order to assess the suitability for layered applications.

4.Method D measures the peel adhesion of double-coated tapes as on a rigid surface, simulating real scenarios of usage.

5.Method E is similar to method D except this one applies to single-coated tapes using extra flexible faces, so the single-coated tapes can be assured to be compatible with different surfaces.

6.Method F involves testing the adhesion of the tape following prolonged exposure to a set of environmental conditions such as temperature and humidity or cycling through such phases, thus assessing its long-term behavior.

Each method, therefore, presents its own set of operational parameters so that manufacturers may perform exhaustive evaluations and thereby ensure the meeting of the tapes with application requirements.

Overview of Testing Methods

The testing methods for adhesive tapes are intended to test essential performance parameters for reliability under various applications. Acceptable nowadays are peel strength, shear adhesion, tensile strength testing. Peel strength tests are performed, for example, according to ASTM D3330, to ascertain how much force needs to be applied to remove the tape from a particular substrate and thus to test the quality of adhesion. Shear adhesion tests determine how well the tape can resist static loads applied under particular conditions in view of its durability and structural applications. Tensile strength tests determine how the tape holds under stresses of stretching, making them more capable of resisting atmospheric stresses. These standard methods guarantee that adhesive tapes pass all performance criteria and provide manufacturers with an organized way to ascertain quality.

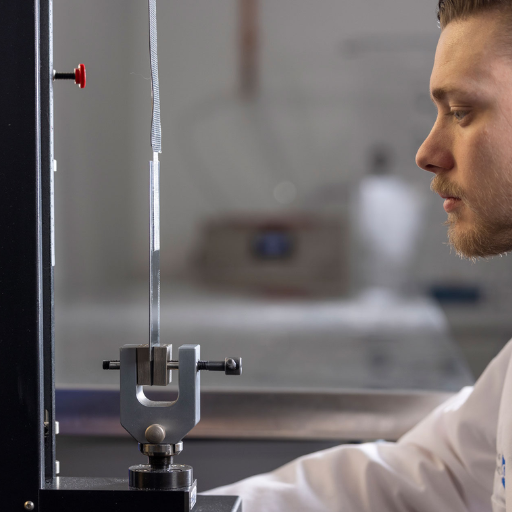

Peel Adhesion Tests Explained

Peel adhesion tests measure the force required to peel a tape from an adhesive surface attached to some substrate at a certain angle and speed. Normally carried out at angles of 90 or 180 degrees, a peel adhesion test produces measures representing bonding force of the adhesive under controlled conditions. Amongst others, variables are the type of substrate (like metal, plastic, or glass), adhesive formulation to be used, and environment conditions like temperature and humidity. Results are given in force per unit width in such units as ounces per inch or Newtons per meter so the manufacturers can decide how well the adhesive bonds to different surfaces. Testing is paramount in ensuring the adhesive behaves as expected with respect to certain performance requirements in its application, such as packaging, building, or electronic components. Peel adhesion tests, when conducted in accordance with recognized standards such as ASTM D3330 or ISO 8510-2, ensure a consistent, repeatable, and reliable method of evaluation for the adhesive products themselves.

Scenarios for Each Test Method

When determining the appropriate test method, the specific application requirements and conditions must be considered. ASTM D3330 is best suited for pressure-sensitive tapes in packaging or industrial applications when adherence to some measure of peel strength under a variety of environmental conditions for long-term reliability is of essence. ISO 8510-2 is more suited to adhesives for structural bonding where performance under stress is paramount, for instance in automotive or aerospace industries. In this way, the test methods are used to simulate the on-and-off requirements of actual products and ensure adhesives can be expected to meet these mechanical and environmental demands in their intended use.

Practical Applications of ASTM D3330

ASTM D3330 is broadly applied to evaluate the peel adhesion strength of pressure-sensitive tapes. Industries such as electronics, automotive, and packaging especially find this standard useful as it facilitates uniform performance of the tape. It is used within the electronics environment to guarantee proper assembly of components, while within automotive applications, it verifies the strength of tapes used for trim and insulation. Because of the rigorous precision of the standard method, manufacturers can check materials for quality, formulate better materials, and check for regulatory and performance compliances.

Testing Tape Adhesion in Industrial Settings

Testing tape adhesion in industrial sites involves standardized methodologies measuring tape’s ability to bond, durability, and suitability for a given application. Common tests comprise peel adhesion tests that basically measure the force of tape coming off the surface as it is removed at a constant angle, and shear adhesion tests that register how much resistance the tape offers when it is placed under pressure-forces in a sliding mode. These tests definitely guarantee that tapes will comply with quality and performance standards set for industrial use, particularly in demanding sites where reliability counts. Also, there may be tests for environmental and aging factors simulating temperature change, relative humidity, and presence of chemicals to ensure long-term good effect.

