The strength and ductility of metals are primary factors that determine their performance and reliability in a variety of industries, including construction and manufacturing. A common method employed to determine these properties is bend testing, which provides insights into how metals will act under stress. This article takes an in-depth look at the role of bend tests, with emphasis placed on the ISO standards that govern these tests. Whether you’re an engineer or materials scientist looking to delve deeper into the field, or simply curious about metal defectology, this blog provides a firm grasp on the contribution bend testing makes toward safety, durability, and quality control of metal applications. So, let’s get into the key concepts, procedures, and importance of this fantastic testing method.

Purpose of the Bend Test

Assessing Ductility and Strength

Ductility and strength are mainly measured using bend testing on metal materials. Ductility, the ability of the material to be deformed under a tensile stress, is important when the application involves bending of the metal without causing a fracture. This test procedure would enable an engineer to evaluate how far a metal material can elongate or flex before in the form of crack formation or even fracture, thereby giving a clear indication of its degree of bending or pliability and strength.

The bend test is used to establish a material’s strength in resisting mechanical stresses without failure. Strength is needed in applications where metals are subjected to loads that may be dynamic or static for an extended period. A material is reliable compared to a specific application if it behaves well under these conditions, be it in construction, manufacture, or industrial applications.

Knowing the ductility and strength from the bend test will enable an engineer to predict the behavior of the material in various real-life situations to confirm that the metal selected for the job will satisfy safety and performance criteria so as to eliminate the possibilities of structural failures and promote the longevity of the end product.

Importance in Material Selection

Material selection is a critical process in engineering and industrial applications because it directly affects the performance, safety, and longevity of a product. Choosing the right material involves assessing its mechanical properties, such as strength, ductility, and resistance to wear or corrosion, to ensure it meets the specific demands of the intended application. The results from bend tests and similar analyses provide engineers with the necessary data to evaluate these properties effectively.

One of the key reasons for prioritizing material selection is the prevention of structural failures. Materials must be capable of withstanding the forces and conditions they will encounter during use. For instance, in construction, selecting a material with insufficient strength might lead to catastrophic failures under load. Similarly, in manufacturing, improper material selection can result in products that degrade prematurely, increasing maintenance costs and reducing reliability.

Additionally, the correct material selection improves efficiency and optimizes costs. Materials suited to their tasks often require less maintenance, perform better under stress, and have longer life spans. For example, using a corrosion-resistant metal in environments exposed to moisture ensures durability while minimizing replacement needs. Ultimately, careful material selection not only satisfies safety and performance requirements but also contributes to sustainable and cost-effective design solutions.

Impact on Structural Integrity

The materials or more aptly the engineering approach adopted in any project consequently become the determinant of structural integrity. Basically, the material used defines the structural performance against the acting measures, such as loads, weather, or natural hazards over time. For instance, strong materials such as steel and reinforced concrete support huge constructions and keep them stable and safe under loads of several classifications.

Other entities that safeguard a structure include proper engineering design. These designs ensure structural integrity when they include considerable calculations toward load distribution, stress points, and environmental impact, preventing structural failure. Safety margins and building codes ensure durability and safety in standards. Maintenance may increase structural integrity because it picks out weak areas and takes remedial action at an early stage.

When working with good materials and sound engineering practice, these structures will definitely perform successfully over time. By saving lives and protecting property, this greatly diminishes the enormous expenditures tied to repairs and replacements. Through this focus, structural integrity could be assured in a very timely and cost-effective manner.

Types of Bend Tests

3-Point Bending Test Overview

The 3-point bending test is ideally for measuring the flexural strength and stiffness of materials. A force is applied to the specimen supported at two ends while the response to loading is recorded. This experiment provides very vital information on the performance of materials under bending stresses and is thus used to assess structural integrity and to ascertain whether a material is suitable for a given application.

The specimen is positioned horizontally and supported at two fixed points underneath. A downward force is applied to the midspan by means of a rounded loading nose. The force is slowly increased until the material breaks. The collected data include the highest load that the material can withstand and the deformation it incurs; these data will be further used to find the flexural strength and modulus of the material.

