When it comes to understanding material performance, flexural strength plays a crucial role in determining a material’s ability to withstand stress and deformation under load. Whether you’re working in construction, engineering, or product design, knowing how to calculate and interpret flexural strength can help you make informed decisions about material selection and application. This guide is designed to unpack the concept of flexural strength, provide practical insights into its importance, and walk you through the calculation process step-by-step. By the end of this article, you’ll have a solid grasp of how flexural strength impacts real-world projects and why it’s a key factor for ensuring structural integrity and performance.

Introduction to Flexural Strength

What is Flexural Strength?

Flexural strength, also called the modulus of rupture, is the highest stress a material can withstand under bending before it fails. It is a critical measure of its ability to resist deformation under load. This test is usually conducted by applying a force at the center of a sample supported on two points, which is known as the three- or four-point bending test.

This property becomes very important in structural engineering, construction, and manufacturing, where materials such as concrete and wood composites are frequently subjected to bending forces. The greater the strength, the greater is the ability of the material to withstand bending loads without failure-it speaks about the long life of a structural unit such as a beam, a floor, or a bridge.

Factors that affect flexural strength include the material composition, cross-sectional shape, and how the load acts on the specimen during testing or in application. A material with a uniform texture or internal structure will generally have a uniform strength. That property enables the engineer or designer to predict the response of a material under a stress and to meet standards and specifications for safety and performance.

Importance of Flexural Strength in Material Science

It is important in material science because it relates to a material’s resistance to bending forces, which lead to failure. It is thus regarded as the main parameter for realization. Materials having a particular use on structural applications are assessed and validated with this parameter, and engineers use it to predict and simulate how a material will react in certain mechanical loadings to in the process provide solutions for secure and well-performing structures.

Construction materials with excellent flexural strength are highly sought after in all industries that deal with bending stress-prone components such as beams, bridges, and floor panels. The materials act as barriers protecting the structure from fracturing or deforming under loads applied to it such that it may stand intact and usable with time. This property is of utmost importance in the aerospace, automotive, and civil engineering industries.

Hence, flexural testing is crucial in several areas: manufacturers have the option to ensure a product meets all required standards and regulations; by knowing the exact bending capacity of the material, they will design the product better for greater efficiency and cost-effectiveness. Therefore, flexural strength is not just conceptual but also a utilitarian term that guarantees the safety and service life of any material application.

Applications Across Various Industries

Being a flexural testing process, it has found use in a wide variety of fields when determining material behavior under stress. In another set of industries, construction materials such as beams, concretes, and rebars undergo flexural testing for structural stability and safety. Engineers evaluate the maximum load a material can receive before cracking so they can promote the safest selection of materials for a particular infrastructure under which eventual failure will be largely reduced.

In addition to the automotive industry, aerospace also extensively uses flexural strength testing. Being the very subject of high stress during operation, manufacturers must test components of composite panels, frames, and any other structural parts. This testing assures that materials can undergo bending forces while maintaining their structural integrity and are efficient in doing so, thereby leading to safety and durability.

It benefits flexural testing in packaging. Corrugated boards and packaging materials were tested to see their resistance to bending and pressure. So, the packages need to stay intact during handling, transport, and storage so that the safety of the contents is not at risk. It is these applications that have made flexural testing so important for retaining the reliability of materials in various fields.

Understanding the Formula for Flexural Strength

Components of the Flexural Strength Formula

The Flexural Strength Formula

Where:

- σ stands for the flexural strength (force per unit area), such as Pascals or psi.

- F stands for the maximum force or load that is applied during testing.

- L stands for the support span (the distance between supports in the test setup).

- b stands for the width of the tested material sample.

- d stands for the depth (thickness) of the tested material sample.

Comparing Flexural Strength with Tensile Strength

They are including flexural strength and tensile strength, important characteristics used when assessing materials for mechanical performance, yet both do show different ways of describing material behavior. The flexural strength is a measure of a material’s resistance to deformation under bending loads and reveals the behavior of the material when subjected to loads causing bending or flexural stress. On the other hand, tensile strength measures the greatest force exerted on the material when it is being stretched or pulled, right before it breaks.

The main differences lie in how forces get applied to the sample during testing and how the samples respond to those forces. Flexural strength testing applies forces to the specimen simultaneously causing compression on one side and tension on the other, with the results indicating how the specimen can resist bending stresses. Conversely, tensile strength involves pulling along one axis, giving direct information about stretching resistance and the final breaking point of a material.

