When it concerns footwear, performance and durability are at the top of the lists, and consumers expect shoes to perform well every time. But then, how would manufacturers ensure that their footwear would otherwise look great and yet hold up under pressure? This comes through lab performance assessment-a capable form of evaluating where shoes are tested under controlled conditions to undergo stress in simulated real-world life for determining their level of quality and resilience. This blog goes into the sciences behind the testing of footwear, focusing on new techniques to measure comfort, durability, and safety. Whether you’re a footwear enthusiast, a product designer, or just an innocent consumer, get ready to discover the rigorous steps involved to ensure your shoes are fit for function.

Importance of Footwear Testing

Ensuring Durability and Safety

The testing of footwear is a crucial step in ensuring durability and safety to consumers. Durability means that shoes can endure prolonged usage under different conditions. Some of the tough methods applied during testing include one-time flex tests and abrasion resistance tests until the ends of the rubber out-coating. These tests represent actual wear through the life cycle of the shoe and they reveal any weakness that might have crept into the build of the shoe, well before it goes into the markets. If the shoes are tested for durability, the users are kept in mind so that they eventually get to use the shoes which have stood against time.

Safety means the vulnerable wearer has been protected from harm during use or use. Slip resistance testing makes certain that footwear provides proper traction to resist slips and falls, more so under wet conditions or uneven conditions. Impact resistance and puncture resistance are other ways of preparing the footwear for hazards that may take place but may not always be detrimental to wearer safety. It is this safety consideration that becomes extremely important when you would like to make footwear for specific environments, either a work area or outdoor activities.

In concert, both testing for durability and safety are factors that go into customer satisfaction and create trust among customers for the product. With proper testing, a shoe Lifetime would be longer, and performance would be dependable and protective of the product. This helps greatly in reaching consumer expectation, and thus compliance to regulation standards can be used to back testament on behalf of the manufacturer for their commitment to quality assurance. Due to the implementation of these testing criteria, consumers shall feel assured and full of confidence while purchasing their footwear.

Impact on Consumer Satisfaction

Customer satisfaction is increased by proper testing and quality standards. When tested rigorously for way of durability, comfort, or application, the customer feels certainty about the product quality. Customers returning to brands that always stand the test of reliable, good-performance shoes are because of their confidence that the purchase is exactly or better than satisfying their expectations.

This testing that meets customer requirements also earns customer loyalty and gives rise to positive word-of-mouth. Customers who are happy will tend to recommend the products to their friends and relatives, which just adds to the manufacturer’s good name. Any experience for the customer where expectations match product performance will, for sure, reduce returns or complaints, thus increasing positive brand exposure.

Ultimately, long-term sustainment of customer relationships by claiming compatibility with high standards put forth in the test. When customers feel that their needs are taken into account and quality is firm, they trust the manufacturer and hence support their products. This trust helps build consumer satisfaction and brand endorsement growth and success.

The Role of Footwear Performance Testing in Brand Credibility

One of fashioning itself a brand has been the performance testing of shoes, in other words, it assures the quality, durability, and safety with which the product is made. The tests ascertain a host of factors such as comfort, shock, water resistance, and durability enough to reassure the consumer that the shoes would perform well under varying conditions. In time, the consistent performance of the product builds credibility for the brand.

Curtailing product failures remains one of the main aspects of performance testing. When footwear undergoes strenuous tests before the product hits the market, problems such as early wear or operational defects are detected and rectified. This avoids a negative customer experience, reduces returns, and also brings down complaints. The brand thus becomes synonymous with reliable quality in the customer’s view, and they are likely to remain loyal and make repeated purchases.

Revealing the results of performance tests also serves as a testament to the company’s commitment to quality and customer delight. By sharing relevant records indicating the product had undergone tests for durability or met industry standards, consumers feel assured about their purchase decision. Eventually, the continual presence of such transparency would see the brand rise among all competitors, fortifying its credibility and guarantee long-term growth.

Key Aspects of Performance Testing

Evaluating Flexibility and Comfort

Flexibility and comfort are the key criteria in footwear performance testing to ascertain how well a shoe adapts to natural movements of the foot and aids the person carrying out the activity in question while in use. Flexibility tests consist in ascertaining how easily the sole and upper materials bend, stretch, or move under several situations. These shoes generally feel more comfortable and result in better performance, mainly if the wearer is involved in any form of physical activity, as they allow the natural movement of the foot to take place and maintain their own structural integrity.

