When it comes to material classes and their mechanical properties, common terms appear in front of us, such as “crush strength” and “compressive strength.” These phrases are quite interchangeable at first; however, they do refer to different things, thereby an essential factor for materials science and engineering. This article aims to destroy the mysticism of those terms by defining them and explaining the distinctions between them, as well as their applications. Whether you are an engineer making a choice about a material or merely curious about how materials stand up to pressure, this guide will open your eyes and shore up your understanding of the fascinating chemistry of force and materials. Stay with us as we bring these designations down to earth and clarify the concepts.

Understanding Crush Strength and Compressive Strength

Definition of Crush Strength

Crush strength, in a nutshell, would be the utmost quantity of compression a material can face before it breaks physically or fractures. It is frequently used to indicate a material’s durability and structural integrity to the applied pressure, whether a ceramic, metal, or composite. Materials with great crush strength ruin deformation and collapse with much compressive load, and they find wide application in several industrial and construction projects.

Generally speaking, it is determined by the method of subjecting an increasing amount of compressive force to a specimen until the material fails. The ultimate value reached serves as a definite point in the compression performance of the test material. Knowledge of crush strength is important for selecting materials subjected to heavy loads, i.e., in building structures, manufacturing machinery, and transport systems.

Crush strength differs from other mechanical properties such as tensile strength, which considers pulling forces, or shear strength-witches act as sliding forces. In being a pure compressive magnitude, crush strength allows designers and engineers to assess the suitability of any material for an assignment where weight, pressure, or load-bearing capacity are considered paramount.

Definition of Compressive Strength

Compressive strength, a measure of resistance, is the ability of the material to resist being squeezed or compressed under an external load. It is considered one of the major properties used in engineering and construction as to how much load a material can bear before breaking down under crushing pressure. The units used for compressive strength are force per area, e.g., pascals (Pa) or psi.

Usually, a piece of uniform size is placed inside a testing machine where increasing controlled pressure is exerted on it until it fails. This test determines the maximum stress the material can sustain just prior to fracture or to the point of discontinuous deformation beyond which the deformation is and will remain permanent. The yield point evaluated from this test helps engineers judge whether they can use the material for heavy load applications like construction of supports for building structures, making of bases for foundations, or fabrication of intermediary components that will experience genuine compressive loads.

In other words, materials differ tremendously in their compressive strength. For example, concrete, which is commonly tested, has relatively high compressive strength; thus, it is a preferred material for buildings and bridges. Materials such as wood and some polymers, on the contrary, are limited by their very low compressive strength in carrying heavy loads. This comparison illustrates the need to look for materials compatible to the demands and conditions of a given project.

Key Differences Between Crush and Compressive Strength

Materials can be considered with regard to crushing strength-the magnitude of force that a material would resist before it fractures or crumbles in crushing failure. The property is generally attributed to the materials which are brittle in nature, like ceramics or concrete. It is tested when a material is stressed to the point where it breaks into discrete pieces. Crush strength helps to determine how the material might react to pressure and high impact forces, and in consequence, may lead to determining whether it is fit for a given application.

Compressive strength is, conversely, a measure of the maximum compressive load a material can undergo without undergoing indefinite deformation or failure. So it by no means insists that the material be crushed outright-but remains a well-admitted criteria on how a given material can resist an applied compressive load. It is hence a very important aspect in structures where materials are supposed to carry enormous loads with little deformation, such as in beams and foundations.

A major difference between the two lies in their respective considerations of the primary forces and failure types, with crush strength checked against forces that induce complete breakage or disintegration of a material and compressive strength checked against forces involved with deformation. Both are important depending on the intended application-under crush strength for materials subjected to crushing forces and compressive strength for maintaining structures under load. Understanding these differences aids engineers and designers in making informed decisions about material selection for construction, manufacturing, or other engineering purposes.

The Importance of Compressive Strength in Various Industries

Applications in Construction

Its compressive strength is perhaps one of the construction industry’s most fundamental properties, as it directly relates to a material’s ability to resist applied loads without failure. This attribute compels selection in many construction materials, such as concrete, brick, and natural stones, with the intention of imparting to the edifices and infrastructure durability and stability. For example, foundations, walls, and columns should be made from good compressive-strength materials that disperse loads adequately and ensure the structure will not collapse.

Of all construction materials, concrete, by virtue of its high compressive strength and flexibility of application, is preferred most. It makes an ample show in the building of structures, bridges, roads, and dams. In most cases, concrete is tested, and its strength is designed according to specifications so that it can safely perform under expected loads. Longevity and sustainability are ensured by using construction materials with optimum compressive strength since they will rarely undergo repairs or even replacements.

