If materials are loaded constantly over a long period, tensile creep testing will analyze this aspect to determine their long-term performance. Industries in which materials are subjected to extreme conditions, such as heat and stress, should not overlook the phenomenon of creep. This article focuses on an in-depth assessment of tensile creep phenomena, the factors that depend on it, and the standardized methods available to measure and evaluate it. Therefore, you will understand why tensile creep testing is necessary for protecting materials and ensuring safety under demanding conditions. If you are in engineering, research, or material sciences, this piece will provide you with insightful information to use in your projects and decision-making.

Introduction to Tensile Creep Testing

Creep in tension testing is a process in which materials are deformed over time when subjected to a constant tensile load at a specific temperature. This is an important test to assess the long-term strength of materials under sustained stress, primarily used in the aerospace, building, and energy industries. By monitoring the strain over time, tensile creep tests provide detailed data on creep rate, failure, and structural soundness of the tested material, allowing engineers and designers to forecast material life, ensure safety, and make informed decisions regarding suitable materials for applications involving high stresses.

Definition of Tensile Creep Testing

Tensile creep tests refer to the methodical evaluation of a substance’s behavior as it deforms under constant tensile stress over an extended period in a controlled environment, which may include temperature and humidity. Using a sophisticated testing system, the substance is subjected to a constant load, while measurements of deformation or strain are taken at regular intervals over time. Important parameters targeted are assessed as primary (transient), secondary (steady-state), and tertiary (accelerated) creep stages. With improvements in testing methodology, data can be obtained in real-time, and strain analyses can be highly resolved, thereby allowing for a more profound understanding of the microscopic causes of the measured creep behavior. Based on this granular data, which has emerged from more recent studies, tensile creep testing is at the cutting edge of material tailoring for severe stress applications, offering optimum reliability for today’s engineering applications.

Purpose and Relevance in Material Science

Creep testing enables the study of long-term deformation of materials subjected to constant stress at a specific temperature. It plays an essential role in materials science, particularly in assessing how materials perform in real-life situations, such as in aerospace, energy, or infrastructure, where components are subjected to severe environmental conditions for extended periods. By determining creep behaviors of materials, scientists can enhance material modifications and arrangements, resulting in better structural integrity. These observations, along with the advanced materials being developed based on them—new alloys, composites, etc.—are the key to addressing the challenges posed by the exigencies of present-day engineering. Hence, incorporating exact creep data into the design and manufacturing phases adds value to the safer, more durable, and efficient implementation of high-stakes applications.

Importance of Creep Testing in Evaluating Material Durability

The testing of creep is indispensable in operational conditions with severe application environments, including aerospace, power generation, and construction, where prolonged stress and high temperatures applied to materials are detrimental. These kinds of tests inform engineers about the amount of deformation that occurs in materials over prolonged periods, allowing for prediction, reduction of failure dangers, and assurance of safety standards. The test helps determine time-dependent strain behavior, allowing materials to be selected that conform to the integrity of varying environments and thus establish an acceptable reliability level for design and performance.

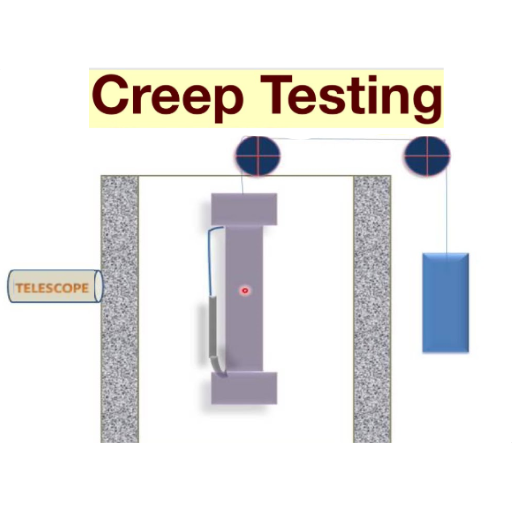

Methods and Equipment for Tensile Creep Testing

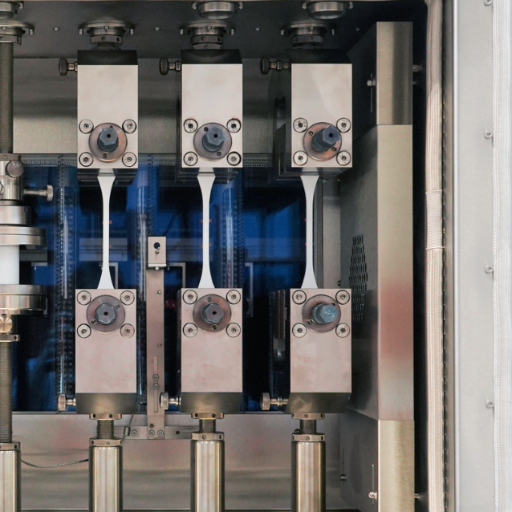

Tensile creep testing is conducted by applying a constant load or stress to a material specimen at a controlled temperature for an extended period, while measuring the resulting deformation. Among the principal methods, we find uniaxial tensile creep testing, where the test is performed on specimens under uniaxial tensile stress, and accelerated creep testing, in which the test is shortened by increasing the temperature or stress while maintaining precision in the measurement.

