In the most basic sense, tensile strength is the quality of a material that dictates how much it can resist forceful pulling or stretching before breaking. In various sectors, either in construction or manufacturing, the materials are usually tested for tensile strength for purposes of durability and operational capabilities. This blog post will further discuss tensile strength by looking at the basic components of tensile strength—ultimate strength and elongation—and how they are applied through various tests. Whether you’re an engineer, a scientist, or someone who wonders about material characteristics, this article will sculpt into your mind how tensile strength gets measured, why it really matters, and how it is utilized in real-life contexts. Prepare to delve into the fascinating dynamics of materials under stress!

Understanding Tensile Strength

Definition of Tensile Strength

Tensile strength is generally recognized as the capacity of a material to withstand tension without breaking. More precisely, it is the maximum tensile stress a material can undergo before it fails. Since it relates to tensile forces that try to pull materials apart, tensile strength is an essential factor in studying material behaviors.

Key Classifications of Tensile Strength:

- Yield Strength: The strength at which a material starts to undergo plastic deformation

- Ultimate Tensile Strength: The maximum stress that a material can withstand before it fractures

- Fracture Strength: The point at which the fracture actually occurs after the material reaches its limit

Tensile strength values are very important in construction, manufacturing, and engineering because they help decide if a material has the strength needed to safely perform in its intended work. With tensile strength data, engineers are able to select materials capable of maintaining structural integrity under stress, a crucial aspect of reliability and durability of any finished product.

Importance of Tensile Strength in Different Materials

Tensile strength is an index of the accommodation a suitable material has to impart tensile force before its failure. Different materials possess different tensile strengths, and selecting one for a particular use is quite under question. Metals like steel and aluminum are used extensively in construction and manufacturing for their high tensile strength; thus, any structure or product should absorb quite a lot of stress and still never break.

Metals

High tensile strength materials like steel and aluminum used in construction and manufacturing for structural integrity.

Polymers & Plastics

Lightweight and flexible materials used in packaging, electronics, and consumer goods applications.

Composites

High tensile strength yet lightweight materials like carbon fiber, useful in aerospace and advanced engineering.

Tensile strength in polymers and plastics defines their potential to resist loads in packaging, electronics, and consumer goods applications. While they are not really as strong as metals, they can be capable or preferable in particular instances due to their lightweight and flexibility. Following that idea, composite materials such as carbon fiber are designed to have high tensile strength yet be very lightweight, making them incredibly useful in aerospace and advanced engineering.

Considering the tensile strength of glass, ceramics, and fibers is important for industries concerned with construction, medical devices, and textiles. These applications tend to favor materials with the capacity to resist breaking under particular stress loads while at the same time retaining other properties such as durability or wear resistance. Overall, tensile strength assures safety, performance, and longevity for a whole array of products and structures.

Factors Affecting Tensile Strength

A few factors govern tensile strength wherein a material resists stress without breaking. Composition is basically one of the prime causes of tensile strength, for, if the molecules and their bonding within the material vary, then its strength also varies. For example, metals have high tensile strength due to tightly packed atoms or in the case of ceramics, due to strong ionic and covalent bonds. The composition can be altered for better performance by way of mixing in some alloys or perhaps by introducing reinforcing fibers.

| Factor | Description | Impact on Tensile Strength |

|---|---|---|

| Composition | Molecular structure and bonding within the material | Varies strength based on atomic arrangement and bonding types |

| Microstructure | Grain size, phase distribution, and defects | Smaller grain size generally increases strength |

| Environmental Factors | Temperature, chemicals, moisture exposure | Can degrade material performance over time |

| Processing Conditions | Heat treatment, forging, extrusion methods | Can improve strength by changing internal structure |

Another factor affecting tensile strength is the microstructure of the material. Various microstructural features such as grain size or phase distribution and defects affect the strength of a material. Generally, smaller grain size means higher tensile strength as the grain boundary obstructs the dislocation movement. Conversely, defects like voids, cracks, or impurities act to concentrate the stresses and thereby reduce strength against tension.

