Friction is one of the basic forces in nature that greatly affects our daily lives and influences the tiniest to the largest situations. It is the force that allows us to walk without slipping, it makes it possible to use the brakes of a car safely, and a lot more. Although the force of friction is so common in our lives, we hardly ever think about the factors that determine its magnitude, let alone its variation among different situations. Therefore, it is truly worthwhile to delve into the world of friction and its science. The present article will deal with the scientific aspects of the static and kinetic coefficients of friction, giving a detailed experiment-based approach to the comprehension of the interaction of forces. The article is intended for anyone curious, whether a student, educator, or physics enthusiast, as it explains the principles, presents hands-on methods, and discusses the implications of friction in an engaging and enlightening manner. Get ready to reveal the unseen mechanics of the resistance to motion and its significance in numerous applications!

Understanding the Coefficient of Friction

Definition of Friction

Friction is defined as the resistance produced when two surfaces are in contact and either move or try to move concerning each other. This force prevents motion and is caused by the interactions among the tiny irregularities of the contact surfaces. Friction is a force that keeps everything in its place, making it impossible to walk, drive, or securely hold items without it.

The frictional force is determined mainly by two factors: the characteristics of the surfaces in contact and the force pushing them together. Generally, smooth surfaces produce less friction than rough ones, while the frictional force increases with the pressure applied to the surfaces. Friction is an important factor in our daily activities, as it gives us hold and control; however, it can also be the cause of wear and energy dissipation in engineering systems.

Friction comes in various forms, including static friction, which is the force that stops the motion of two still objects; and kinetic friction, which is the force opposing the movement of sliding surfaces. The knowledge of friction basics helps scientists and engineers to make systems and tools that either exploit friction or reduce it, leading to increased durability and efficiency in the areas where it is necessary.

Types of Friction: Static vs. Kinetic

There are two distinct classes attributable to the association of friction, namely, static friction and Kinetic friction. It is essential to do away with the confusion between the two.

Static friction occurs mainly between two surfaces that are not in relative motion. It comes into play to counteract forces applied to slow down this initiation. This kind of friction lets objects remain when put on a surface with some slope.

Kinetic friction, however, comes into being while the object has already begun in motion. It only opposes relative sliding motion among those surfaces while in contact. Kinetic friction is significantly weaker than static friction in an identical situation-thus needing more force in order to start the motion.

Both static friction and kinetic friction are dependent on factors such as the properties of surfaces in contact and the normal force pushing them. Such distinctions are profound when designing things like brake systems for vehicles and apparatuses that perform based on controlled motion or stasis.

Importance of the Coefficient of Friction

The coefficient of friction is a crucial value in understanding and predicting the behavior of materials in contact. It quantifies the ratio of the force of friction between two surfaces to the normal force pressing them together. A higher coefficient indicates greater frictional resistance, while a lower value suggests smoother sliding between surfaces. By accurately measuring and applying this value, engineers and scientists can design systems that operate safely and efficiently under various conditions.

This concept plays a vital role in numerous applications, particularly in industries such as transportation and manufacturing. For instance, in designing braking systems for vehicles, the coefficient of friction ensures effective stopping power. Similarly, in manufacturing, knowing the coefficient helps in material selection and machinery design to minimize wear and tear while optimizing performance.

Beyond industrial uses, the coefficient of friction is integral in daily life. It impacts everything from the grip of tires on wet roads to the stability of shoes on different surfaces. Understanding and leveraging this value allows for better safety measures and improved functionality in products and environments we interact with regularly.

Purpose of the Coefficient of Friction Lab

Educational Objectives

The coefficient of friction lab’s main objective is to know how friction acts and to quantify it using practical experiments. The students will get the chance to do hands-on work with the factors that affect the frictional force, including the surface texture and normal force, by doing various measurements with different materials and surfaces.

The link between theoretical knowledge and real-world applications is another major objective. Students get to know the process of friction coefficient derivation from experimental data and how to use this understanding to tackle technical problems in areas such as engineering, product design, and safety evaluation. All these activities help develop the skills of precision, critical thinking, and data analysis which are crucial in scientific methodologies.

Finally, the lab that teaches the coefficient of friction encourages teamwork, problem-solving, and communication skills. The students will work in pairs, will be involved in experimental reporting, and will share their ideas and clearly present their findings. These skills, which are very important for success in both academic and professional careers, also reveal the larger significance of the coefficient of friction’s comprehension in applied sciences.

Real-World Applications of Friction

Friction is an essential force in many applications of the real world. It is the main factor of safety, efficiency, and even the functionality of many aspects of everyday life. Among the most obvious uses is transportation. The friction that occurs between the wheels of vehicles and the road is what makes it possible for the vehicles to move forward, come to a stop, and keep their positions while turning. If friction were insufficient then traveling would be unsafe across all the roads with rain or snow being the most critical adverse weather conditions.

Friction is also an inseparable part of mechanical systems and industrial processes. The braking systems of cars, bicycles, and other vehicles depend on friction to stop them safely. In the same way, friction is a necessary condition for the joining of parts inside the machines and the passing on of the force to the moving parts, i.e. motor, etc. In this way, it is also the quality of friction that makes screws, nails, and nuts among other fasteners, which are used to hold together structures, so indispensable.

The area of friction applications has already expanded to include, besides transportation and mechanics, practically all the functions people perform in their day-to-day activities, such as walking to or carrying and manipulating objects. The outsoles of shoes are made to be of a certain friction configuration to increase the grip and at the same time prevent slipping. Even the most elementary action of marking the paper with a pencil is nothing but the effect of the friction rubbing the pencil against the paper which leaves a mark. Friction can thus be considered a main force for the different fields and activities to innovate, because it parades along safety and convenience.