Comfort or lack thereof is tested through-while-test; the wearer gives information about cushioning, fit, and support to the foot that can reduce fatigues or injuries. There is about good cushioning to absorb shock, steady yet giving fit, that offers stability. This type of comfort also depends on how adaptable the path is to different foot shapes.

Flexibility and comfort tests emulate real-life examples, allowing manufacturers to solve problems before the products hit the market. Test results guarantee consilience that would help brands in further tailoring designs and materials for better footwear that really serves the needs of consumers. By giving priority to these two areas, the company can promote their consumer base’s satisfaction and convince them of their reliable performance.

Assessing Breathability and Water Resistance

The breathability of a footwear concerns the extent of water management and air circulation with which it keeps one’s feet dry and comfortable during wear. During breathability tests, manufacturers determine how quickly water vapor escapes through the material from which the shoe is made. Indeed, the more any shoes encourage breathability, the less they allow for sweat build-up, which creates odors and reduces comfort when wearing for a long time, especially during hard or warm weather.

In the case of water resistance, the ability of a shoe to resist penetration of water is tested. This process involves exposing a shoe to set quantities of water and evaluating how well the materials repel moisture. Water resistance does wonders for soaking the feet in wet terrain, the durability of the shoes, and keeping the wearer comfortable when the skies change.

Focusing on testing for both breathability and water resistance will give manufacturers the best compromise between a shoe that is comfortable and protecting, thereby ensuring footwear that suits a bagful of activities and attracts varying weather conditions with consumer needs and maximum performance.

Testing Slip Resistance and Safety

Slip resistance is one pivotal parameter that must be tested to verify the performance of the footwear, as this directly relates to the safeguard of the wearers and their confidence on different surfaces. The testing of slip resistance considers checking the capability of footwear to hold on to slippery surfaces under conditions such as wet, oily, or uneven; usually, some standardized tests known to mimic real-life situations are employed to check if the shoes really aid in reducing slipping and falling.

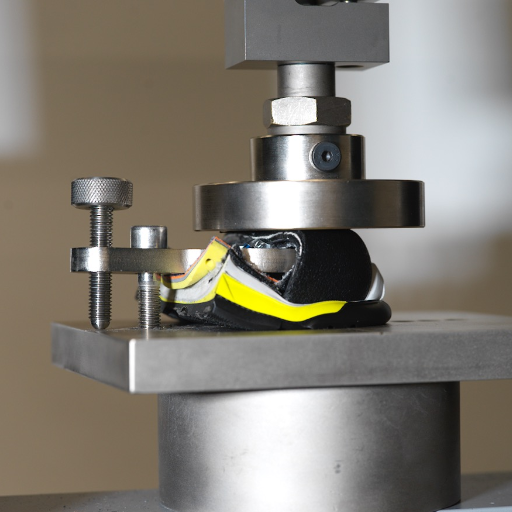

These safety tests also assess the structural soundness of footwear. This may check if, for example, the shoe sole thicknesses, the tread designs, and the general solidity of shoes can support proper stability. It may even test the abilities of the shoes to absorb and lessen shock, especially for activities where the wearer constantly hits hard surfaces down there. These are all working together to guard against injuries like spraining or fractures by offering better protection.

Depending on the rights of the footwear, the slip resistance and safety testing will ensure testing of the performance standards; these include, be they workplace, outdoor activities, or just a walk in the park tests, provide an excellent opportunity for manufacturers to work towards consumer safety and reliability. Customers depend on these test results while making their choices, knowing that their footwear should have their safety assured in various situations.

Common Test Methods in Lab Testing

Wear Testing Techniques

Wear testing is the integral part of evaluating footwear performance where the assessment is made of how shoes hold in actual-use conditions. It focuses on durability, comfort, and practical functionality during use of an extended period. Typically, footwear is worn by test participants in an environment that closely simulates normal activities, such as walking-grading scenarios, running, or hiking-so that any potential flaws in materials or design can be exposed and rectified by the manufacturers.

