Understanding material behavior is crucial to engineering, design, and manufacturing. The fracture toughness test is crucial in determining a material’s ability to resist the propagation of cracks under stress. This test provides pertinent information about the durability, reliability, and performance of materials used in the various industries, including aerospace, construction, and automotive sectors. In the article, we’ll discuss the conventional method of carrying out fracture toughness tests, key parameters measured, and why performing this test is a prerequisite for establishing structural integrity. That said, brace yourselves because whether you are an engineer or a mere learner, this guide shall proffer an insightful journey into the wonderful science of fracture toughness and its real-life applications. Stay tuned to learn about the underlying principles that the test provides for material safety and innovation.

Introduction to Fracture Toughness Testing

What is Fracture Toughness?

The ability of the material to resist the advancement of a crack upon stress is termed fracture toughness. It is an important parameter that provides a means to determine how materials behave in the presence of flaws, cracks, or defects, especially under conditions of high stress. This property guarantees that the material would meet practical requirements while ensuring its ability to remain functional and safe under any related mode of loading.

When testing for fracture toughness, engineers assess how much energy a material can absorb before a crack grows. This entails the quantification of the stress intensity factor-a parameter that indicates at what level of stress intensity a crack present in a material may just commence propagation. Materials with high fracture toughness can endure higher loads of stress or strain without failing suddenly. Thus, they are of utmost importance in applications requiring safety from failure, such as aerospace, construction, and automotive industries.

Having a good grasp of fracture toughness is important to determine the state and safety of a structure. It helps engineers decide on what material to use in the construction for a particular application or to identify from the design and testing phase where there is a risk of failure. Through studying fracture toughness, engineers are able to design and develop safer and reliable technology and systems to meet the challenges of the present-day engineering world.

Importance of Fracture Toughness in Material Selection

Key Benefits

- Critical Safety Applications: Materials with high fracture toughness prevent sudden failure in aerospace, construction, and automotive industries

- Performance Under Stress: Higher stress tolerance before crack propagation occurs

- Environmental Resistance: Better performance under temperature variations and environmental stresses

- Cost Effectiveness: Reduced maintenance and replacement costs due to longer material lifespan

Fracture toughness is an important property in material selection because it essentially defines the capacity of a material to resist crack propagation; that is, a material with a high fracture toughness must go through a higher stress before the crack propagates, thereby averting a sudden failure, and hence one that can be used in more critical applications such as aerospace, construction, or automotive industries. In contrast, materials with low fracture toughness crack quite easily and may result in structural failure unless properly remedied.

Fracture toughness is taken into consideration by engineers while choosing materials to allow the substance to effectively perform under anticipated conditions, such as heavy loading, temperature variation, or additional environmental stresses. For instance, materials applied in cold climate conditions must possess low-temperature toughness for their fracture is highly probable under such environmental conditions, while in those heavy impact or heavy load industries, materials of high fracture toughness are considered to maintain good performance and safety.

Considering fracture toughness in material selection directly helps engineers design safe yet economically sound systems or structures as high-toughness materials potentially reduce frequent maintenance or replacement, thereby increasing the lifespan of any product or structure. Therefore, fracture toughness is a concept that finds practical application in modern technology and assures the optimization of material functionality from a safety point of view.

Overview of Testing Services Available

Testing for fracture toughness is an important service to ascertain a material’s resistance against crack propagation under stresses. The testing is carried out to find out how the material will perform in environments where mechanical failures due to cracks could have considerable consequences. By analyzing parameters such as critical stress intensity factor (KIC), it provides engineers with indispensable information to verify the structural integrity and safety of an engineering component.

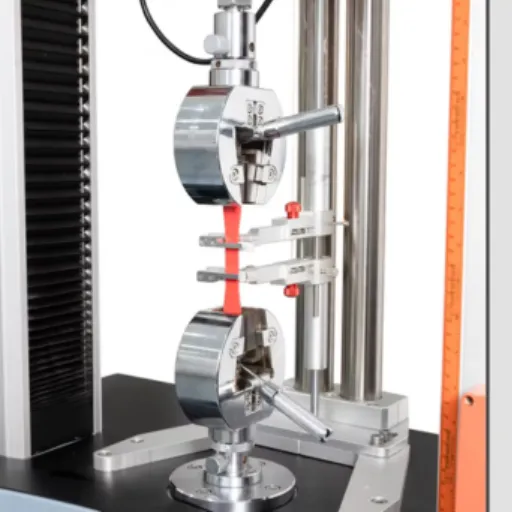

The test procedure follows a standardized method typical to ensure that results have consistency and reliability, and one of these could be a compact tension test, while the other could be a three-point bend test. These methods subject the material being tested to stress conditions that replicate the actual application and measure their toughness values in a controlled environment. All kinds of materials are subjected to tests: metals, alloys, ceramics, and composites that are used in the industries underpinning durability and safety.

