Daily necessities require packaging to guarantee product integrity, safety, and customer satisfaction. Technology advances faster than ever, and consumers demand more from packaging. One thing that has never changed is the need to ensure packaging reliability and durability. This is where the daily necessities testing machine—a high-tech solution used to test packaging materials and processes—introduces itself.

This comprehensive guide explores how these highly specialized machines advance quality control, lessen errors, and enforce industry standards while making manufacturers’ operations smoother. Whether you’re a packaging professional or merely curious about technologies surrounding everyday products, this guide provides an in-depth look into the marriage of innovation and quality assurance in the packaging world.

Introduction to Daily Necessities Testing Machines

Daily Necessities Testing Machines are important instruments for assuring the reliability, safety, and quality of everyday products. These sophisticated machines perform tests for durability and strength, as well as analysis of material composition, to ensure products meet industry standards and regulatory requirements.

Some of the product categories they commonly evaluate include:

- Household articles

- Personal care products

- Packaging materials

By providing uniform and accurate measures, these machines minimize chances for defects on the manufacturers’ part, thereby allowing them to uphold standards of quality for consumer safety and satisfaction.

What are Daily Necessities Testing Machines?

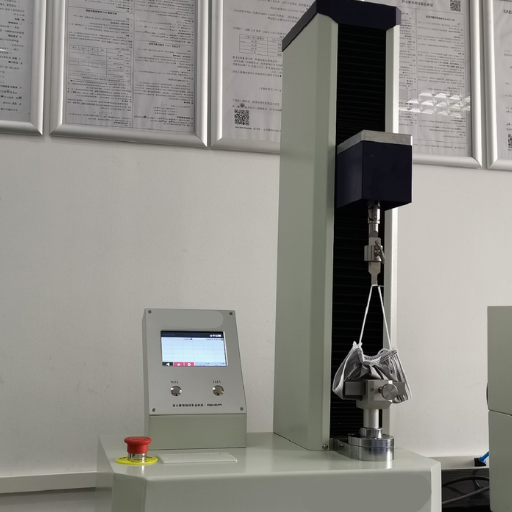

Testing machines for daily necessities are specialized instruments that cater to the testing and evaluation of consumer goods regarding their quality, operation, and safety. These machines use advanced technological means to perform common tests, including:

- Tensile strength testing

- Abrasion resistance testing

- Compression testing

- Environmental durability assessment

Through the use of accurate sensors and automated systems, these testing machines simulate real-world environments, subjecting household tools, personal care equipment, and packaging materials to thorough quality standard checks.

Importance of Testing in Product Quality

Testing ensures that products conform to customer expectations and regulations by catching defects during various stages of production. According to leading industry sources, rigorous product testing:

- Greatly reduces the risk of product recalls

- Protects brand reputation

- Ensures product safety and functionality

- Prevents manufacturer inconsistencies

- Builds customer trust

- Avoids costly liability suits

Testing is particularly crucial in industries like automotive, electronics, and healthcare where performance and safety standards cannot be compromised.

Overview of Applications in Various Industries

Daily necessities testing machines play pivotal roles throughout various industries, ensuring product quality, conformity, and durability:

Consumer Goods Industry

Tests textiles, plastics, and paper materials for strength, flexibility, and longevity under standard conditions.

Packaging Industry

Tests materials for resistance to pressure, punctures, and environmental stresses during storage and transportation.

Food & Beverage Industry

Tests packaging seals and monitors material safety for hygiene and regulatory compliance.

Medical & Healthcare

Ensures reliability and safety of products ranging from PPE to medical-grade plastics.

Electronics & Appliances

Tests components for thermal, mechanical, and environmental resilience.

Key Features of Effective Testing Machines

- Precision and Accuracy: High-quality testing machines must provide exact and repeatable results, ensuring data reliability for proper evaluation and product acceptance confirmation.

- Versatility: The ability to test various materials under different conditions is necessary to cater to diverse industrial needs and applications.

- Durability: Robust construction and high manufacturing standards ensure machines withstand regular use while performing consistently.

- Automation and Integration: Advanced automation and seamless software system integration facilitate data collection, analysis, and reporting.

- Environmental Simulation: Effective machines provide environmental parameters such as temperature, humidity, and mechanical stress for comprehensive product testing.

