Performance and reliability of pressure-sensitive labels must be accurately evaluated. One of the most widely recognized testing standards in this field is ASTM D6252, which covers the procedure for the measurement of peel adhesion. It is a crucial parameter for determining how well the label will adhere to its designated surface under the application of different conditions, having applications in packaging, logistics, medical, and automotive industries.

This article will provide a complete understanding of ASTM D6252 by detailing the nature and significance of the test method, providing an insight into the practical aspects for manufacturers, QC personnel, and industrialists concerned. Herein, the industry standard compliance, product improvement, or just a thorough understanding of the test method can be discussed. Stay tuned to learn how this method is affecting the testing of pressure-sensitive labels and thus its practical implications.

Introduction to ASTM D6252

ASTM D6252 represents a test method intended for the peel adhesion test of pressure-sensitive tapes. It denotes the test force necessary to withdraw a tape at a defined angle and speed from a standardized test surface. Thus, controlling the conditions in this manner is of utmost importance to investigate microwave adhesive properties of tape because of their effect on final end-use quality and reliability. The test method was drafted by ASTM International and provided a reliable, generally accepted basis for manufacturers and end-users alike to determine if the measured adhesion properties of a tape conform to performance criteria agreed upon.

What is ASTM D6252?

ASTM D6252 is a standardized and specified test method developed by ASTM International for determining the peel adhesion of pressure-sensitive tapes. The force involved in pulling off the tape from a stainless steel test panel is measured at a predetermined angle, usually 90° or 180°, and speed. Repeatable and reproducible measurements of the adhesive strength of the tape allow the manufacturers to reliably determine product performance in accordance with specifications.

The measurement is carried out within predefined limits of environmental conditions to prevent other factors from affecting the measurement, and therein, ASTM D6252 also prescribes in great detail how the samples should be prepared, how the test panel is to be cleaned, and how the testing machine should be calibrated. ASTM D6252 is also regarded as an essential quality control procedure in industries such as automotive, aerospace, packaging, and electronics, where the adhesive tape performance is vital for ensuring product integrity. Standardization according to this method weighs the tape manufacturer versus the application of his products, legitimizing the quality-related claims regarding product performance.

Scope and Context of the Standard

The ASTM method 6252 shall furnish a series of tests for determining static shear strength of pressure-sensitive adhesive tapes under accepted laboratory conditions. The specified standard will be useful in circumstances where adhesive tapes are expected to perform under hostile or varying stress/temperature environments. Thus, ASTM 6252 specifies the testing procedure for measuring a tape’s ability to resist shearing force for a few hours, hence establishing product durability and hence reliability on the tape.

The field of usage of ASTM D6252 includes automotive, electronics, aerospace, and packaging industries; where strict adhesion criteria are required from adhesive tapes to guarantee high standards of product performance. Operating the standard guarantees product quality which in turn facilitates trade at the global level by meeting international criteria while ensuring the end-user is totally satisfied and well secure. ASTM D6252 also facilitates the comparison of adhesive tape products based on a common criterion, which improves market transparency and fosters healthy competition.

Importance of Compliance with ASTM D6252

Adherence to ASTM D6252 is paramount in assuring that adhesive tapes meet high-quality performance standards. It defines tests pertinent to adhesion properties, enforcing conformity and unwavering performances under specified test conditions. By adhering to ASTM D6252, product reliability is assured to its applications and gets accepted by the global arena, hence also becoming recognized otherwise as best practice and for interoperability. It further ensures manufacturers can mitigate product failure, increase consumer trust, and also assert trading competitive advantage in markets that require high standards for labelled and tested materials.