The main advantage of the 3-point bending test is its simplicity, as well as the small specimen size required for the test. This method is very useful for comparing materials or for examining areas in manufacturing where potential faults may exist. Loading rate, geometry of the specimens, and homogeneity of the material affect the results and must be controlled to obtain correct results. A good understanding of these limitations and the correct conditions for testing will make the 3-point bending test a valuable method for evaluating materials.

4-Point Bend Test Explained

Commonly used in material testing, the 4-point bending test was run to find the flexural properties of the sample. A force is applied to a beam-shaped specimen, supported at two points, with two additional points equidistant from the supports across which a downward force is exerted. This set of distances helps maintain that maximum stress lies between the two loading points, which helps in targeted and precise measurement of the material’s flexural strength and deformation attributes.

If compared with a 3-point bend test, the bigger advantage of the 4-point bend test is the load application over a large area of uniform stress lying between the two loading points. This feature becomes very important as the material studied might have local defects or local inconsistencies, whereas the 3-point bending tests suffer well if the defects concentrate at one point. The 4-point bend test can find properties of flexural strength, flexural strain, modulus of elasticity, etc., crucial in understanding the behavior of materials under loading.

The 4-point bend test finds numerous applications wherever knowledge about the behavior of a specimen under bending stress is essential in construction, manufacture, and aerospace. Preparation of the specimen, alignment of the supports, and the load points must be accurate, with reversing of the position to ensure proper working. These tests provide pertinent inputs related to the structural integrity of a material under consideration, making them very useful for comparative analysis, quality control, and highlighting probable failure points in engineering applications.

Comparative Analysis of Test Types

Usually, tensile and compressive testing are analyzed when studying the behavior of material in different test types. While tensile testing evaluates the response of a material to pulling forces with respect to strength, ductility, and failure point, compressive testing describes the material’s ability to resist squash forces, and hence, the compressive strength and deformation behavior of the material. These characteristics are very important for analysis in deciding whether a material is suitable for a particular application.

Other fundamental methods involve fatigue testing, which is to evaluate the material response under repeated cycles of loading and unloading. It estimates the life of components that are subjected to variable stresses in the corrosive environment of drying, such as the aerospace or mechanical engineering fields. Meanwhile, impact testing determines a material’s resistance to sudden forces, giving insight into its toughness and resistance to fracture when subjected to quick stresses. Information from every testing method becomes crucial in making engineering decisions.

Selection of testing depends on the application of the material and the types of stress it will be exposed to. For example, tensile testing is the test of choice for materials that will be in tension, whereas compressive loads are suitable for compressive testing. Fatigue testing is quite appropriate where the design will be exposed to cyclic stresses, and impact testing for abrupt stresses. Combinations of tests from several areas allow an engineer to gain a more comprehensive knowledge of the strengths and weaknesses of a material.

Performing a Bend Test

Step-by-Step Testing Process

- Preparation of the Specimen: Start preparing the material specimen using the standardized dimensions given for bend testing. Also, ensure that the sample is free from any surface defects to avoid inaccurate results. For reproducible and reliable results, correct specimen preparation is essential.

- Setup of the Testing Equipment: Clamp the test specimen in the bending fixture, ensuring proper alignment of the specimen. Calibrate the equipment such that a uniform force is applied at the required speed. Do a final check to verify that the bend test setup conforms to standards, such as ASTM or ISO regulations.

- Application of Force: Force is increased slowly on the specimen, keeping it stable and consistent till it reaches the specified angle or is broken by force. Observe the behavior of the specimen, noting the initiation of cracks or distortion, or a complete break. Record quantitative data of force applied and deflection during the test.

- Assessment of Results: Once testing is completed, perform inspection of the sample to evaluate whether it performed satisfactorily. Indications of cracks or failure should be inspected and compared against the expected bend properties for the tested material. Use the recorded data to compute values such as bending strength or ductility, which can be used to judge the quality of the material and application suitability.

