Fatigue testing is the utmost procedure required for ensuring durability and reliability of materials as components may exhibit extraordinary performance under repeated cyclic stress. Be it aerospace, automotive, construction, or any other demanding industrial sector, deep insights into material behavior under fatigue could go a long way toward the difference between proper function and failure. This blog entry explores the fundamentals of fatigue test services and the way they are used in materials analysis and performance optimization. Here, you will learn about the processes involved in fatigue testing, its benefits, and applications to industry, and why it is still at the forefront of innovation and safety for engineers and manufacturers. Stay with us as we embark on a journey to explore the science of fatigue testing and contribute to a sturdy future.

Understanding Fatigue Testing Services

What is Fatigue Testing?

Testing for fatigue explains how materials behave when subjected to stress or strain for repeated cycles across time. With loads that change with time, the process subjects a material to varying real-world occurrences, thereby testing its weakness and reliability prior to failure. Such a test is paramount to investigate and understand the material lifespan and behavior under use for long periods or for repetitive use.

A fatigue test subjects certain samples to a cyclic loading with controlled parameters in terms of stresses, whether tension, compression, or bending. These stresses are periodically applied to the test specimen in order to reproduce service conditions which a material could experience in its intended application. Results obtained from fatigue tests furnish important knowledge about the fatigue limit of the material, meaning the maximum stress that the material can tolerate during a certain amount of cycles before cracks appear or failure occurs. Engineers and designers employ this information to guarantee safety, to optimize designs, and to prevent catastrophic failures in structures, such as bridges, automotive parts, and aerospace structures.

Since fatigue testing deals with ensuring safety and reliability, it is thus placed in critical industries. Any improvement in the material, design, or manufacturing process is handed down to fatigue testing through earlier determination of weaknesses and failure modes, as this reduces the cost of long-term maintenance. It is invaluable for making transportation, energy, and construction produces of better materials and constructs: stronger, safer, and more durable.

The Importance of Fatigue Test Services

Fatigue testing seeks to quantify the endurance and integrity of materials and structures under repetitive stresses. These tests simulate real-life conditions by placing cyclic-type loads on materials to establish performance characteristics as a function of time. From the results, potential failure points of a material are known to ensure it does not undergo breakage or become unsafe for prolonged applications.

By pinpointing early-stage weaknesses for corrective measures, fatigue tests ensure the safety and reliability across different sectors like aerospace, automotive, construction, and energy. From a gross application standpoint, this knowledge will test and push the limits of materials for designs, stronger, more efficient, and time-intensive. This, in turn, translates into performance enhancement with a reduction in the risk of adverse instances occurring in crucial applications.

Fatigue tests statistically increase cost-saving through appropriate material selection and better manufacturing processes. The identification of the failure modes as early as possible would later stave off an expensive repair, replacement, or recall. In the end, fatigue testing tends to ensure the product meets not only regulatory requirements but also consumer demands for quality and safety, thus acting as a very important aid for modern engineering and design.

Overview of Fatigue Testing Capabilities

Fatigue testing refers to a paramount process that evaluates the resilience of materials or components when viewed through the cyclic loading and unloading of forces along time. It seeks to predict the durability or the useful life of a product so that it could stand real applications. It also points out the weakening or failure of materials, hence allowing engineers to create a safer and more reliable product.

Fatigue-testing capabilities usually involve combinations of stress situations of an axial, bending, torsional, and multiaxial nature. Testing should also take into account the combination of forces and motions to which the product is going to be subjected in-service. Advanced instrumentation in fatigue testing can record very accurately, parameters like load cycles, deformation, and stress-strain behaviors, which are of great help in characterizing materials and carrying out lifecycle analysis.

With fatigue testing incorporated into the design and manufacture process, the businesses are better placed to ensure product quality, prevent sudden failures as well as comply with industry-established requirements on safety and performance so that their products remain serviceable in extreme working conditions. This builds customer confidence and satisfaction.