Environmental and processing variables affect tensile strength. Exposure to environmental actions such as high temperatures, chemicals, or moisture would, over a length of time, degrade the materials in their ability to perform their functions. Conversely, various processing conditions could improve the strength of a material by changing the internal structure, for example, heat treatment, forging, or extrusion. Being aware of all these can help in designing a material and product that would satisfy a particular application in performance and safety.

Ultimate Tensile Strength and Its Significance

Defining Ultimate Tensile Strength

Ultimate tensile strength is the maximum tensile stress the material can carry and still not be fractured or failed upon. It is a vital mechanical property, defining the maximum capability of a material under tension. The ultimate tensile strength is measured during the tensile test by elongating a test specimen until it fractures. The highest stress of the test specimen computed prior to breaking is termed the ultimate tensile strength.

Key Points About UTS:

- Maximum tensile stress before material failure

- Measured during controlled tensile testing

- Critical for material selection in engineering

- Expressed in MPa (megapascals) or psi (pounds per square inch)

The value of this property is great, offering a view to engineers and designers of the strength of the material in the various uses that are assigned to it. If a material has a high tensile strength, then it must be strong and able to withstand considerable stress, making it suitable for structural applications and load-bearing purposes. Conversely, those materials with lower UTS may best be used for less demanding purposes. Knowledge of UTS hence helps to select a material that can satisfactorily perform and safety under the given operating conditions.

Ultimate tensile strength is usually expressed in units of force per area. The more common units are megapascals (MPa) or pound for an inch square (psi). It is a measure taken under well-controlled test conditions and standards so that its value is always accurate and verifiable. By knowing the UTS along with other properties such as yield strength and elongation, an engineer can assess the material thoroughly regarding its stress behavior and dependability. This information matters in choosing the material and designing products that will withstand the test of time while being safe for use.

Calculating the Ultimate Tensile Strength

In order for one to determine a material’s Ultimate Tensile Strength, the maximum load a material can take during a tensile test is first determined. This load is measured usually in Newtons (N) or pound-force (lbf). Load values are determined so accurately as the material is tested under increasing tension until it finally breaks.

UTS Calculation Steps:

- Determine Maximum Load: Measure the peak force during tensile testing (N or lbf)

- Calculate Original Cross-sectional Area: Measure specimen area before testing (m² or in²)

- Apply Formula: UTS = Maximum Load ÷ Original Cross-Sectional Area

- Express Result: Final value in Pascals (Pa) or pounds per square inch (psi)

Next, calculate the original cross-sectional area of the metal sample. The area is measured usually in square meters (m²) or square inches (in²), depending on the unit system in use. The cross-sectional area is derived from the initial shape and dimensions of the specimen before performing a tensile test, for example, the diameter of a cylindrical specimen or the cross-sectional width of a rectangular specimen.

UTS Formula

UTS = Maximum Load / Original Cross-Sectional Area

This provides a quantitative measure for material strength assessment

This gives the final value of UTS expressed usually in Pascals (Pa) or pounds per square inch (psi). This provides a quantitative measure for strength, and engineers use this result to judge whether a material is suitable for a certain application where durability and resistance to stress are important.

Applications in Various Industries

Construction Industry

Materials such as steel, aluminum, and concrete are selected according UTS to sustain tensile forces. Engineers use UTS in designing buildings, bridges, and structures to specify safety conditions against various loads—lateral winds, seismic forces, etc.

Automotive & Aerospace

Strong but lightweight materials are required for optimal fuel efficiency without compromising safety. UTS helps manufacturers choose metals, composites, and alloys that bear forces during operations—vibrations, impact, high-speed motion.

Medical Devices

Materials used in surgical instruments, implants, or prostheses must have sufficient tensile strength to withstand repeated stress and resist breaking. UTS testing ensures reliable and long-lasting performance under demanding conditions.

The Tensile Test: Methods and Processes

Overview of the Tensile Test

The tensile test is the core material testing operation used to ascertain the strength and ductility of materials. A material breaks once acted on by a force until failure occurs under imposed conditions. Critical mechanical properties—of which ultimate tensile strength (UTS), yield strength, and elongation are among the most important—are of interest for analysis, as an understanding of these quantities essentially translates into knowledge on how a given material behaves under stress.

