When it comes to analyzing how long materials last under diverse conditions, tensile versus break strength are often the two concepts mentioned. Then how are they similar if they measure-two completely varied properties crucial for construction, manufacturing and engineering works? If you want to learn how things are pressured or why selecting the appropriate materials for your job is important, this article is for you. We will discuss the differences between tensile strength and break strength with real-world applications so that you may comprehend both better in different industries. By the conclusion, you will be familiar with these fundamental concepts that guide the design and use of materials.

Understanding Tensile Strength and Break Strength

Definition of Tensile Strength

The tensile strength is the greatest amount of tensile stress a material can sustain before breaking. It is an inherent property useful in engineering and material sciences, describing how much force a material carries under stretching or pulling. Tensile strength is measured in force per cross-sectional area, commonly denoted in megapascals (MPa) or pounds per square inch (psi).

The understanding of tensile strength is worth knowing when selecting materials suitable for areas in need of resistance under pulling or stretching forces. For instance, cables or beams should be strong enough in tensile strength to bear loads safely. Hence, in manufacturing, materials such as metals, polymers, or composites are chosen for their ability to resist deformation under tensile forces.

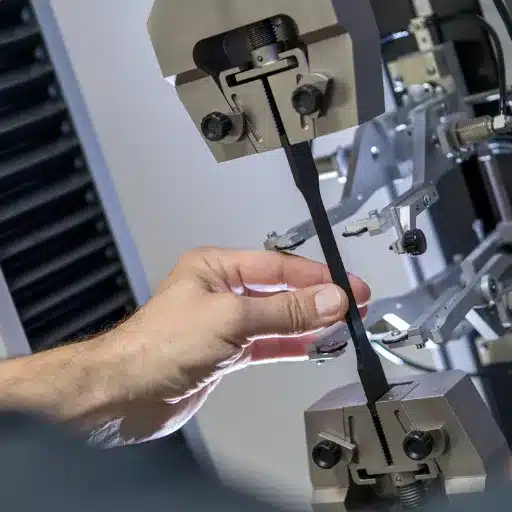

One performs tensile strength tests with equipment such as a universal testing machine, which applies a gradually increasing load to the test sample until it breaks. The outcomes of these tests allow engineers and designers to expect how a material performs and design products that can be confidently used for demanding applications. Knowledge of tensile strength assures industries of the safety, longevity, and efficiency of designs.

Definition of Break Strength

Break strength refers to the greatest amount of stress or force that a material can sustain before failing or breaking. It is the point where the tested material has completely lost its structural integrity under tensile load. This characteristic is very important in judging the feasibility of employing materials in various applications, mainly construction, manufacturing, and engineering.

Break strength is determined by studying the material under a tensile test. Here force is applied with controlled increment until the breaking of the material occurs. This tension test basically shows the heavy loads a product could actually bear and the conditions under which it might fail. With break strength data, the product or structure can be safely designed within the parameters of strength.

This property of break strength is important to be considered in the process of material selection since it affects the fate and functionality of a product. Engineers use it to select materials to best suit conditions of high risk of fail and warranting a high safety standard. Whereas break strength can be regarded as their protective antidote away from over-design or under-adsorption of materials in extreme pressure environments.

Comparison: Tensile Strength vs. Break Strength

Key Differences:

- Tensile strength identifies the highest stress a material can sustain while being stretched or pulled before it finally fails or breaks

- Break strength is a force that is measured and required to break a material

- Tensile strength determines the load a material can carry without being plastically deformed or fractured

- Break strength expresses the point where a material under stress goes into separation

Engineers and designers need to comprehend differences between these two sets of properties when selecting materials for projects. For example, tensile strength is commonly used in determining if a material will withstand expected work loads over time, e.g., cables or beams of construction. Break strength is more critical in applications where failure is out of question, such as in life-supporting components. These values taken together give a clear picture of how a material will behave in varying circumstances.

