Adhesion testing is a fundamental part to determine the performance and reliability of PSAs and tapes, especially in high-precision-durability industries. It may be a matter of ensuring that some tape of the medical grade simply sticks to skin, or to check whether or not certain materials bond well in industrial cases. Hence, adhesion testing methods, from the point of view of the equipment and its uses, almost need to be understood by producers as well as end-users. This blog is a primer into adhesion testing and its principles and into the machinery required for obtaining accurate and repeatable results. All-in-all, it aims to leave you with more technical but conversational knowledge of adherence testing in support of product development, quality assurance, and regulatory compliance of wide-ranging applications throughout industries.

Introduction to PSTC 101

PSTC 101 is an educational program in PSA tape technology, created and imparted by the Pressure Sensitive Tape Council. The basic topics such as PSA tape materials, performance aspects, and applications constitute this course. This is one training program suitable for any professional looking to improve his understanding of tape technologies and cover technical specifications, test methods, and best industry practices. Hence, manufacturing, product designing, or quality-oriented persons will suitably acquire expertise from this training program, aligning with their industrial practices.

Overview of PSTC and its Importance

The Pressure Sensitive Tape Council plays an influential role in furthering the science and technology of pressure-sensitive adhesive (PSA) tape applications. Being a foremost trade association, it works on the creation of technical standards and educational materials and also provides an industry forum. The Council undertakes the development and keeping of very rigorous test methods, thus taking the lead in the establishment of quality standards for PSA tapes used in many fields such as automotive, medical, electronics, and construction. These standards allow manufacturers to assess and guarantee their products’ reliability, durability, and performance in working conditions. Further, the Council organizes training events and seminars to stimulate innovation and propagate best practices. In manufacturing, quality assurance, or product development settings, the knowledge of PSTC rules combined with their proper application will assure all involved that their products and developments meet the requirements welcomed by the industry’s competitive market.

What is Adhesion Testing?

Adhesion testing is a process in which strength and durability of the bond between two surfaces are being assessed. Generally, one side involves an adhesive or a coating, and the other is a substrate. This testing is very important in industries like construction, automobile, and electronics, where the bond strength with adhesives actually affects the performance of the product, that is, on safety. There are different forms of testing adhesion, such as peel, tensile, and scratch, each suited for specific requirements. Recent improvements in adhesion test technologies, Google’s search trends show, include automated systems and digital analysis tools that can better measure bond strength amid varying environmental factors like temperature, moisture, and chemical interactions, thereby leading to more accurate predictions of how materials will perform in their intended life span.

Key Terms in PSTC Testing

1.Adhesion – This term covers the concept of bond strength between a pressure-sensitive adhesive (PSA) and a substrate, which is measured through particular test methods like peel or shear. It therefore determines an adhesion’s ability to keep in contact under various circumstances.

2.Cohesion – This term is about the internal strength of the adhesive material. It refers to how well it resists separation within itself when stressed. It comes into play in situations where adhesives have to withstand stress over extended periods or are exposed to higher temperatures.

3.Shear Resistance – It is a measure of how well an adhesive resists being moved under sustained load. High shear resistance is desirable for the durability of bonding side.

Such terms form the basis for material performance when tested under PSTC testing protocols. They hence become important for the interpretation of results in diverse industries, so tapes conform to the standards required for their applications.

PSTC Test Methods

The PSTC testing methods constitute a group of standardized testing procedures that assess the performance and quality of pressure-sensitive adhesives and tapes. These methods represent the characterization of a tape in terms of pull adhesive force, shear resistance, tack strength, and tape durability. For instance, PSTC-101 finds out peel adhesion, an indication of tape adhesion to a particular surface considered under specified conditions. PSTC-107 provides shear adhesion which describes the load sustaining ability of the tape over time. These standardized procedures help manufacturers realize consistent results irrespective of application methods, so end users are able to have standardized products from which they choose in meeting their particular requirements.