Tensile Test Process:

- Specimen Preparation: Test specimen is carefully prepared and measured

- Installation: Specimen is installed in the testing machine

- Force Application: Controlled uniaxial force stretches the specimen

- Data Recording: Force and elongation data are continuously recorded

- Analysis: Stress-strain curve provides insights into material behavior

Generally, preparation of test specimen serves as the first step in testing. It is installed in the tester, which exerts a controlled uniaxial force that stretches the specimen while recording the force and elongation data. During analysis, a stress-strain curve is obtained, giving us valuable insights into how the material behaves through the elastic range, plastic range, and finally fracture.

In tensile testing, failure estimation is critical in any industry, especially when structural components are being designed and manufactured. In addition, tensile testing yields information on the tensile properties of a material, making it possible for an engineer to be certain that the product has been thoroughly tested for safe uses and durability and that it fulfills all performance requirements; if these materials were to be misused in this way, there would be a chance of their failure in very critical applications. The test provides a guarantee of reliability and, hence, serves as a safety assurance for the consumer of the proven item.

Test Methods for Measuring Tensile Strength

Tensile strength testing is required to understand how a material behaves under stress and thereby confirm that it fulfills requirements in design and safety. The most common form of tensile strength test is a uniaxial tensile test where a tensile force is applied in a controlled manner to the sample material until failure. Engineers considered the ultimate tensile strength, yield strength, elongation, and modulus of elasticity as key parameters for evaluation.

| Test Method | Description | Key Measurements |

|---|---|---|

| Uniaxial Tensile Test | Controlled tensile force applied until material failure | UTS, yield strength, elongation, modulus of elasticity |

| Universal Testing Machine | Versatile and accurate testing with stress-strain analysis | Material properties through stress-strain curves |

| Temperature-Influenced Testing | Testing at various temperature points | Performance in heat-sensitive environments |

The universal testing machine (UTM) is another popular tensile strength test and is designed for ultimate versatility and accuracy. The material is held between two clamps while force is applied at a gradual rate, and deformation values are recorded simultaneously. The test allows material-property determination through analysis of the generated stress-strain curve and thereby guarantees reliability and consistency in application throughout manufacturing.

In addition, tensile testing under the influence of temperature may be applied when the influence of temperature is under consideration. It evaluates tensile strength performance at various temperature points to assess the capacity and robustness of materials in heat-sensitive environments. These tests, performing in conjunction with each other, ensure that a material is fully evaluated for its performance, based on which an engineer can plan its safe and efficient use.

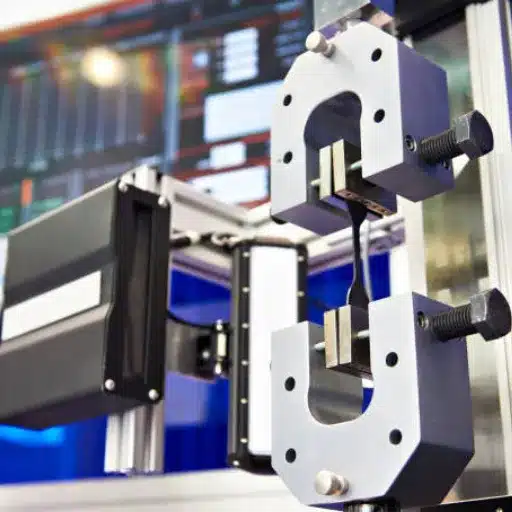

Using a Universal Testing Machine

The UTM, namely Universal Testing Machine, is one of the vital equipment used for testing the mechanical properties of materials under different conditions. The machine does tensile, compression, or bending tests to obtain results such as strength, ductility, and elasticity. By applying a known force and measuring how the material behaves in response, an engineer can determine if it is fit to be used in a particular situation or if it needs more testing to undergo safety certification.

UTM Operation Process:

- Sample Clamping: Material sample is clamped rigorously using hydraulics or mechanics

- Force Application: Controlled force is applied while monitoring material response

- Real-time Monitoring: Sensors measure load, deformation, and time to failure

- Data Analysis: Results processed to generate stress-strain curves

- Performance Assessment: Material limits and behavior under working conditions determined

The UTM procures the application of force by clamping the material sample rigorously, using hydraulics or mechanics. Sensors measure various parameters real-time such as the load applied, amount of deformation, time to failure, and others. All these data are processed to give stress-strain curves that make evident the manner in which a material behaves under stress. Such results are of paramount importance for determining material limits and performance under diverse working conditions.