Ensuring Medical Adhesive Performance

Performance of medical adhesives requires a multipronged approach, combining the selection of materials, testing, and adherence to medically relevant standards. Selection starts with biocompatibility considerations, wherein adhesives must adhere to ISO 10993 for cytotoxicity, sensitization, and skin irritations to assure patient safety. Testing of performance involves the evaluation of adhesives regarding their tack, peel adhesion, and shear strength suitable for the application in question, guaranteeing that adequate adhesion is achieved during use. Testing against environments of moisture, sterilization, and length of wear factors further proves durability under differing conditions. Furthermore, adhesives offer a balance of skin friendliness and reliable adhesion, thus being suitable for application on sensitive or compromised skin. Manufacturers also continually tweak formulations through intensive R&D and feedback from real-life applications to achieve best results in various medical conditions.

Benefits of Adhering to ASTM D3330 Standards

1.Reliable Adhesion Testing: Adhering to ASTM D3330 would ensure a method that is standardized for the measurement of peel strength of adhesive bonds, and consistent and reliable data will then be produced that can be used as a basis for product performance evaluation.

2.Improved Product Quality: Usage of these standards permits the manufacturers to detect and resolve an adhesion problem so that better-graded adhesives can be produced.

3.Compatibility Across Industries: ASTM D3330 acts as a common yardstick, allowing adhesive products to be compatible and comparable for a variety of industries and application.

4.Regulatory Conformance: Following ASTM D3330 would facilitate regulatory acceptance, mitigating the risk of violations, and is considered best industry practice.

5.Greater Customer Reliance: Being able to demonstrate compliance with ASTM D3330 convinces the end-users and customers that there is a commitment to uniformity, reliability, and safety.

Industry Standards and Regulatory Compliance

Being ASTM D3330-compliant would be a public benefit for a product, helping it enhance performance, meet regulatory issues, or simply win customer confidence. Hence, a product conforming to these test methods is said to be in line with the technical specifications, within control in terms of quality, satisfies safety, and legal requirements, thereby creating a true market environment of trust and reliability.

How ASTM D3330 Fits into Compliance Frameworks

Primarily, ASTM D3330 holds importance in compliance frameworks for providing uniform procedures for peel adhesion testing of pressure-sensitive tapes with reliable and consistent results to satisfy both manufacturers and regulatory agents. By offering rigorous methodologies, ASTM D3330 proves to be beneficial for businesses in adhering to safety and legal regulations such as ISO or REACH, depending on the geographical location or industry. Moreover, adopting these standards in manufacturing processes further improves the quality assurance means and levels, which effectively reduce variances in product manufacturing and ensure that the product complies with technical and regulatory specifications. Conformance to ASTM D3330 yields risk reduction in liability issues and, importantly, boosts marketability as it testifies to the earnestness of manufacturers to conform with truly international benchmarks.

ASTM D3330 in Relation to Other Standards

ASTM D3330 relates to other standards such as ISO 29862, PSTC-101, JIS Z 0237, and DIN EN 1939, focusing on peel adhesion performance for pressure-sensitive adhesives.

|

Standard |

Region |

Scope |

Focus |

Adhesion |

|---|---|---|---|---|

|

ASTM D3330 |

Global |

Adhesive tapes |

Peel strength |

High detail |

|

ISO 29862 |

International |

Adhesive tests |

Adhesion value |

Moderate |

|

PSTC-101 |

North America |

Adhesive tapes |

Performance |

High detail |

|

JIS Z 0237 |

Japan |

Adhesion tests |

Peel, shear |

Consistent |

|

DIN EN 1939 |

Europe |

Adhesive tapes |

Peel tests |

Harmonized |

The Role of ASTM in Quality Assurance

1.Standardization of Tests

ASTM gives Universal Testing Procedure to ensure that adhesive tape is tested under identical conditions with the least possible variations and so that the results can be compared equally with test results from parallel standpoints or applications.

2.Material Performance Investigation

ASTM standards such as ASTM D3330 provide a basis for testing peel strength and other properties of materials, thereby allowing manufacturers to test for product reliability.

3.Help Gained in Regulatory Compliance

Adoption of ASTM standards assists manufacturers in compliance with industry and regulatory requirements, thus leading to product approval worldwide.

4.Enhancing Quality

For checks on quality during fabrication, the ASTM method will stand rigorously; therefore, this method will never allow a slip in standard quality.

5.Basis of Innovation

If testing procedures are developed, refined, and published, then these serve as a foundation for developing methods of testing as well as for researching the enhancement of adhesive technology.