For tensile creep testing purposes, the setup typically includes a high-precision testing frame, a furnace or environmental chamber for temperature control, and extensometers or strain gauges for strain measurement. Some more sophisticated facilities would comprise computer-controlled systems for real-time acquisition and monitoring. Calibration and strict adherence to standards such as ASTM E139 or ISO 204 are required for reliable and reproducible test results.

Overview of Commonly Used Test Methods

Most of these commonly used test methods for material characterization and performance evaluation are typically governed by specific standards, ensuring that materials can be uniformly tested and results can be compared. Tensile testing is one of the most common methods for characterizing materials and is conducted under ASTM E8/E8M or ISO 6892 to determine their strength, ductility, and modulus of elasticity. Hardness testing using ASTM E18 (Rockwell) or ASTM E384 (microhardness) standards measures resistance to penetration as an index of wear resistance. The fatigue test specified in ASTM E466 is suitable for materials subjected to dynamic loads; it evaluates resistance to cyclic stresses, thereby indicating the long-term durability of a material. Across all methods, accurate instrumentation, accompanied by environmental controls and attention to calibration guidelines, remains key to ensuring reliable data for engineering purposes.

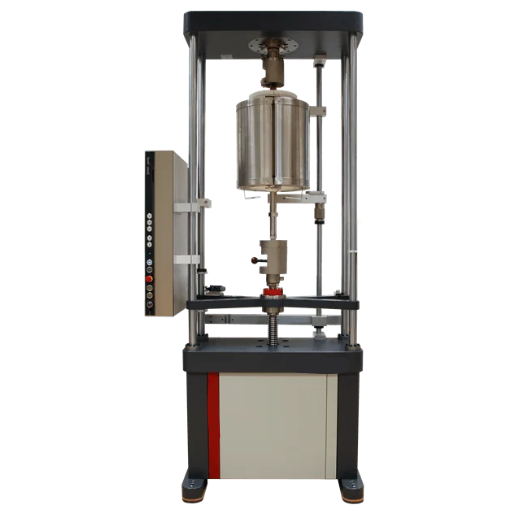

Equipment Required for Creep Testing

Creep testing requires very special equipment for accurately assessing the deformation of a material under sustained stress at elevated temperatures. The prime element is the creep testing machine, where the load frame is designed to maintain constant stress for very long durations. The testing fixtures, such as high-temperature grips or extensometers, are also crucial for holding the test specimen and measuring elongation or strain during the test. Precision furnaces equipped with top temperature control systems provide uniform heating to the specimen within stringent criteria of thermal stability and uniformity. Data acquisition systems also interface to continuously monitor several variables, such as strain, time, and temperature, thereby providing comprehensive data sets for detailed analysis. Depending on the material’s specifications and test conditions, environmental chambers or specialized gas flow systems may also be required to create suitable working environments or prevent oxidation during high-temperature tests. The careful calibration of all the instruments must be ensured to comply with ASTM E139 for creep testing.

Calibration and Standardization Procedures

To obtain true and dependable results, all calibration and standardization procedures must comply with established standards, such as ASTM E139. Calibration involves using certified reference materials or instruments to adjust the equipment so that its readings accurately reflect true values. Regular checking against a recognized and traceable standard will recognize deviations and enable corrections to be made. Standardization entails operating according to already agreed-upon test protocols, thereby ensuring that results are consistent. Each testing instrument should be verified for precision and reliability, especially as to its operational condition expected during material testing. Documentation on this matter will provide traceability and ensure compliance with industry regulations. The frequency and specific requirements for calibration will be specified in the ASTM for the respective instruments used, based on sensitivity.

Industry Applications of Tensile Creep Testing

Tensile creep testing is used in many industries to evaluate the long-term performance and reliability of materials under a constant load and temperature. It ensures that a material can withstand sustained loads at elevated temperatures in applications such as turbine components in the aerospace industries. In construction and infrastructure, tensile creep tests investigate, for example, the deformation behavior of materials (such as concrete, steel, and polymers) under load-bearing conditions. The energy industry, particularly concerning power generation and pipelines, benefits from these tests for qualifying the materials for extended exposures to stresses and thermal challenges.

