Adhesives have become a necessity for almost every type of industry-from construction, automotive, medical, and other consumer goods. Yet it is equally important to understand if a bonding method is strong or reliable enough for application in real life. This manual provides an educational and more in-depth look at adhesive strength testing and adhesion measurement-fixture insight into why these test measures are taken and how they are conducted accurately. Whether you are a manufacturer looking to achieve the best results for your products or a researcher studying material properties, this blog will take you through the tools, techniques, and best procedures for adhesive strength assessment. It’s your gateway to the science of adhesion with tips on achieving the strongest, most durable bonds based on your specific needs.

Introduction to Adhesive Strength Testing

What is Adhesive Strength Testing?

Adhesive strength testing is a procedure where one attempts to provide a material with adhesive bonding capable of keeping materials joined together. It measures the force required to separate two surfaces from one another, which is a good basis for judging the relative performances of an adhesive under a stated condition. Engineering-wise, it is vital to ensure that adhesives conform to strength requirements specific to their intended application.

The procedure usually involves applying controlled stress upon a bonded joint between two materials until failure occurs. Albeit it has the advantage of establishing the quantitative performance of the adhesive, it also distinguishes whether such failure is due to the adhesive or other causes such as failure in the substrate or the bond interface. This in-depth knowledge can give the user confidence in selecting, specifying, or even developing appropriate adhesives for widespread application in construction and automotive systems down to delicate electronics.

Adhesive strength tests are essential in testing the quality, safety, and durability of a product so as to reduce the risk of bonding failures that may cause defective products or system failures. Adhesive strength testing performed according to standardized methods ensures the accuracy of tests; hence supports innovation and trustworthiness in all sectors.

Importance of Adhesive Strength Testing

Adhesive strength testing is necessary for determining whether a bond can withstand the forces it has to face in any particular situation. It also tests adhesion under conditions so that the product may perform under safe and effective conditions. This test is fundamental for avoiding any possible risk related to the malfunction of the product, structural failure, or other hazards related to safety.

In industries like construction, aerospace, automotive, and electronics, adhesive strength testing is imperative to ensure the highest quality. For example, adhesives should hold materials together in construction when subjected to varying environmental stresses, while in the automotive field, the same should hold against vibration, heat, and pressure. Performance and durability assessment of adhesives thus helps provide reliable and durable solutions across fields.

If adhesive strength tests are conducted systematically, this will foster innovations and ensure compliance with safety regulations. By having standard tests, manufacturers would be able to improve their products, yet at the same time, they also strengthen consumer confidence concerning the reliability of adhesive bonds and their endurance. After all, an adhesive strength test is the ultimate means of protecting product finish and performance.

Relevance Across Various Industries

Adhesion strength testing is done for ensuring product functionality and safety in different industries. In construction, adhesives can be used to bond materials such as tiles, wood, and structural panels. Testing under all conditions ensures that the materials stay bonded when subjected to varying environmental elements such as temperature changes and humidity, thus increasing the building’s structural integrity and durability.

For aerospace and automotive industries too, adhesive-testing procedures are relevant. As reliance increases on lightweight yet strong materials, adhesives are extensively used in place of typical fasteners. Testing of adhesives would ensure that vehicles and aircraft are reliable at times of extreme stress, at high speeds, and varying pressures; in other words, it ensures the safety of passengers and operational efficiency.

On the other hand, in medical glue testing are of paramount importance for products such as medical tapes, prostheses, and wearable health devices. Adhesive bonds must be made strong enough to uphold patient comfort and device functionality. Sound testing procedures in these various industries result in better, safer, and more efficient products, thus encouraging consumer confidence and innovation.

Methods and Techniques for Testing Adhesive Strength

Peel Tests

Runner-up is one of the basic tools for assessing the mechanical strength of materials. These tests measure the force that would be able to break the adhesive bond between two surfaces at a controlled angle and rate of separation. Usually, these tests measure the resistance force an adhesive can muster to applied peel-off forces, which are key issues in ensuring the real-world usefulness of such adhesives.