Types of PSTC Test Methods

The key PSTC (Pressure Sensitive Tape Council) test methods include PSTC-101, PSTC-102, PSTC-107, PSTC-133, and PSTC-200.

|

Test Method |

Key Focus |

Parameter |

Purpose |

|---|---|---|---|

|

PSTC-101 |

Peel adhesion |

Strength (lbs/in) |

Measures adhesion to surfaces |

|

PSTC-102 |

Liner release |

Force (oz/in) |

Assesses release from liner |

|

PSTC-107 |

Shear adhesion |

Load (kg) |

Evaluates holding under load |

|

PSTC-133 |

Thickness |

Mils (thickness) |

Determines tape thickness |

|

PSTC-200 |

Unwind force |

Torque (g/in) |

Examines roll-off effort |

Standard Procedures for Peel Tests

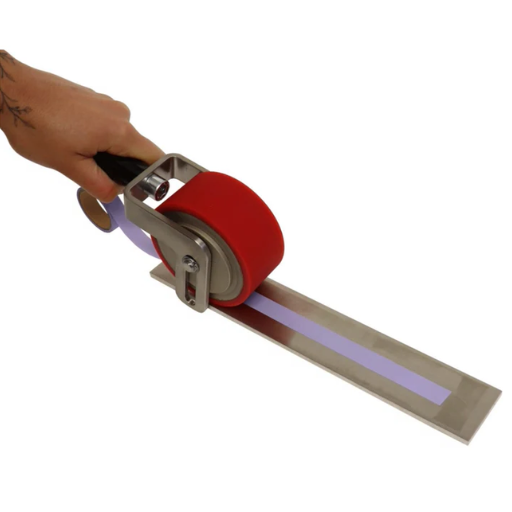

Peel tests, as standardized, are performed to determine the adhesive strength of adhesive products. According to the specifications in PSTC-101 guidelines, the tape is applied to a substrate with uniform pressure, rolling it down to make full contact. Following a given dwell time, the tape is peeled off at a specified rate and angle, usually 180 degrees or 90 degrees, depending on the test configuration. The force required to pull off the tape is measured, thus giving an indicator of how well it adheres. Other factors affecting the results include surface preparation, environmental conditioning, and the calibration of test equipment. This test is extremely important in ensuring product reliability and its performance in various sectors.

Understanding Test Strength and Results

Test strength in adhesion performance evaluation is directly tied to several parameters considered paramount in the evaluation of adhesion properties. Therefore, surface material properties such as texture and cleanliness, in conjunction with that air’s chemical compatibility toward the adhesive formulation placed on it, could be considered the strongest of all variables. Other factors, like temperature and humidity, may be environmental parameters influencing the resistance of adhesion during the test. Standardized methods maintain test variable consistency; for instance, ASTM D3330, tape adhesion test, specifies conditions for peel rate and peel angle. The analysis of test results involves comparing measured forces to stipulated or defined reference values to ascertain whether the considered adhesive has reached required criteria of sufficient adhesion for its intended use.

Equipment for Adhesion Testing

The core equipment for adhesion testing is made up of universal testing machines where peel rate or angle can be finely controlled. These machines are generally furnished with load cells to measure the force exerted during the separation of the adhesive. Also, test fixtures, clamps, and alignment guides are employed for correct sample positioning to ensure test reproducibility. Environmental testing usually entails the use of chambers where temperature and humidity can be accurately controlled. Adhesion testing devices are widely used for special tests including loop tack testing and peel adhesion analysis.