Such testing may involve control trials where participants are engaged in giving feedback with regard to aspects of fit, comfort, and general performance, while tread wear, sole flexibility, or material degradation measurements are taken objectively, thereby either attesting to or diminishing the safety and quality standards the footwear is supposed to adhere to. These are very critical tests, especially when dealing with shoes made for special environments, be that workplaces or sports.

Thus, from the wear testing, manufacturers decide on design and materials likely to improve product performance and build consumer confidence. In return, by resolving issues highlighted during wear-testing, brands can provide footwear that fully meets the user’s needs in myriad settings from typical wear to more demanding terrains.

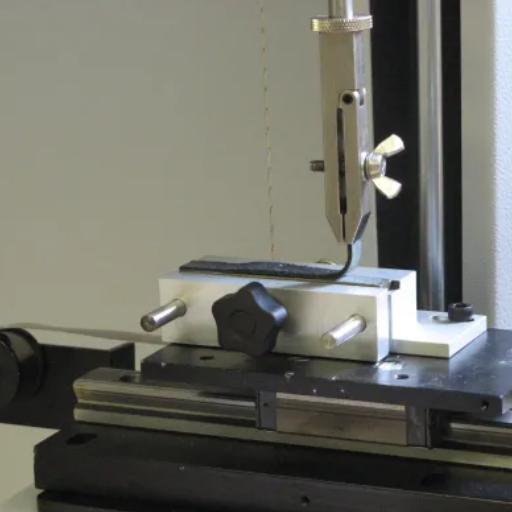

Materials Analysis Procedures

Materials analysis is a necessary phase in footwear performance testing for ensuring that the materials used satisfy the parameters of use or wear with regard to durability, flexibility, and comfort. Generally speaking, it entails the evaluation of the physical and chemical characteristics of materials to check their suitability for the required application. Tests may go on to measure tensile strength, abrasion resistance, or elasticity conditions in bioprobes, giving an indication of the performance of the footwear in different conditions.

Environmental tests promote the understanding of how materials would react to moisture, heat, or UV-radiation. Testing is needed to longevity the materials for both everyday and extreme environments. Manufacturers use this mode even in simulated environments of heat or water for extended full exposure so that the weaknesses in any design arrangements may be fixed prior to setting.

Materials analysis will also involve determinations toward safety/environment check tests. It assures that no harmful or hazardous substances exist in footwear and that the standards binding to them must protect consumers and the environment. Through good material analysis, manufacturers adhere to enhanced levels of performance and quality that will produce consumer satisfaction.

Advanced Laboratory Simulations in Footwear Performance Testing

Advanced laboratory simulations ensure footwear manufacturers offer the best of performance and durability. By simulating actual scenarios, the footwear performance under different extreme conditions such as varying temperature, moisture conditions, and repeated stress is studied. The weak points in the design or the materials are identified, and potential failure is looked into before the product goes out into the market.

Resistance to wear is one test; walking and running cycles are simulated to study how the materials of the sole and upper behave with time. Then there are tests on traction as well, which measure the grip over different surfaces for safety and stability. Tests for water resistance or breathability are also done, so the shoe is comfortable to wear in any environment. These are necessary to ensure the quality is maintained consistently and the consumer can trust these products.

Design improvements, material selection, and life predictions are made possible through rigorous simulation tests. This greatly reduces risks to end users and helps meet safety and environmental compliance criteria as well. Advanced techniques thus guarantee the functionality, durability, and satisfaction of the consumer while also ensuring that the industry is focused on sustainability and innovati

