Material testing demands accuracy and reliability, key attributes that must be ensured. Considered as an extremely versatile and indispensable machine for industries and researchers, it ensures exact checks of mechanical properties of materials. It is the standard for tensile, compressive, bending tests, and other results for unwaveringly and exact uniqueness. Here, we further note several advantages, and by doing so, win the massive role of universal testing machines in quality control, product development, and innovation in several industries. Let us unfold this technology’s enhancement toward saving time and costs while upholding safety standards in your projects.

Introduction to Universal Testing Machines

What is a Universal Testing Machine?

The Universal Testing Machine is multifunctional and is used for the mechanical characterization of materials subjected to different types of loadings. Tests like tensile, compressive, bending, and shear tests are carried out on a Universal Testing Machine to determine the strength, toughness, or elasticity of materials. By applying a certain force and by accurately determining the resultant movement, the Universal Testing Machine gives data for the study of material behavior.

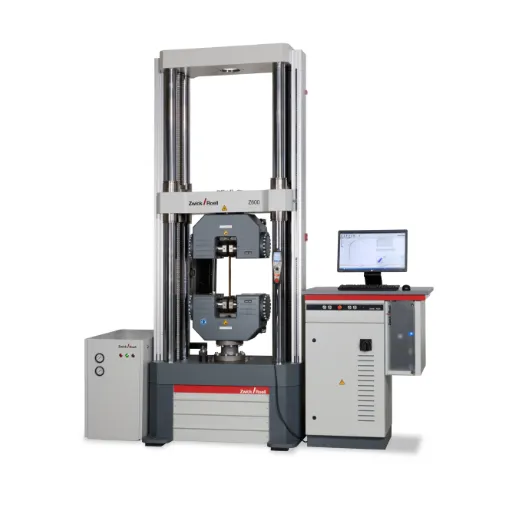

Typically, a Universal Testing Machine consists of a loading frame, crosshead, load cell, and grips or fixtures. The loading frame holds the test material in place while the crosshead moves to apply force. The load cell makes measurements of the force applied during the test, and the grips or fixtures hold the test specimen. Thus, the combination of grips and frames etc., is used in the testing of a very wide range of materials with different geometries and ensures very accurate test results.

Universal Testing Machines are used in quality control programs across industries, including construction, automotive, aerospace, and manufacturing. With the help of the UM, materials can be made sure by engineers and researchers to meet the standards specified and to be safely operational under given conditions. Universal Testing Machines produce accurate and repeatable results, making them very useful throughout the product development and enhancement, safety assurance, and industry regulatory compliance processes.

How Universal Testing Machines Work

The Universal Test Machine acts upon a controlled force on a material specimen, recording its response to the stress. Tests of that nature include tension, compression, bending, and shear tests to identify mechanical properties of the material. A UTM employs a myriad of grips and fixtures to hold the test sample during the tests. Therefore, the machine is programmed to gradually increase the load while simultaneously recording readings such as force applied, elongation, or material behavior under stress.

The central part of a UTM is the load cell; it measures the force being exerted. Another component is the extensometer, which measures changes in dimensions of the specimen being tested while stresses are applied. Meanwhile, the crosshead moves, either creating tension or compression. Then advanced software systems cooperate with these components to assure accurate measurement and automatic data analysis, allowing engineers and researchers to evaluate key mechanical material properties, including tensile strength, yield strength, and elasticity.

The design of this machine was intended for the purpose of being versatile enough to test various materials, including metals, plastics, composites, and textiles. UTMs crucially test product development and quality control; they yield data that can be used in assessing the physical performance of materials. By pushing a material to its limits and looking at what it can do, manufacturers can further contribute design aspects, improving safety as well as matching it to the set industry standards.

Key Features of Universal Testing Machines

Universal Testing Machines (UTMs) are the mainstay of any laboratory. They provide precise and reliable testing upon a vast spectrum of materials. Their greatest characteristic lies in their versatility that allows them to perform different mechanical tests, i.e., tensile, compression, flexural, and shear tests. Based upon their adaptability, a certain industry ranging from construction to aerospace finds their respective applications in testing the performance of materials.