Using the UTM, one can test materials in a standardized, controlled fashion, ensuring consistency with respect to results, conformity to set standards. UTMs are very crucial for quality control, research, and development that supply engineers with information required in making crucial decisions concerning materials’ choice and use across such fields as construction, manufacturing, and aerospace.

Elongation and Its Role in Tensile Strength

Understanding Elongation

Elongation is defined as the capacity for stretching or lengthening under tensile stress before a material breaks. It is expressed as a percentage of the original length and describes the ductility of the material. Usually, a higher degree of elongation may mean that the material is more ductile and will become more appropriate in the end for some applications which need a degree of flexibility or deformation under load.

Elongation Characteristics:

- Definition: Capacity for stretching before material failure

- Expression: Percentage of original length

- Indicator: Material ductility measurement

- Application Impact: Determines suitability for flexible applications

Elongation has an impact on tensile stress. Materials exhibiting higher elongation absorb more energy before failure during applications where durability to dynamic loads is required. On the other hand, materials with very low elongation are brittle—needing less strain to fracture, which suits their austere applications with less deformation.

The correct measurements of elongation provide the right knowledge to engineers and researchers in creating materials and products for applications that need such considerations. This brings about safety and functionality whilst simultaneously providing leverage in terms of their application, be it construction, aerospace, or manufacturing. When one understands elongation, one can depict the probable application behavior and the reliability of a material under a given set of circumstances, making it a fine candidate for the execution of the project it was originally intended for.

Strength and Elongation: A Critical Relationship

Strength and elongation share a critical relationship that principally characterizes a material in judging its sensor performance under stress. The strength of a particular material is the ability or force it has to withstand some pressure without failure, while elongation refers to the deformation or stretching of the material before it finally breaks. Alongside these, strength and elongation determine the behavior of a material in various applications wherein engineers may want to provide an optimum amount of flexibility or durability for the given project.

High Strength + Low Elongation

Characteristics: Stiff and brittle materials

Behavior: Fracture under sudden or intense forces

Applications: Structural components requiring rigidity

Lower Strength + High Elongation

Characteristics: Flexible and ductile materials

Behavior: Absorb energy through deformation

Applications: Impact-resistant and flexible products

Such materials with high strength but low elongation are stiff in nature and tend to fracture if subjected to sudden or intense forces. On the other hand, materials with lower strength but higher elongation can absorb much energy by means of deformation and thus are often utilized in applications where impact resistance or flexibility is required. The two properties must be balanced so that the material’s capabilities meet the needs of a particular application, for example, in civil engineering, product fabrication, or high-tech industries.

Real-World Applications:

- High-Strength Steel (Moderate Elongation): Construction beams requiring rigidity with resistance to sudden collapse

- Polymers (Medium Strength, High Elongation): Flexible films and protective coatings

- Composite Materials: Optimized strength-to-elongation ratios for specific applications

The rational choice for use in the construction of beams would be high-strength steel with a moderate degree of elongation, affording certain rigidity and concurrent resistance to immediate collapse under load. Polymers of medium strength and high elongation may thus be used for flexible products such as certain strong films or coatings. To know and control the profile of strength versus elongation is to know how to select materials fit for the purpose in the long run, able to go through and withstand the service conditions.

Impact of Elongation on Material Performance

The elongation of a material holds a significant place in defining material behavior under stress and strain. High in elongation, these materials exhibit increased flexibility and so, they can absorb more energy before actual failure occurs. Such materials find application wherever flexibility and resilience are required, such as in cables, films, and protective coatings. Materials having low elongation, on the contrary, are mostly associated with rigidity and conform to structural purposes by offering strength against deformation.

| Elongation Level | Material Characteristics | Typical Applications |

|---|---|---|

| High Elongation | Flexible, energy-absorbing, resilient | Cables, films, protective coatings |

| Intermediate Elongation | Balanced strength and flexibility | Structural components with load variation |

| Low Elongation | Rigid, brittle, high structural strength | Load-bearing structures, precision components |

The performance of a material is highly tied to the elongation properties it shows under specific conditions in service. In circumstances where loads vary or are extreme, the materials with intermediate elongation may optimally accommodate stresses so that the structure retains integrity balanced with strength; insufficiently elongating materials, however, may either break or fail before the due time, highlighting the importance of making a good choice of materials when it comes to different applications.

