One of the vital construction materials available today, steel was once considered a material of unparalleled hardiness, strength, durability, and versatility. Typical application considerations and performance standards must still be considered in defining its behavior under particular stresses. The bending test of steel is a fundamental test that provides constructive information regarding the strength and ductility of steel. In this context, the science of bending tests for metals is examined, including the method behind the tests, their applications, and their relevance in addressing structural and industrial problems. You will now be able to appreciate the significance of this standard test in contributing to the definition of steel and assessing its ability to resist deformation without failure.

Introduction to Bending Tests

The bending test is a standardized method for measuring a steel’s ductility and strength, based on its resistance to deformation under stress. More specifically, a steel sample is bent under a controlled force such that it does not crack or break. Thus, properties are tested, such as flexibility, tensile strength, and the material’s ability to sustain mechanical stress without losing structural integrity. Bending tests are extensively used during construction, manufacturing, and quality control to ensure that the steel meets safety and performance requirements.

What is a Bend Test?

Bending can be considered a mechanical test to establish ductility, strength, and resistance to cracks caused by stresses in materials. A bending force is applied in a controlled manner to a specimen, usually shaped as a bar or a plate, until it reaches a certain angle or condition. The object of the test is to analyze the ability of the material to sustain deformation without breaking down or suffering any permanent damage. This test is crucial for steel materials that require both flexibility and durability in structural and engineering applications.

Recent developments in material testing have brought to the forefront the importance of bending tests in an industry where safety, in conjunction with quality assurance, must be maintained. Modern-day acceptances aim for the utilization of precise devices and digital measuring tools so that data collected is validated for possible weakness identification on materials in question. Therefore, the bending test is considered the most.

Importance of Bending Tests in Material Testing

Bending tests are probably the basic type of material testing to study the flexibility of the material, the extent to which it can be ductile, or resist deformation under applied stresses. Constructive bending forces are induced during the test, revealing other critical material properties, such as tensile strength, yield strength, and fracture strength. These are also the basis for estimating the material’s performance in everyday use, particularly in environments that require high structural integrity. These bending tests are used in the construction and aerospace industries, among others, to determine whether the material complies with stringent inspection codes for safety and performance. Moreover, modern bending tests also adopt state-of-the-art technologies comprising load sensors and precision measurement instruments for securing the exact test results to gain direct use for development and quality assurance of the product. From this perspective, these tests indeed stand for an assured balance between the life cycle of a material and its performance.

Overview of Steel Properties: Strength and Ductility

Anytime the strength and ductility of steel are considered, they stand as two properties that play an indispensable role in determining its performance under certain circumstances. Strength means that the material would resist forces applied against it, without being deformed or breaking down. Strong steels are widely accepted for use in construction, automotive, and industrial operations where resisting heavy loading is critical. Ductility, on the other hand, is the ability of a material to undergo plastic deformation without fracturing. This plastic deformation offers the material a remarkable ability to absorb energy under stress. This balance between strength and ductility comes about through alloying elements such as carbon, manganese, and silicon, and manipulating these with suitable thermal treatments of quenching and tempering. Together, the two properties enable steel to be used in situations where toughness and flexibility are needed in harsh conditions.

Types of Bending Tests

There are several types of bending tests, including the three-point bending test, the four-point bending test, the cantilever bending test, and the guided bend test.

| Test Type | Purpose | Specimen | Load Type | Key Metric |

|---|---|---|---|---|

| Three-Point Bending | Measure flexure | Beam/Bar | Point Load | Flexural Str. |

| Four-Point Bending | Assess flexure | Beam/Bar | Distributed | Elasticity |

| Cantilever Bending | Test bending | Bar/Rod | Moment | Stiffness |

| Guided Bend Test | Assess ductility | Plate/Welds | Gradual Load | Bend Angle |

Three-Point Bending Test

A crucial test that helps evaluate the flexural properties of materials, including their strength and stiffness, is the three-point bending test. It is placing the beam or bar specimen between two supports and applying a point load at the center of the beam; the bottom experiences tension while the top absorbs compression. The test develops the flexural strength, which is the maximum amount of stress a material can bear before deformations are induced despite positive bending moments.

