Every process of testing materials is fundamental to several industries—construction, manufacturing, aerospace, and automotive design. As a matter of fact, it is vital that materials be held to accepted levels of strength, durability, and performance in any undertaking because the project’s success and safety rest on this feature. So, what’s involved in material testing, and why is the subject so important? This blog explores the processes and techniques involved in analyzing and evaluating materials, thereby enabling you to understand the measures taken to ensure that the materials stand up to set standards as well as suitability for their various engineering applications. So if you are a concerned person from the industry or just an interested person curious to know the scientific principles that drive the study of material integrity, do go through these materials to refresh your mind on how to appreciate the importance of material testing along with some of the intriguing methodologies. Keep reading to learn how these tests serve as launching pads for innovation and ball-bearers for reliability in modern engineering and design!

Overview of Material Testing

What is Material Testing?

Material testing refers to a procedure that evaluates material properties such as physical attributes, mechanical properties, and chemical attributes. It ensures that materials meet certain requirements for their applications. Testing of materials helps engineers and designers understand how strong, durable, or flexible a material is; these are crucial parameters that are consequently considered for their methods of construction and manufacturing.

Material testing mainly assures safety, reliability, and fitness of a product for its purpose. Considering operational purposes, it reveals potential defects or limitations that threaten failure of materials. With regular testing, manufacturers assert their compliance with industry standards and regulations; thus, containers of final products whose quality is assured and whose use is determined with benefits for the consignment.

Material testing materializes in common forms such as tensile testing, hardness testing, impact testing, and fatigue analysis. Each method evaluates specific properties, such as the ability of a material to resist forces, wear, or repetitive stress. These tests enhance the product’s performance and provide specifications for the research of new materials. In contrast, the betterment of materials leads to new developments in various sectors.

Importance of Material Testing

The process of material testing is very important for ensuring the safety, reliability, and performance of different products and structures. Testing materials under known conditions allows engineers and scientists to evaluate their mechanical, chemical, or physical properties, such as strength, resistance to wear, or corrosion. Hence, this process detects any flaws or weaknesses within the material, preventing its use in applications where failure poses an unacceptable risk in actual use.

Another key function of material testing lies in innovation and development. Testing aids manufacturers and research scientists in evaluating new materials and improving old ones, driving developments in myriad fields such as construction, aerospace, automotive, and healthcare. Before any new materials are used to produce better or safer products or technologies, they must be tested to ensure that they meet all set standards and specifications.

Furthermore, testing materials aids cost-effectiveness and sustainability. When material behavior is identified under different conditions, designers and engineers pick appropriate choices to suit an application to have less waste and utilize resources to a maximum. Besides reducing production costs, such design and engineering promote environmentally friendly goals through the use of durable and efficient materials for manufacturing and infrastructure.

Types of Materials Tested

Materials testing covers a wide variety of substances, all of which are relative to the evaluation of specificities and the performance under certain conditions tested. Commonly tested materials encompass metals, polymers, ceramics, and composites.

Metals

Tested for strength, ductility, and resistance to tension or compression. Vital for construction and manufacturing industries.

Polymers

Like plastics, tested for flexibility, durability, and thermal resistance for consumer and industrial applications.

Ceramics

Tested for hardness, brittleness, and thermal stability. Important in electronics and aerospace industries.

Composites

Tested for lightness, strength, and resistance to wear. Essential in automotive and aviation industries.

Specific conditions are implemented during mechanical testing depending on natural use. Environmental testing consists of obsession with temperatures, moisture, or corrosive substances, which plays the key into defining the longevity and reliability of a material. These tests certify each material to be in compliance with safety standards and industry specifications so that the chance for failure in any industry application is as low as possible. Depending upon the application, materials undergo testing to allow the industry to innovate while still ensuring quality and sustainability of their product.

Non-Destructive Testing Techniques

Overview of Non-Destructive Testing

The term “nondestructive testing” (NDT) refers to numerous testing techniques and methods used to evaluate the properties of a material, component, or structure without inducing damage. These methods are necessary for defect detection, safety assurance, and maintenance of the working conditions of equipment in different industries. NDT is a highly desirable consideration as it preserves the usability and integrity of the object under consideration; hence it is a cheap and efficient means of quality assurance.

Some commonly used NDT techniques are visual inspection (VT), UT, MT, RT, and of course, liquid penetrant testing; and the selection depends largely on the nature of materials, types of possible defects, and industrial requirements. For instance, UT is provided for internal defects in metallic materials, while PT is meant for surface defects on non-porous materials. Hence, employing any of these methods enables manufacturers to ensure early detection of any defects and hence prevent an eventual failure in service.

