In the foam and sponge industry, precision and quality assurance call for compression and hardness testing. These tests ascertain whether foam materials have needed durability and resilience to meet the demands of an application and conform to industry standards. A foam sponge testing machine is an extremely specialized instrument for testing such properties with high accuracy and repeatability.

This comprehensive guide delves into the reason behind and the workings of foam compression and hardness testing, further enlightening the reader about the technology, methods, and aspects affecting the reliability of the results. If you are a manufacturer, quality control specialist, or even a materials engineer, understanding the intricacies of these testing processes becomes an absolute necessity in passing on product excellence to the consumers.

Introduction to Foam Sponge Testing Machines

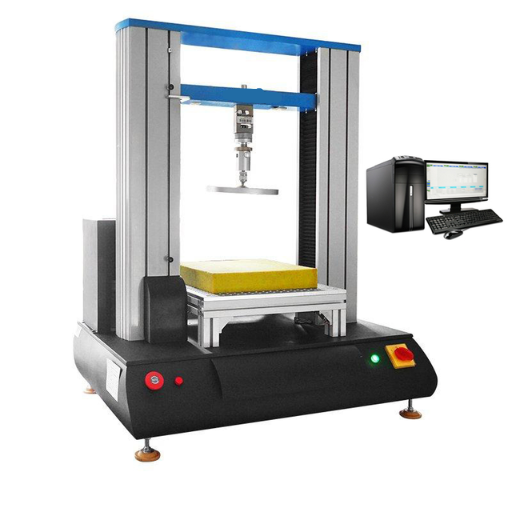

Foam sponge testing machines are precision instruments that measure the physical properties of foam and sponge materials—real compression strength, hardness, and elasticity. Such machines maintain materials in accordance with certain standards and functional application expectations.

Key Features:

- Controlled forces with state-of-the-art sensors

- Uniform, reliable data collection

- Essential for quality control and product development

- Industrial presence in automotive, furniture, and packaging sectors

What is a Foam Sponge Testing Machine?

A Foam Sponge Testing Machine is an extremely specialized instrument for the measurement of physical and mechanical properties of foam and sponge materials. Different tests such as compression, resilience, IFD (Indention Force Deflection), and tensile strength are conducted by these testing instruments, which are further aided by highly precise measurement systems.

Employing advanced sensor technology and controls, they assure the validity and repeatability of testing results. They find application in the bedding, automotive interiors, packaging, and furniture manufacturing industries, where the performance of materials has a direct bearing on the end product quality and the durability of that product.

Importance of Hardness Testing in Foam Materials

Hardness testing applied to foam materials is an important factor to be considered to evaluate the foam materials in question for their structure and integrity and also comfort and performance in the varying harsh climatic conditions. Indentation hardness gives the real measure of the material’s load-bearing capacity and its deformation behavior.

Key Testing Methods:

- IFD (Indentation Force Deflection): This generally measures the force required to compress foam to 25, 50, or 65% of its original thickness. Typical values might range between 5 and 50 N, depending on whether softer foams are being used for cushions and firmer ones for mattresses.

- Compression Set Resistance: This tests the foam’s ability to resume its original shape after being compressed over a long period of time to assert its ability to perform in any given application consistently.

- Density Correlation: Even though not directly a hardness parameter, density (kg/m³ or lb/ft³) has a great influence on hardness and plays a role in defining foam characteristics for particular applications.

Overview of Compression and Rebound Tests

Compression and rebound tests are basically a method of assessing foam materials with respect to their mechanical properties, thereby giving an indication of the foam’s life span, comfort, and utility. The tests measure how a foam responds to an applied force and how it attempts to regain its original shape once that force ceases.

Testing Elements:

- Compression Testing: In this test, a controlled load or pressure is applied to the foam specimen, and the amount of deformation is measured. The test helps one find properties like indentation force deflection (IFD) and compression set, which convey about how the material resists compression and also speaks to its ability to return back to its thickness after prolonged stress.

- Rebound Testing: This evaluates the ability of the foam to regain energy once compressed. The drop-ball test is a common impact test used to see the bounce-back height and thereby assess foam’s energy retention and elasticity.

These tests are normally carried out following standard methods, for instance, ASTM D3574 or ISO 3386, for the sake of consistent and reliable results.