Main Types of Peel Tests:

- 180-degree peel test: One substrate is pulled back completely over itself so that a straight line exists between the two materials

- 90-degree peel test: The adhesive is pulled at a right angle to the surface to which it is bonded

Peel testing offers unique insights into the durability and performance of adhesive bonds. These tests assist manufacturers in improving product design and ensuring safe use by simulating the stresses that adhesive materials undergo in real life. If testing is carried out consistently and precisely, adhesive products are ensured to meet the required standards concerning durability and performance in their anticipated range of applications.

Shear Tests

Shear tests involve the evaluation of forces parallel to the plane of the material or adhesive; hence, this class of tests checks the capacity of materials for swift destruction. This type of testing forms the basis of how materials behave when exposed to shearing forces in the real world, such as in structural situations or mechanical systems. The main purpose of these tests is to apply a measurement of shear force to some material inadvertently and observe the deformation or failure behavior from some zones of the material or finish points in the behavior of the adhesive under those forces.

Apart from this, several other industry processes in which these tests are specially relevant are considered; any given industrial process which requires precision and reliability in safe load bearing under constant or repetitive stress, say construction or aerospace applications where materials are vying to maintain their integrity. This kind of data enables shear testing to teach manufacturers how to improve their designs to create more durable and efficient products. Once again, the results from tests serve to guarantee that the product complies with the regulatory standards and safety guidelines established within the industry, increasing consumer assurance and furthering product reliability.

The testing process checks the strength of the material or bonding by holding the specimen in a fixture and applying shear force until it fails or deforms. By analyzing results, such as maximum load capacity or tolerance of strain, manufacturers find out the actual performance limits of the material or the bond. Such information plays a pivotal role in deciding what material to choose, in design improvements, and in quality control in manufacturing processes.

Tension Tests

In the tensile test, one tries to determine a material’s ability to withstand pulling forces, to characterize the material’s strength, ductility, and elasticity. In the test, a sample or specimen is held by clamps on each end and pulled apart until it breaks. Some of the most important properties evaluated are tensile strength, yield strength, and elongation. These properties are tested to understand how a material reacts when subjected to stress.

Results obtained from these tests could be used to select the desired material in engineering and manufacturing projects. Materials with high tensile strength find application in structural ones, whereas a material with higher ductility is suitable for applications promoting, say, bending. This testing ensures that the material undermines the basic safety and quality standards, thus preventing any failures in real applications.

The tension test provides manufacturers with the necessary information for design improvements and quality control since these tests reveal the stress-strain relationships of the material. With this information, decisions can be made on how best to develop a product or purposely engineer a material for a specific application. Such considerations must be made in many industries-from construction to automotive-making sure the product really does meet its performance requirements.

Tools and Equipment for Adhesive Strength Testing

Universal Testing Machines

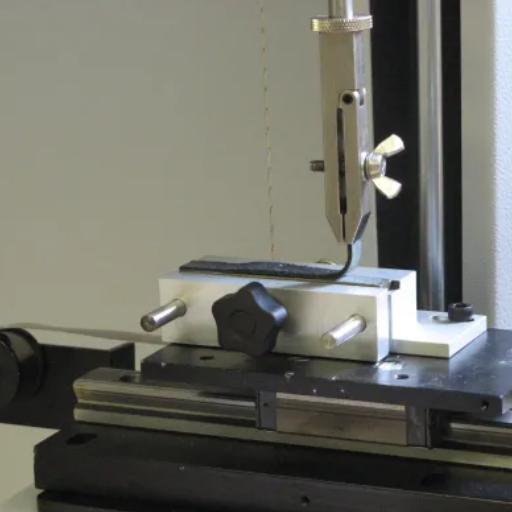

The Universal Testing Machines are considered as the vital instruments to measure the mechanical properties of materials, including forces acting between adhesives. These machines subject materials or bonded components to a series of stresses involving tension, compression, or shear force, in specified conditions, and seek to determine their capacity to resist stresses. Such pieces of information regarding adhesives are useful to engineers and researchers to confirm that products meet the required specifications for strength and durability.

In a setup using a UTM, a force will be steadily applied on the specimen at different possible speeds, and the specimen will be made to elongate until it fractures or yields plastically under the tensile stress. Universal testing machines are highly adaptable in that, depending on the setup and parameters, they can be used for tensile strength, peel, and shear resistance testing. This makes them highly valued in construction, aerospace, and consumer goods industries.

