Introduction to Impact Testing Machines

Impact testing machines are highly specialized devices that measure the capacity of a material to resist any sudden forces or shocks. In essence, the impact testing machines simulate real-life impact conditions to test materials for toughness and durability, thus helping in determining their applicability for particular uses.

Properties such as absorption of energy and resistance to fracture are investigated in these tests; hence, the data produced are eminent in construction, automotive, and aerospace industries. Therefore, these machines are considered extremely important in material testing for meeting safety and performance standards.

What is a Computerized Impact Testing Machine?

Computerized impact testing machines are highly sophisticated gadgets for testing the mechanical properties of a material when a sudden force or shock is applied, which adds value regarding precision and accuracy with its digital twang. An array of advanced sensors alongside a data acquisition system integrates with the machines to measure the parameters with high accuracy, such as:

- Impact energy

- Resistance to fracture

- Deformation characteristics

The computerized element allows real-time monitoring and automatic analysis of data and provides comprehensive information on material performance under pressure. Those machines find their use in commercial and industrial sectors where worthiness and safety of materials are considered paramount, mainly aerospace, automotive, and construction.

Types of Impact Testing Machines

The main types of impact testing machines are Charpy, Izod, Drop Weight, and Instrumented Impact Testers.

| Type | Purpose | Material | Load Type | Specimen |

|---|---|---|---|---|

| Charpy | Measure notch toughness | Metals | Pendulum | Notched bar |

| Izod | Assess notch sensitivity | Plastics, metals | Pendulum | Vertical bar |

| Drop Weight | Simulate large mass impact | Polymers, metals | Free-fall | Flat plate |

| Instrumented | Advanced energy & force testing | All materials | Dynamic force | Customizable |

Importance of Impact Testing in Various Industries

From industrial perspective, this testing is to impart safety, reliability, and performance of materials and products. In these tests, material will be subjected to sudden force or impact-tests to provide the properties of the material viz., impact strength, brittleness, or resistance to failure under dynamic conditions.

Key Benefits: With this material behavior knowledge, construction, automotive, and aerospace industries can prevent failures and use designs so as to provide strength and resilience. Thus, crash simulations are used in the automotive industry to assure occupant safety, and construction materials undergo testing for resistance under environmental conditions and operational stress.

Functionality of the Computerized Impact Testing Machine

The computerized impact test machine determines accurate measurement of impact resistance by observing how well the material responds to sudden forces. The system ensures uniformity and reproducibility of results by using sensors, advanced data acquisition, and controlled energy delivery.

Key Features

- Automatic calibration

- Real-time data display

- Adjustable parameters to suit different materials and standards

- Efficient reporting capabilities

- Integration with quality control processes

How Computerized Systems Enhance Testing Accuracy

Accuracy in testing is greatly enhanced by computer-assisted systems, which use the latest algorithms and digital sensors to minimize human error along with precision in measurements. These systems maintain the consistency of data by automatically calibrating measuring instruments using a standardized method, completely eliminating human variability.

Measurement data are represented in real time so that its anomalies and deviations can be known and viewed instantaneously. Computerized testing also ensures that the data can be managed centrally, traced, and complied with industry standards by integrating with data management systems.

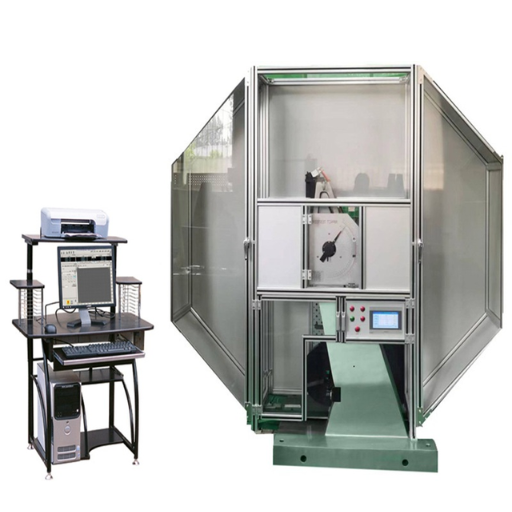

Components of a Computerized Impact Tester

- Impact Pendulum or Hammer – It is the first and foremost part that strikes the specimen occasioning it to resist impact.

- Specimen Holder or Anvil – Fixture designed to safely hold and clamp the test specimen during impact testing.

- Load Cell or Sensor – A sensor of precision is situated to measure the force applied during the impact event.

- High-Speed Data Acquisition System – The system allowing the data to be acquired from the load cell or any other sensor at specified time intervals to guarantee precisely.

- Control Unit – Controls test parameters, for example, impact velocity, specimen alignment, and commencement of test sequences.

- Motorized Arm or Latch Mechanism – Positions or resets the pendulum or hammer prior to every test cycle.

- Digital Display and Interface – Operates as a graphical interface for entering test parameters and evaluating test results in real-time.