There are applications related to the aerospace, automotive, and construction industries, in which the fracture toughness testing is highly required, given that the materials are, in most cases, subjected to high stresses or extreme conditions. Materials should be chosen through the most pertinent data obtained using these tests; hence, this will help to improve the design of the product and guarantee that all safety regulations are adhered to. By using these tests, industries work to prevent structural failure, decrease maintenance costs, and increase operational reliability.

Standard Test Methods for Measurement of Fracture Toughness

ASTM Standards Overview

| ASTM Standard | Description | Application |

|---|---|---|

| ASTM E399 | Plane-strain fracture toughness of metallic materials | Metallic components under plane-strain conditions |

| ASTM E1820 | J-integral and crack-tip opening displacement (CTOD) | Advanced fracture mechanics analysis |

These ASTM standards offer a detailed framework to evaluate fracture toughness in materials employed in diverse industries. The standards, acclaimed for their accuracy and reliability, guarantee the fitness of critical components for harsh usage conditions. They lay down the guidelines for testing materials for their properties, which further aid the engineers and manufacturers in deciding the appropriate materials and designing products.

Some of the major ASTM standards cover ASTM E399 test method to establish the plane-strain fracture toughness of metallic materials and ASTM E1820 test methods for determination of fracture toughness in terms of the J-integral and crack-tip opening displacement (CTOD). These standards present several test arrangement conditions for specimen preparation, loading configuration, and evaluation criteria, giving laboratories and end-applications a consistent basis for carrying out independent fracture toughness tests.

Through these standards, industries can ensure the structural integrity of components, increase safety, and enhance performance. Because there is less random variation in test results when using standardized methods, they are more comparable and reliable. Hence, in an engineering context, ASTM fracture toughness standards serve as essential tools for improving engineering practices and ensuring safety regulations adherence.

Common Test Methods for Measurement

Compact Tension (CT) Test

A tensile load is applied to a pre-notched coupon specimen to calculate critical values such as KIC. Most widely used due to its applicability to various material types.

Single Edge Notch Bending (SENB)

Used to study crack growth in brittle materials like ceramics by applying bending load to notched specimens.

Chevron Notch Test

Primarily used for rock and brittle materials, providing essential data for material selection and engineering safety criteria.

There are several standard methods of fracture toughness testing employed to achieve a uniform community and reproducibility of results. Among these tests under consideration are the Compact Tension test, Single Edge Notch Bending test, and the Chevron Notch test. Each method aims at quantifying and characterizing the material resistance to crack formation and propagation under predetermined conditions.

Choosing the Right Method for Your Application

Selection Criteria

- Material Type: Brittle materials (ceramics, rocks) vs. ductile materials (metals)

- Loading Conditions: Impact, tensile, bending, or compression

- Environmental Factors: Temperature, humidity, corrosive atmosphere

- Application Requirements: Safety criteria and performance standards

Many factors go into determining which test should suitably characterize a material; therefore, such considerations might include the mechanical properties of the material and the environment in which it is supposed to be used. In cases of need for combination stress-impact situations, the Charpy Impact Test will furnish such insight into behaviors of the material under sudden loading. It mainly tests the ductility and toughness of the material.

These tests will be more suitable for brittle materials such as the Single-Edge Notch Bending (SENB) method or the Chevron Notch test. They study crack propagation in low tensile strength materials, making them ideal for ceramics or rocks. For instance, SENB shows the bending behavior under applied stress, while the Chevron Notch test studies crack propagation behavior particular to rocks and similar substrates.

On the other hand, finally, the choice of a test depends on the type of material and the environment that it will be exposed to, i.e., the method of stress application itself, which might also condition the actual tests. Having the right test for the right thing not only means support for the performance of the material, but will try in return to assure safety and reliability of the engineering work itself.

Understanding Crack Propagation and Fracture Mechanics

Principles of Crack Propagation

A crack may propagate in a material under stress until the system reaches failure. In essence, such a process is thought to depend on the material properties, the type and magnitude of stresses applied, and the environmental conditions it faces. The basic understanding as to when and why such cracks propagate is needed for predicting material behavior and developing safe engineering applications.