Significance of ASTM D6252 in Industry

ASTM D6252, thus, acts as a quality and performance measure of the myriad uses of pressure-sensitive adhesive (PSA) tapes in industry. It provides uniform test methods to compare adhesive strengths, shear resistances, or tensile strengths. PSA tapes, however, are enviably subjected to harsh environments and high standards in automobile, aerospace, building industry, and electronics arena. So, ASTM D6252 ensures product uniformity and lessens failures, cementing a strong base between manufacturers and end-users. Broadly, ASTM also assists in regulatory compliance and aligning products to recognized international standards.

Why Peel Adhesion Matters

Peel adhesion is a crucial parameter which, in various applications, tends to spell reliability and performance for PSA tapes. It is defined as the force exerted to strip an adhesive layer from a substrate, and this force directly renders the product incapable of sustaining any period of peel adhesion for long. Under varying conditions such as changes in temperature, moisture changes, or mechanical stresses, high peel adhesion is required to maintain the bonding for long periods. Measuring and conversing about optimization of peel adhesion in specific industrial fields are crucial since failure of adhesion leads to loss of life or impairment of functionality.

Impact on Quality Control

When it comes to quality control, ASTM D6252 is an important tool to ensure that all similar products are testable against peel adhesion in order to ensure reliability and uniformity of the products. Tests under agreed conditions will reveal inconsistencies in bond performance between adhesives and substrates that will be eliminated in the early stages of production. Finally, standardizing products on ASTM D6252 allows me to prove that the adhesives and coatings are fit to perform on varying substrates and guaranteed under required industrial standards. With this detailed process,” garanting the high quality of a product which fulfills both regulatory consumers expectations and attaining high results in practical fields of application; it reduces evident cases of failures.”

Regulatory Requirements and Standards

Regulatory requirements governing adhesives and related materials come principally from institutions like ASTM International, ISO, and then regionally through the FDA or EU REACH. These bodies set forth the minimum safety, environmental compliance, and performance standards under agreed test conditions. For instance, ASTM D1002 evaluates shear strength, whereas ISO 4587 deals with testing tensile behavior of adhesive bonds. Conforming to these standards implies that the products comply with the mandatory safety and functionality standards, are less likely to become subject to liability, and make it easier to get global market entry. Then additionally, manufacturers are subjected to industry-specific legislations, such as FDA 21 CFR 175.105, for food-contact adhesives or CLP Regulations of the EU for chemical safety-providing protection of consumers as well as the industries.

Step-by-Step Breakdown of ASTM D6252 Procedures

1.Specimen Preparation: Preparation of adhesive or material specimens for testing must be in accordance with the given dimensions and conditions stated in ASTM D6252. Surfaces must be free of any foreign material and dirt; if required, surface treatment can be applied for bonding.

2.Testing Configuration Setup: The testing equipment should be adjusted according to specified conditions as per ASTM D6252. The specimens should be securely mounted in order to avoid any instance of slipping during testing, thereby affecting results.

3.Temperature and Humidity Control: Conditioning of specimens should be done in a controlled environment with temperature and humidity held at predetermined levels to simulate the expected real-life service conditions.

4.Application of Load and Testing: Apply tensile or compressive load at a rate specified in ASTM D6252. The mechanical response of the adhesive bond should be monitored and recorded including such parameters as peak stress, extension, or describing characteristics of failure.

5.Data Analysis and Reporting: The data collected shall be analyzed for strength, deformation behavior, and failure mode. The results shall be compiled in a conclusive report in accordance with the ASTM format and content requirements for traceability and audits.

Preparation for the Adhesion Test

The competently preparing for adhesive tests (given ASTM D6252) involves a set of steps under control to signify accuracy and consistent results. First, select test substrates and prepare the surface according to material specifications: this usually requires cleaning of contaminants and the application of a surface treatment. Keep in mind that the adhesive should be mixed or prepared according to the instructions of the manufacturer, keeping the ratios, curing parameters, etc., strictly to those instructions. Keep the room temperature and humidity according to the range set by ASTM D6252. The specimens are assembled, and the adhesive bond is allowed to cure in an environment under control. Testing should be done only after full curing of the bond since otherwise, the results may be invalid. The testing instruments then have to be calibrated according to ASTM standards, whereby the calibration of the load cells and extension measuring devices is checked to ascertain that the measurements are valid and traceable. These preparation steps minimize variability and ensure that subsequent performance analysis is founded upon valid data.