Four-Point Bending Test

The four-point bending test, an improvement on the three-point bending test, is conducted to determine the flexural properties of fresh materials with greater accuracy by increasing the stress limit on the material in a more uniform manner. In this method, unlike the 3-point, two supports situated symmetrically concerning the middle of the sample are used; therefore, the bending moment is adjusted between the supports only, and the shear deformation is minimized. This configuration provides more data on how materials behave under realistic bending scenarios, especially for composite materials or advanced alloys.

Flexural Tests and Their Applications

In any construction, flexural testing has core importance, namely, in determining the strength and modulus of the material to resist bending forces. It is essential in all industries. Depending on the sector, some examples of its application include assessing beams or structural components, analyzing composite behavior in aerospace, or evaluating material performance in tests to inform the use of polymers or other plastics in the created structure. Such tests are helpful in terms of knowing how much load it can carry, how it fails, and what the extent of deformation is, and hence the design of the materials within the working conditions it will be exposed to.

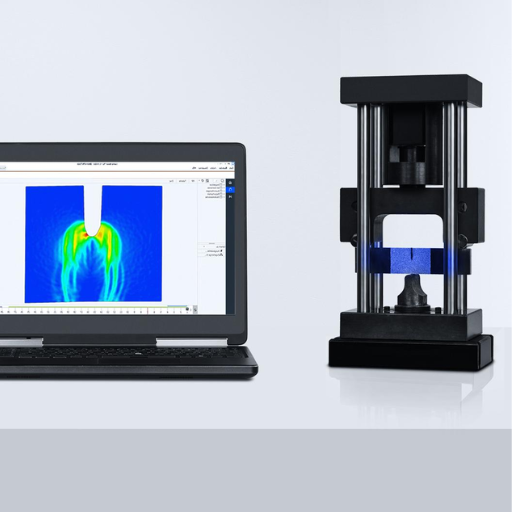

Equipment Used in Bending Tests

Equipment used for bending tests usually comprises a universal testing machine equipped with a bending or flexural testing fixture. This fixture usually consists of two support rollers and a loading roller set to apply force at a controlled rate onto the midpoint or a specified point along the length of the test specimen. Load cells are often part of the equipment used to measure force accurately, and extensometers can be used to measure deformation. The presence of these instruments guarantees a meaningful evaluation of the material behavior under bending loads.

Universal Test Machines

Universal Test Machines (UTMs) are versatile, exact instruments capable of subjecting materials to various mechanical tests, including tensile, compression, flexural, and shear tests. They apply specific forces to a specimen in a controlled manner and measure the amount of deformation that occurs, along with other properties of the material. Typically, the standard features include load frames, load cells to accurately measure the force, and an extensometer or strain gauges to record the strain or elongation. They are thus essential in determining the nature of materials under certain conditions and in ensuring that they meet specific standards, namely ASTM and ISO, for end-product quality control, research, and development.

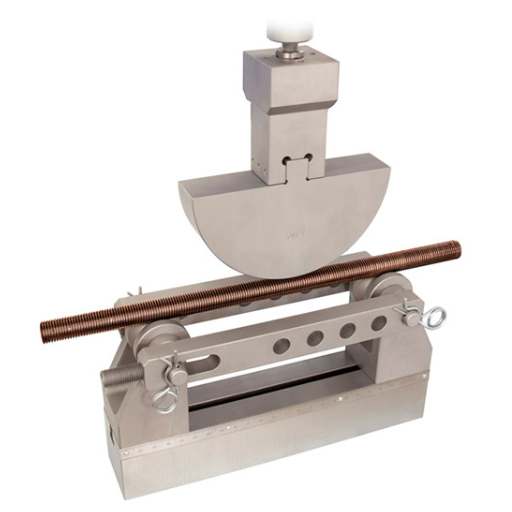

Specialized Bending Apparatus

Specialized bending apparatuses are designed to measure the flexural strength and behavior of test materials under bending loads. Typically, these systems comprise means for applying the load with precision, fixtures tailored to the specimen’s geometry, and sensors that record deformation and failure points. It is specifically designed for metals, plastics, and composites, determining the modulus of elasticity, yield point, and resistance to bending. The test setups and procedures are standardized to ensure reliable and comparable data, as specified by ASTM D790 and ISO 178.