Types of Fatigue and Their Implications

High Cycle Fatigue vs. Low Cycle Fatigue

| Aspect | High Cycle Fatigue (HCF) | Low Cycle Fatigue (LCF) |

|---|---|---|

| Stress Levels | Low stress levels | High stress levels |

| Cycles to Failure | Often exceeds 10,000 cycles | Fewer than 10,000 cycles |

| Common Applications | Turbine blades, fasteners | Engine components during startup/shutdown |

| Failure Origin | Micro-level defects growing progressively | Plastic deformations under high strain |

High cycle fatigue and low cycle fatigue are the two main types of material fatigue, distinguished by cycles to failure and associated stress levels. HCF usually occurs at low stress levels where the material survives a high number of cycles that often cross 10,000 cycles. This phenomenon is common in components subjected to repeated minor stresses, such as turbine blades or fasteners. Failure in HCF mostly comes from micro-level defects, which grow progressively over time.

LCF, on the other hand, occurs when operating under high stresses or strains that can create the required plastic deformations. This type of fatigue occurs at few cycles for failure-greater than 10,000 cycles, with respect to displacement. Examples of LCF would include a significant stress alteration, as in engine components during startup and shutdown. As there’s a higher level of strain imposed on the material, LCF proceeds faster than HCF.

It is essential to underscore the varied operational environments that define these fatigue types so that component design can be targeted for specific conditions. Fatigue testing provides endurance limits for high-cycle fatigue and strain limits for low-cycle fatigue so that manufacturers have some idea as to durability and potential points of failure. This information assures safety, reliability, and performance in crucial job scenarios.

Cycle Fatigue: Definitions and Examples

Cycle fatigue refers to any form of degradation or failure produced in a material as it gets subjected to repeated loading and unloading. This happens over time as materials become subjected to repeated stress cycles, generally below their ultimate strength, eventually causing cracks or fractures. Invariably, the failures in many components across various industries are because of fatigue, and so the need to understand it and test for it arises.

Real-World Examples of Cycle Fatigue:

- Metal components subjected to vibration

- Fluctuating air pressures against an aircraft wing

- Bridge under various traffic loads

- Rotating machinery components

These repetitive loads would create microscopic flaws in time, which if left untreated, shall develop into cracks. Testing for fatigue involves subjecting materials or components to cyclic loads, mimicking real-life scenarios to determine their time of service.

This process of fatigue testing aims to serve in predicting the timing and nature of failure to allow for the engineering of safer, more long-lasting products. Thus, such stresses as might be exerted on components under practical working conditions are simulated in fatigue testing by means of rotating bending or axial loading tests. Such tests are necessary for establishing a safe limit for operation so that materials and structures can perform to a satisfactory level with reduced chances of failure occurring unexpectedly.

Fatigue Testing Methods and Techniques

Common Fatigue Testing Methods

Fatigue testing is crucial in determining how materials or components behave under repetitive loading and to find out their limits under cyclic stresses. The most common types of fatigue testing are rotating bending, axial loading, and flexural fatigue tests. These tests simulate different stress conditions to assess material performance and durability.

Rotating Bending Tests

The rotating bending tests subject the cyclic stresses on a material by means of a rotating shaft or specimen. In this mode, alternating compressive and tensile stresses are generated, which in turn helps to determine how materials withstand repeated bending motions. This kind of testing approach is very effective for actual components such as shafts or beams.

Axial Loading Tests

Axial loading tests simulate load effects applied directly along the length of the specimen by applying cyclic tensile or compressive forces over the specimen along its axis. This type of acting load is mainly assessed in materials intended to be employed in structural applications for determining the levels of fatigue induced by axial forces.

Flexural Fatigue Tests

Flexural fatigue tests try to simulate repetitious bending stresses by placing one load perpendicular to the length of the material. The tests would be appropriate for checking beams and such structures under conditions of flexural or transverse stresses. The stresses are alternatively imposed and released to determine the fatigue limit of the material as well as possible failure under repeated bending.