Ensuring Compliance with ASTM D3330 Guidelines

1.Understand the Standard

Review the ASTM D3330 specification in full, paying special attention to the scope, requirements, and parameters involved in the test for pressure-sensitive adhesive tape performance.

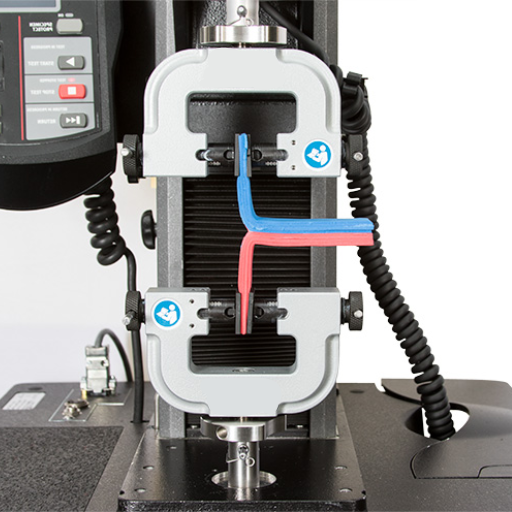

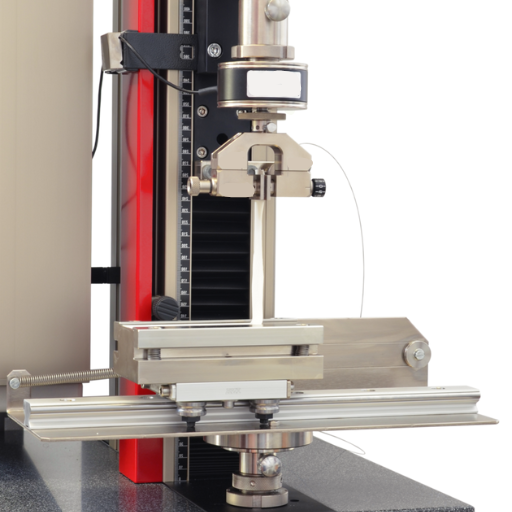

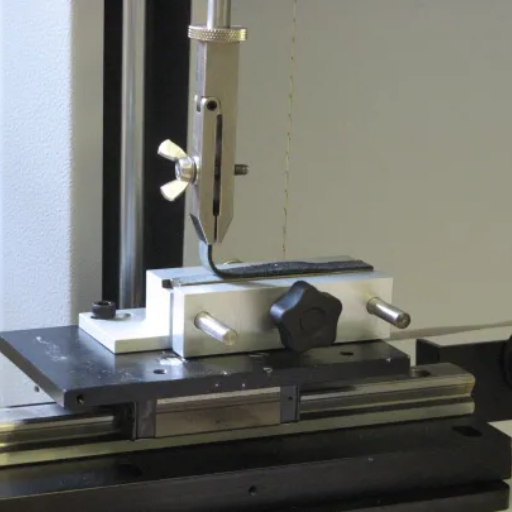

2.Calibrate Testing Equipment

Use testing equipment that satisfies the ASTM D3330 requirements and ensure that it is regularly calibrated for accurate and reliable test results.

3.Perform Tests Under Specified Conditions

Conduct the peel adhesion tests within the environmental conditions defined as standard, such as temperature and humidity levels.

4.Document Results and Procedures

Keep records of testing methods, conditions, and results to show that the testing has been performed according to the standard, and to back up assurance activities.

5.Maintain Regular Training

Give ongoing training to personnel involved in testing and analysis to guarantee proper procedures and correct interpretation of ASTM D3330 test requirements.

Training Staff on ASTM D3330 Standards

Training staff on the ASTM D3330 standards includes providing an understanding of the procedures and technical requirements as per the specifications in the test method. Staff should be aware of the sake of the standard, which is the testing of peel adhesion properties of pressure-sensitive tapes. Such training should involve familiarizing the staff with the practical aspects of setting up the test, including the correct alignment of specimens, calibration of the test equipment, and control of all test variables, such as speed and peel angle. They should also be trained in best practices for data recording, analyzing test results, and common problems they may encounter in adhesion testing. Furthermore, these trainings should be repeated through workshops and updates in line with any amendment to the ASTM D3330 standard to maintain consistent quality control and compliance.

Consulting with Experts in Adhesive Testing

It is important that you consult with people who are experienced in adhesive testing, as they can guarantee that the results are accurate and reliable. The experts ensure that their advice leads you through preparation of test setup, calibration of equipment, and the precise control of variables within a standard, such as ASTM D3330. Consequently, you will learn from these experts how to go about the interpretation of results and resolving issue techniques that are specific to your applications. Using this knowledge can help you comply with industry standards, improve quality control procedures, and minimize any incidences of errors during testing procedures.