- Compliance with Standards: Conformance to international testing standards ensures machines meet rigorous regulatory requirements and industry benchmarks.

Precision and Accuracy in Measurement

Precision and accuracy remain fundamental to effective testing machines, determining measurement quality. High-precision systems implement state-of-the-art sensor technology, including:

- Load cells for force measurement

- Extensometers for displacement tracking

- Advanced data acquisition systems for real-time recording

Accuracy involves calibration processes aligned with recognized standards such as ISO 7500-1 or ASTM E4, ensuring consistent measurements with real-world units. Temperature and environmental control also play crucial roles in maintaining accuracy across varying conditions.

Durability and Reliability for Long-Term Use

Testing machines must be ruggedly built for long-term use in repetitive or extreme conditions. Key durability features include:

- Hardened steel frames

- Corrosion-resistant alloys

- Superior maintenance-free mechanisms

- Rigorous lifecycle testing

Ease of Use and Automation in Operation

Modern testing machines prioritize user-friendly design through:

- Intuitive touchscreen displays

- Configurable menu systems

- Automated workflows minimizing manual input

- Automatic specimen alignment and preload

- Real-time monitoring and reporting

- IoT integration for remote control and diagnostics

Types of Daily Necessities Testing Machines

| Type | Function | Key Feature | Usage | Material |

|---|---|---|---|---|

| Tensile Tester | Measures tension | High precision | Textiles, Plastics | Flexible Solid |

| Compression Test | Checks durability | Strong load capacity | Packaging, Materials | Rigid Solid |

| Abrasion Tester | Tests wear & tear | Surface contact | Coatings, Fabrics | Variable |

| Impact Tester | Evaluates shock | Energy absorption | Glass, Metals | Hard Solid |

| Thermal Testing | Assesses thermal properties | Temperature cycling | Rubber, Insulation | Heat-sensitive |

| Packaging Tester | Evaluates integrity | Seal strength | Boxes, Containers | Packaging |

Check Weighing Machines for Accurate Product Weight

These precision instruments ensure products comply with weight requirements quickly and accurately. Key features include:

- Real-time weighing during production

- Automatic comparison with preset criteria

- High-speed data recording

- Integration with automated systems

- Quality control and waste minimization

- Regulatory compliance assurance

Horizontal Packaging Machines for Efficient Packing

These machines efficiently wrap products horizontally, suitable for:

- Food products

- Pharmaceuticals

- Cosmetics

- General consumer goods

Modern horizontal packaging machinery features:

- Servo motors for precise control

- Heat/cold sealing capabilities

- Modular design for production line integration

- Intelligent product-position detection sensors

- Real-time size adjustments

Customizable Machines for Specific Industry Needs

Manufacturers provide customization options including:

- Automated feeding system integration

- Specialized sealing technology

- Multi-axis controls for precision manufacturing

- Industry-specific package configurations

- Modular and scalable designs

- Future-proof retrofit capabilities

Testing Methodologies in Daily Necessities Packaging

Comprehensive testing methods ensure packaging performs effectively and remains reliable:

- Compression Testing: Checks packaging ability to withstand pressure loads during stacking and storage processes.

- Drop Testing: Simulates real-world scenarios where packaging is dropped from various heights to assess impact resistance.

- Seal Integrity Testing: Tests packaging’s ability to maintain seals and prevent leaks, keeping products fresh and preventing contamination.

- Vibration Testing: Simulates transportation conditions to study packaging stability and resistance to transit vibrations.

- Barrier Testing: Assesses packaging material effectiveness in preventing moisture, oxygen, and light penetration that could cause content deterioration.

Inspection Techniques for Quality Assurance

Quality assurance inspection techniques encompass systematic processes and tools for checking products against established standards:

Visual Inspection

Fundamental procedure using naked eye or magnification to detect physical defects, misalignments, or inconsistencies.

Automated Optical Inspection (AOI)

Uses high-resolution cameras and software algorithms for defect detection during assembly, ensuring speed and consistency.

Non-Destructive Testing (NDT)

Includes ultrasonic, X-ray, or infrared testing to verify material integrity without damage.

Dimensional Analysis

Measures physical dimensions using calipers, micrometers, or coordinate measuring machines for specification compliance.

Functional Testing

Recreates actual operational conditions to determine pressure resistance, leakage, and vibration tolerance.