Executing the 90° Peel Test

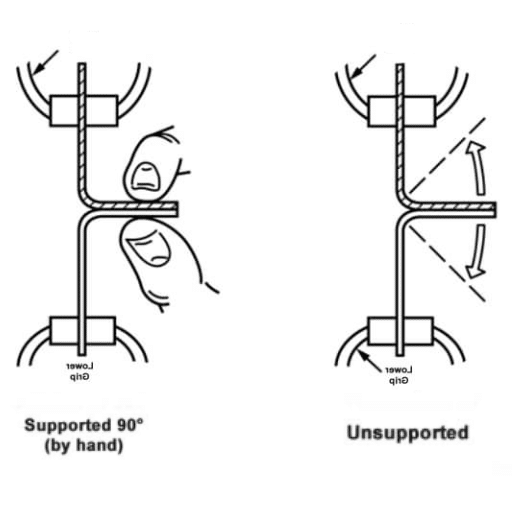

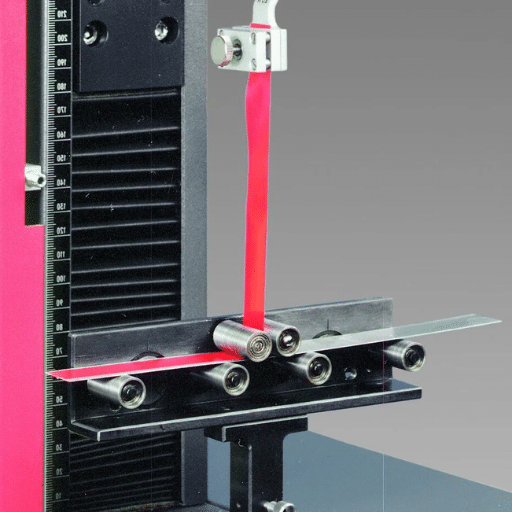

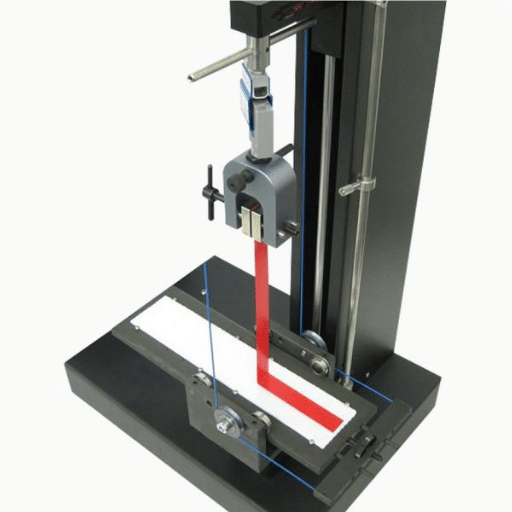

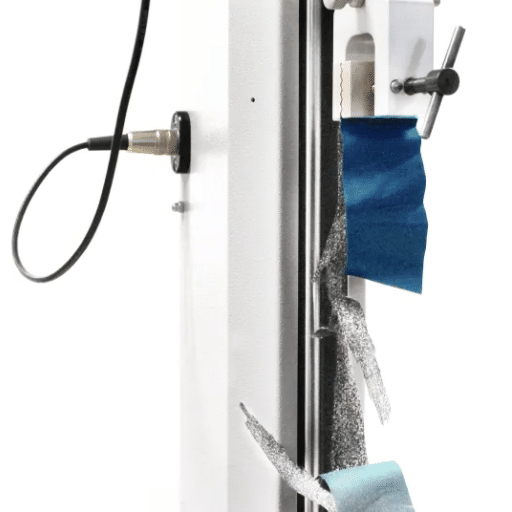

The 90° peel test conforms to ASTM D6252 to determine the adhesive strength between two bonded materials and is a typical test for pressure-sensitive adhesives. The substrate is placed flat on a rigid platform and then clamped or adhered to the platform so that it will not move during testing. One end of the adhered flexible material is attached to the gripping mechanism of the tensile testing equipment.

