The mechanical properties of materials are sometimes essential knowledge for engineers, designers, and researchers from different industries; amongst these properties, the modulus of elasticity, or basically the measure of a material’s stiffness, is essential in materials deformation under stresses. In this blog post, we shall be looking into modulus of elasticity testing, especially pertaining to compression and elastic moduli. We will take a look at why these properties matter, how testing occurs, and that famous application to tech. Whether you are running through material selection or merely want to understand the behavior of materials under load, this article will share some basic principles and practical tips. Follow along as we discuss these indices and learn their contemporary applications in materials science and engineering!

Understanding Modulus Testing

Definition and Importance of the Modulus

The modulus of a material is considered another name for the elastic modulus; it signifies the behavior of the materials when applied stress. They relate the applied stress (force applied per unit area) with strain (deformation relative to the length of the material prior to application of force). It indicates basically how stiff a material is; in other words, its resistance to being elongated or contracted. The two most referred moduli are Young’s modulus for tensile and compressive stresses and shear modulus for deformations caused by shear forces.

It is important to understand the modulus to analyze the application area of a material. High modulus materials, like metals and ceramics, are good for potential applications demanding minimum deformation when loaded, whereas low modulus materials such as rubber, on the other hand, work well for applications that require flexibility. Another way engineers use modulus is to design structures economically. It guarantees the selected materials will safely and efficiently perform when expected loads are applied.

Some modulus measurements are applied tensile tests, meaning they extend a specimen and measure the deformation for a certain applied force. This provides precise data about the elasticity and strength of a material. Once industries like construction or aerospace can identify a material’s modulus, they can make better decisions about the design of their products for the best performance and longevity.

Overview of Types of Modulus

There exist several different types of moduli that are largely used when describing the mechanical properties of materials. The most often cited ones are Young’s modulus, shear modulus, and bulk modulus. One differs from another in the physical quantity measuring or, in other words, in the kind of load or deformation being exerted on a material.

- Young’s Modulus: Unlike the others, measures a material’s resisting ability for elongation or compression under axial force. It is associated with stiffness in structures of few types or those subjected to stretching or bending, such as beams or supports.

- Shear Modulus: Resists deformation of the material by shear stress in which different layers of the material are forced to slide against each other. This kind of modulus is of utmost importance while studying materials for torsional loading such as in gears or shafts.

- Bulk Modulus: A measurement of the resistance of a material against uniform compression and is critical for applications wherein a material is put under pressure changes, like in fluid dynamics. In conjunction with these other types of modulus, engineers and scientists are able to design materials for specific applications across many fields.

Applications in Engineering and Materials Science

Materials with specific modulus properties find applications in many fields of engineering and materials science. For the civil and mechanical engineer, the elastic modulus is important in the design of load-bearing structures such as bridges, skyscrapers, and beams. These structures are supposed to resist the stresses applied so that they do not deform permanently under the action of stresses, thus exhibiting safety and performance under variable loading.

The shear modulus finds direct applications in those components subjected to torsional or twisting forces, e.g., automotive axles, aircraft components, and precision machinery. By engineering according to the shear modulus, failure of these important components can be avoided when under operational stresses, thus enhancing their life and efficiency.

I had hit rock bottom studying the bulk modulus and was completely lost at the myriad of uses in fluid mechanics and high-pressure systems. It also comes in handy in the design of hydraulic systems, underwater exploration equipment, and pressure vessels. Given the right bulk modulus, a material can withstand almost all pressures posed in any environment, thereby ensuring reliability and performance. These are the modulus of elasticity mentioned earlier that, together, allow engineers to compellingly drive technological innovations in several domains.

Modulus of Elasticity

What Is the Modulus of Elasticity?

Being the fundamental property that measures a material’s ability to resist deformation under stress, modulus of elasticity, or Young’s modulus, essentially denotes the linear relationship between stress (force per unit area) and strain (proportional deformation) for a material subject to tensile or compressive forces. Put simply, the modulus of elasticity conveys how stiff or flexible a certain material is and provides essential knowledge about its mechanical behavior.