Types of Foam Testing Machines

The primary types of foam testing machines include compression testers, tensile strength testers, rebound resilience testers, tear strength testers, and dynamic fatigue testers.

| Type | Purpose | Key Metrics | Features |

|---|---|---|---|

| Compression | Measures foam’s load-bearing capacity and deformation behavior | Hardness, Load | ASTM/ISO standard |

| Tensile Strength | Evaluates the foam’s resistance to stretching forces | Strength, Elongation | Precision clamps |

| Rebound | Assesses elastic recovery when compressed | Resilience | Drop weight mechanism |

| Tear Strength | Determines foam’s resistance to tearing under stress | Tear Force | Single-edge notch |

| Dynamic Fatigue | Tests long-term performance under cyclic loading/usage | Durability | Automated cycles |

Hardness Testers for Foam Materials

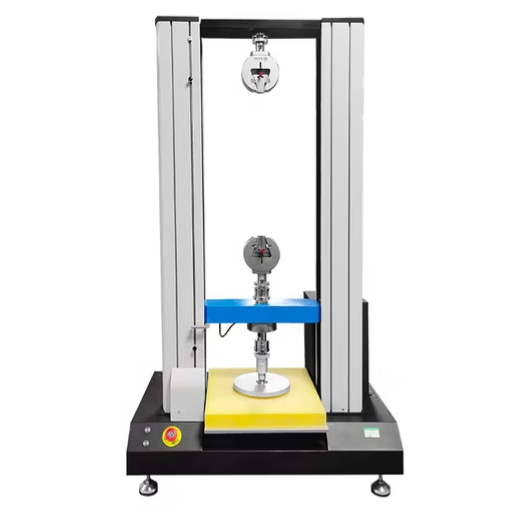

Hardness testers oriented for foam materials are customized devices used to measure indentation hardness or firmness of flexible foam products. These testing machines might operate using varying methodologies such as Indentation Force Deflection (IFD) or Shore hardness depending on the requirements of the test and type of material.

- IFD Testing: Considers the force required to compress a foam sample by a set percentage of its original thickness and is vital in analyzing foam comfort or support properties

- Shore Hardness Testing: Measures surface resistance to indentation and is mostly used for harder foam types

- Standards Compliance: Ensures products abide by industry standards such as ASTM D3574

Applications of Foam Sponge Testing Machines

The role of foam sponge testing machines is prevalent across various industries, where they evaluate the durability and performance of foam materials. These machines enable manufacturers to investigate material weaknesses, optimize formulations, and verify their ability to bear certain loads or provide comfort.

Use in Furniture Testing and Quality Control

The use of compression testing machines in furniture testing and quality control verifies if materials are durable, safe, and fit for purpose. By applying controlled pressure on the foam materials, these machines simulate their use in real life and measure their deformation, resilience, and load capacity.

Typical Tests Include:

- Compression set or retention

- Tensile strength

- Fatigue resistance

- Load capacity evaluation

Applications in Automotive and Aerospace Industries

Foam sponge testing machines serve an important function in the automotive and aerospace industries to ensure that their products are safe, comfortable, and truly conform to exacting industry standards.

- Automotive Applications:

- Vehicle seat cushion testing

- Long-term comfort assessment

- Stress resistance evaluation

- Aerospace Applications:

- Aircraft interior component testing

- Fire resistance verification

- Impact absorption assessment

- Compliance with FAR 25.853 standards

Role in Consumer Product Testing

Foam sponge testing machines are essential for checking the performance, durability, and safety of consumer products employing foam or sponge components. Such machines test vital properties such as:

- Compression resistance

- Tensile strength

- IFD (Indentation Force Deflection)

- Rebound characteristics

Choosing the Right Foam Sponge Testing Machine

Appropriate selection of a foam sponge testing machine requires consideration of several critical factors. These considerations ensure optimal performance and compliance with industry standards.

Factors to Consider When Selecting a Tester

- Accuracy and Precision: Ensure the tester delivers highly accurate and repeatable results, as these are critical for reliable data and compliance with industry standards.

- Load Capacity and Testing Range: Determine if the load capacity and testing range of the machine fall within the application and materials you will be testing.

- Software and Data Interface: Check for user-friendly software interfaces and data handling mechanisms with strong support for interfacing with third-party systems for reporting and analysis.

- Durability and Build Quality: Testing machines should be durable and well-built to withstand frequent testing operation under load-induced conditions.

- Calibration and Maintenance Requirements: Ensure calibrations can be performed easily, with maintenance requirements being less frequent and technical support available whenever needed to maximize operation time.

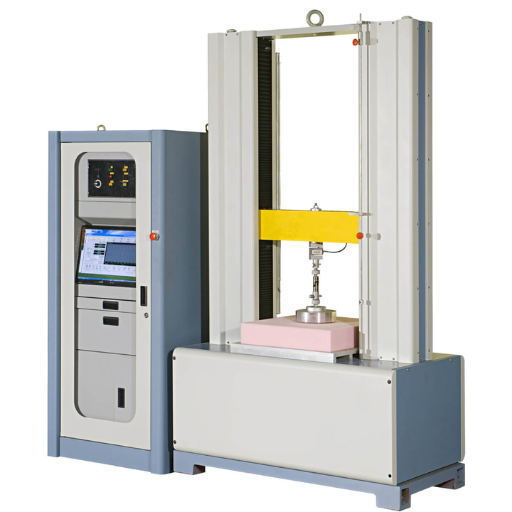

Key Features of Effective Foam Compression Test Machines

- High Precision Load Press: Designed to be a force-measuring instrument with an emphasis on force accuracy, an effective foam compression testing machine can generate force measurements that are sufficiently accurate, while force values can be reliably reproduced under the same testing conditions.