Results from UTMs enable very precise testing of adhesives under conditions approaching the real-life application of the adhesive. This is an essential step in ordering the further development of adhesive formulations, optimizing the product designs, and ensuring safety and quality. The universal testing machines, providing reliable and repeatable results that are used in product development, hence act as a landmark in the development and testing of adhesive solutions for varied applications.

Specialized Probes and Accessories

Quite specialized are these probes and accessories, since they make sure that adhesives are tested accurately and efficiently. They are designed to impinge upon testing precision by varying requirements for different applications of adhesives. Custom grips and fixtures, for instance, may be used to hold certain materials or test substrates firmly and consistently, regardless of the use of the adhesive or testing environment.

Key Accessories Include:

- Environmental chambers for temperature and humidity testing

- Custom grips and fixtures for different materials

- Specialized probe designs for peel, tensile, and shear testing

An environmental chamber provides another important site-setting accessory that is used to test adhesives in accordance with ambient air temperature and relative humidity. This concept is important to find out how adhesives behave in conditions of extreme heat, freezing temperature, or very high humidity. Thereby, by simulating these scenarios, researchers can learn about the durability and reliability of adhesives.

In addition, for peel, tensile, and shear testing, special probe designs must be selected according to the adhesive’s mechanical properties. These probes ensure that within the test, the stress applied is the same as the forces applied on the adhesive in actual situations. This specific accessory makes the test results relevant and reliable, thus fostering the production of advanced adhesives for use in many industries.

Calibration and Maintenance of Equipment

Proper calibration and maintenance of testing equipment assure accuracy and reliability to the results. Calibration involves adjusting the equipment to match or conform to a standard measurement, thus ensuring consistent and exact readings. The calibration schedules should be strictly followed, depending on the recommendations set forward by manufacturers or industry standards. Any sort of deviation from the schedules will render the testing results incompetent.

Maintenance equally ensures a long lifespan of the equipment and keeps it functioning. This includes cleaning the parts after every use, checking the parts for any signs of wear or possible damage, and replacing the damaged parts in case they could affect the accuracy of results. Preventive maintenance ensures that the equipment will not fail in the middle of critical phases of testing.

Calibration and maintenance activities shall consistently be documented in the interest of traceability and compliance. Keeping records will track the adjustment activities performed at certain times and help to comply with industry standards and regulations. Usually, calibration and maintenance activities ensure proper testing and encourage the manufacture of the best adhesives and materials.

Factors Impacting Adhesive Performance

Temperature and Humidity Effects

Temperature and humidity play a great role in the operation of an adhesive. When temperatures soar, they can act to lower the bond strength of any adhesive and this can make them softer or even cause the adhesive to fail. Low temperature, on the other hand, reduces flexibility and bonding performance, especially for adhesives that depend on curing or setting mechanisms. Therefore, it is advisable to work in the best temperature possible to ensure better, long-term performance of the bond.

| Environmental Factor | High Conditions | Low Conditions |

|---|---|---|

| Temperature | Lower bond strength, softer adhesive | Reduced flexibility, poor bonding performance |

| Humidity | Bond weakening, swelling, reduced stability | Brittleness, ineffective adhesion |

Humidity, really; it comes along and does everything to an adhesive: chemical composition, adhesion properties, etc. Mysterious moisture in the air can now weaken bonds, promote swelling, or reduce stability, especially if the adhesive is water-sensitive. Equally, dry air can make a particular type of adhesives become brittle and ineffective. It is therefore wise to bid consideration to the humidity tolerance of an adhesive before application to gauge the suitability of same within the environment.

Then, adhesive bonding is affected by temperature and relative humidity, and for this reason, adhesives must be conserved and applied under conditions recommended by the manufacturers. Adhesion bonding must be performed under proper environmental conditions so that consistency and reliable bonding are present. Also, adhesives designed for specific environmental conditions may improve bonding performance and its life under demanding conditions.