Associated with every fatigue test is a fathom of information concerning the duration and reliability of materials or components during their unsafe or anticipated load application. They are thus complementary, providing a more comprehensive approach toward the realization of engineering designs having material failure and durability as its challenges.

Stress Testing and Strain Analysis

Performing stress tests and strain analyses in materials under various loads is very significant for understanding their performance and resistance regimes. A stress test deliberately subjects materials or structures to forces in order to identify their limits and the points at which they are deformed or fail. An application of stress test would ensure that materials will be able to resist the stresses that they encounter in their real-world usage without being detrimentally affected in their structural integrity. Strain analysis examines how materials deform under influences of stress. By measuring strain, engineers are able to predict material behavior under various conditions and use that information to optimize materials in their designs.

Key Benefits of Stress Testing & Strain Analysis:

- Safety margin ascertainment

- Material selection optimization

- Design efficiency improvement

- Deformation pattern verification

Safety margin ascertainment is the main function of stress testing. It is the ultimate test of force before a material undergoes permanent damage, after which the construction is designed to be strong yet efficient. Some well-known stress tests are tensile, compressive, and torsional, with each test specific for particular stresses that the materials might be subjected to during actual application. Such tests lay stress on elasticity, yield strength, and ultimate tensile strength that a material might display in order to help an engineer in making a correct choice during designing.

Strain analysis is a method that in a way complements stress testing to verify deformation patterns. Strain gauges or other instruments like digital image correlators are used to check the amount of stretch or compression of a sample when it is subjected to certain loads. It is in fact important for elements subjected to dynamic or cyclic forces, like bridges, aircraft parts, or mechanical gears. While stress testing is often carried out, strain testing is always carried out to ensure that materials are studied for their strength and flexibility to ascertain the safety and long life of engineering applications.

Working with Fatigue Tests

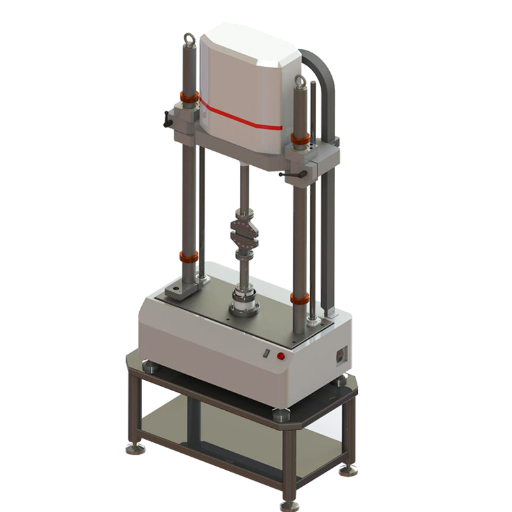

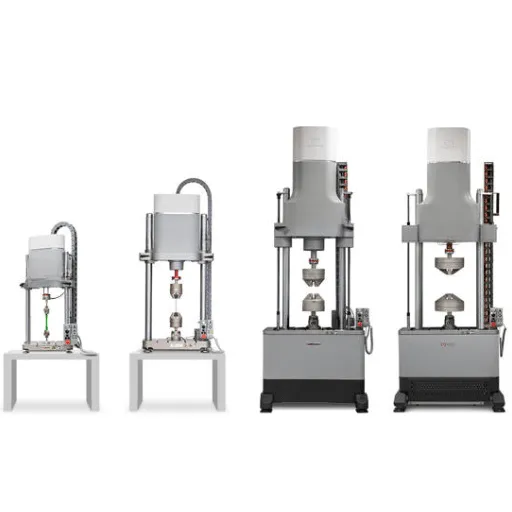

Fatigue testing machines are essential instruments used for evaluating how materials last and perform when recurrent stress or strain is applied. The load being applied on the specimen is alternate: Applying load from time to time so that numerous materials appear to weather building usage in the long run. Due to such dynamic environment, the engineer simulates failure of materials, their improvement, and ensures utmost safety in critical engineering projects.