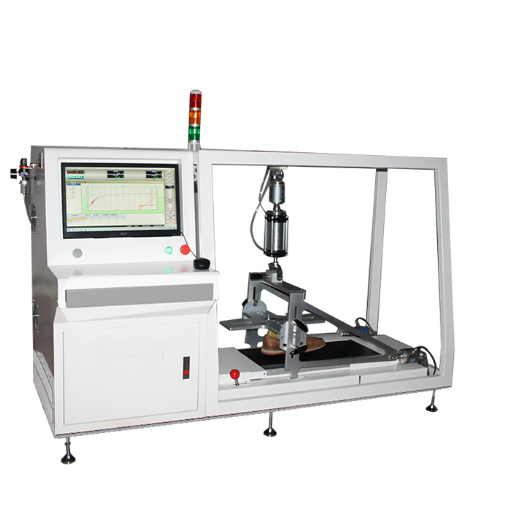

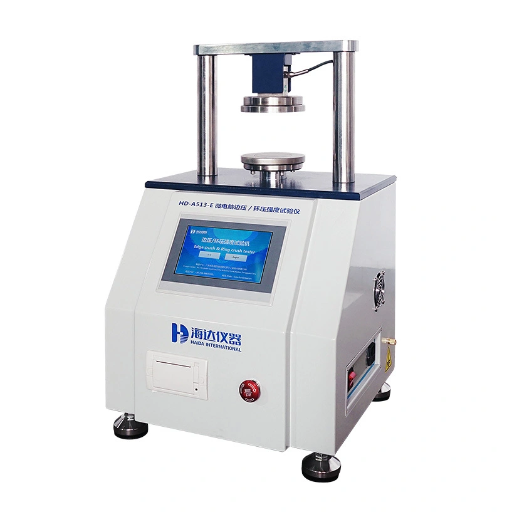

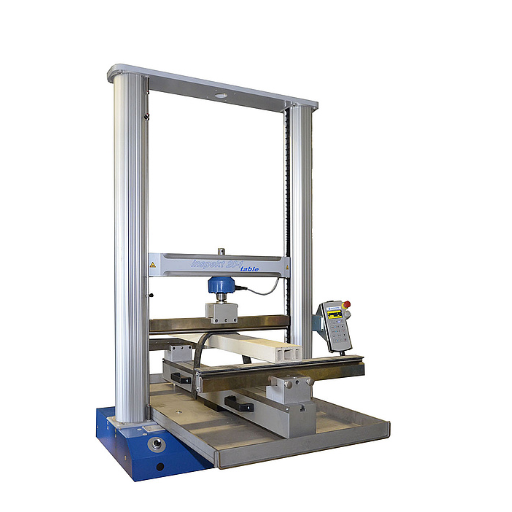

Footwear Testing Equipment

Essential Tools for Performance Testing

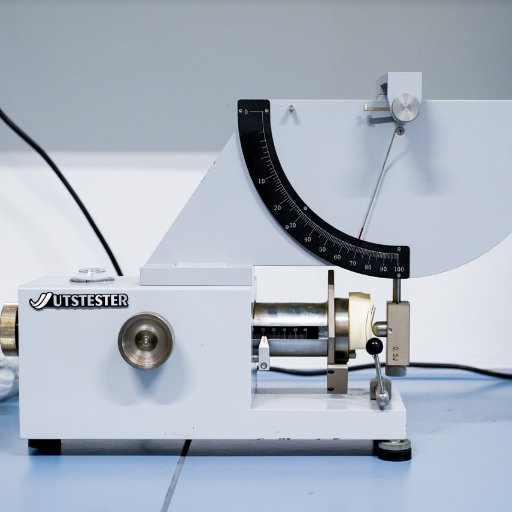

Performance tests of footwear are carried out using such equipment that looks at the different aspects of durability, comfort, and safety. All these simulate forces experienced in real life through running, walking, jumping, etc., to ensure that footwear withstands regular wear-and-tear while maintaining quality. For example, flexing testers perform flex tests on materials to resist cracking, making these materials reliable for a long time. Another part of the equipment is the slip resistance tester, which checks the traction of shoe soles against various surfaces. Preventing slips and falls on slick, wet, or uneven terrain is vital. Comfort tests include cushioning and arch support tests for sneaker insoles to guarantee user satisfaction. Environmental testing chambers would see how the shoes had fair weathering by temperature, humidity, and UV insult, guaranteeing that shoes remain functional under differing climatic situations and their structure. Thus, these tools go a long way in carving top-notch, safe, and comfortable shoes worthy of all purposes.

Innovations in Testing Technology

From the point of history, anything may have seemed obvious or rather traditional. Nowadays, with this advancement in technology applied to footwear engineering testing, utmost precision and reliability are achieved. One of the major breakthroughs in modern times was the introduction of artificial intelligence into the testing systems. AI-based systems will sift through innumerable performance data results derived from wear trials and laboratory tests to analyze durability, comfort, and effectiveness with perhaps more precision than conventional systems, thus affecting the overall market testing timeframes and rapid prototyping enhancements.