Surface Preparation Techniques

Surface preparation has to be properly done to ensure successful adhesive bonding. The first step involves cleaning the surface so that contaminants such as dust, grease, or oils may not hinder adhesion. Cleaning usually involves wiping with solvents, washing with detergents, or ultrasonic methods. Any cleaning method must be compatible with the substrate and environmental constraints of the adhesive application.

Surface Preparation Steps:

- Cleaning: Remove dust, grease, oils using solvents or detergents

- Mechanical Treatment: Abrasion or sanding for rougher texture

- Chemical Treatment: Etching or primer application

- Protection: Keep surface clean until bonding

The surface may then require mechanical and/or chemical treatments that improve its adhesion properties. On the mechanical side, abrasion or sanding creates a rougher surface texture that is more suited for adhesive bonding. The chemical approach to surface treatment involves etching or the application of primers that modify the surface chemistry for better bonding. These two types of treatments are an added layer of security toward a durable and long-lasting bond.

Finally, it is vital to keep the surface clean for bonding. The surface, even when prepared properly, can lose its capability of accepting the adhesive in situations where moisture, dust, or any environmental factor affects it. Hence, it is wise to keep the surface clean or protected right until the time for adhesion. This guarantees consistency and reliability in bonding procedures.

Material Compatibility Considerations

Adhesive selection depends on material compatibility, which goes by the end of the bonding process ensuring: while knowing special properties of adhesive and the material subject to bonding will guarantee their working together in different situations. The factors to consider are surface energy of the material, porosity, and its reaction to the adhesive. For instance, if a material has a surface energy that is high like that of metals, it may go into bonding very well; whereas, the materials with low surface energy like plastics may need a primer or special adhesive.

The environment is a key compatibility factor. Adhesive properties change depending on the temperature, relative humidity, and chemicals to which they are exposed. When evaluating these stresses, the adhesive should resist them so bonding will last strong into the future. The heat-exposed substances usually need adhesives protecting against heat, while moisture-environment substances need adhesives that resist moisture.

Before full-scale application, testing is crucial to confirm compatibility. Very small trials and lab testing can find potential problems such as poor adhesion or unpleasant chemical interaction. By solving compatibility problems beforehand, users will improve the bonding strength and optimize the performance of the adhesive systems.

Best Practices for Accurate Adhesive Testing

Proper Calibration of Equipment

Properly calibrating equipment is a step in adhesive testing that ensures reliable and consistent results. During calibration, all measuring instruments and testing machines are checked to verify that they provide accurate data regarding the adhesive performance. In simple terms, it is all about comparing the measurement of a piece of equipment with a known standard and adjusting it to remove any discrepancy.

Calibration is carried out at intervals with proper documentation. The time interval is contingent upon the type of equipment and the extent of its use. The machinery used those times very often would need to be calibrated frequently, considering the wear and tear. You should base your parameter on your manufacturers’ recommendations and the widely accepted standard in the industry.

Calibration, if not handled correctly, would give rather erroneous results; thus, only trained calibrators should be engaged. Certified calibration tools and professional services should be used whenever possible to improve the reliability of the result. By keeping their calibration methods tight, the users can rely on accurate and repeatable adhesive testing, thus better Decision-Making and Product Outcomes.

Consistent Testing Protocols

A reliable adhesive test comes with its requirements for consistent protocols to ensure that the results are accurate, precise, and reproducible. By setting consistent procedures, the same test is carried out under predefined conditions to eliminate variables created by human errors or ambient conditions. Users of these procedures are then assured that the results are comparable over time and across different adhesive batches.

Establishing a common ground for testing would mean that all relevant conditions such as temperature, humidity, and substrate preparation be kept constant. Any of these variations would bring about variability in the adhesive performance. Thus, it is important to document every step of the operation so that in the future, all personnel will be subjected to the same guidelines, thus standardizing the practice among groups or even facilities.

Testing equipment personnel should come under intensive and regular trainings in conjunction with thorough proficiency testing. Greater are the adherence and understanding of the agreed methods by the testers; lesser are the chances of discrepancies to occur. Also, periodic review and modification of testing procedures should be made to conform with the current industry standards and best practices for the good of general reliability and quality of adhesive products.