Importance of Tensile and Break Strength in Various Industries

Aerospace Applications

In the aerospace industry, tensile strength and break strength are key properties because materials face extreme stresses under varying conditions. Aircraft components, such as wings, fuselage panels, and fasteners, must undergo the highest tension ever applied while in flight. Along with other requirements, the tensile strength has to be sufficient to ensure that the components can resist deformation under prolonged stress. Break strength is equally important; it measures the largest load that can be placed on a material before failure. This is crucial for components whose failure may bring about catastrophic consequences, such as landing gear or engine parts. It is through rigorous consideration of such values that aerospace engineers pick materials whose break strength values provide for a very large safety margin beyond expected stresses.

On top of this, the severity of the environments of aerospace-almost as if that environment in itself demands inconsistency-high-speed airflows, pressure fluctuations, and temperature extremes-demand materials to perform consistently. Testing for tensile and break strength ensures that such materials are evaluated against stringent safety and reliability standards, and thus in operation, the aircraft and spacecraft remain robust in their service.

Automotive Considerations

The automotive industry focuses on materials that deliver a fine balance between performance, safety, and cost considerations. Vehicles are to undergo various stresses, such as vibrations, impacts, or presence under severe environmental conditions, including extreme temperatures and corrosive elements. Hence, in the process of design and manufacture, those materials with high strength, ability to wear, and ability to resist corrosive forces are preferred.

Key Automotive Requirements:

- Light materials for enhanced fuel efficiency

- Reduced emissions compliance

- Advanced alloys and composites usage

- High-strength steels for safety

Safety is always at the forefront of automotive engineering. Structure components, frame, and crumple zones materials are tested to absorb and manage the dispensation of energy in an accident so that passengers are safeguarded. Material science and engineering help toward the development of enhanced safety so that vehicles abide by strict regulatory requirements and provide assured performance for the entire lifespan of the vehicles.

Construction and Structural Integrity

Construction and structural integrity take their toll on vehicle safety, durability, and performance in modern contexts. Materials get chosen depending on how much stress they can take before they give up or some compromise occurs between strength and versatility. A combination of advanced metals, usually ranging from high-strength steels to aluminum alloys, gets chosen based on tensile breaking strength-the higher the tensile strength, the better reinforcement it gives structural assembly coupled with low weight.

The tensile breaking strength is perhaps one of the most important parameters considered in selecting a material because it denotes the maximum stress a material can endure before it fails. Materials with high tensile strength are at the core of crumple zones that absorb impact energy during collisions so as to save passengers. These zones must remain rigid but sufficiently flexible to deform in a controlled way to dissipate energy from the impact, which would otherwise result in heavy knockback on the vehicle occupants.

Raw global safety standards and reliability improvements are put to test through the very hostile testing of materials. Ailing of everyone some simulation technology and physical crash tests permit the engineers to verify that all structural components behave as expected under desired conditions. This quest of excellence instituting innovation maintains that car structural integrity and continues to aspire for the protection of occupants throughout the life span of the car.

Factors Influencing Tensile Strength and Break Strength

Material Composition

Material composition plays an important role in deciding the tensile and break strengths of any given structural element. Tensile strength refers to the greatest stress a material can resist while being stretched or pulled before failure, whereas break strength is the stage at which the material fails. These factors are greatly influenced by the choice of materials since different materials offer different levels of resistance, elasticity, and deformability.

| Material Type | Key Properties | Applications |

|---|---|---|

| Steel | High tensile strength, load-bearing capacity | Structural integrity applications |

| Aluminum | Lighter weight, moderate break strength | Weight reduction requirements |

| Composites | High strength-to-weight ratio, fatigue resistance | Advanced engineering applications |

Composite materials that marry two or more components are increasingly used in engineering for having tailor-made properties. Such materials confine carbon-fiber-reinforced polymers with a high strength-to-weight ratio, excellent resistance to fatigue, and flexible design. The knowledge of material constitution and interaction will enable an engineer to draw out optimized properties in terms of performance, resulting in structures that sufficiently meet the safety and serviceability requirements imposed on them under intended working conditions.