A crucial parameter for crack propagation is known as stress concentration. In any crack, stress near the crack tip becomes several times higher than the applied stresses; hence, a greatly localized area of severe strain exists. Growth of the crack occurs due to this stress concentration, especially if the material has less resistance to fracture, defined by its toughness value. Repeated or constant application of loads over time will only increase such effects, eventually resulting in fatigue or gross failure.

Environmental conditions such as temperature, humidity, or corrosive atmosphere encourage rapid crack propagation. In such instances, metals suffer stress corrosion cracking when interaction with chemicals weakens the material near the crack tip. By apprehending these principles of crack propagation, engineers will be in a position to resist the growth of cracks in materials and structures, identify inspections to detect cracking in general, as well as implement some injunction measures to reduce the probability of failure.

Applications of Fracture Mechanics in Testing

Fracture mechanics occupies a pivotal place during the evaluation and improvement of material properties in many industries. In testing, it plays a foremost role in verifying whether a particular component is structurally sound while under the service-like stresses. Once the material resistance of a component is analyzed to initiate crack formation and propagation, this resistance will identify the weaker points of the structure before they meet catastrophic failures. Thus, the application of this technique allows for prevention, providing the utmost safety and reliability in processes like aerospace, construction, civil engineering, and energy generation.

A very important application of this field is very close to non-destructive testing (NDT) that aim to verify the soundness of a structure without causing damage. Ultrasound and radioactive examinations employ fracture mechanics to identify, assess, and characterize possible internal cracks or flaws. The analysis then informs engineers whether the materials or components satisfy critical safety requirements and can continue in service. If not, they will be tested within the specified tolerances and operating conditions.

Another vital domain where fracture mechanics is used is in safety standards and failure criteria formulation for materials. Having information such as stress intensity factor and other fracture properties enables the engineer to either design a material to resist loads defined by those parameters or alter the parametric values to make the material less prone to failure. Such a process not only increases the functional lifespan of the structure in question but optimizes the usage of materials, cutting costs and reducing the environmental load. Ultimately, fracture mechanics provides the systematic basis for assessing and improving durability and performance of materials.

Factors Influencing Material Fracture Toughness

| Factor | Impact on Fracture Toughness | Control Methods |

|---|---|---|

| Microstructure | Finer grain sizes increase toughness by providing more barriers to crack propagation | Heat treatment, alloying, controlled processing |

| Temperature | Decreasing temperature reduces ductility and toughness | Material selection, environmental control |

| Loading Rate | Faster loading rates reduce material ductility | Design for appropriate loading conditions |

| Defects | Voids, microcracks, and inclusions degrade toughness | Quality control, proper manufacturing processes |

Several important factors affect materials fracture toughness, such as the microstructure of the material, temperature, rate of loading, and defects. All these factors, together, resist crack propagation and finally exert an effect on the durability and reliability of any material.

Specimen Preparation and Testing Procedures

Preparing Specimens for Testing

Accurate preparation of specimens is crucial for ensuring reliable fracture toughness test results. Specimens are typically extracted from the material of interest, ensuring they represent the material’s actual properties. The shape and size of the specimens depend on the test method, but common geometries include single-edge notch bend (SENB) and compact tension (CT) configurations. These geometries feature a pre-fabricated notch to simulate a crack for testing purposes.

Before testing, specimens undergo precise machining to achieve the required dimensions and surface finish. The notch is introduced with sharpness that complies with standardized guidelines, often using a fine saw or wire cutting method. The goal is to create a controlled flaw to evaluate how the material behaves under stress near a crack tip. Careful attention is given to avoid introducing unintended stress or defects during machining.

Finally, pre-cracking may be performed to grow a fatigue crack from the notch under cyclic loading, ensuring the crack resembles actual service conditions. Specimen preparation adheres to standards set by organizations like ASTM and ISO to ensure consistency, repeatability, and comparability across different tests and materials. Proper handling and storage of specimens before testing are also critical to avoid contamination or damage that could alter results.

Step-by-Step Testing Procedure

Specimen Setup

Start by fixing and mounting the specimen securely in the testing machine. Ensure that it is in proper alignment so as not to impose any unintended stresses during the test. Check that the grips or sockets are clean and undamaged, as inconsistent holding strength might result.

Calibration of Testing Equipment

Calibrate the testing machine according to the required standards (ASTM or ISO). Check the loaded cell, extensometer, or strain gauges for accuracy to assure all measurements taken are a true reflection of real material behavior.

Loading Parameters Configuration

Set the loading mode as desired (tensile, compression, cyclic) according to test objectives. Enter the required loading rate, strain limit, or cycles for a simulation of actual condition in which the material will be working.