Furthermore, the compressive strength of materials is a major factor that leads to higher and complex structures. Innovation under the compressive domain, such as the invention of reinforced concrete, further improves the compressive strength and allows architects to think big. At the end of the day, an understanding of compressive strength and its integration into construction uplift the life expectancy of structures with great engineering feats achieved along the way.

Role in Packaging Industry

In the packaging industry, protective compressive strength is of utmost importance during transfer and storage of goods. Packaging materials require resistance against being cramped under pressure, as they often face stacking, handling, or shipping stresses. Materials used to provide compressive strength are generally the structural materials in packaging, which aim to use the least amount of packaging material, e.g., corrugated cardboard and molded pulp.

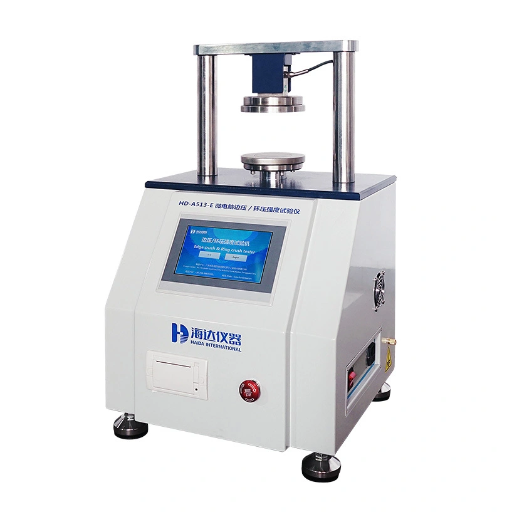

The compressive strength test is therefore necessary to know if a packaging material is able to withstand applied loads. The box compression test, for example, is done to determine the amount of weight a package can hold before it collapses. With isolated knowledge of limits, manufacturers are able to engineer packaging that consistently ensures product safety but is cost-efficient. This is especially critical in the packaging of fragile or highly valuable items because failure may cause exorbitant loss.

More material development is focused on trying to capitalize on compressive strength as a parameter for sustainability. They are more inclined toward using recyclable and biodegradable materials that have enforceable strength, thus keeping the impairment as low as possible. In all, compressive strength helps to make sure that packaging keeps up with its functional and logistical requirements, under which arrangements are made for safe transport and storage within various industries.

Significance in Automotive Engineering

Compressive strength is of secondary importance in the field of automotive engineering to ensure materials can withstand the immense pressures that occur during operation. Components such as the chassis, engine blocks, and structural panels require high resistance to stress to maintain the integrity and safety of the vehicle. Materials with a greater compressive strength can lessen deformation or failure when subjected to load, particularly during impact situations or under high pressure.

Materials with the right compressive strength help amortize different variables between vehicles to optimize design, both performance, and efficiency. Hence, the components used being not only heavy but also with high compressive strength will scale down the vehicle weight leading to increased fuel efficiency and decreased emissions. Components and parts with a greater level of compressive strength ensure their durability and long life, thereby saving a few bucks over time in maintenance or repair costs.

Finally, compressive strength affects automotive design innovation for electric and hybrid vehicles. These types of vehicles often need materials to deal with new engineering challenges. Ensuring the compressive strength of batteries, protective casings, and frameworks are all necessary to engineering reliable and safe alternatives to conventional automotive structures simultaneously with modern energy, and environmental criteria.

Testing Methods for Compressive Strength

Overview of Compression Testing

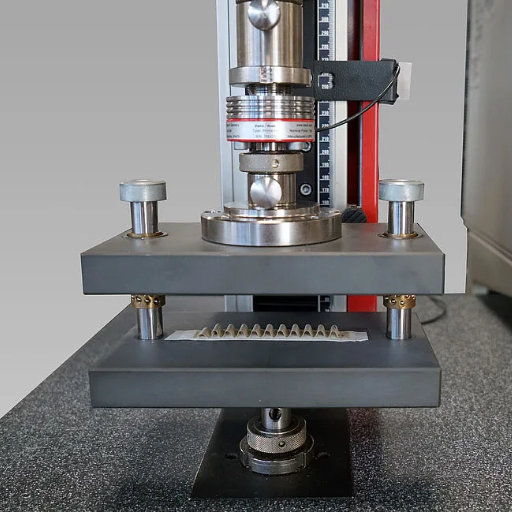

Compression testing is a procedure used to ascertain the compressive strength of a material. A controlled force is applied to a material specimen until it is deformed or broken. The purpose is to observe the amount of stress the material can endure before it fails. Often, such results are used in determining whether the material can withstand stresses that it may be subjected to in real-world scenarios, ensuring its safety and reliability in design.