Both properties are imperative for selection of materials for their varied uses. Materials with high flexural strength are suitable for use where they will be bent, such as beams or floor panels. Materials having a high tensile strength are suitable for applications requiring forces of pulling, for example, ropes or cables. Understanding how they differ and what their correct application is will allow materials to be suitable for the demands of the application.

Testing Methods for Flexural Strength

Three-Point Flexural Test Explained

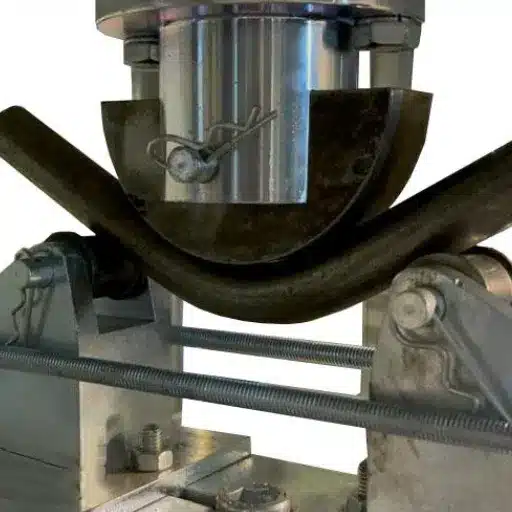

This three-point bending test is used usually for performing a test on a specimen for its bending strength. This test requires the specimen to be opposed by two supports, and the load is applied to the center of the span. The load is increased until the specimen is either fractured or excessively deformed. Through the test, one can gain important information on how the material behaves against bending stress; this is, indeed, crucial information for deciding whether such materials can be adopted for structural purposes.

The test set-up consists essentially of three parts: the supports, the loading point, and the specimen. The distance between the supports is called the span, and the force is applied singly at the midpoint. This force produces stresses in the specimen-the tensile stresses develop on the surface at the bottom, while the compressive stresses develop on the surface at the top. Knowing the maximum force applied and the dimensions of the specimen, the flexural strength may be calculated.

Simple and reliable, this method provides an immediate insight into its bending behavior. Considerations to be kept in mind for the test include aligning the specimen accurately and applying force uniformly to avoid errors from creeping. Through the results, the manufacturers can verify whether the material is suitable for bending loads during construction, manufacturing, or mechanical application with regard to safety and structural integrity.

Four-Point Flexural Test Overview

The four-point flexural test is a method for assessing the flexural strength, stiffness, and resistance of materials, especially under bending loads. Unlike the three-point flexural test, two concurring loading forces are applied symmetrically over a specimen, setting up an area of constant stress between the loading points. This zone of constant stress provides valuable information on the bending response of the material, as stress concentration at a single point is best avoided for such an assessment.

The specimen is loaded by two downward forces acting from above, well enough to be close to its structural failure condition. This setup maintains a controlled scenario where the material response is recorded under evenly distributed loading conditions. By observing the external forces applied and the resultant deformations, an engineer could quantify important properties like the flexural modulus and the maximum stress at which the material fractures or yields.

The strength test is a method commonly employed in construction, aerospace, and manufacturing industries to make sure a material meets the safety and performance standards required for the application. This is distinctly predicted for the brittle materials such as ceramics, composites, and certain plastics to have a clear idea about their behavior under static or quasi-static bending loads. This data which calls for evaluating is used in determining if a material is suited to a given application and structural integrity to assure it can perform reliably under stress.

Choosing the Right Test for Your Materials

Selection of tests for materials depends on the application requirements on the one hand and the nature of the material being tested on the other. Structural materials such as metals or composites generally undergo mechanical tests, including tensile, compression, and flexural strength tests in order to verify their ability to withstand applied forces without failure. The information derived from such mechanical tests is very important as it relates to how much load a material can bear and how much deformation it undergoes when subjected to stress.

For brittle materials such as ceramics and certain plastics, three-point or four-point bending tests are commonly performed at least because such materials respond well to these test methods under static or quasi-static bending loads. There are also hardness tests or tests of fracture toughness that can further tell how much a material resists surface wear or crack propagation.

Environmental testing also becomes essential if the material will be subjected to extreme conditions such as high temperature, moisture, or chemicals. Such tests include thermal cycling, corrosion resistance, long-term durability testing, and many more to simulate a real environment. With careful consideration of each test’s purpose and the operational conditions under which your material will actually be working, you can rest assured that it will fulfill the expected performance and remain reliable for its intended service life.