In addition, UTMs assure very high levels of accuracy and repeatability of the measurement data. Appropriate load cells and extensometers ensure that the best possible data are furnished for particular physical parameters of the materials as strength, elasticity, and ductility, so that these parameters can be evaluated all the time. Such accuracy is vital for consistency during quality control and product development.

Further, UTMs provide intuitive software control and the ability to customize testing parameters for conducting industry or project-specific testing. Today, UTMs allow easy collection, measurement, and analysis of data, and provide crucial insights for expedited design and realization of innately safer and more effective solutions. Because of this combination of features-centricity, precision, technical excellence, and innovations in user interface, they are regarded as the backbone of any testing facility.

Benefits of Using a Universal Testing Machine

1Enhanced Quality Control

Universal Testing Machines (or blast force machines, as they sometimes are called) test materials within industries and even products in a broad sense to ensure that they meet their required standards. These machines are set to test materials for strength, durability, and elasticity through tensile, compression, and flexural types of tests. The Universal Testing Machine enables an industry to maintain consistent product quality and comply with regulations by providing the most accurate and reliable measurement.

Another benefit that comes with the UTMs is the identification of certain defects or weaknesses in materials that could be the point of failure. Issues can be caught early, and tests are done comprehensively to find flaws in materials during manufacturing, thus providing that the faulty product does not reach the customer. This, in turn, leads to less wastage, saving resources, and in preventing costly product recalls, thus contributing to productivity.

Furthermore, UTMs also provide information critical for the optimization and development of new materials. Engineers and product designers then use this information to make decisions about material selection and product design, so their final products work well in different conditions. The ability to support well-founded evaluation and ongoing improvement cements the UTMs’ status as an essential component to every quality control system.

2Versatility in Material Testing

Universal Testing Machines, commonly known as UTMs, are a very flexible type of instrument used for testing material properties. They are primarily used to test for tensile, compressive, and flexural strengths, thus ensuring that materials are safe and suitable for performance in their particular applications. They are adaptable instruments necessary in many industries, such as construction, automotive, aerospace, and consumer products. By answering to testing needs that are so diverse, UTMs have proven their importance in material testing.

UTMs have grown to be well-adapted, with their ability to test different materials from metals to polymers, textiles, and composites. By using interchangeable grips and fixtures, the UTMs accommodate tests for materials of diverse compositions and forms. This gives engineers the flexibility to perform strength tests along with assessments on elongation, elasticity, and energy absorption. The wide range of testing capability ensures that UTMs remain the paramount equipment in research, development, and quality control.

The accurate data obtained from testing with the UTM enables material selection and engineering design decisions. For example, the data may be used to identify a material that performs best under certain operational conditions, whether these conditions include extreme temperatures or heavy loads. This leads to better product designs, fewer material failures, and cost savings. The exactness and reliability of the UTM prove it to be a tool that material scientists and industrial engineers cannot do away with when both need to ensure that there is always a high-quality standard for products and materials.

3Improved Test Accuracy and Precision

Being vital within the realm of material testing, Universal Testing Machines ensure the achievement of better test accuracies and precisions. They allow a material to be tested under very controlled conditions to study its response and measure its mechanical characteristics, such as tensile strength, compressive strength, or elongation values. By reducing unwanted variables, UTMs intend to provide a consistent testing process that guarantees repeatable results verifying the performance of the material under defined conditions.

In addition to precise measurements that exclude the human error factor, automation is another major advantage of UTMs. Advanced machines incorporate sensors and software that record measurements with the utmost precision. This level of precision is indispensable for industries that consider trustworthy material properties on the highest scale, such as aerospace, construction, and manufacturing. The vast amount of data thus gathered backs engineers and scientists as they make decisions about design and production processes.

With a large number of testing standards available through the use of UTMs, there are excellent prospects for compliance with international testing protocols. This adaptability gives them an edge in various industries where securing materials from the competition with worldwide quality criteria is crucially important. UTMs provide intelligent program features that deliver results down to the very last decimal, offering a level of confidence in material testing and product reliability.