Another critical development is the introduction of wearable sensor technology within the world of footwear testing. These sensors will be attached to the shoes or are placed on the test participants themselves to collect real-time data on pressure, gait, and impact. Hence, the manufacturers can know exactly how their shoe would work under various conditions and for different user profiles. Such data-driven design approach may be utilized for jetting the design toward ergonomics and injury prevention.

Lastly, material simulation tools have improved practical predictions considerably during testing. These virtual testing technologies help in addressing how various materials interact under stress, strain, or environmental conditions even before building the first physical prototype. This helps in reducing wastage of materials and development cost, fast-tracking the adjustments and, thereby, ensuring that the final product meets the relevant performance parameters that are very high. Hence, these technologies offer the very base for safer, functionally better, and higher performing footwear suitable for almost any purpose.

Choosing the Right Equipment for Safety and Performance

Testing equipment is the very foundation, and its selection is paramount when safety and performance of a shoe are to be assured. Footwear performance testing measures a variety of attributes required for safety and function: durability, grip, flexibility, and cushioning. Reliable testing equipment will analyze the shoe’s response to stresses, temperature variation, and repeated wear, all of which define performance and safety for the user.

Choosing the right equipment depends on the nature of tests required for a particular category of footwear. Athletic shoes might be tested most rigorously for shock absorption and traction, whereas work boots would be tested mainly for slip resistance and strength. The manufacturer would mostly want the equipment that prints out the most accurate and consistent results. Equipment with the simulation of real lifelike conditions would help gain insight into the performance of footwear over a period of time.

The last way of selecting testing equipment would be the ease of use and adherence to industry standards. Equipment that is easy to use and conforms to accepted safety guidelines will produce a result that is accurate and meets the regulatory requirements. Versatile and reliable testing equipment will enable the manufacturers to build footwear that comfortably, safely, and efficiently balances performance attributes.

Industry Standards and Regulations

Overview of Standards for Footwear Testing

Industries develop testing standards to ensure effective safety, convenience, durability, and function of footwear. The standards concentrate on the intertwining factors of slip resistance, tensile strength, abrasion resistance, flexing endurance, and impact absorption. By following these standards, manufacturers will be able to provide footwear matching consumer requirements and legal or regulatory prescriptions.

Slip resistance is considered to be an important one among the areas of footwear performance testing. These standards, such as those from ASTM or ISO, provide methods to test the frictional properties of soles under various surfaces to ensure that the footwear will minimize the chances of slipping and falling, important considerations for occupational and day-to-day footwear.

Another shoe performance test is durability, checking for abrasion resistance and flexing endurance. This test method simulates various wear over time, for instance bending and scuffing of materials repeatedly. This makes sure that the footwear withholds everyday use without compromising its structural integrity or comfort. In conformance with these standards, manufacturers will now be in an advantageous position to produce their shoe in good looks, decent comfort, and everlasting performance.

Compliance with SATRA and Other Organizations

SATRA, among other recognized bodies, plays a key role in setting international standards for footwear performance testing. These specifications need to be adhered to so that the final product satisfies safety norms, durability, and comfort requirements, thereby benefitting both manufacturers and consumers. Accordingly, companies that show adherence to such regulations demonstrate their commitment to high standards of footwear production that meets global expectations.

The conformance to such standards requires the procedure of stringent testing with respect to several performance parameters, which includes, but is not limited to, abrasion resistance, slip resistance, durability, and structural integrity. Organizations such as SATRA provide the testing procedures and certification required to prove that a particular footwear design will perform in real-life situations. This ultimately aids manufacturers in developing better products and instills greater confidence among consumers about the product quality of consistently high standards.

By conforming to the requirements of SATRA and similar organizations, manufacturers can better access the world markets, as certification guarantees acceptance of products by different regions, thereby facilitating easier exchange at the international levels. Compliance further gives rise to competition as companies endeavor to meet and better their standards, negatives superstar of which is footwear safety and durability for consumers across the globe.