- Measurement Capabilities over a Wide Range: The testing machines are built to measure foam materials of varying densities and thicknesses.

- Easy-to-Use Software: The latest machines include software packages with user-friendly interfaces that equip even the least technically trained operator to conduct tests, analyze data, and present complete reports.

- Automatic Data Logging: Such systems allow automatic recording and storing of all data, essentially eliminating manual errors and facilitating smooth reporting for compliance and quality control.

- Variable Test Specifications: Adjustable test parameters such as rate of compression, load limits, duration of hold allow for standards and specifications to be adequately adapted in the context of testing.

Latest Trends and Advancements in Foam Testing Technology

The recent developments in foam testing technology have tended toward automation, accuracy, and data integration. These innovations continue to add to foam testing efficiency, reliability, and flexibilities across industries.

Innovations in Foam Indentation Hardness Testing

- Precision Automation: Automated test rigs now include advanced robotic arms exhibiting micron-level accuracy in the exertion of force and variability-immunity against manual operations

- Cloud-based Data Integration: Cloud connectivity feature allows data synchronization across many testing locations, enabling collaborative analysis and long-term compliance tracking

- Adaptive Testing Algorithms: Machine learning algorithms are being integrated into testing software, providing predictive modeling to foresee behavior under various load conditions

The Impact of Automation on Testing Processes

The scope of testing has been immensely transformed by automation in terms of precision, efficiency, and budget. Automated testing provides several key benefits:

- Reduces human error

- Accelerates data collection

- Provides consistent results for speedy decision-making

- Allows for more comprehensive testing coverage

- Frees resources for critical analysis and innovation

Future Directions in Foam Testing Equipment

Future developments in foam testing apparatus are expected to focus on several key areas:

- Real-time Monitoring: Integration of instant performance parameter viewing with proactive intervention capabilities

- Machine Learning Integration: Higher-accuracy pattern recognition and prediction of outcomes

- Sustainability Focus: Development of eco-friendly testing processes that ensure less waste and energy consumption

- Modular Design: Customization for specific testing needs with scalability options

Frequently Asked Questions (FAQ)

What is a foam indentation hardness testing machine?

This testing machine is a special kind of equipment that gives a hardness value to foams, including sponge foams. It also measures the force needed to indent the foam and provides data on compression characteristics and durability of the material.

How does a sponge resilience tester work?

The sponge resilience tester evaluates whether the sponge foam can return to its original shape after being compressed. It measures the rebound rate of the foam upon the application of a given load, thus providing information on the material’s elastic quality and durability.

What are the uses of furniture testing equipment?

Furniture testing instruments like foam compression testers and impact testers assess furniture performance and safety. This equipment ensures that the furniture meets industry norms of durability, comfort, and resilience, especially concerning the use of foams and other materials in their construction.

What is the importance of the rebound resilience coefficient?

The rebound resilience coefficient is significant for assessing the working capabilities of foam materials. It stresses the ability of foam to continue to deform, giving utmost importance to conditions like mattresses and cushions, where the foam is a key element for expressing comfort and support.

On what standards is foam indentation hardness testing based?

Foam indentation hardness testing is mostly performed under different industry standards, such as those from ASTM and JIS. These standards lay down appropriate methods of testing, requirements for equipment, and criteria of performance acceptable for foam and sponge materials.

Can the foam ball rebound test machine be used on sponge materials?

Yes. The foam ball rebound test machine can be efficiently applied for testing on sponge materials. This equipment benefits from recreating the impact-and-rebound behavior of foam, which in turn helps manufacturers in evaluating the behavior of their sponge products under dynamic conditions.

What is the foam testing purpose for the compression tester?

Foam compression testing is done to find out how hard or soft a particular foam will be under pressure and its endurance under such pressure on compression. A specific load is applied to a foam specimen coupled with tracking of its deformation, providing vital information of how a foam will behave under pressure with time.

How does foam compression differ from sponge compression?

Foam compression is the generic term for applying pressure to any foam materials while sponge compression deals explicitly with testing of sponge-like materials. Both testing are aimed at evaluating material resistance, though the two may differ in their methods and test apparatus used.

Reference Sources

-

Sponge Foam Compression Testing Machine – Haida Test Equipment

This source provides details on machines used for fatigue and compression testing of foam materials. -

Sponge Foam Compression Fatigue Testing Machine – QTS Test

This page explains the use of foam compression testers for measuring indentation hardness and other properties. -

Sponge Indentation Hardness Foam Compression Tester – Made-in-China

This source discusses the principles and standards for testing foam hardness and compression. -

ASTM D3574 C Foam Force Deflection Testing – ADMET

This article outlines the ASTM D3574 C standard for foam compression testing, including methods and applications.