Understanding Lap Shear

Definition of Lap Shear

Lap shear is a test that measures the shear strength of an adhesive bond between two substrates. It determines how well an adhesive holds materials together when forces are applied that push the bonded layers to slide over each other. This test finds application where adhesive behavior under shear stress needs to be assessed.

In a typical lap shear test, two overlapping substrates with the adhesive under test between them are bonded together. The bonded substrates are pulled apart by a force applied in opposite directions to the substrates until the force breaks the bonded area. The bond strength obtained by measuring that force offers a quantitative means to compare adhesives.

Lap shear testing is key for sectors where bonds have to be strong and reliable, such as the aerospace, automotive, and construction industries. By understanding the performance of adhesive under a particular set of conditions, the engineers and manufacturers appreciate the specification in order make sure that the bonded components are safe, durable, and fit for use in their applications.

Importance of Lap Shear Tests

The lap shear test is required to give assurance to the reliability and safety of bonded materials in manufacturing across various industries. This test provides a widely accepted method for measuring shear strength of adhesives under controlled conditions. Such data then allows an engineer to determine if a bond will withstand the stresses encountered in real-life applications. Emphasizing this point further is the fact that there are some applications, such as in aerospace and automotive sectors, where failures of materials may lead to catastrophic results.

Another important advantage of lap shear tests is their applicability to quality control and product development. Through the measurement of the performance of an adhesive in different parameter variations, such as temperature, humidity, and load conditions, manufacturers may adjust formulations to enhance adhesive performance in specific areas and improve bonding methods accordingly for greater bonding efficiency and increased life-span reduction of maintenance costs in the long run for the bond contaminants themselves.

In essence, lap shear testing advances engineering solutions by providing the exact data necessary for the design of safer and durable products. These tests enable decision-making regarding materials selection with due consideration to safety standards and regulations. Such level of accuracy and reliability is essential to uphold confidence and dependence in high-stake industries where the bonding plays a fundamental role.

Applications of Lap Shear Strength in Engineering

Being one of the essential parameters among many used in engineering, the adhesion is tested for its ability to withstand shear stress. So, adhesives with too much or too little lap shear strength may be an impediment to the work in suspect applications. In aerospace, automotive, and building industries, among others, these bonds are important from the standpoint of performance, safety, and durability.

Industry Spotlight: In aerospace, for example, the lap shear strength ensures that aircraft body panels and structural members remain bonded together even under extreme loads and severe environmental conditions. Likewise, in the automotive industry, testing adhesives with this measure is becoming the norm in assembling vehicles that are to be judged for lightness, fuel efficiency, and crashworthiness.

And lap shear strength tests find great applicability in construction materials. These types of adhesive bonds in the construction elements, such as between metal beams or composite panels, must bear long-term mechanical stresses and possibly environmental conditions that might include temperature variations or moisture. Then there remains the crucial design factor in favor of structures that can stand long and are reliable by virtue of achieving high lap shear strength; thereby attesting to the Importance of this testing in the present engineering practices.

Lap Shear Test Methodology

Overview of the Lap Shear Test

The lap shear is a standardized method of determining adhesive strength by the measurement of force employed to shear one material over the other. This test becomes important when determining the bonding capability of adhesives, especially in industries where materials are expected to perform under some mechanical stress, such as in aerospace, automotive, or construction. The test is conducted by introducing a limited load onto the bonded materials with overlapping areas that simulate shear forces present in real structural applications.

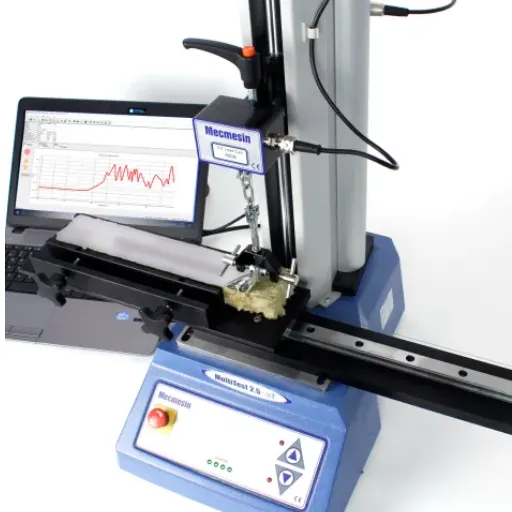

Samples are prepared for the test with overlapping areas by way of bonded lap joints. The samples are installed into the tensile testing machine, which applies uniaxial force on the samples until failure. The resulting force at failure is recorded as the lap shear strength and expressed as force per area, such as psi or MPa. Proper test equipment alignment and calibration are the keys to accuracy and repeatability of the data.