The peel force is measured as the flexible material is pulled at a speed of 300 mm/min (12 in/min, as specified by ASTM D6252) at an angle of 90° to the substrate. In this test, the angle of 90° must be maintained all through the test using special fixtures or alignment systems. The testing machine then records the peeling force necessary to separate the materials, usually expressed as average peel strength over the length tested.

All parameters of testing include sample dimensions, adhesive cure time, and environmental conditions, in accordance with ASTM D6252 specifications to standardize the results. Doing so ensures that the testing is reproducible and allows the collected data to be used for actual evaluation of adhesive performance.

Interpreting Test Results

When evaluating the results as per ASTM D6252, I first look at the average peel strength and then check for variations within the data from the test sample. Peel strength variations, if any, might be due to the uneven adhesive application or surface preparation that would possibly affect the performance. I also compare the obtained results to the performance criteria to ensure they meet the application requirements. Environmental conditions such as temperature and humidity during testing are also taken into consideration, as these factors may greatly affect the behavior of the adhesive. Through this kind of thorough assessment, one would develop a clear picture of the adhesive’s reliability under controlled conditions.

Best Practices for Compliance with ASTM D6252

Ensuring compliance with ASTM D6252 calls for approaches systematically tested, with accuracy and repeatability as major criteria. Initially, the standard must be reviewed in full to appreciate the scope of specified test protocols and equipment requirements. Measuring instruments should be calibrated for measuring adhesive properties, with all instruments conforming to specified numerical values within a relevant range of precision. Moreover, it is necessary to maintain environmental conditions, such as temperature and relative humidity, strictly since these functions are integral to the adhesive properties. Sample preparation must also be regulated, as factors such as slight variations in specimen size, surface condition, or application method can generate unreliable results. Conduct numerous tests to explore variability analysis and reproducibility in the data. Finally, procedural information and results should be recorded accurately, providing a clear audit trail both for confirming compliance and for analysis of the data.

Efficient Methods for Testing

Standard ASTM D6252 signifies measurement procedures for assessing pressure-sensitive tapes’ adhesion strength. Test proceeds swiftly with correctly specified test equipment such as tensile testing machines and test environment. Tape specimens will be prepared before test according to the standards of ASTM with adherence to the preparation of test surface of adhesive and ensuring the application of tape itself is uniform on the test substrate.

Maintain calibration of the test apparatus to ensure a constant peel angle and a constant peel rate, 180° and 300 mm/min, respectively. A replication of peel tests should be conducted to observe any variation in adhesion performance from one sample to another. Use of automated systems whereby a high level of precision in the operation is possible will, therefore, facilitate in streamlining the whole process and greatly reducing errors introduced because of human incompatibility.

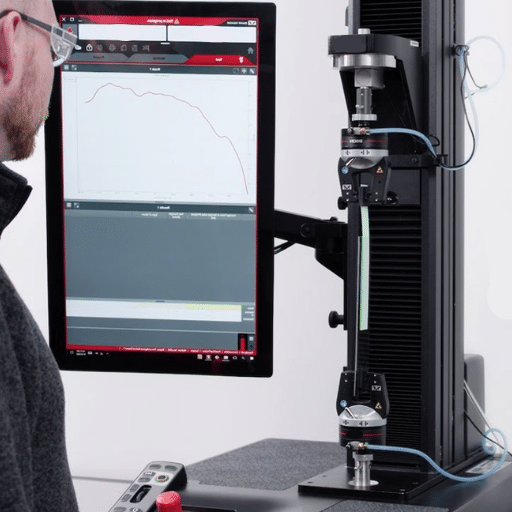

Besides, using a digital data acquisition system integrated with the tensile testing machine greatly facilitates the collection and analyses of test results. Through further in-depth analysis, these systems ensure test reporting as required by ASTM D6252, facilitating internal adoption for quality control and external validation required by regulators.