Materials with comparatively higher modulus values, such as steel, possess rigidity with lesser deformation under stress and thus find applications in constructions requiring firmness and strength. Materials of a lower modulus value, on the other hand, with rubber sufficing as an example, offer greater flexibility and deformation and suit purposes where such material elasticity or shock absorption is desired. The modulus of elasticity is usually expressed as pressure units, commonly Pascals.

This property is very important in engineering and materials science because it helps determine how materials will perform under real-world circumstances. Modulus of elasticity operational considerations comprise choices for designing bridges and buildings to manufacture medical implants and automotive components with safety, efficiency, and reliability being the fundamental stakes of structural and mechanical designs. It constructs a mathematical expression for this elastic behavior so that engineers can estimate how materials will react under certain conditions, thereby rendering it vital in technological developments.

Calculation Methods

Calculating the modulus of elasticity involves determining the ratio of stress to strain within the elastic limit of a material. This process typically requires measurements from a tensile test, where a material sample is subjected to a gradually increasing force until deformation occurs. The stress (force per unit area) and strain (relative deformation) are recorded, and their relationship forms the basis of the modulus calculation.

The formula for modulus of elasticity (E) is expressed as:

E = σ / ε

Where:

- • E is the modulus of elasticity,

- • σ (sigma) is the stress applied to the material, and

- • ε (epsilon) is the strain produced due to the stress.

To compute accurately, stress is obtained by dividing the applied force by the cross-sectional area of the material (σ = F / A), while strain is the ratio of the material’s elongation to its original length (ε = ΔL / L₀). These values are plotted on a stress-strain graph, and the slope of the initial linear portion of the curve represents the modulus of elasticity.

Accurate modulus of elasticity calculations are critical for predicting material behavior in engineering designs. This property ensures that structures and components are built with sufficient strength and deformability to handle operational demands without failure.

Factors Influencing Elastic Moduli

There are several factors that determine the value of the elastic modulus of a material, thus ultimately affecting the ability of the material to resist deformation under an applied load. The prime factors affecting this property, along with the recent studies and data about them, are as follows:

| Factor | Description and Impact |

|---|---|

| Material Composition | An intermolecular force relationship governs material stiffness. Metals like steel and titanium exhibit high values of elastic moduli because the atoms are very strongly bonded. Steel, for example, has an elastic modulus of about 200 GPa, and aluminum has about 69 GPa. Advanced composites, such as carbon fiber-reinforced plastics, can present different moduli, depending on the fiber orientation and resin properties. |

| Temperature | Both the elastic modulus and the temperature are inversely related for most materials. In general, for example, steel exhibits an elastic modulus of about 150 GPa at 500°C: The vibrations of the atoms hamper the bond strength in its structure. Most components in architecture related to high-temperature situations are thus very much affected by this phenomenon–Jet engines and power plants are two examples. |

| Microstructure | Elasticity is altered by its grain-size variation phase distributions and defects in the microstructure. Fine-grain materials tend to have higher moduli compared to coarse ones due to increased resistance to dislocation motion. Heat treating and machining processes modify such parameters to optimize materials. |

| Density | The density and subsequent porosity of the material play a vital role in determining the elastic modulus. The stiffer the tungsten (elastic modulus-400 GPa), it is because of higher its density. Porosity, which commonly develops during manufacturing, blocks stiffness owing to the voids that interrupt load transfer. |

| Anisotropy | Some materials exhibit anisotropy, meaning their stiffness may differ with direction; single crystals, for example, actually can have different elastic moduli depending on the direction of the applied stress. Anisotropy is an important design consideration when directional loading must be addressed. |

A good understanding of these factors and consideration of them during the design and material selection phases guarantees that optimized performance and reliability are achieved in various engineering applications.

Compression Testing

Purpose and Significance of Compression Testing

The compression testing is an important mechanical test by which a material can be evaluated in terms of its behavior against compressive loads. In many instances, a material does not undergo a complete failure during its life, but it gets loaded under conditions that reduce its size or change its shape. To ensure that the material is sufficient for a given duty, knowledge of its compressive strength, yield strength, elastic modulus, etc., is necessary.