Finally, the correlation of elongation and material performance allows an engineer and a designer in material selection for a certain application. Whether flexibility, tensile strength, or a combination of both are needed, elongation offers one measurement to guide a decision intended toward safety, durability, and efficiency in applying and designing materials.

Real-World Examples of Tensile Strength Applications

Tensile Strength in Steel Used in Construction

Steel being one of the materials considered important in construction due to its high tensile strength. The tensile strength is the maximum load and stress applied to a specific material while it is being stretched or pulled in opposite directions until it ruptures. Because of such characteristic, it is beneficial for carrying heavy loads in structures, thus providing durability and safety.

Steel Applications in Construction:

- Building Skeletons: Main structural framework for buildings and skyscrapers

- Load Distribution: Steel beams and reinforcements handle heavy loads without deforming

- Dynamic Resistance: Withstands static loads (building weight) and dynamic forces (wind, seismic)

- Bridge Construction: Long spans and enhanced load-bearing capacity

The tensile strength of steel finds application in constructing the main skeleton of buildings and skyscrapers. Steel beams and reinforcements can take heavy loads without deforming when placed under tension. This allows structures to maintain their integrity against static loads such as the weight of the building itself and dynamic loads like that of wind pressure or seismic actions.

Also, steel is used extensively in making bridges, where tensile strength permits long spans and enhanced load-bearing capacity. The high tensile steel cables in suspension and cable-stayed bridges balance the load while maintaining rigour. This is how tensile strength in steel becomes an asset for creating safe, sound, and efficient structures in global construction projects.

The Role of Tensile Strength in Polymer Materials

Tensile strength in polymer materials is an important property, defining its ability to resist the forces of extension or pulling without rupturing. When stress is put on polymer materials, this property becomes highly important: packaging, fibers, or construction materials are indeed good examples. Those polymers with high tensile strength go in industries where these materials must withstand all kinds of variable situations with durability and reliability.

Crystalline Polymers

Tight and ordered chain arrangement provides higher tensile strength compared to amorphous polymers.

Cross-linked Polymers

Cross-linking structure enormously aids in resisting mechanical deformation and increases tensile strength.

Enhanced Polymers

Additives, fillers, and processing methods can alter the final tensile behavior and performance.

Tensile strength varies according to the molecular structure and bonding of the polymer. Structure-wise, crystalline polymers, having a very tight and ordered chain arrangement, tend to have chequered tensile strength vis-à-vis an amorphous polymer. Injection of cross-linking into a polymer structure enormously aids in resisting mechanical deformation. Additives, fillers, and processing methods may also alter the final tensile behavior.

Being versatile, tensile strength finds numerous applications in polymers. Such high tensile polymer fibers provide long-term service in highly demanding environments if used in ropes or textiles. Polymers with moderate tensile strength would come handy for applications requiring flexibility such as plastic wraps. Knowledge of tensile strength can allow manufacturers to choose or tailor a polymer material for a chosen function, aiding in the efficient and safe usage of polymers in many industries.

High Tensile Strength Materials in Manufacturing

Importance of High Tensile Strength Materials in Manufacturing A high tensile strength material is an object that withstands significant stress without breaking. With respect to buildings, automotive, and aerospace industries, these materials conferring the attributes of strength, safety, and reliability under demanding conditions become a necessity; in short, they provide resistance to mechanical forces, reducing the risk of structural failures and improving their performance.