Aerospace Industry Needs and Applications

Tensile-creep testing finds its highest use in aerospace applications to ensure the long-term capabilities and reliability of materials used for vital components. In aircraft and spacecraft, materials undergo extreme thermal and mechanical stresses during operation. Tensile creep tests are performed to assess these materials, including high-temperature alloys, composites, and polymers, to evaluate their response to sustained conditions over time. The tests help predict material deformation and failure rates, an essential step in ensuring long-term flight safety and the functioning of major systems, such as engines, airframes, and turbine blades. Understanding this behavior enables engineers to optimize both material selection and design to meet stringent regulatory and operational requirements.

Construction and Structural Integrity

Tensile creep testing involves applying a constant load/stress to a material at an elevated temperature for a specific period to observe the material’s deformation behavior. The apparatus for tensile creep testing typically consists of a load frame system, a heating chamber, and a strain measuring instrument (e.g., an extensometer or digital image correlation). All these units work together to maintain well-controlled and repeatable testing conditions.

To ensure structural integrity, the process must operate under constant stress and uniform temperature conditions. There will be on utmost importance for well-calibrated load cells and advanced temperature control to minimize any variation that could influence the accuracy of the data. High-resolution sensors with the ability to capture every micro-movement in the extension of the material they measure will give high-quality data on creep behavior in its primary, secondary (steady-state), and tertiary stages. The results from fine creep measurements, in turn, offer the material-performance characterization that engineers use to design for the limits of material long-time reliability and to qualify materials for the aerospace, energy, and construction industries for critical applications.

Automotive and Energy Sector Requirements

Tensile creep testing is crucial for the automotive industry and energy sectors, where materials must withstand prolonged periods of elevated temperatures, stresses, and corrosive atmospheres. In automotive applications, creep testing ensures the reliability of engine and turbocharger components, as well as other materials, that are exposed to thermal cycling and mechanical loads. Similarly, in the energy industry, which encompasses power plants and renewable energy systems, materials are tested to determine their resistance to deformation over time under extreme conditions of high temperature and constant stress. Such organizations’ evaluation programs form the basis for constructing safer, more efficient, and more durable components that constitute the frontiers of advanced technologies in these industries.

Advantages of Conducting Tensile Creep Tests

Key Benefits

Tensile creep tests provide crucial information on the long-term performance of a material subjected to constant stress and elevated temperature. They can be used to predict behavior over some time, ensuring the safety of implementation where deformation may compromise structural integrity. They aid in selecting materials suitable for an operational environment and in optimizing design to prevent failure. Furthermore, tensile creep tests help ensure compliance with industry standards and federal regulations, promoting superior quality and durable components for the aerospace, construction, and energy sectors.

Improved Material Selection and Design Decisions

Better material selection and design decisions are highly dependent on accurate data from tensile creep testing. These entail critical insights into how the material behaves under high levels of sustained stress and temperature, so that the engineer can choose materials that meet the mechanical and environmental requirements specific to the application. Once a material’s creep limit and deformation characteristics over time are established, designers can begin improving component design to increase performance and reduce the weight of the materials, thereby increasing their lifespan. This will also lead to failure prevention, thereby ensuring complete safety and reliability in critical structures through the implementation of stringent industry standards.

Enhanced Safety and Reduced Long-term Costs

Ensuring kind safety and top reduction of costs rests on strategic design and material selection that takes into consideration the operating condition and all possible failure modes. An advanced material, such as a composite or high-performance alloy, offers the best resistance to fatigue, corrosion, and heat, which is crucial for the extremely critical structure’s long life. Enforcement of predictive maintenance strategies by way of real-time monitoring techniques incorporating IoT sensors that will be able to detect wear or defect at the onset and therefore prevent any catastrophic failure and reduce downtime. A comprehensive lifecycle cost analysis (LCCA) approach should help assess the total cost of ownership, balancing initial investment costs and operational savings throughout the component’s lifespan. Thus, this integrated mechanism primarily aims to enhance reliability while reducing costs in the long run, resulting in a win-win situation for both economic and safety concerns.

Predicting Potential Failures through Creep Testing

Creep testing is important for analyzing how materials respond when subjected to stress over a long period at a constant temperature. According to the leading resources, this test can indicate when a material may potentially fail by observing its deformation characteristics, identifying the critical strain limits, and then estimating when it will fail under operation. By establishing creep limits and long-term elasticity data, this test can provide precise information on durability, ensuring that maintenance is carried out ahead of time and avoiding any unexpected failures in high-stress, hazardous environments.