A compression test is carried out through several stages. Generally, a sample is placed between the two compression platens in the testing machine. A loading increased at a constant rate is applied while deformational changes in the specimen, shape, or dimensions are recorded. Important parameters obtained are: final compressive strength, elastic limit, and deformation behavior of the workpiece under compressive load; thereby, this information helps the engineers make their decision on whether or not this material can be used for structurally or load-bearing applications.

Compression testing becomes an important procedure in the construction, automotive, and aerospace industries. In automotive design, for example, compression tests inform manufacturers whether battery casings, protective parts, and vehicle chassis can withstand the stresses to which they should be subjected. Standardized testing methods, according to industry bodies, provide valid measurements and guarantee that materials can be consistently evaluated in different applications.

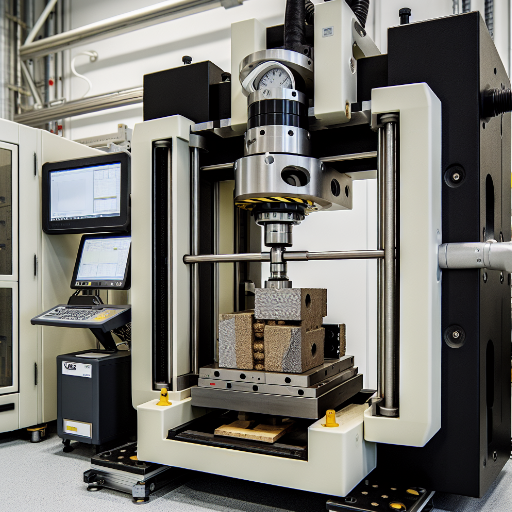

Using a Universal Testing Machine

Universal testing machines are very versatile, since one of their many uses includes testing compressive strength in materials. A given amount of force is applied spontaneously by the machine, which presses the specimen until restriction or deformation. The force acting upon the specimen sets off the deformation, offering vital clues about the resistance of the material for compression.

For the compressive strength test, the specimen is placed between two parallel plates of the testing machine, after which the machine applies force at the predetermined rate, and sensors are used to gauge the material response. Maximum force applied on failure is crucial for calculation of compressive strength and ultimately pertinent to assess performance in real-world conditions.

The results that come through from universal testing machines further industries in assuring that the materials meet minimal safety and performance criteria. The data is reliable to promote design of components such as beams, supports, or casings adequately for the life to which they will be exposed. This process also entertains the application of this process to help manufacturers try out new materials in view of their strength, durability, and applications.

ASTM Standards for Strength Tests

ASTM outlines numerous testing standards for compressive strength. They ensure that the strength testing in various industries remains consistent, reliable, and comparable. Compressive strength testing is essential for materials such as concrete, metals, and composites to determine the capacity of these materials to resist axial loading without failure. ASTM standards act as the basis for carrying out testing accurately, considering specimen preparation, test conditions, and reporting.

ASTM C39, perhaps the most popular of standards, deals with the testing for compressive strength of concrete cylinders. It provides details regarding an acceptable size of specimens, how they should be cured, and how to load them during testing so that their load-bearing capacity may be determined and used for confirmation that concrete satisfies the requirements in design and structural application.

ASTM E9 is another important standard, which concerns the testing of metallic materials for compressive strength, at room temperature. In addition, it provides detailed instructions regarding the setup, alignment of specimens, and interpretations of the test. They are widely used and accepted by engineers and manufacturers since such standards aid material selection, quality control, design changes that ensure safety, and durability in applications from infrastructure to aerospace.

Factors Influencing Compressive Strength

Material Composition

Material composition significantly enters compressive strength determination. The kind, proportion, and arrangement of the elemental constituents within a material can have an adverse bearing upon its resistance to compressive forces. For instance, materials with a neat atomic structure, like metals such as steel, generally show greater compressive strength than less dense materials like some polymers or porous ceramics.

The presence of impurities or alloying elements affects compressive strength considerably. For example, adding carbon to iron forms steel, which generally displays a higher compressive strength because of the altered microstructure and bond strength. On the contrary, excessive impurities or poor processing of a material tend to create weakness in the material, whereby voids, cracks, inconsistencies, and the likes can reduce the strength and performance of the materials.