Applications of Non-Destructive Testing

Aerospace Industry

Used for inspections of aircraft components to detect contrasts, damage, cracks, etc., ensuring compliance with safety standards.

Oil and Gas

Periodic inspections of pipelines, pressure vessels, and storage tanks for leaks, defects in welding, or areas of wear.

Structural Engineering

Testing bridges, buildings, and infrastructure for signs of fatigue or failure using visual or acoustic emission testing.

Common Non-Destructive Testing Methods

| Method | Description | Applications |

|---|---|---|

| Ultrasonic Testing (UT) | Uses high-frequency sound waves to detect internal or surface defects | Thickness measurement, crack detection in metals and composites |

| Radiographic Testing (RT) | Uses X-rays or gamma rays to create images of internal defects | Aerospace and automotive weld inspections |

| Magnetic Particle Testing (MPT) | Uses magnetic fields and fine particles to detect surface defects | Fatigue cracks in tools, pipelines, and industrial equipment |

Conducting Material Tests

1. Preparation for Testing

Good preparation is key to proper material testing, ensuring the accurate and reliable results. The first step of preparation is usually to clean the material thoroughly of any dirt or contaminant. Grease or corrosion can affect the testing process and lead to distortion of results.

- Material Cleaning: Remove dirt, grease, or corrosion through mechanical or chemical means

- Visual Inspection: Look for surface irregularities, cracks, and visible damage

- Environmental Setup: Control temperature, humidity, and vibration factors

These preparatory measures, if adhered to, will give effective and significant testing under consideration.

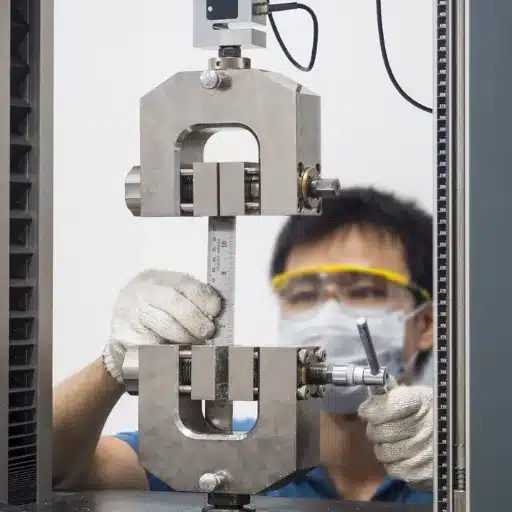

2. Equipment Setup and Calibration

Correct equipment setup and calibration are paramount if test results are to be high quality, accurate, and precise. In the beginning, make sure to check the equipment for any observable defect or damage that could restrict its functions.

Calibration Process

- Use reference materials with known traceability

- Follow systematic calibration procedures

- Adjust settings to minimize measurement error

- Document all calibration data for compliance

Before any actual evaluation, it is good practice to conduct a trial run to ensure the system is functioning correctly under actual testing conditions. Regular maintenance and recalibration intervals should be planned ahead to maintain the integrity of the testing process.

3. Analyzing Test Results

First, ensure the testing data analyzed are correct. It is good practice to compare results to expected parameters defined in the initial planning stage. Cross-checking values for any strange or anomalous behavior is highly recommended, as such factors can adversely affect the validity of the justification in the tests.

Follow this by evaluating the results with respect to predetermined standards or benchmarks to assess the performance capability of the subject under investigation. It further helps to find out how well the test subject meets the required specification or design expectation.

Finally, document your findings in a clear and organized manner. Note the key outcomes, identify any patterns or trends, and, where applicable, offer recommendations for changes. Proper analysis of the testing process in a thorough and systematic manner enhances the strength of the conclusions; at the same time, it can provide directions that can be taken for future testing or development.

Industry Standards in Material Testing

ASTM Standards

The ASTM standards provide very important guidelines and methods for testing of materials so that results of experiments and research can be compared for consistency, reliability, and accuracy. These standards cover a huge array of materials—from metals to polymers to ceramics and composites.

Key Benefits

- Establish common platform for testing procedures

- Enable result comparison across laboratories

- Reduce errors through standardized methods

These standards are kept current with new technological developments and industry needs so that they remain useful for new applications.

ISO Standards

ISO standards are worldwide-ruling guidelines to maintain quality, safety, efficiency, and interoperability of myriad industries. These standards are formulated through international consensus, so that practice may be made consistent.

Global Impact

- Enable international trade and fairness

- Improve organizational efficiency

- Ensure product quality and safety levels

From healthcare to technology, industries depend on ISO standards to maintain competitive advantages and foster perpetual improvements.