Recent Innovations in Tensile Creep Testing Technologies

Recent innovations in tensile creep testing technologies have geared towards higher-precision measurements and advanced data analysis methods. High-resolution digital extensometers can now monitor their deformation to a respectable level of minute changes with impeccable accuracy. Furthermore, the use of machine learning algorithms has facilitated the analysis of complex deformation patterns, ultimately leading to the rapid identification of trends in material behavior. These advances reduce human error, require less testing time, and yield greater accuracy in predictions related to aerospace, energy, and manufacturing industries.

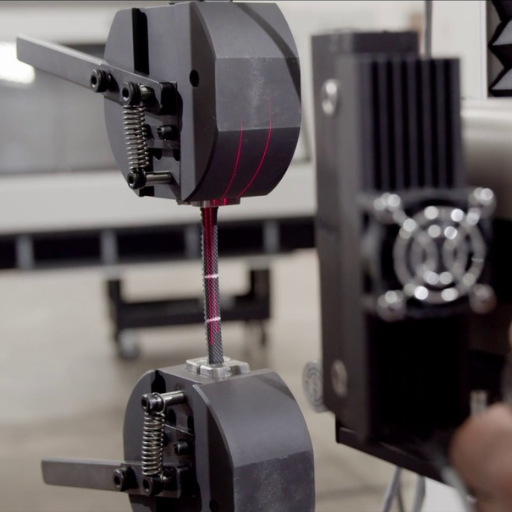

Advancements in Sensors and Measurement Techniques

Recent innovations in sensors and measuring techniques have enhanced the accuracy and efficiency of tensile creep testing operations. High-resolution digital image correlation (DIC) systems are now being widely used to provide precise strain measurements without contact over the surface of the material. These systems provide full-field strain data that capture localized creep variations previously unobservable with traditional tensile creep testing instrumentation.

Additionally, laser-based interferometry techniques, such as laser extensometers, enable exceptional sensitivity in measuring minute elongations, even in high-temperature environments. The tools bypass the limitations of mechanical sensors by enabling real-time monitoring with almost no thermal drift, which is an indispensable feature for applications where even the slightest change in material condition over time can significantly affect its utilization.

Innovation in wireless sensing enables remote data acquisition, while IoT sensors facilitate continuous monitoring of samples under test. Thus, their integration, assisted by cloud architecture for data management and analytics, significantly accelerates the ability to process large-scale experimental data. The integration of state-of-the-art measurement techniques has significantly enhanced the establishment and reliability of tensile creep testing, allowing researchers to more accurately predict the lifespan and performance of tested materials in harsh conditions.

Automation in Creep Testing Processes

Automation in creep testing processes has brought about a significant revolution in evaluating materials for long-term stability under stress. Today, with automated setup systems, robot arms are placed for specimen placement, load application, and alignment to ensure repeatable setup with minimal human error. Advanced software enables the monitoring and control of test parameters, such as temperature, load, and displacement, in real-time. Also, with IoT-enabled devices supporting enhanced efficiency for remote operation, they will support remote control and data acquisition. From this trigger, testing workflows will be streamlined for high-throughput testing with advanced data analysis on the fly, thereby significantly reducing the time required to obtain important information on material performance.

AI-Driven Data Analysis in Material Testing

Material testing, facilitated by today’s AI-driven data analysis, has enabled algorithms and advanced computational models to mine large datasets efficiently and effectively. By scanning through complicated patterns and correlations within experimental data, these AI systems can offer insights that are either extremely difficult or simply impossible for humans to fathom through traditional means. As an example, such predictive modeling can be used to forecast the behavior of materials under different conditional parameters, hence reducing the amount of requiring physical trials.

Additionally, these anomaly detection algorithms can identify irregularities or defects in materials that have previously gone undetected. This will provide improved confidence in quality control. This is further enhanced through the combined use of an AI system with a real-time updating database, a database that can update with new scientific findings, case studies, and industrial applications on a continuous basis. This enables material scientists to compare and validate their conclusions against the most recent global research and industry trends. Such a mechanism greatly improves accuracy and provides the ability to evolve quickly in meeting the dynamic challenges of the material engineering field, thus reengineering the way materials innovations are being identified and applied.

Reference Sources

-

Tensile Creep – an overview – A detailed explanation of tensile creep and its testing methods.

-

Creep Test – A glossary entry explaining creep tests and their significance.

-

ISO 899: Creep test on plastics – Standards and methods for conducting creep tests on plastics.

-

Tensile creep rupture testing for long-term strength – Insights into tensile creep rupture testing and its applications.

-

What is creep, and why is it important? – An article discussing the importance of understanding creep behavior in materials.