Equally, grain size and possible orientation in crystalline materials do have an influence on compressive strength. Small grains that are homogeneous tend to enhance strength due to grain boundaries preventing dislocation movement under compression. For non-metallic materials, like concrete, the cement, aggregate, and water composition, including their ratios, directly govern its compressive strength. Thus, having a sound grasp of material composition and the ability to optimize it is what one uses to select and design materials that suit specific load-bearing concerns.

Manufacturing Processes

Manufacturing processes determine the compressive strength of a material. During production, microstructure, porosity, and the integrity of the material are largely affected, which determine the ability of the material to perform optimally under compressive loads. For example, if temperature and pressure are controlled during manufacturing, particle-to-particle bonding will increase, thereby reducing defects and increasing strength.

For concrete production, it is of great importance to emphasize the mixing and curing processes. Properly carried out mixing ensures that cement, aggregate, and water are correctly distributed to develop consistent strength throughout the material. Keeping the spirit of curing, i.e., the maintenance of an adequate moisture content and temperature for a specified time, is required during the hydration reactions of the cement. Proper curing improves the concrete’s density and durability, so it can resist compressive forces excellently.

Forging, rolling, or extrusion are generally applied to metals in order to improve grain structure and remove voids. Heat treatments, i.e., quenching and tempering, can be applied to vary hardness and toughness of metals and accordingly improve compressive strength. In other words, considering manufacturing methods at all stages results in the best formulation of materials for load-bearing applications.

Environmental Conditions

Environmental conditions play a considerable role in determining the compressive strength of materials. Physical parameters of the material may find alteration by factors such as temperature, humidity, corrosive environment, etc., and this alteration often tends to diminish its strength under compressive loads: a case in point is high temperature, wherein materials tend to lose strength owing to thermal expansion and changes in microstructure.

Other examples include materials subjected to moisture or high humidity: degradation occurs especially if the materials absorb water, which in the case of porous solids like concrete would mean a loss of strength from water entering its pores. Corrosive environments, such as those consisting of acid or saline mixtures, might also tend to slowly weaken metals through the creation of surface irregularities or internal disruptions.

Thus, mere correct standards that cover material choice and application of varnishes would be taken care of against environmental affronts. It includes selecting materials intended against certain environmental factors and instituting maintenance routines to provide for compressive strength and structural reliability across varying conditions.

Compressive Strength in Product Design and Quality Assurance

Importance in Material Selection

Compressive strength is a very critical factor to be considered in choosing materials for any type of product design. The compressive strength is the ability to withstand forces that tend to reduce the size of the material, which, during the process load is applied to maintain structural integrity. Thus, an application with an appropriately recognized compressive strength withstood may go under pressure, such as construction, packaging, and manufacturing.

In selecting materials, engineers should consider the specific load requirements of the product and the environmental conditions to which it will be subjected. For example, concrete is widely used in construction for its compressive strength; however, metals like steels might be more appropriate because of their sturdiness and malleability. Materials that lack the minimum compressive strength can succumb to premature failure, incurring loss or unsafe situations.

Thorough testing in accordance with the set standards should be followed to ensure that the material chosen for the application can withstand the required compressive stress. Proper investment on material analysis during design helps to enhance product performance and guarantee long-term reliability and thus assures the product to withstand operational demands by maintaining safety and quality.

Enhancing Durability through Strength Testing

Strength testing is an important procedure in determining the durability and reliability of materials, usually under compressive stress. This testing evaluates the ultimate strength of a material when exposed to huge stresses or loads in real-life scenarios, suggesting to manufacturers whether such a material can be used for an application. These evaluations ensure that the material meets the necessary standards regarding performance, thus minimizing the risks of deformation or failure in operation.

Generally, compressive strength testing is carried out by applying a controlled loading on a specimen until failure is observed. This offers an insight into the load that a material can bear without permanent deformation or cracking. By performing tests consistently under correct conditions, products can meet safety standards even in extreme operating environments.

Proper selection of materials using compressive strength analysis is of utmost importance in improving product life and performance. By knowing where different materials draw their limitation and strength, engineers can comprehend design decisions to secure safety to protect end-users. This will also cut maintenance and ensure extended life time for a product in different industries.

Case Studies and Industry Examples

Construction Industry Application

One example that describes the importance of compressive strength testing can be found in the construction industry, particularly for concrete consumption. Concrete being a fiberglass is used as a degenerative material for bridges, skyscrapers, or highways. The engineers ensure that the concrete is tested for its compressive strength to ascertain that it can bear the heavy loads and environmental stressors that it would encounter. For example, by adhering to safety standards, the structure can resist in possession of cracking or structural collapse, thus prolonging the lifespan of the structure and protecting human lives.