Processing Methods

The processing techniques hold paramount importance to exhibit superior properties in such advanced materials. The method of processing depends upon the type of material, property desired, and its end application. Whether it may be molding, casting, or additive manufacturing, processing caters to engineering requirements posed by an end application. Such manufacturing techniques enable the shaping and structuring of materials, and thus functionalizing and enhancing their performance.

Processing Methods for Carbon-Fiber-Reinforced Polymers:

- Autoclave Curing: Controlled temperature and pressure for strong, uniform material

- Resin Transfer Molding: Best for complex shapes with optimal strength-to-weight ratios

- Filament Winding: Ideal for cylindrical or spherical shapes with maximized directional tensile strength

Knowledge of the working fluids used and the processing method selected ensures that the tensile-breaking strength and other requirements of performance are met by the engineered materials. By adjusting processing parameters like pressure, temperature, and curing time, engineers promote the realization of the material’s capability to endure the stress of working conditions, hence ensuring reliability and safety in the long run.

Environmental Conditions and Temperature Effects

Environmental conditions may impose the degradation of material properties that include extremes of temperature, humidity, and chemicals. Variations in temperature may enlarge or shrink a material, developing internal stresses or leading to deformation. Such a process will lead to the failure of the object and shorten its life, especially under situations in which the temperature changes rapidly.

Temperature Effects on Materials:

- Hot Environments: Materials degrade faster from oxidation, surface softening, or melting

- Cold Environments: Materials become brittle, prone to cracking

- Polymers: Lose flexibility at cold temperatures

- Metals: Become prone to fatigue and fracture

Such concerns are taken into account in the choice of materials, often with treatments and reinforcements applicable to the specific conditions. Testing under simulated environmental conditions can help guarantee materials that will survive both normal and extreme service application with no failure. The correct material choice and its evaluation are important for safety, reliability, and durability under lines of extreme environmental variations.

Testing Methods for Tensile and Break Strength

Standardized Testing Procedures

Generally speaking, standardized testing methods for tensile and break strengths are designed for accurate and reliable measurement of distributed forces so that results are comparable to a set of tested references. Such methods will include application of forces to the specimen until it fractures or until it attains ultimate strength according to a controlled application of either uniaxial tensile force. The measured properties may include tensile strength, elongation, and break point.

The specimen must be taken from representative samples of an exact dimension, and the whole operation will be executed according to the standardized methods to have freedom in testing for comparison. Once testing starts, a tensile testing machine will apply tensile forces progressively upon the specimen while simultaneously recording the relevant data: for example, the force applied when deformation occurred, wherein important characteristic parameters such as yield strength and ultimate tensile strength stress are computed from the recorded stress-strain curve.

These test methods are helpful in identifying material behavior under stress and are integral to the assessment and selection of materials for particular applications. By ensuring that the methods are tested in accordance with accepted standards, manufacturers and researchers can predict how their materials will perform to guarantee that their materials are appropriately safe, compliant, and able to withstand day-to-day as well as extreme conditions.

Advanced Testing Techniques

Advanced testing techniques for measuring tensile breaking strength consist of highly accurate methods to determine the maximum stress a material can endure. The tensile test usually involves stretching or pulling the test specimen until the material breaks, and the results give information on the amount of stress and strain the material may endure. Knowledge of these parameters is very useful in assessing the use of the material.

The tensile breaking strength depends heavily on several factors und such as the compositional materials, temperature, and the conditions in which testing is carried out. Materials with harder strengths, such as metals and composites, tend to manifest higher tensile breaking strengths, making them more suitable in construction or aerospace areas. On the other hand, plastics may be preferred when lower tensile strengths are desirable. Lower tensile strengths also are due to their lower stretchability and inexpensive cost.

