Price ascertainment of universal testing machines is essential for industrial companies and manufacturing establishments intending to make the best investment in their testing abilities. With 2025 approaching, various achievements and advancements within the industry, fluctuations in market dynamics, and changing tastes and preferences of consumers, among others, are sure to have their sway on price trends. This guide extensively covers the factors impacting universal test machine prices in 2025 in order to arm you with insights pertinent to your purchasing decision. If you intend to replace your older equipment, wish to know the new models in the market, or just intend to pencil down the costs based on your budget, this article bears all the information you require. Time to check into the future of testing technology and see how that concerns your bottom line.

Understanding Universal Test Machines

01 What is a Universal Test Machine?

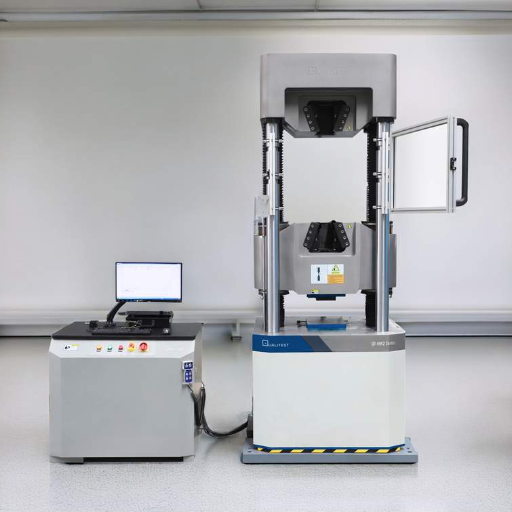

A Universal Test Machine offers flexibility in testing mechanical properties under various types of loads. These machines usually perform tests of tension or compression, bending, shear, or any other test to determine the behavior of materials under various stress conditions. The data collected helps in determining, among other things, the durability, strength, and elasticity of a material.

A UTM mainly comprises a loading frame, control systems, and grips or fixtures for the test specimen. The amplitude of the force applied by the machine upon the specimen is kept relatively constant, while sensors and software technology record its response very precisely. Insetting, for example, tensile strength, yield, elongation, toughness, and elastic modulus constitutes invaluable information that by majority of the manufacturers and researchers is used in material selection, design, and quality assurance processes.

UTMs function to lend importance to various industries such as construction, automotive, aerospace, and manufacturing. They enhance product reliability and safety by ensuring that materials meet the standards and specifications laid out. Their adaptability to different materials and requirements makes a UTM an indispensable tool in a host of applications.

02 Types of Universal Test Machines

H Hydraulic UTMs

Hydraulic UTMs use hydraulic power to apply force and are best suited for testing high-capacity materials due to their ability to accommodate very heavy loads. These machines are commonly used in industries handling robust materials such as metals and construction materials. They are best suited for long durations of testing with a steady force or load promotion.

E Electromechanical UTMs

Electromechanical UTMs apply force to the test specimen by using a motor-driven system. These machines are the most precise and versatile instruments, capable of testing virtually any material: plastics, textiles, and composites. Being able to linearly control speed and load very accurately is the key for performing those tests which require those settings to be changed or maintained with detail.

S Servo-Hydraulic UTMs

Servo-hydraulic UTMs use both the strengths of the hydraulic system and that of an advanced servo control. These machines can be used for dynamic and fatigue testing and are often applied in the execution of repetitive and complex testing operations in aerospace and automotive industries. Its advanced control system guarantees precision and adaptability for today’s material testing.

03 Applications in Material Testing

In material testing, these machines have been the backbone for determining mechanical properties measuring force-displacement quantities. Their major applications include tensile, compression, and flexural testing; with these tests, researchers and engineers ascertain strength, elasticity, and the deformation under various loads of materials. These tests assure standards relative to performance and safety for materials used in construction, manufacturing, aerospace, and the likes.

UTMs also comprise an important part of quality control, verifying materials that conform to design specifications and manufacturing standards. Any V-plots about weaknesses or inconsistencies prevent any disasters of critical applications-from bridges and airplanes to everyday consumer goods. It is this versatility and reliability that has made UTMs indispensable tools in a broad range of research and industrial settings.

Factors Affecting Universal Testing Machine Prices

Material Quality and Construction

Price is greatly influenced by material quality and construction of a testing machine. Such machines are known to test longer and reliably if coloured with the best-durable materials, so they command a high price. Load frame, actuators, and sensors are made precisely and perform well under any testing demand imposed upon them.

Good construction makes the machine able to work in rigorous conditions while ensuring accurate measurements. Load frames constructed with the best alloys can bear high forces without deformation, which is crucial for reliable results. On the other hand, cheap machines are made with lower quality materials, whereby the wear will require repair or replacement quite fast.

Testing Capabilities and Features

The most versatile among the testing apparatuses, universal testing machines are meant to test all the mechanical properties of any material or component. For instance, they may execute tests of tensile, compression, bending, or shear and compare results with the specifications of and standards laid down by an industry.