Data Analysis and Interpretation

Meaningful interpretation of data is imperative to ensure the trustworthiness of any adhesive products. Test results can be used to analyze adhesion strength, endurance, or performance in various scenarios. Emerging trends can then be examined to ask if the product is of adequate quality to be dispatched to the user. Statistical tools such as standard deviation or mean analysis can be used to cross-check across batches and reveal deviations worthy of further scrutiny.

Insights should be derived reliably while gathering the data in an orderly fashion with thorough scrutiny maintained over them or other environmental aspects such as temperature and humidity that may impinge on adhesive performance. Results should be confronted with predetermined benchmarks to establish whether quality control requirements were met. Whenever there is a departure from anticipated values, immediate action should be taken, and areas of re-examination may include raw materials or possibly testing procedures for potential errors.

Decision-making is facilitated by presenting findings clearly and concisely. Summarized results with charts and other aids would hasten the interpretation of salient traits or issues. Recommendations arising from the data must be pragmatic and workable so that the process may be improved or the formulation adjusted. Thus, highlighting one more time that complete analysis and good communication upon which to base it will continue to guarantee whatsoever reliability and quality in the adhesive products.

Frequently Asked Questions (FAQ)

Q: What is the best method to measure adhesive strength by means of tests?

A: The test method for adhesive strength differs according to the actual application and the type of adhesive used. Some commonly used methods are peel tests for a flexible bonded to rigid specimen, lap shear tests, and standard test method for tensile strength. Each test method yields a different kind of information concerning the strength properties of the adhesive and substrate.

Q: What sort of strength is measured from adhesives?

A: Strength testing can be carried out on various types of adhesives including structural adhesives such as epoxies and polyurethanes as well as on pressure-sensitive adhesives. To accurately measure strength properties and determine performance in diverse conditions, different adhesive testing methods may be called upon.

Q: Why is shear strength important in testing adhesive qualities?

A: Shear strength tests in adhesives are paramount to understanding indicators related to an adhesive’s power to resist forces acting parallel to the bond line. This strengthens the selection of an appropriate adhesive where lateral forces in the application are expected, so they will be able to form strong adhesion under stress.

Q: How do pull-off adhesion testers work?

A: Pull-off adhesion testers apply the force perpendicular to the plane of the adhesive joint until failure of the joint occurs; thus, direct measurements of strength are obtained and conditions under which failure in adhesion may occur are ascertained.

Q: What factors affect the strength of an adhesive?

The fact that an adhesive’s strength depends on some factors, such as composition, surface preparation, curing conditions, environmental conditions, temperature, or humidity, is well known. Very possibly the greatest strength manifests when the adhesive has been suitably selected and applied.

Q: What are the differences between static shear and dynamic shear testing?

A: A static shear test measures the strength of an adhesive under a constant load, and a dynamic shear test measures the performance of the adhesive when loads and conditions vary. These tests serve to understand how adhesives behave in real-world life scenarios and to discern if the adhesive is considered appropriate to a specific use.

Q: What is the function of viscosity pertaining to adhesive strength?

A: Viscosity plays a great role in its application and performance of an adhesive. High viscosity adhesives may be better for filling gaps, whereas low viscosity adhesives might penetrate and bond better on porous surfaces. Knowledge of adhesive viscosities assists in determining application for maximum strength.

Q: What’s the way to find out the adhesion failure mode?

A: One can analyze the bonding surface after testing in order to identify the adhesion failure. Typical modes are failure cohesion within the adhesive, adhesion failure at the interface, or substrate failure. Understanding the failure can assist in evaluating the effectiveness of the adhesive so as to take informed decisions for future applications.

References

- Forza Built – Adhesive Strength Tests: Common Methods & Analysis

An overview of the three main tests for adhesive strength: tensile, shear, and peel. - Master Bond – How Do We Test the Mechanical Strength of Adhesives?

A detailed explanation of tensile testing and other methods for evaluating adhesive strength. - ADMET – How to Perform an Adhesive Strength T-Peel Test

A guide to various adhesive strength tests, including peel, shear, cleavage, and tension tests. - BDK – How is Adhesive Strength Measured?

A breakdown of adhesive strength measurement using tensile, shear, and peel strength tests.