Conduct the Test

Start the test after recording and observing loads, displacements, and changes occurring in the specimen, with staid loading conditions as per the test procedure. Record observations systematically with the aid of the measurement devices attached.

Completion and Post-Test Analysis

Once the test reaches its end, either failure of the material or the predefined criteria of testing, stop the machine. Take care of removing the specimen for further inspection, and record the visible failure modes. Proceed with the analysis of the data to extract properties such as strength, ductility, or fatigue life.

Documentation and Reporting

Consolidate all test results, consisting of raw data, stress-strain curves, and failure analysis, in a single report. Mention standards deviations, and provide an analytical discussion about the effects that have been involved. Give clear-cut conclusions and recommendations based on the test objectives.

Interpreting Test Results

Key Results Analysis

- KIC Value: Primary measure of fracture toughness under plane-strain conditions

- Validity Criteria: Specimen geometry, crack size, and applied loads must meet standard requirements

- Application Context: Compare results against design requirements and operational conditions

Fracture toughness tests give an idea of a material’s resistance to crack propagation under stress. The most important results from this test denote fracture toughness; for example, the symbol used in the case of plane-strain conditions is KIC. This value quantifies a material’s resistance to fracturing and is therefore important in situations where structural integrity and reliability are at stake.

In the analysis of test data, one has to inspect the corresponding stress-intensity factor near the crack tip and verify whether the examined sample has satisfied the validity criteria of the test method. For example, the specimen geometry, crack size, and applied loads should satisfy the requirements laid down in the standards, so that the KIC value so obtained gives an acceptable and meaningful measure of the fracture toughness of a material. One should take into account any deviation or irregularity from the specimen data and be able to explain them.

Lastly, the fracture toughness value ought to be put in the context of the intended application of the material. The KIC result is compared against the design requirements, operational stress limits, and agent factors affecting the material on-site, such as temperature or corrosion. This evaluation would guide the appropriateness of the fracture toughness of the material for safe and efficient performance under the conditions foreseen for the service.

The Critical Role of Fracture Toughness Testing

Significance in Various Industries

Aerospace Industry

Critical assessment of aircraft components under extreme stress conditions to ensure safety and reliability of high-performance alloys and composites.

Oil & Gas

Essential for pipelines, drilling equipment, and storage tanks facing harsh environments with high pressures and corrosive substances.

Construction

Vital for bridges, dams, and skyscrapers to ensure materials withstand various loads throughout operational lifespan.

In general, fracture toughness testing plays an important role in those industries where structural integrity is of utmost importance. Thus, for instance, fracture toughness testing in the aerospace industry assesses how materials undergo fracture under extreme stress or considers the behavior of aircraft components so that the components are safe and reliable. High-performance alloys and composites are tested to endure the application of immense stress and sustain any kind of catastrophic failure while in operation.

Similarly, fracture toughness testing is required for pipelines, drilling equipments, and storage tanks in oil and gas exploration. These equipments and systems face harsh environmental conditions involving extremely high pressures, varying viz-a-viz temperatures, and highly corrosive substances. Testing would ensure the materials can withstand these challenges for an extended period without compromising their performance and safety.

Construction and infrastructure provide a huge application for fracture toughness data. Bridges, dams, and skyscrapers are constructed using materials that must withstand different loads of parametric nature. Such evaluation could further provide all necessary insights that materials of a particular magnitude might need in order to retain structure functionality throughout its operational career.

Impact on Cost Reduction and Safety Compliance

Cost Benefits

- Reduced replacement and repair costs

- Prevention of overengineering

- Optimized material usage

- Lower maintenance expenses

- Extended operational lifespan

Safety Compliance

- Meeting safety standards and building codes

- Preventing structural failures

- Protecting human life

- Reducing liability risks

- Regulatory compliance assurance

By applying fracture toughness analysis in securing materials from failure, cost reduction is achieved. This data allows a manufacturer or engineer to select material which is less likely to fail under the stresses it has been expected to encounter, thus reducing costs of replacement and repair. When the behavior of materials under stress is foreseen on the basis of certain given conditions, it will lessen any consideration of either exaggerated design or overengineering, which adds to the increase of production costs.

Conversely, knowledge of the fracture toughness assists in the certification of safety wherein materials that enter into important safety applications meet the required safety standards and building codes. Such materials provide for structure and infrastructure that are able to withstand bridges, buildings, vehicles, and other similar applications under extreme stress conditions until and unless failure occurs. A credible set of tests for measuring fracture toughness shall only assure such material performances to the relief of human life and at least curb the probability liability risks of such companies alongside the regulatory agencies.