Calibration and Maintenance of Testing Machines

I ensure that the measuring testing machines are calibrated and maintained according to standards and best practices. This is a periodic calibration that ensures all the words being examined are accurate and precise, following certification measures, such as ASTM and ISO standards, among others. It implies calibration of testing machines using certified reference materials and calibration instruments to prove their performance. I will conduct routine inspections for any signs of wear, misalignment, or deterioration in parts and arrange for repairs if such issues are discovered, in order to prevent errors. Maintenance will involve cleaning, lubricating moving parts, and updating software to ensure reliability in operation. Another key aspect is to properly document all calibration and maintenance activities for traceability and compliance.

Industry Standards for Bending Tests

The industry standards have a protocol or set of guidelines to ensure that the results of bending tests are consistent, accurate, and reproducible. Key standards include ASTM E290, which describes the testing procedure for plastic deformation of metallic materials, and ISO 7438, which deals with the bending test method for determining the ductility of materials and their behavior under bending stress. These guidelines provide detailed instructions on how to prepare test specimens, specify their dimensions, and outline details about the testing apparatus, facilitating industry-wide coordination. Compliance with these standards ensures the evaluations will stay consistent and their comparison between materials will be reliably established.

ISO Standards for Bending Tests

ISO 7438 emphasizes that bending tests aim to determine the ductility of materials and the ability to withstand deformation by stress. The test procedure lays down the specifications of the standard specimen dimension, of the environment in which the test is to be carried out, and of the bending equipment to be used so that the test may be reproducible. Parameters to be measured include the bend angle, radius, and force applied, each within tolerances specified by the ISO standards for proper consideration. A bending test reveals irregularities in the material, such as cracking, surface breaking, or loss of ductility; hence, performing it within the stipulated ISO 7438 is valuable for quality control and comparison purposes.

ASTM Guidelines for Testing Steel

ASTM standards provide testing methods for evaluating the mechanical properties of steel for structural performance and quality assurance. They include ASTM E8/E8M for tension tests, ASTM E18 for Rockwell hardness tests, and ASTM E290 for bend testing. The ASTM standards, hence, provide uniform procedures for specimen preparation, testing conditions, and equipment calibration to minimize variability amongst tests.

For tensile testing under ASTM E8/E8M, specimens machined to ASTM-specified metric or imperial dimensions are subjected to elongation and tensile force for evaluation of ductility and material strength. ASTM E18 covers the hardness-testing method by precise indentation, considering forces applied under controlled conditions to rank materials based on their ability to resist deformation. Likewise, ASTM E290 covers bending test procedures intended to gauge ductility and performance of steel under stress, primarily for weld validation. These ASTM test standards, when adhered to, ensure that such data can be relied upon in various applications, thereby leading to quality assurance and comparative tests in the steel industry.

Comparing International Standards

Bending test standards include ASTM E290, ISO 7438, JIS Z2248, BS EN ISO 5173, and GOST 14019.

| Standard | Region | Purpose | Specimen | Key Param | Use Case |

|---|---|---|---|---|---|

| ASTM E290 | USA | Ductility Test | Metal Rods | Weld Valid. | Quality Check |

| ISO 7438 | Global | Flexural Analysis | Metal Bars | Min. Bend | Compliance |

| JIS Z2248 | Japan | Bend Test | Flat Bars | Angle Limit | Materials R&D |

| BS EN ISO 5173 | Europe | Bend Welds | Weld Joints | Strength Req. | Standards Ens. |

| GOST 14019 | Russia | Steel Testing | Plates/Rods | Stress Param | Product Dev. |

Conducting a Bending Test: Step-by-Step

1. Specimen Preparation

Ensure that the sterilization procedure for the test specimen adheres to the relevant standard (e.g., ASTM E290, ISO 7438). The dimensions and surface finish must satisfy the specified criteria to get accurate results.

2. Test Machine Setup

Perform calibration and configuration of the bending test machine. Select the suitable bending fixture (such as mandrels or rollers) depending on the material and the specified radius of bending.

3. Specimen Positioning

Place the specimen inside the testing machine, ensuring it is appropriately aligned. The specimen is to be secured inside with no minute stress applied until the test is started.

4. Load Application

Apply the load or displacement gradually, following the standard procedure. Watch out for the bending angle or radius to achieve the required deformation.

5. Post-Test Evaluation

Inspect the specimen for cracks, fractures, or other defects upon reaching the specified bending angle or load. Record all observations regarding deformation measurements and compliance with acceptance criteria.

6. Documentation

Gather and analyze data, keeping it well-documented for compliance verification and research analysis.