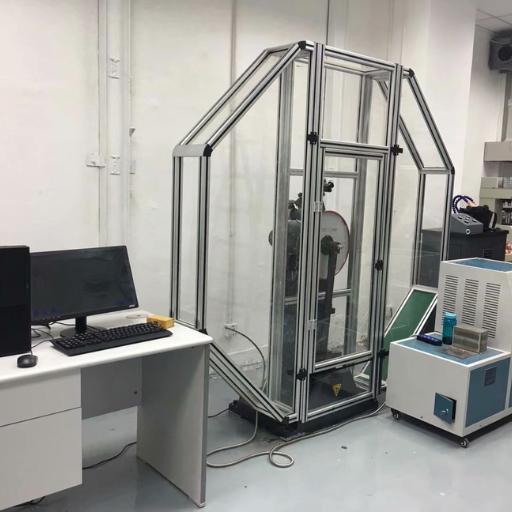

- Safety Enclosure or Guarding System – Whenever in operation, the operator is prevented from any unintended contact with moving parts and, thus, ensured safety.

- Calibration Tools and Fixtures – A special set of components to calibrate and maintain precision for impact testers as per set industry standards.

- Software Platform – An integrated software platform dedicated to controlling the equipment, analyzing the test data, and creating its detailed reports and graphs.

Operation of Charpy and Izod Impact Testers

Both the Charpy and Izod impact tester work by testing the capacity of a material to withstand sudden external forces. First, a sample is precisely prepared according to the test standards and its dimensions and notch specifications.

Key Differences

- Charpy test: Specimen is held horizontally in a V-notch configuration

- Izod test: Specimen is secured vertically

Once the specimen mounts, the pendulum for the testing machine is released and swings down to strike the material for a given energy. The energy absorbed by the specimen in the impact was determined by measuring the lost kinetic energy of the pendulum and is shown as the value of impact strength for the material.

Benefits of Using a Computerized Impact Testing Machine

Increased Precision and Consistency

With its advanced force sensors, sturdy mechanical design, and finely tuned digital controls, a computerized impact tester ensures much greater accuracy and repeatability in applying forces during testing. Human intervention automatically introduces errors; computerized systems remove this variable factor in the testing process.

Efficiency in Testing Processes

- Automated impact testing machine improves efficiency while standardizing the performance of repetitive tasks

- Superior software control enables real-time data acquisition and interpretation

- Programmable test configurations and flexible parameters

- Integration with digital data repositories for seamless storage and retrieval

Data Management and Reporting Capabilities

- Integrated digital storage with automatic data recording

- User-defined report generation

- Statistical analyses and graphical output

- Compliance with international standards

Applications of Computerized Impact Testing Machines

Computerized impact testing machines span a large number of industries and research fields. They are used for measuring material toughness and behavior under various impact conditions in aerospace, automotive, construction, and manufacturing industries.

Industries Utilizing Impact Testing

- Automotive Industry: Safety testing for vehicle structures to provide passenger protection

- Aerospace Industry: Testing lightweight materials with strength properties for aircraft performance and safety

- Construction Industry: Testing concrete, steel, and other materials for strength and reliability

- Energy Sector: Materials for pipelines, pressure vessels, and offshore structures

- Manufacturing: Consumer items such as helmets, safety gear, and durable plastic goods

Future Trends in Impact Testing Technologies

Several emerging trends are shaping the future of impact testing technologies:

- Advanced Automation and AI: Enhanced test precision and reduced human errors

- Environmental Consciousness: Green alternatives using recyclable materials for testing specimens

- Additive Manufacturing (3D Printing): Creating complex and customized test samples for better simulation of actual applications

Choosing the Right Computerized Impact Testing Machine

Factors to Consider When Selecting a Tester

- Measurement Range and Resolution: The tester should operate in the expected measurement range and allow sufficient resolution to detect slight variations

- Data Analysis: Select a tester with advanced data analysis capabilities, including real-time monitoring, trend analysis, and report generation

- Build Quality and Durability: Assess the construction of the tester for long-term durability under rigorous conditions

- Calibration and Maintenance: Give preference to a tester that allows simple calibration procedures and requires little maintenance

- Compliance with Industry Standards: Make sure the tester is certified according to pertinent industries and standards

Factors to Consider When Selecting a Supplier

- Reputation and Reliability: Consider the supplier’s past records of product or service delivery

- Product Quality and Consistency: The supplier must ensure that products delivered always match or surpass the quality specifications

- Cost and Value: Consider the supplier’s price vis-a-vis what it delivers in value

- Technical Support and Service: Technical support, training, and attentive customer service requirements

- Scalability and Capacity: Ensure that the vendor has the infrastructure to fill production or service needs

Maintenance and Calibration

Ensuring that a computerized impact testing machine works at its best and for the longest consideration requires following a strict maintenance routine. Following the manufacturer’s recommendation, clean and lubricate the machine to prevent excessive wear of the major components.

In calibration, the equipment’s measurement accuracy is always verified by certified calibration tools traceable to international standards. Calibration days are scheduled periodically following the manufacturer’s recommendations or depending on the intensity of the machine’s usage.

Reference Sources

-

Impact testers & Charpy impact testers – This source discusses automated solutions for impact testers, enhancing reliability and cost-effectiveness.

-

DWT-1800 Computer Controlled Drop Weight Impact Testing Machine – Provides details on a specific computerized impact testing machine and its adherence to industry standards.

-

Learn About Impact Tests – Offers insights into controlling standards for reliable impact testing methods, such as ASTM standards.

-

Pendulum impact testers – Highlights features and advantages of pendulum impact testing machines, including modern interfaces and reliable results.