Lap shear tests carry a lot of importance for determining the best adhesive and bonding materials for the job, as well as for analyzing the actual condition of the bonded structure, i.e. to know how best the bond withstands given conditions. An understanding of adhesive performances under a shear force-based condition will help engineers and designers make more conscious design choices about safety, reliability, and performance aspects of any structural system. This testing also can point out the weak areas or the development for the adhesives that are to confirm to industrial standards and requirements of the allotted application.

Specimen Preparation for ASTM D1002

Key Preparation Steps:

- Materials must comply with ASTM D1002 specifications

- Two metal substrates (usually aluminum) are prepared

- Metal sheets trimmed to 1 inch width × 4 inches length

- Surfaces cleaned and abraded for proper bonding

- Adhesive applied evenly to 1-inch overlap area

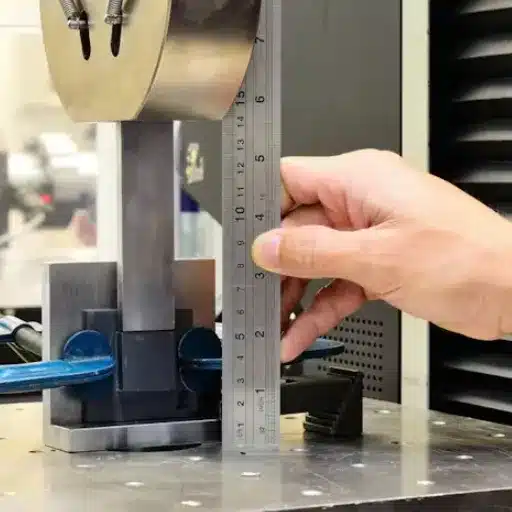

For ASTM D1002 testing, all materials must comply with the specifications laid down by the standard. In most cases, two metal substrates, usually aluminum, are bonded using the adhesive to be tested. The metal sheets should be trimmed to the exact size dimension of approximately 1 inch in width and 4 inches in length to meet the testing requirements. The surfaces must then be cleaned and abraded to prepare them for bonding. Proper surface preparation ensures good adhesion and accurate results.

Afterward, the adhesive is applied evenly to the bonding area, covering an overlap of 1 inch between both substrates. The specimens are then carefully placed with correct alignment so as not to allow misalignment during adhesive curing. The bonded parts are secured with the help of clamps or fixture tools holding them in position until the cure of the adhesive as per the manufacturer’s recommended time.

Once the curing process is complete, the bonded specimens are inspected for defects like voids or bubbles or for inconsistent adhesive application. All these can adversely affect test results, and thus defects should get discarded. The specimens will further be conditioned before testing to expose them to conditions they realistically encounter in the environment or during operation for precise results.

Testing Procedures and Equipment

Testing procedures and methods play an important role in the measuring, verification, and evaluation of bonding specimen performance and reliability. The process is initiated with the meticulous preparation of the test specimens and considered critical for ensuring accurate and consistent results from the tests. The specimens are then loaded into machines which test tensile strength, shear strength, peel resistance, and any other parameters that might be important. The machines exert controlled forces upon the bonded samples to measure and characterize their mechanical properties under actual conditions.

Environmental testing chambers have long been used as means to simulate real-world conditions such as temperature extremes, humidity, or chemical exposure. How does the bonding material hold together as time passes and different environments? The equipment must, however, be properly calibrated and set up to make sure the results are repeatable and reliable. In addition to test results being recorded in accuracy, high-precision sensors, and data, acumen systems are put into use.

Safety Considerations

During testing, safety considerations are of paramount importance. Operators involved in the experimental process must follow all safety guidelines and wear protective equipment so as to minimize hazards. Often, results are analyzed and compared to set standards or references to ascertain if the specimen fulfills respective criteria of performance.

Hence, at the end of such procedures and using suitable instruments, the testing process guarantees the bonded materials to hold integrity and reliability in actual applications.

ASTM D1002 Standards

Overview of ASTM D1002

The shear strength of adhesives using single-lap-joint specimens becomes the stuff of ASTM D1002. It rates the competence of adhesive bonds to hold up under shear stress. The test is specified for rigid metal adherends, although some testing forces have been applied to other materials. The test technique in ASTM D1002 involves applying a uniaxial tensile load to a precisely prepared bonded specimen to measure the state change to stress evenly across a single bond line.

Industries like aerospace, automotive, and construction, for which performance of the adhesive is paramount, greatly benefit from having usage of this test method. Tests using this method give equivalent repeatability and reproducibility data to help manufacturers choose adhesives that meet performance requirements for a given application. Also, test results can be applied in quality control for materials conformity to predetermined standards.