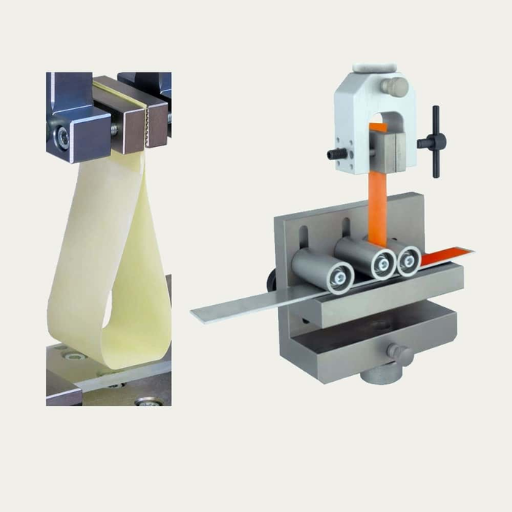

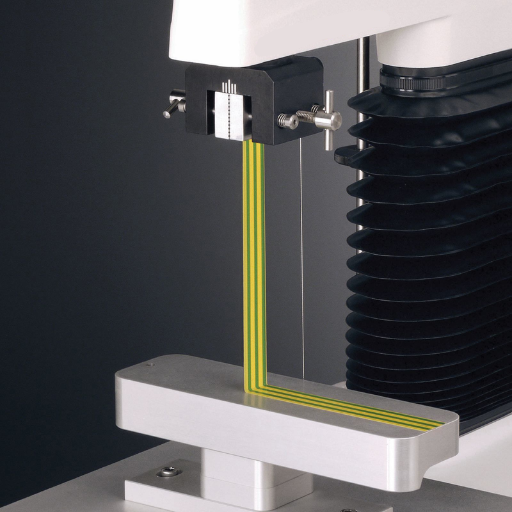

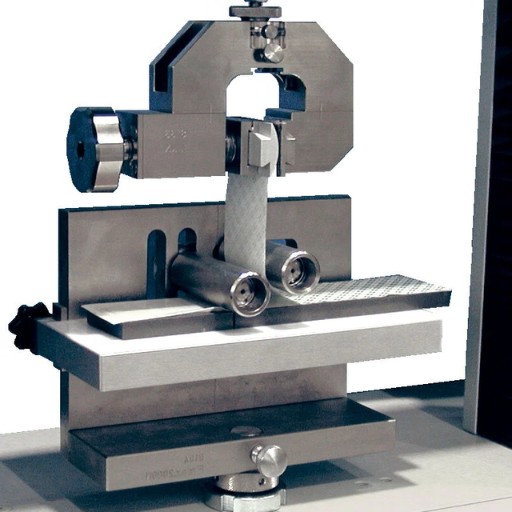

Types of Equipment Used in PSTC 101

The testing of adhesives under PSTC 101 often requires special equipment to guarantee the accuracy and repeatability of the measured values; hence, universal testing machines are most often used for versatility in the measuring of tensile, peel, and shear strengths. For peel testing, 180 and 90 probe test fixtures specifically allow the testing of adhesive performance at fixed angles. A precision scale measures the force, or a load cell incorporated within the machine measures the force, in line with the established standards.

To evaluate how environmental factors may affect adhesive performance, programmable environmental chambers are employed. The chambers can tightly control the temperature and relative humidity to mimic certain real-life conditions. Roller applicators are among those additional pieces of equipment that help in actually applying the adhesive and applying preconditioning to the adhesive surface before testing to achieve uniform pressure.

Failure mode and deformation analysis during peel or shear testing are also facilitated through the use of high-speed video systems and optical measuring instruments in study setups. The instruments provide in-depth analysis, which is necessary for assessing adhesive durability and PSTC conformance.

Choosing the Right Equipment for PSTC Testing

When choosing equipment for PSTC testing, I ensure that the instruments meet the standards and criteria established for the industry and that real-world reproducible data can be reliably generated using the instruments. Other things to consider include whether the equipment in fact can handle the type of adhesive and method of test, whether that would be peel, tensile, or shear testing. I look for equipment that has very good precision in measuring forces, and has an easy-to-use interface and a reliable method of collecting data. Another big consideration is the ability of the testing equipment to work with environmental chambers and the possibility for using high-speed video for more in-depth assessments of performance. Committing to a reliable, well-proven set of equipment is a very good investment for putting in place PSTC-compliant processes for generating actionable and high-quality data.

Maintaining Accuracy in Adhesion Testing Equipment

Accuracy is assured through calibration and maintenance of adhesion testing equipment according to industry standards. Periodic verifications by using certified calibration tools assure the accuracy of force measurements and prevent interference. Proper environmental conditions for temperature and humidity are also necessary to ensure consistent testing according to PSTC guidelines. An operator may also conduct inspections for any wear or damage on equipment parts and apply manufacturer-provided updates to the software that would improve data integrity and reliability in testing.

Peel Adhesion: A Detailed Examination

In simpler terms, peel adhesion is the force considered in separating an adhesive, particularly a pressure-sensitive adhesive (PSA), from a substrate with specified or certain conditions. This measurement plays an essential role in determining the adhesive’s bonding capabilities, and it is usually found through a peel strength test of a specific type, for instance, 180 or 90 degrees peel test. Factors affecting peel adhesion include adhesive formulation, substrate surface energy, application pressure, dwell time, and environmental conditions. The tests must, therefore, be conducted within a frame of agreed standards such as ASTM D3330 or PSTC standard testing methods to grant credibility and reliability to the opinions formed.

Defining Peel Adhesion in PSTC

The Pressure Sensitive Tape Council (PSTC) defines peel adhesion as the force required to peel a pressure-sensitive adhesive tape from a substrate under controlled conditions. This metric becomes crucial in evaluating the performance of adhesive materials in industrial applications. PSTC standards such as PSTC-101 describe rugged procedures for the measurement of peel adhesion, which includes parameters such as rate of peeling, angle of peeling, and type of substrate, so that the procedure may be repeated and deemed reliable.-Today-facing-advancements and data indicate that more attention is turned towards optimising adhesive formulations in keeping with the different temperatures they will be exposed to as well as the diverse surface properties and application environments they will face, thereby improving the trustworthiness of adhesive products from industries such as automotive to electronics. Through proper evaluation via PSTC standards, it shall be ensured that the adhesive will fulfill certain performance characteristics under which it is meant to be employed.