Impact of Standards on Testing Practices

Standards serve as a major and ultimate force in shaping and improving testing procedures of diverse sectors, bringing in cohesion, reliability, and accuracy. These standards set protocols and requirements; therefore, they create a common frame of reference in which the various testing entities operate.

Simple-testing methods, tests, and procedures aid with safety and quality assurance of testing undertaken in accordance with standards. They identify possible issues or weaknesses in a product, process, or service before delivery to the end-user.

The introduction of testing standards pushes innovation and cross-industry collaboration along. Standards, by nature of providing a set of rules or guiding principles, allow the researcher or developer to concentrate on design and methodology development, always within compliance.

Expert Tips for Accurate Testing

Avoiding Common Mistakes

Unclear Testing Objectives

Take time to establish specific, measurable objectives before starting the testing phase. Without clear goals, success cannot be measured effectively.

Poor Equipment Preparation

Ensure tools and equipment are properly calibrated and configured before testing to avoid measurement faults and dubious results.

Neglecting Documentation

Maintain thorough documentation of procedures, conditions, and results for traceability and effective team communication.

Ensuring Reliable Results

- Establish Clear Procedures: Use standardized methods consistently. Repeated application under same conditions should yield identical outcomes.

- Maintain Equipment Accuracy: Regular calibration and maintenance guarantee precision of measurements and conform to industry standards.

- Provide Staff Training: Proper training reduces variability from human error, ensuring uniform test execution.

Best Practices in Material Testing

- Match Testing to Material Type: Different materials need different tests to analyze strength, flexibility, or durability properties.

- Maintain Fixed Environment: Control temperature, humidity, and pressure throughout testing to ensure consistent results.

- Document Everything: Record all steps from sample preparation to result interpretation for replication and verification.

Frequently Asked Questions (FAQ)

Q: What is the function of material testing?

A: The purpose of material testing is to assess the properties exhibited by materials in order to check on their suitability for certain applications. They are tested by engineers and manufacturers to know how they resist certain conditions, and in order to meet specifications, they must be treated as per requirements of safety and performance.

Q: What are the general kinds of material tests?

A: Generally, material testing includes tests of tensile, compression, bend, and creep. Each fault measures a specific property of a material that is necessary for the strength requirements of that material, whether tensile, compressive, or flexibility being used as in-place conditions.

Q: How do I decide upon the proper set of material testing equipment?

A: For picking the suitable testing equipment, the considerations differ according to material to be tested and test to be performed. If tensile strength testing of metals is required, then a tensile testing machine shall suffice; but if my tests are varied and applied to various materials, I shall require a universal testing machine that has all features under one roof.

Q: Which materials are customarily tested in a material testing laboratory?

A: Metals, plastics, composites, construction materials, etc., are some commonly tested materials in a material testing laboratory. Determinations of material characteristics and performance are made on materials with an application basis ranging from construction downing to manufacturing.

Q: What is tested by a strength test?

A: Strength tests determine the capacity of a material to withstand an applied force without failure. Such testing entails examining tensile strength, compressive strength, and shear strength, which, in practice, will be of utmost importance for materials subject to external loads.

Q: What are material testing standards?

A: Material testing standards are those formal guidelines set to dictate how tests are carried out and how to gauge what materials qualify. These regulations are put on a pedestal to ensure the honesty of materials testing across industrial applications.

Q: How is field testing different from lab testing?

A: Field testing refers to an evaluation conducted on materials in their environment, thus giving actual data on performance. A lab test, on the other hand, is a paired down experiment to test specific properties using material testing machines. Both methods are essential to complete testing and analysis.

Q: What is the role that a materials engineer has in material testing?

A: Materials engineers have a vital role in material testing; test design, evaluation of the results, and determining if the materials are going to fulfill the specifications. They operate material testing machines to analyze the properties and performances of materials and thus help to develop safer and better materials for application in many fields.

Q: Can you explain dynamic testing and its importance?

A: Dynamic testing subjects materials to changing loads or conditions to observe performance over a given period. This type of testing is required to observe how materials behave under real-life conditions, such as fluctuating temperatures or variations of stress, any of which if not duly tested can cause material failure.

References

-

The Fundamentals and Methods of Materials Testing – AZoM – Explains the principles of materials testing, including mechanical loading and deformation.

-

Materials Testing and Analysis: What You Need to Know – Acuren – Discusses how testing evaluates material properties, performance, and durability under various conditions.

-

What Is Material Testing? An In-Depth Guide – MFE Inspection Solutions – Provides an overview of the process for assessing material properties and performance in industrial applications.

-

21 Different Types of Material Testing – Xometry – Details various testing methods, including clamping and applying force to materials.