Equipment Required for Testing

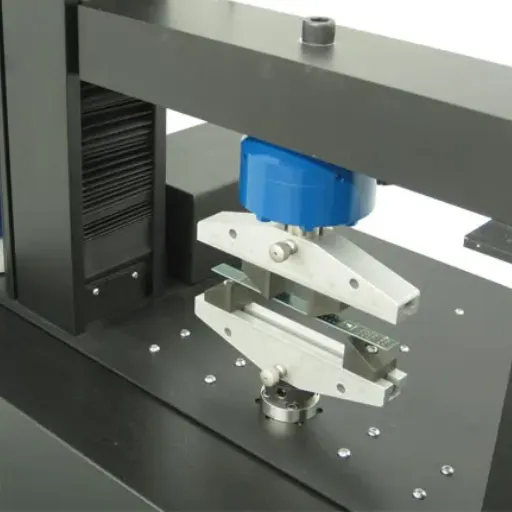

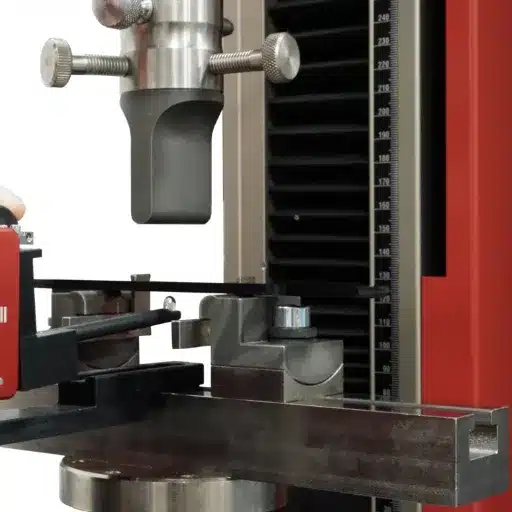

In performing a proper bend test, several pieces of equipment become necessary. First, one needs the highly precise and reliable universal testing machine. The machine applies force on the material with the force applied under controlled conditions; also, it measures the stress and the strain engendered in the material during that very application of force. Repeatability of the result is the essence; nonetheless, this ensures that a testing method produces reliable results.

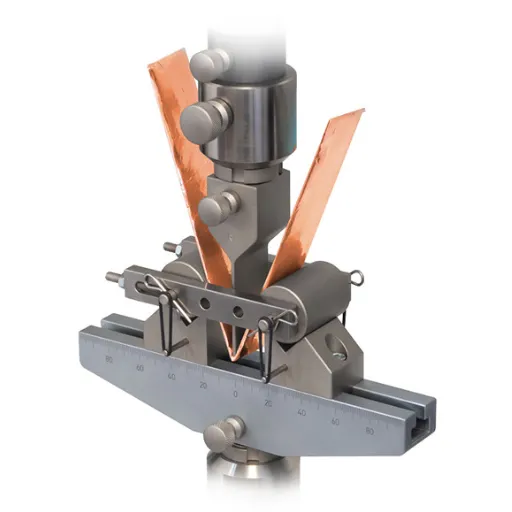

Also, special bending fixtures are necessary. These fixtures, for example, three-point and four-point bending fixtures, provide the support and load application for the bend test. They ensure that the load is properly applied and that the samples are aligned in a stable and reproducible manner.

Next in the use of bend fixtures is the recording and measurement system. These systems include a measurement system used to measure deflection, applied force, and deformation. This measurement is often incorporated into the UTM; also, supplementary instruments like calipers and digital micrometers could be used to measure the sample’s dimensions before and after testing so that evaluations of ductility and material behavior can be properly made afterward.

Safety Considerations During Testing

One of the great considerations is maintaining and inspecting a testing apparatus, testing fixtures, and measurement systems before the test itself is carried out. Defective equipment will bring forth inaccurate results, thus in some cases even the mechanical failure of equipment could cause an injury. The operator must ascertain that all parts are correctly fixed into place and checked for function.

Ideally, personal protective equipment (PPE), such as safety glasses, gloves, and lab coats, should be worn throughout the test. These will provide protection from being hit by flying chips, accidentally touching the equipment, or exposure to harmful chemicals in the event of material failure. Besides this, the testing area must be well illuminated and free from obstacles or other items that might hamper safe working conditions/operations.

Another consideration is working according to established testing procedures and limitations; surpassing forces can lead to unforeseeable breaking of the material or equipment failure, endangering the lives of those nearby. They should also be instructed in performing the tests safely from their inception until the emergency shutdown procedure is activated, ensuring a completely controlled and safe working environment during testing. All these safety considerations work toward an efficient setup that is safe and conducive to producing accurate test results.