One of the utmost features of UTM is its precise application and measurement of force. Resulting from the working of very efficient load cells and controllers, the results obtained are accurate, even when high levels of stresses or strains are encountered.

Brand Reputation and Reliability

One very prominent feature that universal testing machines have in their product catalog is the reliability and reputation in their acceptance among industries. Good testing machines exhibit consistent performance, verify exact results, and are durable over a long time.

A reliable testing machine usually undergoes quality certification with respect to international testing standards, serving as a benchmark for ensuring the accuracy and consistency of the results upon which companies rely in their testing activities.

Price Ranges for Universal Testing Machines in 2025

Price Comparison Table

| Category | Price Range | Key Features | Target Users |

|---|---|---|---|

| Budget-Friendly Models | $2,000 – $10,000 | Basic tensile, compression, flexural testing | Small labs, educational institutions, startups |

| Mid-Range Models | $10,000 – $50,000 | Enhanced accuracy, automation features | Medium-scale manufacturers, R&D facilities |

| Premium Models | $50,000 – $150,000+ | Advanced controls, high precision, customization | Aerospace, automotive, research institutions |

Budget-Friendly Models

Being so inexpensive universal testing machines with prices anywhere between $2,000 and $10,000 are made to serve minuscule-grade testing needs, which include tensile, compression, and flexural testing. An ideal one for a small laboratory, educational institutions, or manufacturers with lower-grade testing requirements.

These models will deliver precise results in simple testing tasks without the advanced automations or the higher capacity for local testing required by the more premium packages. Being small, easy-to-use, and low-maintenance makes them attractive for startups and smaller operating entities that are trying to keep costs down but must still rely on performance.

The specific requirements peculiar to your testing applications have to be considered while choosing a bargain-priced universal testing machine. Assure that the machine is accurate and durable as per industry standards and that there is after-sales support available. Thus, the machine may prove more useful to you in the long run.

Premium Models

They are meant for advanced users needing the greatest levels of accuracy and ruggedness with functionality. They usually incorporate recent technology that allows for an assortment of material-testing capabilities, all in compliance with the strictest industry standards. Laboratories, research establishments, and manufacturing industries should therefore select them to carry out comprehensive testing, quality checks, or more challenging tests.

An excellent advantage offered by these models is their considerable accuracy and reliability. High-precision-machines are equipped with higher-precision load cells and sensors capable of imparting accurate measurements of different application tests.

Additionally, premium models offer utmost customization and advanced software, which allow the instrument to be modified for the performance of specialized testing and provide for quick data analysis. While the upfront cost of these machines may seem more, their versatility, very long-running time, and advanced abilities definitely turn them into an attractive proposition for professionals in search of quality testing solutions.

Comparison of Price vs. Features

Price determination can be approached from the features of a Universal Testing Machine (UTM). The higher-priced UTMs may come with premium features such as automated controls, large testing capacities, or better data analysis software. These features allow for more accurate and better tests in efficient time, which justifies the cost for anyone whose work entails a wide variety of material testing.

Lower-priced models typically offer fundamental performances and functionalities to cover less complex testing applications that are not demanding in terms of precision and efficiency. Though they lack in premium features, for small-scale testing needs, these machines give a very reliable performance.

Therefore, really depending on the intended use, the price-to-feature ratio of a UTM varies. For professionals and organizations who perform testing frequently and in greater detail, accuracy in data may justify their investment in the more sophisticated models and capabilities. On the other hand, for more straightforward or light testing applications, these basic models may provide adequate accuracy and reliability at a reasonable price.

Evaluating Your Needs for a Universal Test Machine

Identifying the Type of Materials to Test

While selecting a Universal Testing Machine (UTM), you should be clear about what materials you wish to test. Metals, plastics, textiles, and composites have peculiarities in mechanical properties that may necessitate specific testing methods. Determining if your material is rigid, flexible, brittle, or ductile will assist your in deciding whether to follow tensile, compression, or flexural tests on the machine.

For example, metals usually dictate higher tensile load application by the UTM because of their strength, whereas softer materials such as plastics would not necessarily need such a high force but are rather concerned with precision measurement of elongation or deformation.

Determining Required Load Capacity

The ultimate load capacity of the Universal Testing Machine is to be determined after ascertaining the maximum force any material or specimen will bear during a test. This guarantees that the machine is fit to be applied for testing without ever getting overloaded, thus raising safety or accuracy issues.

The general practice is to use a machine that has a load capacity of at least 25% above the maximum load anticipated during testing. This safety margin of 25% ensures dependable performance by accounting for unforeseen variations in test conditions.

Considering Industry Standards and Compliance

Any selection of Universal Testing Machines needs to ensure compliance with industry standards and test guidelines. Standards ASTM, ISO, and EN have been set down to stipulate the fundamental specifications for conducting mechanical tests and calibrating equipment.