The most important aim of fatigue testing is to determine the fatigue life of the material, or more simply, the number of cycles the material could endure before breaking. This type of testing becomes essential for components where the warranty is of prime importance: aerospace, automotive, and civil engineering. These testing machines are capable of applying precisely controlled forces, frequencies, and stress ranges on a material and are used to carry out such tests.

Going through fatigue testing provides enormous knowledge to help execute material selection and design. Giving engineers a certain view of a material’s resistance to fatigue lets them decide based on the requirements of contradicting materials, minimize risks other long-term usages pose, and assist in eco-friendly engineering. In general, through approvals related to safety, performance, and reliability in modern engineering applications, fatigue testing machines act.

Testing Systems and Equipment Used

Overview of Fatigue Testing Machines

A fatigue testing machine is a special kind of machine used in evaluating the mechanical durability of some materials under repeated load. Situations are simulated wherein the material might be exposed to fluctuating stresses and strains in real-life applications. With cycles replicated, fatigue testing can be carried out to find out how long a material will last, how it will perform, or where it may fail in the long run.

Fatigue tests exist to shed light on how materials behave during mechanical stress over long hours and to predict behavior in various environments. Such knowledge becomes important in aerospace, automotive, and construction industries, where components undergo severe stress. The testing procedure reveals the formation and propagation of cracks, thus allowing engineers to identify which materials could resist better against particular applications, coupled with diminished risks to life.

Fatigue testing machines utilize a set of more advanced techniques for precise measurement and analysis. Generally, they apply forcing mechanisms with controlled cyclic loading patterns onto a material sample; these could be tension, compression, and bending, or a combination of forces. Observing how the specimen reacts under predetermined conditions is crucial for inferring the study of structure in terms of integrity and its aptitude for time-use. The implication of using fatigue-testing systems lies in enabling industries to improve upon designs for higher reliability, thus maintenance to ensure product lifetime, which, in turn, leads to safer and sustainable engineering processes.

Fatigue Testing Systems and Their Role in Material Analysis

Fatigue testing systems lie at the heart of analyzing materials with respect to cyclic loading. These systems enable one to simulate the stresses that materials may experience under real working conditions during the operational lifetime of the particular product. In other words, fatigue tests determine how long a material will last and how many cycles of repeated stress or strain it can carry within the given conditions before failure. Such information is of utmost importance in the designing of any component in order to meet safety and reliability standards, mostly in aerospace, automotive, and construction industries.

In fatigue testing, the specimen is subjected to controlled amplitudes of stress in alternation between tension and compression, or bending. The data acquired while testing are useful in determining the fatigue life of materials and areas where the crack starts and regions of structural activities where they evolve with time; such data help develop an understanding of failure behaviors toward application optimization with material selection. The advanced testing machines also allow for absolute control and monitoring of the precise testing parameters and provide reproducible results.

The analytics derived from fatigue testing give scientists and engineers avenues to enhance the materials’ performance and also an ability to lengthen the life cycle of the products. By studying the failure of a material with respect to time and under repetitive stress, the industries can work on their safety design, intervention costs, and more sustainable designs. This ensures that the materials can function effectively and reliably in harsh environments and still meet the criteria of performance and sustainability.

Evaluating Composite Materials: Testing Measures

Fatigue testing is a critical tool used with composite materials in their evaluation for durability and performance under cyclic load. The repetitive stresses simulated are considered equivalent to those experienced by materials in service while testing determines threshold stress beyond which failure occurs. Through the application of cycles of mechanical stress, the hood is presented to test fatigue cracking or deformation. The results are critical in learning about material behavior in the long run.