Factors Influencing Peel Adhesion Strength

1.Surface Energy of the Substrate: The surface energy of the material being bonded always plays a pivotal role in determining effective adhesion. Higher surface energy substrates typically promote a stronger adhesive bond compared to low surface-energy materials like polyethylene or polypropylene.

2.Adhesive Formulation: Directly influencing the strength of peel adhesion is the nature and chemical composition of the adhesive. Viscosity, polymer structure, and additives are only a few of the attributes affecting that. Some custom formulations can be designed to enhance performance on certain surfaces and in specific environments.

3.Application Pressure: Another crucial factor in determining the strength of the bond is the force applied during the bonding process. If the pressure applied is insufficient, this will cause weak bonding; sufficient pressure will ensure that the glue adheres properly with the substrate.

4.Environmental Conditions: Environmental conditions such as temperature, humidity, and exposure to UV rays have a tremendous effect on the durability and performance of an adhesive bond. Harsh environmental conditions can degrade the adhesive or change its properties over time.

5.Aging and Cure Time: Yet another parameter influencing peel adhesion is how long the adhesive is allowed to cure or reach full strength. Unfinished curing can weaken the bond whereas fully cured strength equal to that specified by the adhesive will enhance it.

Common Errors in Peel Adhesion Testing

Several common errors, I think, compromise the accuracy and reliability of peel adhesion test results:

1.Improper Surface Preparation: I have noted as one of the principal issues with peel adhesion testing: improper surface preparation. One reason is that contaminants like dust, oils, or moisture can interfere with the bond, resulting in inaccurate test outcomes. Hence, the surface must be properly clean and treated.

2.Variations in Test Parameters: I realized all too often, test angles, peel speeds and environmental conditions were different, producing unreliable data. Hence these parameters have to be standardized and properly controlled for repeatability and comparability of results.

3.Non-Adherence to Manufacturer Guidelines: I have witnessed another common error: not following the adhesive manufacturer’s instructions for application, curing and testing. Deviating from these guidelines can cause the bond to perform less ideally during testing.

4.Misalignment of Testing Apparatus: However, the accuracy of the test equipment should not be taken for granted. Misalignment of the peel test apparatus or incorrect clamping of samples can result in biased results. Periodic calibration and meticulous setting up of the equipment will help minimize this problem.

If these problems are solved, the peel adhesion test will faithfully represent adhesive performance and durability as encountered in the working world.

Applications of PSTC 101

PSTC 101 is used by industry to determine the peel adhesion performance of pressure-sensitive tapes. It serves as a reference standard for quality control to ensure that tapes possess physical prerequisites in the areas of adhesion and durability when applied to real-world conditions. Depending on the industry, the method may be applied in automotive, electronics, packaging, or construction, where adhesive reliability is an important factor. Using this standard effectively ensures uniformity by providing a standardized testing framework, accelerates development programs, and guarantees compliance with code requirements. Using PSTC 101 with effectiveness will give higher product performance in contrast to many failures in the toughest environment.

Use Cases of PSTC in Industry

The testing that follows the PSTC 101 procedures ensures a whole gamut of demanding industries that the adhesive products are up to their demanding performance measures. An example would be the automotive industry, where the tapes require validation for performance and reliability in extremely hot or cold environments before application for wiring harnesses or interior assemblies. The electronics industry relies on adhesive tape testing to ascertain the capability of adhesives in servicing precision applications where mounting, thermal management, and shielding are at stake. From then, in packaging, applying PSTC standards establishes the ability of sealing tapes to keep away temptations or threats of tampering and thus secure good delivery. This exemplifies how extensively standards of PSTC comply with operations that demand durability, efficiency, and performance.

Benefits of Adhering to PSTC Standards

1.Better Product Reliability: Usually standards ensure that an adhesive product meets a consistent performance benchmark and thereby minimize failure in critical applications.

2.Safety Needs to be Ensured: According to the standard, manufacturers design tapes in such a way that minimizes the risks related to improper adhesion or degradation of material.

3.Quality Assurance: While following the PSTC guidelines, manufacturers apply a reliable testing method that assures the same quality of the manufacturing batch.