The purpose of compression testing also lies in its very ability to predict the behavior of a material under different real loading conditions. The real loading consists in many instances of compressive forces, and if these are not taken into consideration while designing, the consequences could be catastrophic. Thus, compression testing safeguards the use of these materials in different trades like building, aeronautics, and automotive engineering, whereby materials must conform to relevant safety and working norms.

Being an evaluation of variables such as deformation, fracture behavior, and stress-strain relations, compression tests allow the engineer to make intelligent decisions relative to material selection and design. This guarantees the best performance of projects and products, maximum longevity, and risk reduction, especially in critical applications, thus ensuring increased reliability.

Equipment Used in Compression Testing

The field of compression testing requires equipment that ensures precise measurements with an evidently reliable nature. Below are the primary types of equipment involved in the procedure and their specific roles:

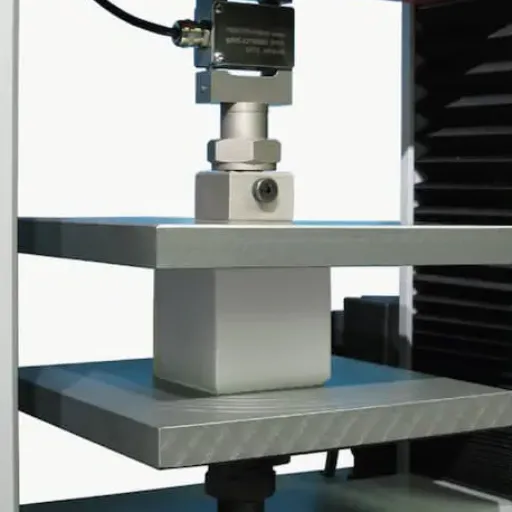

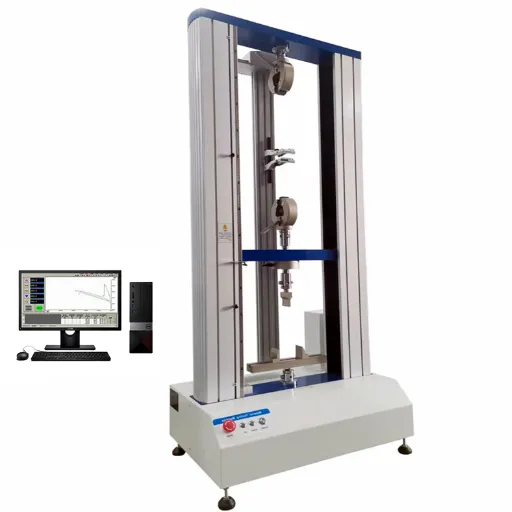

Universal Testing Machine

The most commonly used machine during compression tests is a universal testing machine. These machines accept modular fixtures that apply compressive forces on test specimens. The new wave of UTMs is digitally enhanced so operators may see force-displacement curves and stress-strain relationships as the tests proceed. They can normally machine forces of the order of a few newtons to hundreds of kilonewtons depending on the nature of the application.

Compression Platens

Compression platens form an interesting component in most test setups. They keep the compressive force uniformly distributed on the specimen. They are made from hardened steel or some other pretty hard material, which cannot give way to any appreciable deformation under very high pressures.

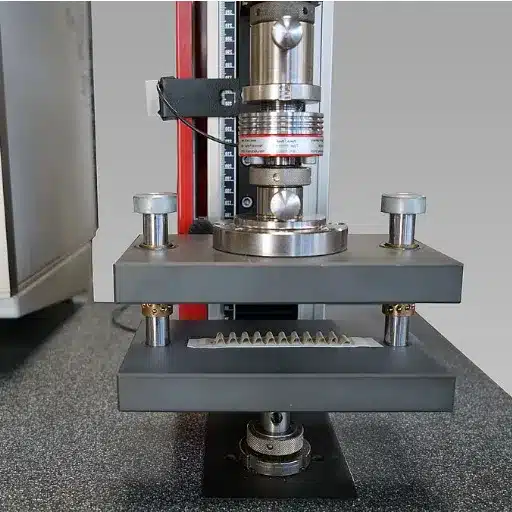

Load Cells

Load cells measure forces actually applied to the sample. High-precision load cells can be selected with respect to the working load range of the test to ensure that the data measured during the test is both precise and reproducible.