In this way, advanced machines such as the universal testing machines help researchers obtain reproducible results. These machines record the forces applied and elongation as a function of time during the test, providing valuable data regarding the material’s responses. These data will aid engineers in deciding upon materials that satisfy safety and function requirements in various industries.

Non-Destructive Testing and AI-Driven Analysis

Non-destructive methods inspect the materials and components without inflicting any damage thereto. Sperl and others described NDT as a technique developed for detecting defects, irregularities, or weaknesses in materials that endanger the services of industries of aerospace, construction, and energy. NDT practitioners do software testing while keeping test objects intact, thus avoiding wastage and cost while supporting sustainability.

AI Integration Benefits:

- Automated data analysis and pattern recognition

- Detection of subtle defects with great precision

- Predictive failure analysis

- Real-time analysis capabilities

- Reduced false negatives

Non-destructive testing and AI-integrated engineering is the giant leap forward in industrial inspection and maintenance. AI-assisted predictive analytics will find current problems and also predict for maintenance the prospective ones, cutting down on the downtime.

Real-World Applications of Tensile and Break Strength

Common Materials Tested: Metals, Plastics, Composites

Determining tensile and break strength forms the bases of how materials react to stress and for what uses they can be applied. Metals are, for instance, tested for strength and elongation properties. This is very much important for safety and performance on the durability of the materials in construction, automobile, and aerospace industries. Testing also aides manufacturers in choosing the proper alloy for a particular application to optimize performance in heavy load or severe condition.

Plastics constitute another set of materials widely tested because of their increasing use in different industries, including packaging and medical devices. With tensile testing, plastics can be analyzed for their flexibility, elasticity, and points of fracture, which are all essential to ensure that products are capable of coping with actual use. For instance, the knowledge of tensile strength of a plastic in food packaging apprehends the plastic packaging to avert breakage during handling and at the same time assures the safety of the product.

As composites are a mixture of two or more materials, they normally require tensile and break strength testing to examine their combined attributes. They find application in industries such as aerospace and wind energy where lightweight material strength is highly demanded. If these materials are tested, they allow engineers to be sure that composites would resist tension, compression, and other forces in extremities compatible to durability measures while enhancing weight efficiency.

Case Studies Highlighting Tensile Properties

Case Study 1: Aerospace Sector

Aircraft components, such as fuselage panels and wings, generally use composite materials given their excellent strength-to-weight ratio. One of the tensile properties that act as proof that these materials can stand high-stress environments-lowering pressure changes, speed, and atmospheric conditions in flight. Tensile-wise, carbon-fiber-reinforced composites excel in strength, thus fit for operations such as retaining structural integrity during turbulence or extreme operational temperatures.

Case Study 2: Wind Energy Field

Wind turbine blades are designed with advanced composites, which must finally withstand the stresses of wind on-forces pulling over days. Tensile testing for these materials ensures that the blades will resist stretching and deformation and assure long-term durability and operational efficiency. The results thus allow engineers to design turbines that efficiently optimize energy production, while standing the environment challenge of strong winds and temperature fluctuations.

Case Study 3: Civil Engineering

Tensile properties have been viable for civil engineering in assisting the use of composite materials in bridge constructions. Bridges are often subjected to the combined effects of dynamic and static loads and thus require materials that can be reliably subjected both to tension and compression. Through tensile testing, engineers can ensure that key components, such as cables and support beams, fulfill the required safety standards while simultaneously achieving the lightweight construction objectives.

Recent Advancements in Material Testing

Material testing has witnessed many recent advancements in pursuit of more precision, cost efficiency, and sustainability. Using this advancement, one can now incorporate digital methods, such as machine learning and AI, into data analysis for greater precision and accurate prediction of performance of materials under different conditions. Now engineering allows the simulation of stress scenarios rapidly, thus lessening the time and money of conventional testing methods.