Critical Applications for Composite Material Testing:

- Aerospace components

- Automotive structures

- Civil engineering applications

- Energy sector materials

Fatigue test results enable engineers to establish the endurance limit of composite materials. The endurance limit may be said to be a stress value that a material can withstand an infinite number of cycles without failure. Fatigue tests can include tension-tension, compression-compression, or tension-compression loading associated with practical load considerations. The tests are fundamental to applications wherein the material undergoes constant mechanical strain, such as aerospace, automotive, and civil engineering.

With the assistance of fatigue tests, a manufacturer could take some critical decisions regarding the design and manufacture of composite materials to instill reliability and go further with product life cycles. These data also aid engineers discover ways to optimize the use of materials, go into safety features, decrease maintenance costs, and look for more sustainable and efficient solutions for applications requiring more rigorous service.

Recent Advances in Fatigue Testing Technology

The Role of AI in Predictive Analytics

Artificial intelligence has significantly advanced predictive analytics for fatigue testing, increasing the accuracy, efficiency, and reliability in the assessment of performance. With traditional methods, fatigue tests need the physical observation of the breakdown of the material-looking for weaknesses to show. Depending on parameters, it may take some time until the process is complete. Testing methods can therefore prove extremely resourceful. AI systems use machine learning algorithms to analyze vast data sets, detect patterns and trends, and thus predict the behavior of the materials during cyclic loading, in the absence of heavy-duty physical known tests.

| AI Contribution | Traditional Method | AI-Enhanced Method |

|---|---|---|

| Testing Time | Extensive physical testing required | Reduced through predictive modeling |

| Cost Efficiency | High prototype and testing costs | Lower costs through simulation |

| Accuracy | Limited by physical constraints | Enhanced through pattern recognition |

Using AI in this field allows for the modeling and simulation of fatigue life under many conditions, constituting one of its most significant contributions. Given extensive datasets collected from previous tests or actual applications, an AI system could predict where a part might fail and the life of certain materials according to the stress of operation. These simulations work to lessen the testing time and reduce costs, resulting in the need for fewer physical prototypes compared to regular testing. Moreover, AI also uses continuous learning to ensure that tests stay relevant and apply to new material technologies.

AI provides valuable information about the factors that influence fatigue performance, including stress distribution, environmental interactions, or microstructural imperfections. Knowing this information early, engineers can adopt design improvements or choose better materials before going into production, thus decreasing the chances of failure in vital components. The introduction of AI in predictive fatigue testing is thus a paradigm shift, opening up the possibilities for safer, longer-lasting, and sustainable applications in the aerospace, automotive, and construction industries.

Enhanced Simulation Tools for Fatigue Testing

The increased use of simulation tools in fatigue testing has revolutionized industrial procedures aimed at predicting material behavior under periodic stresses. Engineers are able, now, by using advanced simulation software, to model complex scenarios wherein materials are put to cyclic loading for extended periods of time. The software uses mathematical algorithms along with databases containing material properties to provide very accurate forecasts of probable failure points in a material. In so doing, the possibilities for extensive physical testing are minimized, hence reducing cost and time in the design phase.

Key Advantages of Enhanced Simulation Tools:

- Modeling complex real-life operating conditions

- Introducing parameters like load frequency and temperature variations

- Evaluating multiple design iterations rapidly

- Reducing material wastage and energy consumption

Simulating the real-life operating conditions is one such striking benefit of the tools. By introducing parameters such as load frequency, temperature variations, and environmental effects, a simulation can closely replicate a service environment. This means the materials and designs will get subjected to tests for reliability under different conditions before being sent to the production stage. Moreover, the simulation can evaluate numerous iterations of a given design within a short period, thereby helping engineers maximize the durability of their products.

Sustainability and cost-effectiveness are also ensured by simulation technologies. With fewer physical prototypes being required, industries can reduce the wastage of materials and energy consumption inherent in conventional testing methods. Early detection of potential weak points prevents costly recalls or repairs once the products have been deployed. Using such technologies thereby upholds a spirit of good, safe, efficient, and environmentally sustainable practice across industries like aerospace, automotive, and civil engineering.