ASTM D1002 Advantages & Limitations

Advantages

- Clarity and precision

- Ease of application

- Reliability of results

- Wide industry usage

Limitations

- Limited to rigid adherends

- May not suit flexible materials

- Specific to metal substrates

ASTM D1002 is known for its clarity and precision in characterizing adhesive strength, but some drawbacks need to be mentioned. Specifically, since it deals with rigid adherends, the test may not yield relevant results for more flexible materials or joints. The standard enjoys wide usage for quite obvious reasons: ease of application, reliability of results, and the information on adhesive shear performance that it bestows.

Key Parameters and Requirements

Several parameters must be taken into consideration when performing an ASTM D1002 test to keep the consistency and accuracy. The preparation of the test specimen is one of the most important aspects. Before applying the adhesive, adherends must be well cleaned as any contamination could deteriorate the results. The setting of the adhesive should also be uniform, and any deviation from the standard preparation must be recorded.

| Parameter | Requirement | Importance |

|---|---|---|

| Specimen Preparation | Clean, abraded surfaces | Prevents contamination effects |

| Environmental Conditions | Controlled temperature & humidity | Ensures consistent results |

| Specimen Dimensions | Specified tolerances | Reduces measurement uncertainty |

| Bond Line Thickness | Uniform thickness | Fair measurement accuracy |

The environmental conditions during testing also play an important role. The ASTM D1002 procedure calls for the use of control conditions for temperature and humidity, as variations in these parameters influence adhesive performance and the shear strength that is being measured. A tensile test machine is used for the test, while proper alignment and load application are important for the accuracy of the results.

The specimen dimensions and the bond line thickness are also strictly governed by the standard. They must conform to specified tolerances to reduce their uncertainty and to provide equal basis for comparison between the tests. The bond line thickness must be kept unbiasedly uniform for the adhesive shear strength to be fairly measured. Following these parameters ensures that the results accurately reflect the performance of the adhesive under standardized test conditions.

Comparison with ASTM D5868

This ASTM D5868 test method is set up to determine the lap shear strength of adhesives bonding rigid substrates. It deals mainly with evaluating the resistance of an adhesive to shear-force applications applied to the specified materials in specific conditions. Despite these similarities with other adhesive testing standards, ASTM D5868 comprises varied procedures and requirements meant for its applications.

An important differentiator between ASTM D5868 and other methods deals with substrate materials and preparation procedures. Unlike others that may use a variety of substrates for testing, ASTM D5868 typically employs rigid substrates such as metals or composite materials while providing precise instructions on surface preparation. These require that either one must reproduce the results exactly or at least see the adhesive as performant under real-world conditions.

The line thickness is indeed specified in ASTM D5868 to maintain the uniformity of tests, much like in any other standard. The dimensions and tolerances, however, might vary with specific standards and must be followed with very close adherence to avoid noncompliance. ASTM D5868 certification thus helps procure data which can be relied upon, compared, and reproduced in common-use situations toward the evaluation of adhesives for industrial or structural applications.

Evaluating Shear Strength

Measuring Shear Strength Properties

Shear strength is measured to enable the determination of the maximum stress that materials or an adhesive bond could withstand before failure occurs in shear loading. For testing shear strength, a sample is prepared according to certain standards, such as ASTM D5868, ensuring that the testing will produce consistent results. The sample is placed under a load applied parallel to the bonded or material surface until failure occurs.

Key Measurement Metrics

- Stress Units: Results recorded in MPa or psi

- Performance Data: Maximum stress before failure

- Safety Assessment: Conditions under which failure occurs

- Design Applications: Safer and more durable structures

The results of such testing are recorded in terms of stress, usually in MPa or psi. They provide useful information concerning the performance of adhesives or materials under certain conditions so that the conditions under which failure might occur can be ascertained. This assists engineers in constructing safer and more durable structures.

The shear strength evaluation is vital in different industries such as construction, aerospace, and automobiles since the performance of the materials dictates safety and functionality. Thus they must be properly measured to ensure that these materials comply with the performance specifications required, while choosing the appropriate adhesives or design structure that will fit the application.

Factors Influencing Shear Strength

Material Composition

Metals, composites, and polymers differ in internal structures and resistance to shearing forces. Grain structure and fiber orientation greatly influence shear capacity.

Environmental Conditions

Temperature and humidity significantly impact performance. High temperatures may destroy internal bonds, while low temperatures can cause brittleness.

Manufacturing Quality

Adhesive layer thickness and surface preparation are critical. Poor processes can cause defects like voids or uneven surfaces.