Factors Influencing Flexural Strength

Material Composition and Its Impact

The flexural strength of a material is strongly dependent on the very material composition. This is the capacity of a material to undergo deformation or fracture when subjected to bending stress. How the material is structured and selected determines the way it can carry the load applied to it.

For example, metals tend to show a uniform flexural strength since they consist of homogeneous materials. Composite materials, constituted by several phases like fibers and resins, tend to respond differently in flexural strength to varying proportions and types of their constituent elements. Fiber orientation and the quality of matrix bonding play a crucial role in how the material withstands stress.

Impurities or inconsistent distribution of components into the given material also reduce flexural strength. Through controlled processing and using high-grade raw materials, one ensures uniformity in the material and enhances its resistance to stress. By varying an alloy to meet certain performance requirements, it can guarantee performance reliability and mechanical efficiency in any given application.

Effects of Temperature on Flexural Strength

Flexural strength in materials and temperature have a strong relationship. At elevated temperatures, most materials need their flexural strength reduced mainly because of the softening or weakening of their internal structure. Under stress, a material cannot withstand deformation or failure, leaving it almost useless in an environment where high temperatures prevail. Metals and polymers, for example, could lose stiffening and strength when exposed to increased temperatures; hence, they become inefficient in structural applications.

In contrast, at low temperatures, materials can sometimes turn brittle, hereby the strength occurring just from rigidity because a lack of ductility makes them more susceptible to cracking or breaking under stress. These plastics, for example, could behave in uncertain ways when cold, ultimately jeopardizing the reliability of their performance.

Concerning temperature effects on the flexural strength, materials are generally conditioned or engineered for the specific operating environments. Depending upon the use of an additive, treatment, or structural configuration, the materials are designed to maintain their strength within the specified range of temperatures. Hence, such effects need to be tested and studied during design to have a long life and serviceability over a wide range of thermal conditions.

Influence of External Forces

External forces greatly change the shape, size, and/or performance of a material. These forces can be mechanical loads: tension, compression, shear, and torsion might cause deformation or failure, depending on the properties and design of the material. The material’s resistance to such external forces is very important in determining its suitability for particular service. Duration, magnitude, and frequency of load application greatly influence the behavior of materials in different working conditions.

Fatigue is the greatest concern related to external forces. A material subjected to repeated or cyclic loading is weakened and develops microcracks until eventually, the object fractures. Fatigue particularly manifests itself in materials used in infrastructures like bridges or aircraft, where the very key lies in standing up to repetitive stress. Testing and the use of accurate models can assist engineers in predicting the probability of fatigue in materials and better their designs for the longer lifespan of a particular material.

In order to lessen the damaging effect of external forces, materials may sometimes be reinforced by mixing in other materials for strength. For instance, the construction of composite materials capitalizes on the strengths of distinct materials to better resist mechanical stresses. Furthermore, the use of advanced simulation techniques coupled with comprehensive material testing under variable loads allows designers superior capability to select materials that exhibit ideal performance and reliability under demanding service conditions.

Real-World Examples and Case Studies

Flexural Strength in Design and Safety

Flexural strength is essential in design and safety concerning structures or components submitted to bending forces. It is the capability of a material to resist deformation when acting under loads, hence ensuring stability and durability. Designers consider flexural strength to avert possible failure in the event of structural instability and hazard to safety. In this way, determination of this property aids in the selection of the material in cohesion with safety and performance criteria.

Flexural strength directly influences safety in practical applications in concrete and composites. For example, flexural strength supports loads on reinforced concrete beams in the fields of buildings and bridges. Similarly, fiber-reinforced composites are used extensively in aerospace and automotive industries with consideration to flexural strength so that the structure can withstand forces acting on it while remaining light. These applications make it a matter of efficient and safe design realization.

Testing and standards are imperative for safety purposes in respect of flexural strength. Tests like the three-point bending test give an ability to evaluate the materials’ behavior under load and to assess critical factors for more safe designs. This reduces risk, provided that standards according to safety codes appropriate to the industry in question are followed. Such flexural strength problems, balanced in a reliable way through testing methods and design methods, have been well handled by engineers to give safer and sturdier constructions.

Impact on Material Selection and Engineering Decisions

Flexural strength testing lays the groundwork for material selection and engineering decisions. Understanding a material’s behavior under load allows engineers to decide on that material for further treatment depending on whether or not it meets a minimum level of performance and safety typical to the application. This reduces the risk of mechanical failure while facilitating efficiency and durability in construction or product design.