Key Advancements:

- Digital Integration: Machine learning and AI for precise data analysis

- Non-Destructive Testing: Ultrasonic testing and X-ray viewing improvements

- Sustainability Focus: Eco-friendly materials and testing procedures

- Energy Efficiency: Reduced energy requirements and minimal waste generation

In recent times, sustainability has taken cover as another large pitching area for eco-friendly substrates and testing procedures. Researchers are looking for alternative materials that can satisfy a trade-off between durability and environmental impact, while developing testing procedures that require little energy and generate minimum wasteful materials. Such developments promote greener manufacturing processes, consistent with ozone-depleting emission-reducing initiatives and sustainable development further promoted internationally.

Frequently Asked Questions (FAQ)

Q: What is tensile breaking strength?

A: Tensile breaking strength is the measure of the utmost tensile stress that a material could register while being pulled apart before it finally tears. The parameter is central to determining the mechanical properties of any material and accordingly is measured in units of force per unit area, such as MPa or psi.

Q: How does one determine tensile strength?

A: Tensile strength is determined by applying a force on a material’s specimen till it breaks. The greatest force exerted on a specimen before it ruptures is recorded and utilized to compute tensile strength either in units of force per unit area. This gives an insight into the tensile strength of the material and how much the plastic can bear both in tension and under load.

Q: What are the types of tensile strength?

A: Generally, there are two types of tensile strength: yield strength and ultimate tensile strength. Yield strength defines the stress at which a material starts to deform plastically, and ultimate tensile strength is the biggest stress that a material can resist before it breaks. Both are important for a specie-wise tensile test.

Q: What is the need to understand tensile breaking strength?

A: Knowing tensile breaking strength is essential for engineers and designers because it helps in the choice and selection of materials for construction and manufacture. When engineers know the tensile strength of any given material, they know that it will resist the forces that it will be subjected to and not break or deform beyond its yield point.

Q: Which are all the factors influencing the tensile strength of a material?

A: Numerous factors influence the tensile strength of a material, including its composition, structure, and the method used to manufacture the material itself. Almost all are factors affecting tensile strength: for instance, ceramics commonly exhibit high compressive strength yet low tensile strength and thus are prone to brittle failure when subjected to tensile stress.

Q: Is tensile strength variable in materials?

A: Yes, tensile strength varies to a great extent from one material to another. To make clearer: steel possesses much tensile strength when compared with rubber and plastics. It is the unique property of any given type of material that defines how much force per unit area it can withstand before breaking.

Q: What is the importance of yield point?

A: The importance of the yield point stems from its indication of a change of state from elastic deformation to plastic deformation in the material. In other words, if a material is subjected to stress less than its yield point, it will regain its original shape after the stress’s removal; conversely, plastic deformation will happen if the applied stress exceeds its yield point, which is most crucial to comprehend in terms of the material behavior under load.

Q: How does temperature affect tensile breaking strength?

A: Temperature often affects tensile breaking strength. At warm temperatures, the material might be ductile and are hardly brittle, thus increasing tensile strength. At cold temperatures, some materials may turn brittle, and hence tensile strength falls with the increase in chances for brittle failure.

Q: What is the importance attached to modulus of elasticity for tensile strength?

A: Modulus of elasticity or the elastic modulus basically gives the measure of a material against deformation in response to stress. Hence, it remains very helpful in deciding the tensile strength since those which have high modulus stand able to bear greater forces without much deformation and hence are able to augment their tensile breaking strength.

References

-

Breaking Strength – an Overview

This article provides an overview of tensile tests and breaking strength, including key metrics like stiffness and elongation.

Read more on ScienceDirect -

Predicting Ultimate Tensile and Break Strength of SLS PA 12

A study focusing on tensile load‒displacement data to predict breaking force and ultimate tensile strength.

Read more on Springer -

The Tensile Behaviour of Paper Under High Loading Rates

This research examines the strain-rate dependent tensile behavior of paper under uniaxial tension.

Read more on PubMed Central