Technical Aspects of Universal Testing Machines

Load Capacity and Range of Tests

Universal Testing Machines are made in several different load capacity versions, so they offer a comprehensive way of testing every material at its different levels of strength. Depending on the material being tested, forces from a few Newtons for fragile materials to several hundred kilonewtons for high-strength components are measured by these machines. Thus, this dessert certainly represents a machine for a lot of testing, dating from soft polymer to a check on the structural integrity of a metallic alloy.

Also, UTMs go through a series of other tests as well. Quite often, tensile tests are carried out to establish how the material withstands being pulled before breaking. They also undergo compression tests, observing how well the material resists compressing forces. Then there are shear tests, in which materials are forced into resisting the stress of being cut against another surface, while bending and flexural tests see how materials act under the strain of being bent against certain conditions. The results allow an understanding of how a material might achieve mechanical performance in its appropriate application through the UTM.

UTMs are very versatile machines, offering the ability for an operator to configure the machine to the requirements of a particular test while fitting grips, fixtures, or load cells relevant to the material under investigation. The high levels of precision in data capture make all variations of tests very reliable, providing consistent results. The final aspect of UTMs is the very limited area of application, making these machines quite essential for any industry that deals with exact material analysis and quality assurance.

Types of Tests: Tensile and Compression

Tensile Tests

Tensile testing is probably one of the most common methods to test an object using a Universal Testing Machine (UTM). The purpose of tensile testing is to examine how a material reacts under tension, essentially stretching the material until it breaks or deforms. During tensile testing, a number of properties are recorded by the UTM, including tensile strength, elongation, and yield strength. These properties are essential to establish the ability of a material to resist forces attempting to pull it apart, thereby determining whether engineers and manufacturers deem it suitable for certain applications.

Compression Tests

In compression testing, the force is applied to a specimen to see how it behaves under compressive load. It is done to characterize parameters like compressive strength, deformation, and elasticity. These tests are much needed for analyzing materials such as concrete, foam, and metal components employed in construction and industrial fields. The test results can then verify whether the material is capable of withstanding imposed loads without cracking or being subjected to permanent deformation, which is a fundamental requirement of structural integrity.

Importance of Tensile and Compression Testing

Both tensile and compression tests provide vital information in industries in which product properties directly influence product performance and safety. Tensile testing is, of course, essential for cable, textile, and structural component manufacture. Meanwhile, compression testing is necessary for construction and packaging materials. Eventually, these tests assist in ensuring the materials meet safety and quality requirements so they can be translated into end products that are functional yet able to withstand the environment they are meant to serve.

Importance of Fixtures and Grips

Fixtures and grips bring about universal testing machine support for installation of the specimens and for testing purposes, delivering an array of accurate and reliable results. In case it slips during the application of force by the fixtures and grips-the sample undergoes inconsistent deformation, or improper orientation with the actual testing force is provided-precise measurement cannot be conducted. Types of implants and grips gear may be supplied for testing different materials of varied shape and size. Such variety allows the testing system to adequately serve the diverse testing requirements.

The primary function of grips and fixtures is to apply and transmit the load uniformly to the specimen without causing unnecessary stress concentration or interference from extraneous external effects. Special grips are available, for instance, wedge or pneumatic grips for tensile tests, whereas compression platens or bend fixtures can be applied for compression and flexural tests. In this way, every kind targets the explicit goal of testing the material under valid, realistic, and controlled conditions suitable for the material.

To maintain safety, high-quality fixtures and grips likewise protect the operating mechanism from damage, as well as the specimen, thus ensuring repetitive results for different tests and diverse operators. Hence, while fixtures and grips for a universal testing machine are to be selected, both material characteristics and test requirements must be taken into consideration to maximize output and evaluation accuracy.

Universal Testing Machines and Product Innovation

Driving Innovation through Testing

Universal testing machines infuse new life into innovation in any industry through the precise means of material and product evaluation. The determination of mechanical properties of materials include tensile strength, compression, and elongation, which are utilized in product development. Universal testing machines present dependable, reproducible results that improve performance, durability, and safety of any new design so that products conform to necessary standards and regulations.