Investing in Proper Testing Equipment

When investing in proper testing equipment, a number of considerations are always on my mind in order to maximize accuracy and reliability according to standards. First, I consider the specific requirements of the tests I perform, such as what materials will be tested and under what condition. This is necessary to choose equipment that meets the ASTM or ISO standard. Consideration is also given to the precision of the equipment and its calibration capability, because if either is inadequate, the results obtained will be useless. I then look at whether it is robust, easy to maintain, so requiring less downtime, and able to yield consistent results.

The next step is to check the data collection and analysis capability of the equipment, especially where the modern ones come equipped with software that can help reduce manpower and cost. Consideration is then given to the reputation of the supplier and what after-sales services can be rendered, such as technical support, training, and provision of parts in situations where these are needed. Considerations based on the above enable increased confidence in investing in test equipments that promote quality and provide accurate, repeatable results.

Reference Sources

-

ASTM D3330 – Instron

This source provides an overview of ASTM D3330, detailing its requirements for determining peel adhesion properties of pressure-sensitive tapes. -

ASTM Peel Adhesion Testing – ATS Lab

Offers insights into ASTM peel adhesion testing, focusing on quality assurance and testing procedures. -

Peel Strength Testing – The Complete Guide – Industrial Physics

Explains the principles of peel strength testing, including its application to adhesive materials. -

USA Testing Lab for ASTM D3330 Peel Adhesion – Matest Labs

Describes the peel adhesion test process and its significance in measuring the peel force for pressure-sensitive tapes. -

ASTM D3330 Peel Adhesion Test Panel – Metaspec

Provides details about the test panels used in ASTM D3330, including specifications and materials.

Frequently Asked Questions (FAQ)

Q:What is the ASTM D3330 peel test method?

A:The ASTM peel test measures peel adhesion under different force application methods. The ASTM D3330 test method serves for pressure-sensitive tape-provided peel adhesion measurements. The tape adhesion to a surface to resist a force that tends to pull it away from the surface results in valuable data for use in evaluating properties of different pressure-sensitive adhesives.

Q:How do the different methods evaluate the peel adhesion of pressure-sensitive tapes?

A:The peel adhesion of pressure sensitive tapes may vary greatly according to the method used according to ASTM D3330. Method A will measure peel adhesion under standard conditions, while Method C will offer data on single coated tape adhesion under varying conditions, such as different peel angles.

Q:What are the fundamental components of ASTM D3330 testing?

A:The fundamental elements include preparation of the test panel, application of the tape, and measurement of force required to cause peel. This means that the tape must be uniformly applied onto a standard steel test panel and tested under controlled conditions to obtain valid test results.

Q:What is the importance of 180-degree peel in ASTM D3330?

A:The 180° peel test is important in ASTM D3330 because it measures peel adhesion while the tape is being peeled back at a straight angle. This test gives lots of information on the performance of the tape in the real world that will enable manufacturers to ascertain whether the adhesion is appropriate to use for some specific usages.

Q:How is transfer tape tested for peel adhesion according to ASTM D3330?

A:Transfer tape stands for peel adhesion testing according to ASTM D3330 by applying it to the standard test panel to peel it away under designated angles. The attached data evaluate the adherence of the transfer tape under given conditions to allow comparison with other types of pressure-sensitive tapes.

Q:What does Method E in ASTM D3330 test for?

A:Method E in ASTM D3330 tests for the adhesive peel adhesion from double-coated tapes. It depicts how well the adhesive inside a substrate holds the tape when it is peeled apart, important to the working procedures where double-coated tapes are quite common.

Q:Is this ASTM D3330 peel test method applicable for various types of pressure sensitive adhesive tapes?

A:Yes. ASTM D3330 peel test can, in fact, be used for different types of pressure-sensitive tapes. The various methods laid out in the standard, for instance, Method B or Method F, cover various tape constructions, including single-coated, double-coated, and adhesive transfer tapes, thus evaluating the whole range of products.

Q:What factors affect the measurement of peel adhesion in ASTM D3330?

A:Factors influencing the measurement of peel adhesion, according to ASTM D3330, will include, amongst others, the type of surface on which the tape is applied, the peel angle (90° or 180°), the environmental conditions under which the test is performed, and the unique characteristics of the tape itself, such as its backing and adhesive formulation.

Q:How uniform is adhesion of pressure-sensitive tapes?

A:Uniformity of adhesion is critical to pressure-sensitive tape performance. Differences in adhesion may cause inconsistencies in performance, thus affecting the tape’s ability to hold over time or under stress. Its variability can be detected through ASTM D3330 testing as a quality control measure to guarantee product reliability.