Preparing the Sample

Sample preparation requires working with accurate dimensions by cutting and shaping the specimens to meet specified standard guidelines, typically ISO or ASTM parameters, to ensure that no irregularities are included. Preparing the surface requires thorough cleaning because any contaminant, such as oil, dirt, or rust, could interfere with the test result. Proper alignment and marking must be carried out to identify the bend axis or key points for measurement. If pre-conditioning is necessary, such as heating or stress relief processes, it must be performed to bring the material into compliance before testing.

Setting Up the Testing Machine

Testing machine setups must be performed under very stringent technical specifications to ensure authentic and reliable results. First, it is necessary to verify that the machine has been calibrated against certified standards to ensure precision in measurement. The load cell and displacement sensors are to be tested to confirm that they are functioning properly; any necessary adjustments should be made prior to the test. The specimen must be held firmly with grips/clamps so that it does not slip during testing and so that the load is uniformly distributed along the axis of the test.

Adjust the testing speed and load application parameters according to the material’s properties and testing standards, such as ASTM E290 for bend testing. Program the software to log data points of force, displacement, or strain, based on the experiment’s objectives. Safety also comes first: protective barriers must be set up and emergency stops must work perfectly.

Executing the Test and Collecting Data

When performing the test, it is first ensured that all equipment is calibrated according to the relevant standards, such as ASTM E290, to ensure accuracy. After this, the testing sequence begins, making adjustments to the machine’s properties as required for the material being tested, with the proper strain rate and force thresholds. Forces, displacements, and strains are recorded during the test through the software interface, and the system ensures that all parameters are taken externally for subsequent analysis. Upon monitoring the test execution, safety protocols were being adhered to, verifying that all barriers were installed and that the emergency stop was always readily available in case of any unusual behavior of the equipment. After completing the test procedure, I then proceed to systematically save and back up its data to be worked on further for more knowledge in the material’s performance.

Reference Sources

-

Essential Guide to Bend Testing: Evaluating Material Strength – This guide provides an overview of the bending test, its applications, and its role in evaluating flexural strength and ductility.

-

Bending test: Suitable for both brittle and ductile materials – This resource explains the bending test method and its importance in testing material properties.

-

Bend Testing – TWI – A detailed explanation of the bend test, focusing on its use to evaluate ductility and material soundness.

-

Bend Testing – AHSS Guidelines – This source discusses the three-point bend test and its application in material testing.

-

Understanding Bend Tests – A comprehensive document on the concept and procedure of bend tests, particularly for welds.

Frequently Asked Questions (FAQs)

Bend Test: What is it and Why is it Important?

Bend testing is universal to characterize the bending properties of materials, particularly steel. This test evaluates the behavior of a material under various forces, i.e., its strength and flexibility. The test helps one learn about the material’s properties and determine its suitability for use in constructing structures and elements.

What are the Different Types of Bending Tests?

The types of bending tests include the 3-point bending test and the 4-point bending test. In the 3-point bending test, the load is applied at the center of the specimen, supported at both ends. In the 4-point bending test, the loads are applied at two points, thereby establishing a uniform bending moment on the center portion of the specimen. Each one reveals a slightly different aspect of the material’s bending behavior.

How are 3-Point Bending Tests Performed?

Three-point bending setups require supports hold that test specimens while a load is applied at the midpoint of the span. The deflection of the specimen is measured as a function of the applied force to calculate the bend strength and, hence, determine the stress-strain curve. Such information is necessary to comprehend the ability of a material to resist bending.

What Is Flexural Modulus and How Is It Calculated?

The flexural modulus is a measure of the stiffness with which a material resists bending. It is calculated from the slope of the stress-strain curve obtained during one of the bending tests. The higher the flexural modulus, the stiffer the material, and the more desirable it is for applications where deflection must be minimal under load.

How Do the Properties of Materials Affect Their Behavior in Bending?

The bending force in a workpiece depends on the material propertie,s such as ductility and brittleness. A ductile material can undergo considerable plastic deformation before ultimate failure. It can thus undergo more bending without breaking, whereas a brittle material, such as some steels, will fracture with minimal deflection. It is therefore vital to know these properties when choosing a material for a particular application.

What is the Maximum Load in a Bend Test?

The maximum load in the bend test is the greatest force that can be applied to the specimen before it fails. This measurement is critical, as it determines the strength of the material and thus whether it can withstand bending without permanently deforming or fracturing.