Tools and Equipment Recommendations

A high-capacity universal testing machine equipped with an extensometer for exact measurement of strain should be the equipment I would suggest to comply with requirements of ASTM D6252 and ensure good quality. It should conform to specified load accuracy tolerances as given in the ASTM Standards. Besides, it is important that the grips selected be compatible with the material to be tested so that they do not cause damage to the sample during tensile testing.

To ensure confident data collection, digital data acquisition systems that describe the necessary interface to the testing machine should be given preference. It should be equipped with software capable of automating the analysis and production of detailed reports as stipulated by ASTM D6252. Finally, it would be essential to ensure a controlled environment for testing, which includes calibrated environmental monitoring systems to record any variability as a result of temperature and humidity so that such variability does not affect the reliability of test results.

Streamlining Operations for Adherence

In order to streamline operations towards adherence, the first course of action is to identify and implement suitable advanced automation tools that inter alia enhance workflow efficiency and abate manual intervention. Also, it would be beneficial to have a centralized data management system that can allow for real-time tracking of compliance metrics and inform responsible persons upon deviations so as to ensure compliance to standards. Moreover, it would be best if all operational units standardized their processes so as to limit variability and increase consistency, hence maintain adherence to specified guidelines such as ASTM standards. Regular training and auditing should be scheduled for keeping teams abreast with updated compliance requirements to maintain a high degree of precision in their operations.

Advancements Related to ASTM D6252

Recent advancements related to ASTM D6252 have been focusing on further fine-tuning the test methods for splitting resistance of flexible barrier materials. Amongst these are the creation of highly precise measuring instruments for force application and material response to achieve greater accuracy and repeatability. Advanced data analysis tools now allow for detailed examinations of the results obtained in test procedures so that cross-comparisons of material types can be better made. These carry forward into assessing the durability and performance of materials with higher reliability so as to keep pace with fast-changing industry demands and quality standards.

Recent Updates in Testing Methods

Recent updates in testing methods to ASTM D6252 have concentrated on enhancing the precision and reliability with which the peel adhesion strength of pressure-sensitive tapes is measured. Improvements in mechanical systems ensure a more uniform application of test forces, reducing variation in results. In addition, these revisions integrate improved calibration procedures, which fit with stringent tolerance requirements and enhance reproducibility of data between labs. All this leads toward the industry’s aim to standardize testing procedures, improve workflow in testing, and ultimately contribute to better tape products meeting strict performance criteria.

Innovations in Pressure-Sensitive Label Stocks

Recent innovations in pressure-sensitive label stock are focused on factors of performance, sustainability, and adaptability to an array of applications. Further developments have led to the commercialization of ultra-thin, high-strength liner materials that greatly reduce wastage without compromising on performance. The use of recyclable and biodegradable materials also supports environmentally conscious regulations and goals. New generation adhesives grant better adhesion on tricky substrates, such as low-energy plastics, yet allow for removal when needed. These advances correlate with the industry’s needs for efficiency, greenness, and flexibility in solutions for product labeling.

Future of ASTM D6252 and Peel Adhesion Testing

In the coming years, ASTM D6252 and peel adhesion testing will see developments in test methodologies, driven foremost by the growing need for precision and efficiency in the evaluation of adhesive performance. These advancements are predicted to harness automation technologies to extend repeatability and consistency, with minimal manual interference. Alongside this, digital measurement systems will be adopted, permitting real-time data recording and processing, so tests are more streamlined, giving fast-track decisions in production environments.