Several factors influence shear strength and, hence, affect the behavior of materials while being subjected to shear stress. One factor is material composition. Metals, composites, and polymers generally differ with respect to their internal structures and how they resist shearing forces. For instance, the grain structure or fiber orientation of a material would greatly influence its shear capacity. Generally, materials tend to exhibit greater shear strength where greater cohesive forces exist within the structure.

Another factor to be considered is the environment, such as temperature or humidity. High temperatures may destroy the bond within the material or reduce shear capacity, whereas low temperatures may cause particular materials to become brittle and fail easily. Exposure to moisture or chemicals for a long time will also degrade the materials, especially adhesives or composites, thereby adversely affecting their shear performance.

The last major factor is the manufacturing or bonding process quality. For instance, with adhesives, the thickness of the adhesive layer and surface preparation are critical to achieve the best bonding and shear resistance. A poorly controlled process could cause defects, such as voids or uneven surfaces, that reduce the shear strength of the material. By considering these issues, engineers can be assured that the materials are suited to the intended applications and meet the required performance standards.

Common Testing Results and Interpretations

Typical Test Results Include:

- Maximum Load: Peak force before failure

- Displacement at Failure: Material deformation measurement

- Corresponding Shear Stress: Calculated stress values

When considering shear strength, testing results usually include maximum load, displacement at failure, and corresponding shear stress. All these data points permit engineers to assess the capabilities of materials in resisting the applied force and sustaining structural integrity when subjected to load. A higher shear strength means that the material stands great applications, while the lesser values pose limitations or are prone to failure under stress.

Interpretations for such results rely on the test parameters and particular applications of the material. Shear testing at temperatures higher than normal might be an attempt on conditions synthetic in some industries. Aerospace industries, automotive industries, and the like rarely see materials spared thermal or mechanical stresses. Engineers hence must make a thorough comparison of test results with industry standards or the given specifications set forth in a given project to ascertain that it meets safety and performance parameters.

Reliable results thus also hinge on the standardized test procedures. They include such elements as specimen preparation, testing velocity, etc. Calibration of instrumentation among others can have a great say on the results. For optimally choosing a material and applying it in as many applications as possible, minimizing variations by adhering to the protocols and rendering correct interpretation works are key areas to be considered by an expert.

Applications of Lap Shear Tests

Industrial Use Cases in Aerospace

Aerospace Applications

Fuselage Testing

Bonded joints in aircraft body structures

Wing Components

High mechanical load resistance

Composite Materials

Lightweight alternatives to metals

In aerospace settings, lap shear tests are predominantly performed to ascertain the strength and durability of adhesive bonds subjected to shear stresses. Given that bonded joints become primary contributors to aircraft structure integrity on the operational side, these tests provide valuable information on the behavior of adhesives under conditions very close to actual operational stress. In the same vein, these tests aid in the validation of materials and bonding techniques for use in fuselages, wings, and other major components subjected to high mechanical loads.

One major application is the testing of lightweight composite materials that are increasingly taking the place of metals in aerospace design to achieve better fuel efficiency. Lap shear testing also ensures that the adhesive joining these composites conforms to safety standards. By representing real-life stresses, these tests enable engineers to evaluate long-term performance, fatigue resistance, thermal cycling, and resistance against environmental attacks, such as moisture or UV radiation.

In the lap shear test, these tests promote innovation in airplane design by allowing the safe utilization of novel materials and hybrid structures. These tests provide the adhesive formulations with certification evidence, guaranteeing that these formulations comply with regulatory standards. The safety and reliability of this process ensure the performance and life of aerospace systems and, thereby, enhance the design of the industry for practicality and sustainability.

Automotive Applications of Adhesive Joints

| Application Area | Benefits | Materials Joined |

|---|---|---|

| Vehicle Body Assembly | Weight reduction, improved fuel efficiency | Metals, plastics, composites |

| Structural Components | Uniform stress distribution | High-strength alloys, carbon fiber |

| Noise & Vibration Control | Sound absorption, vibration damping | Various automotive materials |

There is expansive use of these adhesive joints between metals and many types of plastic and composite materials in engineering of vehicle bodies. In the automotive industry, the contribution of adhesives is also to lessen vehicle weight by replacing mechanical fasteners, thus enhancing fuel mileage and reducing emissions. Another benefit of adhesive joints is their ability to improve durability of structures by applying stresses uniformly over the bonding surface.

Another essential advantage of adhesive joints in vehicle construction is their capacity to join unlike materials. This allows manufacturers to innovate with materials such as high-strength alloys and carbon fiber-reinforced composites in vehicle design. Bonded adhesives provide seamless assembly that does not compromise the integrity of the materials in question, thereby fostering innovations in safety, design complexity, and performance.