The adherence to standards will give the assurance of reliability of results and will be interoperable with worldwide best practices; thus, the test will become trustworthy and reasonable.

Long-Term Costs and Considerations

Maintenance Costs

Regular maintenance is recommended to keep the machine in top working order and provide accurate results, thus avoiding the need for expensive emergency repairs. Annual calibration by certified personnel is key.

Software Updates

Regular software updates ensure optimum working performance by providing enhancements, fixing bugs, and improving efficiency algorithms for accurate testing results.

ROI Analysis

A UTM offers monetary advantages through quality control, reduced defects, operational efficiency, and compliance with industry standards, creating strong market positioning.

Return on Investment Analysis

Quality Control Benefits

Superior product quality leads to fewer returns, higher customer satisfaction, and increased earnings.

Operational Efficiency

Reliable UTM reduces downtime and maintenance costs while providing timely, accurate data for decision-making.

Compliance Assurance

Ensures materials meet standard requirements, minimizing penalties and maintaining competitive market position.

A UTM is universally useful in quality control, testing, and manufacturing. Investing in such a machine therefore offers a monetary advantage, whether in the short or long term. Pre-revenue earnings are quite costly, given the high price of the machines. The very precision and reliability of testing ensure that products do not end up with defects or failures. Hence, superior product quality leads to lesser returns, customer satisfaction, and of course, more earnings. Also, a single machine that facilitates multiple kinds of testing may be the answer to leasing or buying separate machines for each kind of test.

Operational efficiency strengthens the return on investment even further. A reliable UTM lowers downtime and maintenance costs and provides timely and accurate data to decision-makers during production processes. Such efficiency reduces waste and optimizes resource allocation. These factors combined help companies achieve faster paybacks and start infusing steady savings afterward.

At the same time, being compliant with industrial standards and regulatory requirements is another essential aspect for gaining trust and staying competitive in the market. A UTM highly calibrated ensures the compliance exercise by assuring that all materials tested meet standard requirements, thus minimizing the possibility of penalties or lost contracts. Improving operational and product quality will, therefore, create an opportunity for businesses to leverage their investment in the UTM for an even stronger market position.

Frequently Asked Questions (FAQ)

Q1 What price range do universal testing machines come in?

Universal testing machines’ prices tend to vary considerably and depend on many factors: specifications, load capacity, manufacturer, etc. Generally speaking, these test machines sell for somewhere between a few thousand and tens of thousands of dollars, depending upon the degree of sophistication and array of features they present.

Q2 What factors affect the price of tensile testing machines?

Several factors can affect the overall price of tensile testing machines, including type or testing applications they are designed for, precision and durability, automated features, and the reputation of the manufacturer of the testing machine. Price could be higher mainly, for precision machines or those carrying testing software.

Q3 How different are the prices of universal tensile testing machines and compression test machines from one another?

Such a price may be higher for universal tensile testing machines because of wide usage as opposed to a simple test machine for compression. Both types of machines can themselves range in price depending on specification, and the manufacturer.

Q4 What does a testing process of the universal testing machine consist of?

The process of testing follows the preparation of the specimen, setting up the machine with the particular test fixtures, and the testing software which monitors and records the result. The machine applies tensile or compressive force probably until failure, the criterion being very much useful for the material test.

Q5 Where can I find the latest universal testing machine price list?

The latest universal testing machine price list can be searched through manufacturer websites, industry catalogs, or by contacting distributors directly. A website like Jinan Wenteng Testing Instrument Co. provides comprehensive information on their testing systems and price.

Q6 Are there alternate yet cost-effective tensile testers?

Yes, there are indeed tensile tester manufacturers across the globe that provide the cheaper models that just meet the basic standards but still test materials actually. It is important to analyze your needs in testing and choose a testing machine that fulfills the compromise between attributes and price.

Q7 What is the ultimate guide to tensile testing?

The ultimate guide to tensile testing is about the various aspects of tensile strength testing, from the types of machines available, to the order of the testing procedure, to the parameters affecting the results. It is a resource of great value to anyone wishing to make an educated purchase in the material testing line of work.

Q8 How do I navigate my way into considering a universal testing machine?

To build up an informed choice when selecting a universal testing machine, consider the type of testing it will have to perform, the range of testing options required (be it tensile or compression), and the reputation of the manufacturer. Price and features should be compared among the many models for the best choice to fit your needs.

References

WTS Machinery – Universal Testing Machine Cost: Comprehensive Guide

A breakdown of costs for basic to advanced universal testing machines.

Instron – Universal Testing Systems

A resource for electromechanical and hydraulic universal testing systems, including pricing and features.

eBay – Universal Testing Machine Listings

Listings for universal testing machines, including prices for various models.

TestResources – Sans Universal Testing Machine

Information on pricing, specifications, and technical details for universal testing machines.