A synthesis of cost effectiveness and enhanced safety measures renders infrastructures and infrastructures reasonably worthy of operation through the years. Lesser maintenance cost and structural demerit are the major contributors to cost, while adherence to stringent safety standards inculcates a sense of confidence in its stakeholders.

Call to Action: Enhancing Your Testing Procedures

Ready to Optimize Your Material Testing?

Fracture toughness testing ensures that materials are dependable and last through any stress. Implementing these procedures will enhance safety and system performance while reducing costs.

Fracture toughness testing ensures that the materials are dependable and last through any stress. The tools of the technique help the engineer analyze the cracks propagated in the materials under pressure and prove that cracks and stresses are potential causes of engineering failure. Optimizing whatever procedure you are already using with this method would mean safety and enhanced system performance. The method measures the stress intensity factor for the commencement of crack growth in materials. Manufacturing of materials in general must account for extremely harsh conditions, be they high pressures or fluctuating temperatures. By carrying out fracture toughness tests, industries thus achieve compliance to safety standards and regulatory requirements and are able to significantly prevent any damage that can lead to unfortunate accidents and repairs.

Fracture toughness testing can also be adopted to reduce costs by selecting materials suitable for balancing durability with price. Properly carried out testing will improve not only further warranties put up for indefinite periods, but also cement stakeholder confidence in your infrastructures.

Frequently Asked Questions (FAQ)

What is a fracture toughness test?

A fracture toughness test is a laboratory test used to determine certain toughness parameters of a material that relate to resistance to crack propagation under various loading conditions. This test measures the toughness of materials subjected to various modes of loading, thereby characterizing the performance of materials such as ferritic steels in different applications.

How is the value of fracture toughness determined in the first place?

By standardized tests in which the resistance of a material to the growth of cracks is measured, a fracture toughness value is determined. Normally this would apply a tensile load to the specimen and monitor the cracks. Test methods generally conform to standards such as ASTM.

What are the testing methods for fracture toughness?

The analysis for fracture toughness may be performed by linear elastic fracture mechanics or elastic-plastic fracture mechanics. Because mode I fracture corresponds to the opening of cracks, it is most often applied to determining fracture toughness of materials under tensile stress.

Why are fracture toughness tests of importance for ferritic steels?

Because the ferritic steels are used in structural purposes where failure may result in catastrophic results, fracture toughness tests are especially vital. The fracture toughness parameters can be determined so that its performance shall be secured by the engineers while under load.

What parameters are measured in a fracture toughness test?

Generally, the strain energy release rate, J-integral, and critical stress intensity factor are some of the parameters that can be measured in a fracture toughness test. The information from such measurements is used to assess the toughness of materials and the ability thereof to resist cracking.

How does specimen thickness affect fracture toughness?

Thickness specimens influence results of fracture toughness, and various thickness specimens may offer differing toughness values. Thicker specimens usually have higher values of toughness because there is a greater amount of materials that resist crack propagation, whereas thinner specimens may have lower toughness because of surface effect and constraint.

What effect does temperature have on impact toughness and fracture toughness?

Impact toughness is a measure of energy absorbed by a sudden impact in contrast to fracture toughness, which is a measure against the propagation of a crack. Both values are extremely important for showing overall mechanical qualities of a material in high-stress applications.

How do temperature and rate of loading affect fracture toughness?

The test temperature and loading rate are two factors which strongly influence a material’s fracture toughness. Generally, increasing temperature will increase ductility and fracture toughness of a material, whereas decreasing temperature causes brittle fracture. There is also a loading rate effect on fracture toughness where fast rate is usually unfavorable to toughness.

How important is the fracture surface for judging material toughness?

The fracture surface gives important information such as mode of fracture and toughness of the material. By analyzing the features of the fracture surface, it can be interpreted whether the failure was ductile or brittle and the material’s resistance to fracture.

References

- Understanding Material Fracture Toughness Testing – This article covers common standards like ASTM E399, E561, and E1820, and provides insights into testing methods.

- Fracture Toughness Tests: Definition, Purpose, Standards – A comprehensive resource explaining the purpose of fracture toughness tests and their role in determining material properties.

Fracture Toughness Testing – An Overview – A detailed overview of fracture toughness testing, focusing on its principles and applications in material science.- Fracture Test Machines and Applications – A resource for understanding the equipment and methods used in fracture toughness testing, ideal for research and quality assurance.