Industry Standards for Bend Testing

Overview of ISO Requirements

ISO bends testing globally recognized standards give consistency, precision, and safety to any testing procedure. These encapsulate the norms related to test methods, equipment, and reporting of the procedure, thus ensuring parity of uniformity between industries. As an example, ISO 7438 outlines bend test requirements for metallic materials with regard to the conditions that must be met to carry out such evaluation in a correct and reliable way.

The ISO requirements serve to determine if a material can stand deformation without breaking and hence are crucial in investigating qualities such as ductility and strength. The tests must be conducted under the conditions specified by ISO standards to prevent external variables from altering the test results. The test specimens must conform to the dimensions and shapes as described under these standards to enable comparability and repeatability of results.

The standards establish the company and laboratory’s quality assurance, thereby allowing materials-related businesses to trade across borders and giving users confidence in materials’ reliability. Following the standards will allow compliance with essential laws, safety, and quality standards; hence, crucial for certifications and validation of their products.

ASTM Standards and Their Importance

ASTM standards are imperative in ensuring uniformity, safety, and quality through many industries. ASTM standards form the common ground against which systems, materials, and products are tested and defined, and manufacturers, suppliers, and consumers depend heavily on them. When an organization claims to produce products under ASTM standards, it implies meeting the specified performance and safety criteria, thus providing reliability and fostering trust.

One of the most crucial benefits pertaining to the international trade is that ASTM standards help in the facilitation of such trade. Since they are fairly commonly recognized and adopted by markets all over the world, the compliance of such standards implies that the products shall be deemed acceptable in various diverse markets. Such a similar compatibility halts barriers of trade and augments reliability of products in global supply chains. ASTM standards also enable and can fast track the certification process; after all, many standards are designed in accordance with regulatory and legal requirements.

Furthermore, ASTM standards foster innovation and evolution of science and technology. These standards facilitate research and development of new materials and products by setting well-defined procedures for testing and development. By way of consistent methodologies, such standards allow comparison, increased safety, and better performance: all are hence eventually ASTM standards to make advancement in industries like construction, healthcare, and manufacturing.

Ensuring Consistency and Reliability

To ensure consistency and reliability, ASTM standards are developed as standard methods across all industries. They specify precise procedures governing processes, materials, and testing methods, so that ideally an organization obtains a known output that is repeated in practice. Because of variations, problems arise in acceptance, so standards ensure deviations from specifications are kept to a minimum. Accuracy is enhanced in industries where these standards are applied in testing; this increases public confidence in many areas, depending on the product or service.

Reliability is established through the working together of the expert community to prepare these standards. Experts in different technical, scientific, and engineering areas impart their knowledge in the development of standards based on practical and scientifically sound approaches. Thus, an ASTM standard method ensures that recognized industrial needs for which it is intended are addressed, setting high-quality standards.

In addition, the continued enforcement of these standards ensures enhanced communication and compatibility of products across global markets. Joining ASTM standards for international practices will provide a platform for smooth supply chains and cooperate towards growth and innovation while assuring products and processes are dependable and safe.

Understanding Bending Behavior

Ductile versus Brittle Materials

✓ Ductile Materials

Materials like steel and aluminum that can deform considerably before breaking, providing flexibility and resistance.

⚠ Brittle Materials

Materials that don’t deform much before fracturing, offering high compressive strength but risk sudden failure under tensile stress.

The main divide between ductile versus brittle materials is their behavior when implementing stress or strain and with the period before fracture considered. Materials that are ductile, such as steel and aluminum, can deform considerably prior to breaking. Therefore, they have plasticity to some extent and can therefore stretch or bend without cracking under stress. Hence, ductile materials find an application where flexibility and resistance are important.

Brittle types of materials, however, do not deform with much observable changes prior to fracturing. Materials of this kind have a greater compressive strength, but they cannot stretch or bend under stress. They are preliminarily used for applications in hardness or wear resistance, though their characteristic behavior of no bending under stress can cause sudden failure under tensile stress.