Fatigue Testing with Smart Sensors

Fatigue experiments test materials to understand their behavior under cyclic loading, with durability and the time to failure as factors of concern. Smart sensing optimizes the process by supplying real stress, strain, and deformation data. These sensors can capture the slightest variations in material reactions, thus enabling accurate pinpointing of probable areas for fatigue failure. Based on data collected by the sensors, engineers can choose to modify the material or improve the design.

Real-Time Monitoring

Continuous data collection during tests with minimal manual input required

Early Detection

Spot pre-catastrophic anomalies to prevent sudden failures

Automated Testing

Speed up tests and maximize efficiency with automated processes

Also, smart sensors give an opportunity for continuous monitoring during tests, thereby alleviating manual input of data. Owing to its real-time capability, it allows for increased accuracy in results because full detail is recorded over the entire cycle of testing. On the other hand, pre-catastrophic anomalies in material performances can be spotted early so as to avoid possibilities in future of either catastrophic and sudden downtime in applications.

The automated tests can valiantly apply smart sensors to speed up the tests and maximize efficiency while performing fatigue tests. These sensors track analyze how a performance change occurs under varying conditions for the development of materials and systems used in industries like construction, transportation, and energy. Clearly, the sensors bestow a complete fatigue testing framework, which receives reliability and minimize errors and inculcates sustainable practices with them.

Frequently Asked Questions (FAQ)

Q: What is material fatigue testing?

A: It is a kind of mechanical testing that evaluates the fatigue behavior of materials under fluctuating loads. This testing is concerned with how materials withstand repeated stress cycles that can inflict fatigue damage with time.

Q: How does material fatigue testing determine fatigue strength?

A: Fatigue strength is determined through fatigue tests, such as a cycle fatigue test, where the material is tested for the ability to withstand a given stress for a given number of cycles. The results are then often put onto the S-N curve, which shows stress (S) versus the number of cycles to failure (N).

Q: What types of fatigue tests are commonly conducted on metallic materials?

A: Fatigue testing of metallic materials usually involves constant amplitude axial fatigue tests, strain-controlled fatigue testing, and multiaxial fatigue testing. Each kind of testing gives an idea of how the materials might respond to different loadings.

Q: What is the importance of fatigue crack growth in material testing?

A: It is important because fatigue crack growth refers to the propagation of cracks in a material due to cyclic loading. By measuring the rate at which a fatigue crack grows during testing, one can predict the working life of materials, in service.

Q: What is the traditional method of testing materials for fatigue?

A: The traditional test method for measurement of fatigue involves controlled constant amplitude axial fatigue tests. These are standardized tests for ensuring consistent and reliable test results for different materials in many testing environments.

Q: What are the roles of test rigs in material fatigue testing?

A: Test rigs are the most important equipment, as they provide all the necessary set-ups for the fatigue test in terms of carrying controlled loads and monitoring the response of the material. These systems measure the fatigue behavior and crack growth with high accuracy.

Q: What factors affect the frequency of the tests during fatigue testing?

A: The frequency sometimes has its effect on the result of fatigue testing. Depending on the temperature or rate of crack growth from the inside of materials, higher frequencies display different fatigue behaviors compared with lower frequencies.

Q: Why is fatigue testing essential for material reliability?

A: Fatigue testing is essential for material reliability as it allows us to predict the behavior of material under cyclic loading conditions. Knowing the fatigue behavior enables engineers to design safer and more durable structures and components.

References

Wikipedia – Fatigue Testing

An overview of fatigue testing, including its purpose and methods.

WMTR – What is Fatigue Testing?

A detailed explanation of the fatigue testing process and its applications.

Biopdi – Fatigue Testing: Methods, Materials & Applications

Insights into how materials behave under repeated stress and cyclic loading.