Measurement Standards in Chemical and Pharmaceutical Products

Measurement standards in chemical and pharmaceutical fields ensure product safety, efficacy, and regulatory adherence. These standards require:

- Characterization and quantification following GMP and ISO guidelines

- Precise analysis using spectrophotometers, chromatographs, and autotitrators

- Pharmaceutical testing including API assays, impurity profiling, and dissolution testing

- Chemical standards covering purity testing, trace analysis, and material characterization

Impact of Testing on Cosmetic Product Safety

Thorough testing plays an absolute role in assuring cosmetic product safety and quality. Following recognized standards from USP, EP, and ISO, manufacturers can address potential threats including:

- Contamination prevention

- Adverse reaction mitigation

- Ingredient safety validation

- Stability testing

- Legal compliance

- Consumer trust maintenance

The Future of Daily Necessities Testing Machines

The future lies in integrating advanced technologies including artificial intelligence, machine learning, and automation to improve accuracy, efficiency, and scalability. These innovations will foster:

- Faster and more reliable testing processes

- Enhanced adherence to evolving global standards

- Response to increased demand for sustainable products

- Improved flexibility and innovation

- Continued quality control excellence across industries

Emerging Trends in Testing Technologies

Current trends toward automation, accuracy, and sustainability include:

- Advanced Automated Systems: AI and machine learning enhance standardization while minimizing human intervention

- Non-Destructive Testing: Growing popularity allows thorough evaluation without material damage

- Green Testing Methods: Energy-efficient machines and recyclable materials align with sustainability goals

- Enhanced Efficiency: Improvements in safety and environmental responsibility

The Role of Innovation in Consumer Safety

Innovation significantly impacts daily necessities safety through advanced testing methodologies:

- AI-powered analytics for enhanced precision

- Automated testing systems for consistency

- Nanotechnology for microscopic hazard detection

- Early-stage hazard identification

- Green concept application reducing toxic chemical use

- Sustainable material promotion

Final Thoughts on Quality Assurance in Daily Necessities

Quality assurance in daily necessities represents a vital responsibility, ensuring safety, performance, and sustainability standards are met. Rigorous QA processes inherently reduce risks related to harmful defects while increasing consumer trust and regulatory compliance. When sustainability is promoted alongside environmentally conscious production, industrial practices align with ecological objectives while maintaining consumer safety and satisfaction.

Frequently Asked Questions (FAQ)

What is daily necessities testing machinery?

Daily necessities testing machinery applies standards and conducts qualitative examinations of household items such as soap, detergent, and other household articles. These tests ensure products meet industry standards and satisfy customer expectations.

What is the working principle of a liquid filling machine?

Liquid filling machines fill precise amounts of liquid into containers using filling heads. While many operate automatically, manual options are also available. These machines provide higher output for food market and detergent packaging applications.

What custom options do daily necessities packaging machines offer?

Many suppliers allow packaging machine customization, including resizing machines, altering filling capacities, providing coding options, and adding printing features that suit various product descriptions.

What should I consider when choosing a machine manufacturer?

Consider the equipment types they supply, industry reputation, after-sales service, and energy-saving solutions. Review their product line for durable options with long service life.

What are the advantages of fully automatic filling machines?

Fully automatic machines streamline production processes, require less manual labor, and generate greater efficiency. They typically feature conveyor belts, touchscreen controls, and versatility for different product types from liquids to pastes.

How is packaging machine production capacity determined?

Production capacity is measured in units per hour, indicating how many packages can be filled and sealed within a given timeframe, showing operational efficiency and demand matching capability.

Why is stainless steel preferred for packaging machinery?

Stainless steel offers durability, corrosion resistance, and easy cleanability. It withstands harsh cleaning procedures and processing requirements, making it ideal for food and laundry supply processing.

Reference Sources

-

A Comprehensive Guide to Packaging Testing Methods – This guide provides an overview of various methods used to test packaging.

-

Automatic Puff Food Bag Packing Machinery | FUBO – Details about automated packaging processes and on-site testing of machinery.

-

Six Steps to Ensure Packaging Quality and Consistency – A step-by-step guide to maintaining quality and consistency in packaging.

-

Why Quality Control Is So Important in Packaging – Insights into the importance of quality control in the packaging industry.