Data Acquisition Systems (DAQ)

The DAQ systems are set up to record and analyze the data collected during force compression tests, including force, displacement, stress, and strain values. Very modern DAQ systems have advanced software for report generation, mostly graphical.

Environmental Chambers

Materials that require environmental setups for tests are put into an environmental chamber. The chamber sets up the simulations of extreme temperature, humidity, or even corrosive environments, designed to stress the material with real-world behavior.

Extensometers and Displacement Sensors

Extensometers or displacement sensors accurately record the deformation of the sample during the test procedure. A non-contact laser system is often selected for testing delicate or sensitive materials.

The integration of the compression-testing equipment with modern digital technology ensures greater precision and reliability, thus guaranteeing the design of safer and more efficient materials and products by engineers and designers.

Standard Test Procedures

Typical compression tests aim to ensure the consistency of the method and the accuracy of the results. The generic procedure, as per usual, would be to test the specimen prepared according to some guideline and of the same size or shape with the same material properties. With popular standards such as the ASTM and ISO, those standards would stipulate sampling, specimen conditioning, and testing, thus allowing for reliability and comparability of results worldwide.

Once the specimens are prepared, they are inserted and, if needed, loaded into the test machine, but the key is proper alignment with the axis of loading. The specimen is then subjected to a predetermined rate of compression while being kept under constant observation for recording data, including load and deformation, in real time. This stage provides data regarding compressive strength, modulus of elasticity, and deformation characteristics. These recorded data points are very important in determining if the material can take up compressive forces.

At last, the data collected is analyzed and is compared against design requirements or material specifications. Engineers then use this information to determine the material’s response to application in the field, check for quality control, or even use it for design verification for structural application. Proper following of the standard procedures warrants an accurate and repeatable test, justifiably making the testing process and the results.

Modulus of Elasticity Testing Procedures

ASTM Standards for Modulus Testing

ASTM standards prescribe detailed criteria for the testing of the modulus of elasticity to ensure the accuracy and reproducibility of results. One of the most frequently cited standards is ASTM E111, which defines the method for determining the Young’s modulus in tension, compression, and flexure tests. It prescribes sample preparation, test arrangement, and the method of analysis of data for reliable results, irrespective of the material under test.

ASTM D638 is also an important standard, mainly applicable to the modulus testing of plastics. This standard permits testing of a plastic specimen to various tensile stresses to calculate the modulus, elongation, or similar properties. It requires accurate specimen dimensions and testing conditions to be controlled so that test variability is kept to a minimum, and consistent data are produced.

Usually, ASTM D3039 is referred to for testing various composite materials under tension to evaluate their modulus concerning fiber-reinforced composites. This standard should help ensure that a material response is typically determined under axial load, keeping in mind the unique anisotropic nature of composites. Technical properties evaluated using ASTM standards such as E111, D638, or D3039 are reliable and thus may be utilized by engineers to decide whether their product will meet design and application requirements.

Step-by-Step Test Procedure

- 1 Prepare the Specimen

Select and prepare the test specimen according to the required size and procedures as provided in the relevant ASTM standard (e.g., ASTM D3039 for tension test of composites). Ensure that no surface defects exist on the specimen and that it is properly conditioned if so required.

- 2 Set Up the Testing Machine

Calibrate the universal testing machine as per the selected ASTM standard. Attach the required grips or fixtures, which can hold the specimen securely without subjecting it to additional stresses or damage.

- 3 Install the Specimen

Carefully install the specimen onto the grips of the testing machine and ensure that the specimen is positioned vertically so that it will not bend or be subjected to eccentric loading. Tighten the grips sufficiently so as not to exert too much pressure, which may positively or negatively affect the test results.

- 4 Application of Tensile Load

Initiate the tensile test by slowly subjecting the axial load at a constant crosshead speed and in accordance with the ASTM standard. To do so, keep on recording the force applied and the elongation experienced by the specimen.