Flexural strength tests would throw light on the deformations or fracture limitations and any bound advantages of the material considered. For example, materials with greater flexural strength would ideally be used in constructions requiring resistance to bending forces, such as beams or structural supports. From the contrary perspective, materials with lesser flexural strength will be used where there is more of a demand for flexibility. Such types of information assist engineers to weigh among factors like cost, availability, and environmental conditions when planning or designing structures or products.

In a more sustainable and flexible manner, test results combined and considered during materials selection. Correct testing ensures best performance of materials for the given operating conditions, limiting possibilities of over- or underdesign. Such sound engineering conduct will uplift safety and innovation as well as compliance with industry codes and standards in the context of requirements.

Future Trends in Flexural Strength Applications

In material advancements, newer and newer technologies are changing the application of flexural strength. In a market of newly developed composite materials, fiber-reinforced polymer composites show enhanced performances. These materials are lightweight and enjoy a high strength-to-weight ratio, making them suitable for the automotive, aerospace, and construction industries. Continued research may improve the durability and flexibility of the next generation of designs using nano-materials.

The integration of computational tools and simulation technologies in the design and testing phases is one such paramount trend not to miss. Now, advanced modeling software can accurately predict the behavior of materials subjected to various flexural stresses. So, there is less dependence on physical testing, which expedites development. Emerging technologies like AIs and machine learning are also expected to act as major factors in material selection and predict the longevity behavior of the materials in various conditions.

Another focus point in the application of flexural strength is sustainability. Industry concerns grow with the fact that materials used must be recyclable and environmentally friendly, thereby upholding the requirements of performance. This movement would, therefore, align with the global sustainability goals while life cycle costs are diminished with respect to materials. Hence, trends portray a scenario where the future sees the convergence of materials, technology, and sustainability in that they are employed to improve efficiency and resilience of structures and products present in practically all applications.

Frequently Asked Questions (FAQ)

Q: What is the formula for flexural strength?

A: The formula for the flexural strength is determined by σ = (3FL) / (2bd²), with σ being the flexural strength, F being the applied force or load, L the loading span, b the width of the rectangular specimen, and d the thickness of the cross section.

Q: How can I calculate the flexural strength by using a flexural test machine?

A: To calculate flexural strength by using a flexural test machine, you subject the test specimen to a three-point or a four-point test, record the maximum load applied, and note the dimensions of the sample; then apply the formula for flexural strength.

Q: What are some of the ways of improving the flexural strength in concrete?

A: Ways of improving the flexural strength of concrete include, amongst others, using high-grade materials, suitable mix design, some form of reinforcement like steel rods, or fibre composites that enhance the properties of the material.

Q: How does axial force play a role in flexural strength?

A: The axial force acts on the flexural strength of a member by affecting its stress distribution. When axial forces are applied, they can either increase or decrease the overall flexural strength, contingent upon the type of loading and on the geometry of the cross-section.

Q: How does stress-strain behavior influence flexural strength?

A: Flexural strength of materials can mostly be described considering the stress-strain relationship. It tells us how materials deform under stress, and their capacity to resist bending moments without fracturing or undergoing permanent deformation is necessary for structural integrity.

Q: What is the importance of the strength reduction factor in flexural design?

A: The strength reduction factor will consider variabilities present in a material and in load conditions. During design, the factor is applied so that the flexural strength may provide ample margin against failure.

Q: How is deflection related to the flexural strength of a beam?

A: Deflection is the amount that a beam bends under a load. The flexural strength determines the maximum load that a beam can withstand without breaking, whereas being rated more deflected will suggest that the beam is, concrete performing under the given load.

Q: Which materials are commonly tested for their flexural strength?

A: The common materials tested for flexural strength are concrete, steel, timber, and fibre composites. Each material has attributed characteristics against which it exhibits bending under flexural tests.

Q: What is a rectangular sample in relation to flexural strength tests?

A: Such a specimen is simply considered as a bar having a rectangular cross-section and subjected to bending loads in flexural strength testing. Dimensions are of utmost importance because without proper dimensions, computation of flexural strength via the formula would be inaccurate.

References

-

Flexural Strength – Wikipedia – Provides the formula for flexural strength and explains its application in measuring material failure under stress.

-

What is Flexural Strength? – Engineering.com – Discusses the concept of flexural strength and the forces applied during testing.

-

How to Calculate Flexural Strength – Sciencing – Offers a step-by-step guide to calculating flexural strength using the standard formula.