4.Global Compatibility: Since the products conforming to the PSTC standards are more likely to fulfill worldwide standards, this allows their easier entry into the market and worldwide distribution.

5.Operational Costs: Standardized testing, performance, wastage, and inefficiency are reduced, making production cost-efficient and resource-intensive.

Future Trends in Adhesion Testing and PSTC

Adhesion testing and PSTC standards prepare themselves for new materials and new industrial requirements. One major development is the deployment of high-end automation and digital technology, including AI and machine learning, to make the testing process more accurate and efficient, with real-time data analysis capabilities. Another interesting development is the advance of environmentally friendly adhesive and tape technologies, whose tests must adjust to meet the requirements of environmentally friendly production methods.

Another development is the customization of adhesion tests to new materials, such as smart tapes and nanocomposites, which require new testing methodologies to evaluate their performance in diverse applications. Additionally, the process of international standardization is centered on the expansion of interoperability and consistency at the international level to ease and foster international trade opportunities. These developments together reiterate the growing inclination toward innovation and sustainability in adhesion testing.

Reference Sources

-

PSTC-101 Peel Adhesion Test Equipment for Pressure Sensitive Tapes – This source provides details about the PSTC-101 standard test method for measuring peel adhesion strength in pressure-sensitive tapes.

-

PSTC 101 Testing Overview – A comprehensive explanation of the PSTC 101 international testing standard for determining peel adhesion properties of pressure-sensitive tapes.

-

Alternate Test Methods for PSA – A document discussing various test methods, including PSTC-101, for evaluating pressure-sensitive adhesives.

-

PSTC Test Methods – A resource from the Pressure Sensitive Tape Council (PSTC) detailing standard procedures for quality control and performance measurement of PSA tapes.

-

Test Methods to Evaluate Tack – Adhesives – This guide explores different test methods and equipment for evaluating tack properties of adhesives, including pressure-sensitive adhesives.

Frequently Asked Questions (FAQ)

Q:What is PSTC 101?

A:PSTC 101 is the standard test method defined by the Pressure Sensitive Tape Council (PSTC) for determining peel adhesion of a pressure-sensitive tape to a standard steel panel. This gives the tape a quantitative value of adherence to be assessed by manufacturers and users of tape against a surface of interest.

Q:How does the Peel Test Method work in PSTC 101?

A:Such a peel method consists of applying the tape, either single or double coated, to a standard steel panel and determining the force needed to peel it from the surface. This measure gives the adherence of the tape and, thus, its suitability for different applications.

Q:What equipment is essential for the PSTC 101 test?

A:The PSTC 101 test requires a standard universal testing machine, a test panel consisting of standard steel, and fixtures for holding the tape and measuring the peel force. Furthermore, the use of a calibrated scale may be needed to guarantee accuracy.

Q:What does the phrase “measure of adherence” mean in PSTC 101?

A:In PSTC 101, the phrase “measure of adherence” denotes the determination of the peel force required to remove a tape from the specific surface of interest, which is usually a standard steel panel. The results are paramount in deciding the tape’s performance ability in real-world situations.

Q:What types of methods does PSTC 101 describe?

A:PSTC 101 covers methods A, C, D, E, and F that all provide for a measure of adherence under different conditions. These methods are useful to evaluate the tape’s performance on a wider scale including surface texture variations and environmental conditions.

Q:How is release liner adherence tested in PSTC 101?

A:Release-liner adherence is tested by measuring how well the liner detaches from the adhesive surface. This guarantees that, during the application of the tape, the destroyer performs well and causes minimal problems related to adhesion.

Q:Why is standard steel panel used in PSTC 101 testing?

A:Standard steel panel is used in the PSTC 101 testing to provide a rigid, consistent surface upon which to conduct tape-performance evaluations. It is because of this uniformity that reliable and comparable results are obtained for different types of tape and applications.

Q:What is the relevance of friction in the PSTC 101 tests?

A:Friction has a big bearing on the PSTC 101 tests as bond resistance may be accentuated by greater friction during the peel test, which in fact biases the measurement of adherence. It is important to assess the influence of friction for accurate interpretations of tape-test results.

Q:How does PSTC 101 enable quality assurance to tape manufacturing?

A:The PSTC 101 ensures quality assurance in tape manufacture by offering a standard mode of testing to make sure of tape performance consistency and reliability. Using these standards, the manufacturers can better understand customer expectations and meet regulatory requirements, thereby building confidence in their products.