- 5 Monitor and Record Data

Strain gauges or extensometers should be applied for an accurate strain measurement during loading. Continue data acquisition for force, displacement, and strain until failure or until the concrete test parameters are fulfilled.

- 6 Analyze Results

This step should involve processing recorded data to calculate the material properties that include tensile strength, modulus of elasticity, and failure strain. Cross-check the output results with the desired performance requirements of the material.

- 7 Report Data

Prepare a comprehensive report that will include all relevant measurements, observations, and calculations. Also, make sure this report follows the proper format required by the testing standard.

Hence, following these steps can provide laboratory personnel with repeatable and reliable material properties of fiber-reinforced composites that would, in turn, inform critical engineering decisions.

Interpreting Results from Modulus Tests

When interpreting the modulus test results, it is essential to consider the properties the test is designed to measure. An important property obtained during the tests is the modulus of elasticity or rigidity of the material, representing the ability of a material to resist being deformed under stress, thus an important factor in deciding on its suitability for various engineering applications.

Analyze the stress-strain curve obtained during the test first. This step determines the modulus of elasticity for a material. Check if the curve is drawn from accurate data points within the parameters intended for the test. Consistency on at least several tested samples is important too, since major discrepancies may indicate the material itself is inconsistent or that the test process is flawed.

Lastly, juxtapose the actual modulus values with those anticipated or required according to standards for the purpose of the material. Any differences should always be studied to analyze if they fall within acceptable tolerances. Basically, the process confirms if the material really does meet the design requirements and hence aids a decision on the usage of the material, cases of possible improvements, or final considerations toward possible alternatives for the critical structures.

Testing Solutions and Innovations

Advancements in Universal Testing Machines

Universal Testing Machines have undergone great advances to enhance their precision and versatility. Modern UTMs are equipped with the latest generation of sensors that can measure loads and deformations with very high precision. Such precise measurements facilitate testing of metals, plastics, composites, and textiles with equal reliability, further meeting the stringent criteria of aerospace, construction, and automotive manufacturing industries.

On the other hand, software and UTM interlinking methods have changed the way a UTM can be used today. Modern UTMs might feature a user-friendly interface that allows operators to easily carry out relatively complicated tests and perform real-time data analysis. These software systems also incorporate adept automation of test setups, storing standards against test results for immediate compliance reporting, and thereby saving valuable time and reducing any potential errors introduced by the human operator.

UTMs’ versatility continues as a major newly established quality to consider, mainly in resistance to different test environments and materials. Enhanced modularity affords customization in layouts for tensile, compressive, flexural, and fatigue tests with relative ease. Energy-efficient components and safe operating mechanisms are the ones assuring that these new machines remain reliable while coming at low operating and environmental costs.

Emerging Technologies in Modulus Testing

Modulus testing and the measuring and analyzing of properties of materials are being affected by new emerging technologies. An important feature of the recent advancement is integrating automated systems with the power of AI. Such systems increase the efficiency of testing by optimizing testing parameters, recognizing material inconsistencies, and reducing the margin for errors in the results. With an AI-assisted analysis, it is also possible to perform predictive modeling to foresee how materials may perform under a given set of circumstances.

This is yet another heretofore interesting innovation used in modulus testing: the application of non-destructive testing methods. Ultrasonic testing and DIC come to mind as techniques that measure behaviors of materials with impeccable precision while in the state of undamaged conditions. These methods find their highest utility in cases where high-value components are to be preserved. NDT, while preserving the integrity of samples, shall also reduce the time taken for testing without compromising on accuracy.

Additionally, real-time data monitoring and cloud connectivity are reshaping the testing landscape. The current modulus testing equipment is usually equipped with sensors that collect and transmit data for the purpose of real-time analysis and decision-making. Cloud integration allows remote monitoring, providing an excellent platform for the team to interact from different corners. All said, these technologies go on to smooth workflow, allow instant data access, and promote the measurement of modulus testing efficiency.

Choosing the Right Testing Solutions for Your Needs

Check whether the exact requirements of your project or application can be met when choosing the right type of testing solutions for your needs. What kind of materials, environments, or conditions do you want to test? This can narrow down testing methods and tools that will precisely achieve your objectives. What kind of data do you want to collect? Strength, durability, elasticity, and so on? Choose the solutions based on what exactly they will measure.