Adhesive joints also contribute to noise reduction and vibration damping in vehicles. With their flexible characteristics, they absorb sound and vibrations generated by engine operation or road conditions, promising a quieter and comfortable ride experience. As adhesive development continues, joints are designed to resist extreme temperatures, chemical exposure, and mechanical stresses to ensure durability and reliability throughout the lifecycle of the vehicle.

Construction Industry Insights

Construction Advantages

- Material Versatility: Bonds steel, concrete, glass, and composites

- Design Innovation: Enables lightweight construction methods

- Process Efficiency: Faster assembly than mechanical fasteners

- Sealing Properties: Creates airtight and watertight seals

In modern construction, adhesives are a very versatile tool for bonding materials and for actually giving structural integrity to whatever is being manufactured. They are used extensively, so to say, to assemble different materials like steel, concrete, glass, and composite materials, which technically allow for more design innovations and lightweight construction. The other advantage is that adhesives come with the promise of a lot of flexibility and strength, apart from reducing the use of more traditional methods such as mechanical fasteners, thereby speeding up processes and improving efficiency.

One of the biggest advantages of using an adhesive bond in construction is their ability to spread stresses more or less evenly across the bonded surfaces, thus reducing localized strengths and, therefore, increasing construct durability. In addition, adhesives aid in creating airtight and watertight seals between materials, improving energy efficiency in buildings by reducing heat loss and keeping out water. Such attributes are in line with ever-escalating demands for green and environmentally friendly construction practices.

The application of top-quality adhesives has changed construction techniques, awarding faster assembly, higher design freedom, and stronger end result. Adhesive technology continues to evolve to accommodate industry demands for high performance and reliability in circumstances as extreme as temperatures and loads. This innovation marks yet another milestone of importance for adhesives in determining the future path of the construction industry.

Frequently Asked Questions (FAQ)

Q: What is lap shear?

A: Lap shear refers to a kind of adhesive joint where two materials overlap, and shear forces are applied parallel to the adhesive bond. This joint configuration is tested often to assess the bonding strength and performance of adhesives.

Q: How does one conduct a lap shear test?

A: A lap shear test is conducted on a testing machine, like a universal testing machine, in which a test specimen is prepared with an adhesive bond between two substrates. The test involves applying tension loading until failure occurs and measuring shear strength.

Q: Why is lap shear strength important?

A: The lap shear strength is important in terms of describing the bond strength between two materials joined by an adhesive. In return, it is the maximum shear stress that can be withstood by an adhesive before the bonded joint fails.

Q: What were the ASTM standards for lap shear testing?

A: ASTM D1002 specifies a test method for measuring lap shear strength of adhesive bonds for metal substrates. The test covers specimen preparation and test procedures to provide reliable and comparable results.

Q: What affects lap shear strength?

A: These factors include surface preparation of the substrates, the adhesive chemistry, specimen geometry, and the force that is applied in the testing machine. Proper adhesion and bond integrity play a great deal in the successful development of high strength.

Q: How does specimen geometry influence lap shear test results?

A: The specimen geometry influences the distribution of stress and the apparent shear strength of the joint, e.g., the width and overlap length of the bonded area. Such geometry must be chosen to reduce stress concentration and distribute load uniformly.

Q: What are the common failures during a lap-shear test?

A: Typical modes of failure in lap shear tests include adhesive failure, cohesive failure within the adhesive layer itself, and substrate failure. Knowing these failure mechanisms can help in adhesive formulation and in bonding techniques.

Q: Can different materials be subjected to lap shear tests?

A: Indeed, lap shear tests may be conducted on various materials, such as metals, plastics, and composites. The adhesive to be used and the test method may change according to the materials that are to be bonded and their properties.

Q: How are the adhesional properties influencing the lap shear strength?

A: Factors like adhesive viscosity, cure time, and chemical composition affect the lap shear strength. High-strength adhesives are thus favored where durability and reliability of the bonded joints are considered critical.

References

- Lap Shear Test – an overview – Provides an overview of various lap shear tests, including single lap, double lap, and thick adherend shear tests.

- Lap Shear Testing of Adhesives – Focuses on lap shear strength testing for adhesives and its ability to measure material stress resistance.

- Guide to Lap Shear Testing – A detailed guide on lap shear testing, its types, and how it evaluates adhesive capabilities.

- ASTM D1002 Testing Services for Adhesive Shear Strength – Covers the ASTM D1002 standard for evaluating lap shear strength of adhesive bonds between metal substrates.