Sustainability will, therefore, rank high in efforts to refine test procedures by catering to biodegradable adhesives in tandem with eco-friendly substrates that may enter the mainstream sooner. New adhesive formulations for various applications, including the medical and electronic industries, will warrant changes/updates to the standard that encompass diverse peel dynamics under different environmental conditions. The collaborative efforts of industry experts, regulatory agencies, and equipment manufacturers will continue to ensure ASTM D6252 remains flexible and dependable as adhesive technologies progress.

Reference Sources

-

ASTM D6252 | Pressure-Sensitive Labels | Peel Testing – ADMET

This source provides a detailed explanation of the 90° peel test method described in ASTM D6252. -

Peel Testing Adhesion of Labels Per ASTM D6252 – TestResources

Offers insights into the standardized 90° peel technique used to measure the adhesion of pressure-sensitive label stocks. -

ASTM Peel Adhesion Testing – ATS Lab

Discusses the application of ASTM standards, including D6252, for quality assurance in peel adhesion testing. -

ASTM D6252 Test Standard – Victor Testing Machine

Explains the international test standard and its application in quantifying the adherence of pressure-sensitive labels. -

D6252/D6252M Standard Test Method for Peel Adhesion – ASTM

The official ASTM page for D6252, detailing the test method for assessing the uniformity of adhesion in pressure-sensitive label stock.

Frequently Asked Questions (FAQ)

Q: What is ASTM D6252 for peel adhesion of pressure-sensitive labels?

A: The ASTM D6252 test method is a standard test method for testing peel adhesion of pressure-sensitive label stock. This test specifies the bond strength between a given type of pressure-sensitive label and a given substrate (usually a standard steel panel) at 90 degrees. It gives relevant information to manufacturers and users respecting the performance of label adhesives in different conditions.

Q: How does the peel adhesion test method cover the measurement of peel adhesion?

A:The method applies force to the label at an angle of 90 degrees and determines the bond strength against the label stock and substrate. This standardized procedure offers consistent results so that comparisons can be made between different materials and applications.

Q:Why is peel adhesion of pressure-sensitive labels important?

A:The peel adhesion of pressure-sensitive labels must be ensured so that the labels adhere to surfaces properly during their intended use. A good bond prevents label edge lifting, tearing, or stripping away, all of which could lead to product failure, mislabeling, and customer dissatisfaction.

Q:What are the surfaces tested during the ASTM D6252 peel adhesion test?

A: Typically, the ASTM D6252 peel adhesion test is performed on a standard steel substrate or a standard stainless steel panel. These surfaces are chosen because they are perceived to be uniform and reproducible so that the testing conditions are constant and truly reflect the performance of the label stock.

Q:How can the ASTM D6252 test help in determining the applicability of regulatory standards?

A:The ASTM D6252 test method can provide measurable data relating to adhesion performance of label stocks, thereby evidencing or negating adherence to regulatory standards. This data is crucial in complying with safety regulations and assists the user in choosing the right material for a particular application.

Q:What is the meaning of significance of the maximum peel adhesion value in the ASTM D6252 test?

A:The maximum peel adhesion value obtained from the ASTM D6252 test indicated the highest bond strength ever achieved at the pressure-sensitive label onto the substrate. This value is essential in knowing the limits of adhesion so that decisions on the selecting of the label stock for various applications can now be made.

Q:Can the ASTM D6252 test method yield variations in the adhesive performance of the label stock?

A:Yes, by testing two or more label stocks simultaneously under the same conditions, the ASTM D6252 method can identify differences in adhesion and thus illustrate the difference in adhesive nature and total performance of the label, which is vital for a manufacturer wanting to improve.

Q:What factors can alter peel adhesion test results?

A:Several factors can alter peel adhesion test results, including the adhesive itself, label stock facestock, substrate materials, and environmental conditions like temperature and humidity. Being aware of these will assist in interpreting a result and providing for reliable product performance.