Since they can test materials of every nature, metals, plastics, textiles, or composites, the universal machines remain essential to the aerospace, automotive, construction, and manufacturing industries. Once the engineers and researchers comprehend material behaviors under various conditions, they can invent new products that satisfy particular conventional functionality and safety requirements. This, therefore, reduces material wastage and optimizes resources during design and manufacturing.

They also spur innovation through material comparison and ask manufacturers to look at options aside from conventional choices. From a quality control perspective, they guarantee that there exists product manufacture within set standards and vice versa. Looking at the bigger picture, they essentially enable materials and product design decisions that erect the platform of innovation that furthers technology in many spheres.

Ensuring Compliance with Regulatory Standards

The Universal Testing Machine (UTM) is instrumental in providing a final check that materials and products comply with regulatory standards. The UTM ensures a material is tested for tensile, compression, or bending test-for strength, elasticity, and gradual durability. Such tests ascertain that materials conform to the minimum safety and performance criteria set out by the concerned regulatory bodies, thereby instilling confidence in their use.

Being able to spot defects during production through the assistance of the UTM helps a manufacturer keep quality consistent and ensures that companies meet the standards for their final product and thereby avoid risks or failures. The UTM also collects precise data from tests, that is subsequently immediately used for certification purposes and complies with regulations and specifications of the concerned industry.

Moreover, UTMs can supplement improvements in design and innovations with very useful data. When manufacturers comprehensively understand material properties, they can modify a design or process to improve product performance while meeting the stringent regulatory requirements. Thus, a paragon for not just standards meeting but also in pushing forward the advancement of material science and technology will always remain UTMs.

Enhancing Operational Efficiency

In the process of material testing, UTMs have paramount importance in developing operational efficiency. Since accurate and consistent measurements are ensured, the potential for errors and so, wastes and rework, are minimized. In effect, industries will have an easier time in the research and development stage owing to swift and efficient identification of the best material properties.

Testing applications are numerous, such as tension and compression or bending, within a single system. So having all these in one means no machines need to be purchased multi-fold; time and resources are saved. These whereabouts have been automated: data recording, analysis, thus giving much speed to decisions without much intellectual involvement.

Thirdly, UTMs ensure that testing workflows are done in accordance with standard industrial specifications so that regulatory approvals are fast-tracked. As they gather data with respect to which material performance can be determined in a reliable manner, product development cycles are considered shorter and thus the overall productivity is enhanced. Organizations stand to improve upon operational efficiency while maintaining quality standards by incorporating UTMs.

Choosing the Right Universal Testing Machine

Key Considerations for Selection

- Testing Requirements: One of the most important considerations while procuring a UTM is the nature of the testing it will be used for. Identify if it will primarily be used for tensile, compression, flexural, or other types of tests. With machines designed for wide periodic has a range of capacities and compatibilities, a clear understanding of specific mechanical properties to be tested is needed. It is advisable to look out for the range of maximum force of the instrument in relation to the materials of your samples for correct and reliable test results.

- Machine Size and Flexibility: Another factor is the size and flexibility of the machine. The frame size and test space of the machine should cater to the test specimen’s dimension, including any fixtures or grips which may be required. Flexibility is an important concern; a UTM should be capable of taking interchangeable fixtures and accessories to meet different testing needs at an affordable cost later on. Also, determine if you require auto functions or software that can help in optimizing the testing.

- Ease of Use and Maintenance: Lastly, gauge the ease of use and maintenance demands of the system. An interface that is easy to use and clear instructions on how to operate the machine ensure that your team can efficiently work with the machine without any special training. Secondly, ensure the availability of technical support and spare parts so as not to hamper your processes while conducting any critical operations. Making sure that your machine is rugged and backed by intense after-sales support will save you valuable time and money in the long run.

Top Universal Testing Machine Suppliers

When placing an order for a universal testing machine, it is recommended to acquire from companies renowned for high-quality goods, trustworthiness, and lifetime service. Top suppliers usually have an inventory of machines for different types of material testing such as tensile, compression, and bending tests. These suppliers ensure that the machines are calibrated using high precision and accuracy so that they confirm to specifications and produce consistent results.