Because of the distinction between these two major types of materials, let us try to understand the importance while considering the design of structures and products. And so, engineers must make their choice actualizing the load conditions expected and, therefore, the properties desired in the end product to be able to contribute to both operational efficacy and safety.

Real-World Implications of Material Behavior

Material behavior is vital in the designing and functioning of many structures and products. It is the very reason steel and concrete are chosen in construction, for they provide load-bearing strength and durability for buildings and bridges. Similarly, knowing when to work within safe limits of materials-without exceeding those limits-will prevent engineers from building structures that are unsafe while avoiding disproportionate costs.

Another instance of a real-world implication is found in aerospace engineering, where materials such as carbon fiber composites-that are very light but strong-are used to maximize the weight reduction in an aircraft consistent with actual safety and performance criteria. This reduces fuel consumption and thereby increases efficiency. When designing for hyper-environmental conditions, such as in space or underwater, material selection becomes a factor of utmost importance to avoid catastrophic scenarios occurring from atypical stress levels or pressure conditions.

Material behavior has far-reaching consequences in medicine. Biocompatible materials, for example, titanium, or certain polymers are used in implants and prosthetics to ensure their adequate functioning within the human body. Fabrication of materials with controlled properties such as flexibility, strength, and corrosion resistance can affect patient outcome directly; hence material behavior is one field considered seriously when it comes to advancing health-care solutions.

Frequently Asked Questions (FAQ)

Q: What is the purpose of the bend test of steel?

A: The bend test of steel finds its utility in estimating the ductility and strength of a material—that is, to ascertain the ability to undergo bending without premature failure. This test provides an evaluation of material properties and performance under bending loads for engineering application.

Q: How is the bend test of steel conducted?

A: The bend test is most commonly carried out by means of a bend test machine which exerts a bending force upon the test sample. Usually, the sample is supported on two points or supports and when the bending reaches a particular angle, the stress-strain curve is analyzed for yield strength and maximum load values of the specimen.

Q: What are the types of bend tests?

A: There are different types of bend tests such as the three-point bending test and the guided bending test. Each test analyzes the resistance to bending of various materials under specific conditions and thereby assists in defining their mechanical properties.

Q: What materials are tested in a bend test?

A: The bend test is usually performed on materials such as steel, sheet metals, and reinforcement steel. Depending on the application and the properties that are required to be tested, the material to be tested changes.

Q: How does the bending angle influence the results of the bend test?

A: The bending angle influences the bend test results significantly. The greater the angle, the more stress the material is subjected to, possibly causing plastic deformation or failure. Therefore, the knowledge of the relationship between bending angle and the material’s performance becomes necessary for an accurate assessment.

Q: Which factors affect the results of the bend test?

A: The bend test’s results depend on several factors like the strength and ductility of the material, the testing equipment, and the testing method. Depending on either their compositions or on treatments given to them, material properties vary, which reflects on their capacity to resist deformation.

Q: What properties of the material does the bend test show?

A: The bend test provides information on the material’s ductility, strength, and ability to absorb energy. By examining the results of the test, engineers understand the capacity of a material in opposing bending forces and hence its performance in structural applications.

Q: Does the bend test prove that failure could occur for a material found inadequate?

A: Yes, a bend test could lead to a prediction of the failure of a material by finding the point of maximum bending required for the beginning of plastic deformation. This information proves crucial for safety and reliability in engineering design.

Q: What importance is given to the stress-strain curve in the bend test?

A: The importance of the stress-strain curve in the bend test lies in its graphical presentation of the behavior of the material under loading conditions, by which the yield strength, ductility, and overall mechanical performance of the material are selected during bending.

Q: How can a testing expert incorporate the bend test in the evaluation of materials?

A: A testing expert may incorporate the bend test into the evaluation of materials by providing a systematic appraisal of mechanical properties of materials. Utilizing standard test methods and analyzing the results could help the expert in rendering advice on the suitability of materials for specific applications, so as to assure perfect performance and safety.

References

This source discusses the importance of bend tests in evaluating steel’s ductility and weld quality.

The official ISO standard for determining the ability of metallic materials to undergo plastic deformation in bending.

This source outlines various standards like ASTM E290 and ISO 7438 for bend testing of metals.

A discussion on tensile testing standards and their implications, which may provide additional context for bend tests.