Then comes the scale and flexibility of the testing equipment. For projects that will expand later on, test systems that can be repurposed on differing demands will, therefore, prove to be a worthy, affordable investment in the long run. Good games to be tested without grow well are those that are well integratable into existing workflows and employ simple user interfaces during the performance of operations. If tests will originally be procured at more than one remote location, then the portability or remote operation capability has to be considered.

Lastly, guarantee that the testing solutions meet the requisite industry standards and return reliable results. Reliability is necessary to make well-informed decisions from the data procured. Reading reviews or seeking suggestions from industry experts should help you to select reputable options. Give preference to solutions that offer strong technical support and maintenance options, as this guides increased productivity and minimizes downtime. With a structured approach, you can select testing solutions that effectively satisfy your very needs with confidence.

Frequently Asked Questions (FAQ)

Q: What is meant by modulus testing?

A: Modulus testing is the process through which a material is tested for its resistance to deformation under applied forces. This is done by calculating the stiffness or rigidity of a material through the various moduli, such as the modulus of elasticity itself.

Q: What are the types of elastic modulus?

A: Types of elastic modulus refer to Young’s modulus, shear modulus, and bulk modulus. Each type measures the relationship of stress to strain under different modes of deformation, like tension or compression.

Q: How is the modulus of elasticity calculated?

A: The calculation of the modulus of elasticity follows standard test methods, which involve preparing a stress-strain curve from material testing. By choosing the linear portion of this curve, the slope is calculated, which is precisely the modulus.

Q: What is the significance of Poisson’s ratio in modulus testing?

A: Poisson’s ratio is the ratio of lateral strain to axial strain. It plays a major role in modulus testing because it relates a specimen’s behavior to tensile or compressive loads being applied.

Q: Can modulus testing be carried out on polymer matrix composites?

A: The modulus of polymer matrix composites can be tested to confirm their mechanical properties. The test gives details on the tensile modulus and performance of the composite when acted upon by loads.

Q: What is Hooke’s law regarding modulus testing?

A: Hooke’s Law says that strain in a material is proportional to the stress applied to it, so long as these are actions performed within the elastic region. The modulus determined in modulus testing is an elastic modulus, i.e., the slope of the linear portion of the stress-strain curve.

Q: What is related to a test procedure on construction materials?

A: Modulus testing becomes vital for construction materials as it tests materials for their strength and stiffness. For instance, the knowledge of the modulus of elasticity and Poisson’s ratio of concrete will allow engineers to go farther in ensuring a safe and durable structure.

Q: How does the elastic region contribute to modulus testing?

A: Being in the elastic region means that the material will return to its shape after releasing the load. The modulus testing is done in this region because, then, the material’s stiffness and resistance to deformation can be accurately measured.

Q: Distinguish between static and dynamic modulus testing?

A: Static modulus testing measures a modulus of elasticity by applying loads slowly, while dynamic modulus testing describes the response of a test material to rapidly applied forces. The two tests complement each other by revealing different aspects of material behavior.

Q: How different does uniaxial testing contribute to the modulus testing process?

A: Uniaxial tests involve loading a specimen in one direction to examine the response of the material. These tests are considered fundamental in modulus testing for establishing the stress-strain relationships under tensile or compressive conditions so that true modulus values can be calculated.

References

- AMETEK – Modulus of Elasticity Testing – Explains modulus of elasticity testing, including its determination under axial stretching loads and stress-strain relationships.

- Industrial Physics – Modulus of Elasticity, What is it? – Discusses static and dynamic testing methods for modulus of elasticity, including torsional tests.

- California Department of Transportation – Chord Modulus of Elasticity Test Method – Provides a detailed procedure for determining the modulus of elasticity of concrete using a compressometer.

- Touchstone Testing Lab – Modulus Testing – Covers ASTM standards for modulus testing, including Young’s Modulus, Shear Modulus, and Poisson’s Ratio.

- Instron – The Definitive Guide to ISO 178 – Focuses on ISO 178, an international standard for determining the flexural properties of plastics.