Aerospace Industry Insights

Testing compressive strength of composites and metals presents a clear example for the aerospace industry. The components of machines and systems of high technological complexity that comprise aircraft, such as fuselage panels or turbine blades, are exposed to severe environmental conditions, pressure, and temperature variations. By testing the compressive strength of certain materials, dominance is assured; i.e., under such stressors, aircraft maintenance will in itself become the less probable event of a growing critical failure, thus guaranteeing an optimal level of flight safety.

Consumer Electronics Durability

The consumer electronics sector is another great arena that influences compressive strength consideration. These include products such as smartphones, laptops, and wearable devices. Product packages of these products must be able to endure daily pressure and accidental drops without hurting on basic functioning. Through thorough compressive strength analysis, manufacturers choose to reinforce the endurance of such products with materials such as hardy plastics or reinforced glass, thus needing fewer repairs and resultant long life for the end-user.

By tying these industrial examples together, it becomes evident how pertinent an optimization of compressive strength is from the point of safety, durability, and performance.

Frequently Asked Questions (FAQ)

Q: What is crush strength?

A: Crush strength is the maximum load a material can take on before failing under compressive forces. This property determines the ability of materials to withstand stress without deformation, with particular applications emphasizing structural integrity.

Q: How is crush strength enquired about?

A: The crush strength is measured through a test whereby the force acting to compress the test specimen until it fails is registered, with results expressed in units such as megapascals (MPa) or pounds per square inch (psi), which give an idea of the compressive strength capabilities of the material.

Q: What factors influence crush strength?

A: A handful of factors influences the crush strength of a material. They include the composition of the substance, the cross-section area, the length of the specimen, and the direction of the loading. Other concepts related to the mechanical properties of wood, like wood strength and shear strength, also playout in determining wood crush strength.

Q: What does radial crush strength mean?

A: Radial crush strength relates to the capability of cylindrical materials such as tubes and pipes to withstand forces applied across their axis. It is especially important in circumstances where radial loads abound and ensures that the material sustains structural integrity under pressure.

Q: How does the crush test compare to other strength tests?

A: The crush test is done to find out the behavior of materials when loaded in compression, on their compressive and tensile characteristics. Other tests, such as the tensile test, determine the performance of materials when stretched, while shear tests reveal the reaction to lateral forces.

Q: What is the importance of characteristic compressive strength of a material?

A: The characteristic compressive strength of a material is very important in establishing a basis for its performance under load. Thus, engineers and architects need to familiarize themselves with the compressive strength of materials with which to ascertain that structures temporary load may safely support without risking failure due to mechanical causes.

Q: Does the crush strength of wood vary from one class to another?

A: Yes, the crush strength of wood may vary to quite a great extent from one wood species to another, due to differences in wood density, grain structure, and other mechanical characteristics of wood. Knowledge of these disparities is paramount when working with wood in construction or manufacturing.

Q: What does the factor of safety have to do with the crush strength requirements?

A: The factor of safety is an important consideration in the design community; it is a ratio of maximum load to the working load that is expected. It ensures that materials provide an additional margin from unforeseen stresses and loads to inhibit failure of material being considered under crush strength criteria.

Q: What is the correlation of crush strength with the strength of concrete?

A: The crush strength of concrete as determined though compressive tests is the factor considered for structural viability. High crush strength indicates the particular mix of concretes can bear great loads, which is an imperative condition for a construction to be assuredly safe.

Q: How is the crush strength of a material related to the selection of materials for a reactor?

A: Measuring the crush strength becomes important in the selection of reactor materials because these components have to sustain high pressure and thermal stresses. This knowledge about the capacity of a material to stand against these conditions helps in ensuring safe and efficient running of reactors and minimizes the possibilities of mechanical failure.

References

-

ScienceDirect – Crushing Strength Overview

An overview of crushing strength as a function of material density, moisture content, and temperature. -

Mecmesin – Crush Strength Testing of Catalyst Pellets

A guide to single pellet and bulk crush strength testing for catalytic materials. -

Quora – Difference Between Crushing Strength and Compressive Strength

A discussion on the distinctions between crushing strength and compressive strength. -

Safe Load Testing – Edge Crush Test vs Burst Strength Test

A comparison of tests measuring the forces cardboard boxes can withstand during handling.