Considerations to keep in mind are those services delivered in conjunction with the purchase. The top suppliers provide technical assistance along with ensuring that spare parts and maintenance are available so that down time on machines in testing can be minimized allowing uninterrupted execution of tests during working days. Suppliers having global service networks or local support offices are great service providers-needs to be addressed in the least waiting time possible.

Another factor of consideration is the continuous and forefrontly innovative engineering in the supplier’s machines. Select those suppliers who integrate testing programs with user-friendly software and-containing the latest technologies designed to make testing more efficient and further analyze data. Such features reduce complexity, decrease time on learning curve, and promote maximum productivity: hence these factors become paramount when choosing the best supplier for your universal testing machine requirement.

Cost vs. Benefits Analysis

When conducting a cost vs. benefits analysis, one must look at the initial investment in terms of the long-term value and efficiency offered by the testing machine. Universal testing machines often come with huge upfront costs, but being able to carry out many tests accurately means that costs do get saved over the long haul. The machine is further made more useful by the presence of advanced features, such as software that is easy to use and processing that is largely automated, thereby reducing the costs related to labor, and training time and operational time.

Some of the advantages of purchasing a high-quality universal testing machine are increased productivity, enhanced accuracy of results, and versatility in carrying out different applications. Closely following methods ensure constant results with the universal testing machine utilized in R&D, quality control, and standard compliance. Such quality universal testing machines are another cost saver with less downtime and long operational lives for companies with frequent usages.

Maintenance, calibration, or update software fees should be factored in as part of the purchase cost. Compare the features and warranties offered by various manufacturers to ensure the investment meets the needs and budget of the organization. The selection should maximize long-term and short-term values with performance being a middle ground with cost-efficiency.

Frequently Asked Questions (FAQ)

Q: What is the importance of universal testing machines?

A: The importance of a universal testing machine is that it works as a great versatile tool performing many types of tests like tensile, compression, or fatigue. It is able to test a variety of materials such as metals and polymers and is, therefore, adaptable to testing various industries. Plus, a UTM provides very accurate results, which means they must be combined to quality control and material safety.

Q: How does a universal tensile testing machine perform a variety of tests?

A: A universal tensile testing machine, by its name, is meant to create different sorts of tests upon materials by gripping them and applying controlled forces; while, for example, it may measure the tensile strength, elongation, and yield point of a given sample by actually forcing or compressing the material to a point of failure. This dual function of performing both static and dynamic tests makes it very indispensable to any testing laboratory and manufacturing unit.

Q: What types of materials can be tested using a universal testing machine?

A: Universal testing machines have the possibility to test metals, plastics, rubber, and composites. Owing to their versatility in performing various tests, they are well suited for production quality assurance.

Q: Why does quality control require universal testing machines?

A: Universal testing machines are required for quality control because of their accurate test results on materials that help for the performance and durability assessment of products. By subjecting their materials to standardized testing, manufacturers ensure that they conform to the required safety and quality standards so as to prevent the possibility of failures during further processing and in-service.

Q: What role do universal testing machines play in new testing methods?

A: Universal testing machines play a role in new testing methods by means of adaptation. They are adapted to the recent standard and technologies in material testing. With the advances in software integration and electromechanical working, now UTMs can afford the real-time data analysis and somewhat support to new testing methods, which, in turn, refine the efficiency and accuracy of testing.

Q: How do universal testing machines consolidate multiple testing processes?

A: Universal testing machines consolidate multiple testing processes into a single unit, eliminating the need for setting up different appliances for different tests. This saves on space and resources while streamlining the testing phase, so turnaround times can be reduced, thereby increasing productivity in testing laboratories.

Q: What makes a universal testing machine suitable for harsh testing environments?

A: Universal Testing machine is suited to harsh testing environments by its sturdy design and dependable performance. This machine is fashioned to operate in extreme conditions and give reliable results, thus being suitable for industries that need tedious tests on materials in adverse circumstances.

Q: Can you tell me the importance of static and dynamic testing in universal testing machines?

A: The importance of static and dynamic testing in a universal testing machine lies in simulating actual conditions. Static testing brings about strength of materials under constant loads while dynamic testing reveals how it behaves under varying force. Such combined testing gives a valuable insight into performance.