Manufacturing Applications:

- Construction Industry: Cables, beams, and reinforcements using steel’s high tensile strength

- Automotive Operations: High-density polymers and composites for light, strong parts

- Aerospace Applications: Advanced materials for efficiency and vehicle longevity

- Composite Innovation: Materials designed for specific performance requirements

A more notable use of high tensile strength materials exists in the construction industry in cables, beams, and reinforcements. Steel is especially prized for its high tensile strength and is used extensively in buildings and bridges. Likewise, in automotive operations, polymers and composites of a high dense strength are used to produce light and strong parts to enhance vehicle efficiency and ensure longevity.

Development in manufacturing technologies has always been a force motivating innovations in high tensile strength materials. Composite materials have properties of more than one substance to generate a product with enhanced performance. These advancements have allowed the manufacturers to produce materials purposely designed for specific applications, which assure functionality, durability, and cost-effectiveness. Rather, due to its wider adaptability, this is the focal point of modern manufacturing.

Frequently Asked Questions (FAQ)

Q: What are the units of tensile strength?

A: In the international system of units, tensile strength is usually measured in Newtons per square meter (N/m²) or Pascals (Pa). It represents the force exerted on a unit area of the material in order to make it fail.

Q: How is tensile strength determined for a material?

A: Tensile strength is measured by performing a tensile test, in which the tensile load is gradually applied on the sample until it breaks. The tensile force applied at breaking point and the cross-sectional area of the specimen are measured, and using the formula tensile strength = maximum force/cross-sectional area, the tensile strength is computed.

Q: What factors affect tensile strength?

A: Apart from composition, temperature, and defects or impurities, factors affecting tensile strength may also be related to a material’s mechanical properties, since the stress a material can endure to a certain point is determined by its mechanical properties.

Q: What is the yield point in relation to tensile strength?

A: The yield point is the moment when the material starts to deform plastically and cannot revert to its original shape. It is important for tensile strength because after the yield point, the behavior of the material goes from elastic to plastic of maximum stress interrelated in former which can be experienced by a material without permanent deformation.

Q: How is tensile strength measured?

A: This value is measured by a tensile testing machine that subjects a specimen to a tensile load until failure; from the results, tensile strength is calculated in units of force per area, which collectively describe the ability of a material to withstand tension.

Q: What’s the difference between tensile strength and breaking strength?

A: We call tensile strength the maximum stress withstood by a specimen to begin deformation, but breaking strength is the actual force needed to break the specimen. Both are significant, but tensile strength broadly defines a specimen’s resistivity to tension.

Q: Why is tensile strength important?

A: Tensile strength is an important property that determines how well a material can resist forces applied so as to pull it apart. It becomes imperative to know the tensile strength when working in construction, manufacturing, or materials engineering to ensure safety and performance in the given application.

Q: Which material has the greatest tensile strength?

A: The materials that typically have the greatest tensile strength include carbon nanotubes, some forms of steel, and Kevlar. These materials are capable of bearing much heavier tensile loads compared to conventional metals and polymers, which makes them suitable for engineering applications where the utmost strength and durability are required.

Q: How does temperature affect tensile strength?

A: Temperature is something that influences the tensile strength of a material significantly. Generally, at elevated temperatures, the decrease in tensile strength is evident as materials tend to become more ductile and less capable of resisting stress. On the other hand, a fall in temperature increases the tensile strength of a material, and with it, the brittleness.

Q: What is the role of cross section area on tensile strength?

A: The cross-sectional area of a specimen is crucial in the calculation of tensile strength. In fact, higher tensile strength will be recorded for larger cross-sectional areas, as force is distributed over a bigger area leading to lower stress on the material. This relationship underscores the importance of geometry in material performance.

References

- Xometry: Everything You Need to Know About Tensile Strength

This resource explains tensile strength, its measurement in SI units (MPa or N/mm²), and its application in material testing. - Instron: Tensile Strength

A glossary entry that discusses tensile strength, its measurement in units like Pa or psi, and its importance in material evaluation. - Britannica: Tensile strength | Definition, Unit, & Facts

A comprehensive definition of tensile strength, including its units and dimensions in both SI and English systems. - Converters Blog: What is Tensile Strength?

This blog covers the basics of tensile strength, its units (psi, N/m²), and the different types of tensile strength. - Maeden: Understanding Tensile Strength, Elongation, and More

A detailed guide on tensile testing, including the units used (cN, N) and their relevance in material testing.