The Role of Retailers in Ensuring Quality

Footwear retailers who uphold high standards for quality select only those products that meet the criteria of safety, durability, and performance. Collaborating with manufacturers who are adamant about harnessing the strictest test methods and ensuring compliance with international standards, retailers can guarantee that their footwear satisfies consumer expectations for reliable performance under varying circumstances. This emphasis on rigor increases user confidence, while noncompliance leads to faulty products being thrust on unsuspecting customers.

So, it is imperative that retailers ascertain that the products of footwear they source have indeed been through proper performance tests. Slip resistance, impact resistance, and durability tests, among others, are methods intended to ensure that the products satisfy the consumer’s practical needs as well as comply with legislative requirements. Often, the retailer will insist on third-party certification or reports from organizations such as SATRA to substantiate the claims of safety and quality, thereby fortifying the standing of their offer, while at the same time limiting their liability.

Furthermore, the retailer acts as a vital feedback channel between consumers and manufacturers. Through the gathering and subsequent analysis of customer complaints or reviews, retailers and manufacturers can identify common concerns, such as defects or performance-related issues, and relay this information for improving the quality of future products. The joint efforts of the retailer, manufacturer, and testing organizations ensure continuous improvement in footwear performance that ultimately benefits the consumer.

Frequently Asked Questions (FAQ)

Q: What do we mean by performance testing of footwear?

A: Performance tests of footwear cover a series of assessments that measure the capacity of a shoe to protect under the simultaneous criteria of safety, durability, and functionality. Thus, testing ensures that the shoe conforms to specifications and protects the wearer during use.

Q: Why are resistance tests for footwear important?

A: Resistance tests for footwear are important as they determine the resistance of a shoe against numerous conditions like wear or tear, abrasiveness, or abiotic components. They determine the overall durability and reliability of the footwear, thus ensuring the product is consistent in quality.

Q: What kind of performance tests are applied to footwear?

A: Performance tests commonly include strength testing, slip resistance testing, and water resistance testing. Each distinguishes a certain parameter like how well the outsole can grip a surface under certain environmental conditions or whether the shoe upper resists the penetration of water.

Q: How do the testing labs run performance tests on footwear?

A: Testing labs use specialized machines to perform performance tests on footwear; for example, they use durometers to measure the hardness of materials, calipers to measure the size of the shoe, or clamps to test the stiffness of the outsole and midsole.

Q: What role do footwear brands play in performance testing?

A: Footwear brands play an important role in performance testing by ensuring the products are tested to meet the standards of the industry, typically via cooperation with the testing institution. They usually specify the material and design to be used in their footwear before testing for resistance and durability is carried out.

Q: How does having more shoe sizes affect performance testing?

A: Different shoe sizes might significantly affect how the footwear is fitted and hence how it performs during testing. Therefore, testing has to be performed on more shoe sizes to ensure that all customers, in safety and performance, receive footwear that does make a difference.

Q: What is the importance of midsole foam to performance testing?

A: Midsole foam is extremely important for comfort and shock absorption. Performance testing determines if the foam is dense and resilient enough to offer support, based on which it enhances the overall experience of the footwear user.

Q: Can environmental factors fall under performance testing of footwear?

A: Yes, indeed performance testing could have environmental factors such as room temperature or humidity. That is especially important when these factors affect materials such as foam and outsoles, and testing under such conditions confirms the footwear performance according to real-world situations.

Q: How does the test evaluate the effectiveness of the heel counter?

A: The test evaluates the effectiveness of the heel counter in conferring stability and support by measuring the stiffness and resistance to deformation of the heel counter under load so that the wearer is protected through that heel area during different activities.

References

- SATRA – Performance Footwear Testing

SATRA offers services to assess the comfort and performance of footwear materials and constructions. - QIMA – Footwear Laboratory Testing for Safety & Performance

A guide to laboratory testing methods for ensuring the quality and safety of footwear. - Framas – Footwear Testing Methods (Part 1)

Details various testing methods, including tensile strength, abrasion resistance, and traction. - Precision Testing – Footwear Testing

A resource for maintaining consistent product quality through comprehensive footwear testing. - Intertek – Footwear Testing Services

Accredited testing services for physical, mechanical, and chemical performance of footwear.