Importance of Static Friction Measurement

Static friction measurement is a fundamental process that reveals how immobile objects resist the force applied to them, thus hindering their motion. It helps to determine the maximum force required to break this resistance and to impose stability in practical applications. These measurements are very important as they provide the basis for the safe use of installations, the designing of reliable products, and, ultimately, the reduction of risks in all the sectors involved.

One of the most remarkable examples where the deadweight friction measurement is applied is in the field of transportation. Apparently, the association of the static friction between tires and the road surface is of great importance in terms of vehicle safety. It leads to effective tire designs, better braking systems, and skidding prevention. Besides that, the collection of precise static friction data promotes the production of road materials with improved grip, thereby increasing the overall traffic safety.

Apart from the transportation area, static friction measurement has become indispensable in construction and even product design. Engineers are required to determine the static friction so that they can ensure the buildings are not going to be easily brought down by nature in the form of earthquakes or heavy winds. At the same time, the designers of the products are depending on these values in various situations, including making the tools for various industries, domestic items, and so on. With the knowledge of static friction, even the most complex problems can be tackled, and solutions that are both safe and effective can be built.

Methodology for Conducting the Experiment

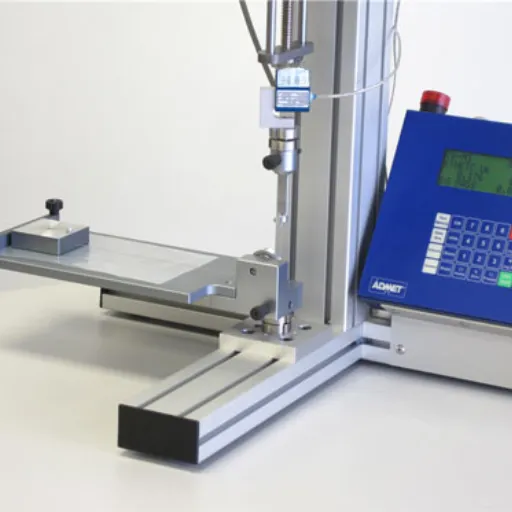

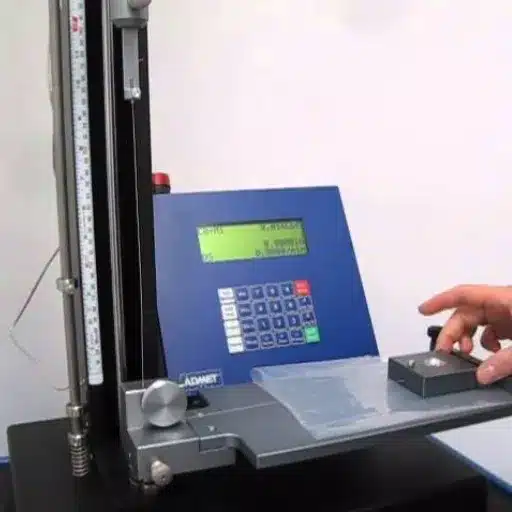

Overview of the Experimental Setup

The focus of the experimental setup is on the frictional force measurements under different conditions to determine its effect on the material interactions. The main elements of the apparatus are a flat surface, an adjustable incline, and objects made of different materials. The entire setup of these elements is made in such a way that during the interaction of the objects with the surface at different angles and weights, the frictional forces can be seen and measured.

For experimentation, the test object is first placed on the flat surface and then the surface alignment is gradually changed till the inclined position is reached. The angle at which the object slides denotes the threshold where the gravitational force overcomes the static friction. Different trials are done with different combinations of materials, surface roughness, and weights to guarantee complete data gathering. The control of the factors is so that the environmental factors, like vibrations or uneven surfaces, do not affect the results.

The analysis of the data gathered from the experiment is done for the purpose of finding out the relationships that exist between the material properties, the surface conditions, and the static friction coefficients. The process of comparing these results leads to the experiment giving valuable ideas for the design of tools and structures that are safer and more effective in case of friction being the crucial factor for their performance.

Step-by-Step Procedure

- Prepare the Materials and Equipment: Bring together all the essentials, including a flat surface, a variety of test objects, a force measuring device (e.g., a spring scale), and a ruler. Prepare the surface so it is clean and uncluttered to get the most precise measurements.

- Measure the Weight of the Object: Weigh the object you intend to test using a balance. Make a note of this figure as it will be referred to while determining the normal force exerted on the object.

- Attach the Force Measuring Device: The test object should be gradually pulled along the flat surface, with the spring scale attached securely. While pulling, make sure the force is applied horizontally and it is also at a constant rate.

- Identify the Static Friction Limit: The pulling force should be increased gently till the object starts to move. This maximum force should be noted as it equals the static friction force.

- Calculate the Coefficient of Static Friction: Apply the equation μ = F / N, where μ means the coefficient of static friction, F is the static friction force (the maximum force before movement), and N is the normal force (the same as the weight of the object). Don’t forget to write down your answer.

- Repeat the Experiment: Conduct the experiments with different materials and surfaces to investigate how the coefficient of friction changes due to the different conditions. Each test should also be repeated several times for accuracy.

- Analyze Results: The coefficients of static friction obtained from different materials and surfaces should be compared. Look for patterns and suggest reasons for them based on the factors influencing friction.

⚠️ Safety Considerations during the Lab

In the case of experiments with friction, the personal safety and the safety of the people around you should be the first thing to think of. Using personal protective equipment (PPE) that includes safety goggles and gloves is a good way to prevent injuries in case of an accident. Furthermore, long hair should be tied back and loose clothing should be tucked in so that lab equipment does not get caught in it.

A clean and organized workspace is a good way to avoid accidents. Spills, especially of lubricants or other substances that can change friction, should be cleaned immediately to avoid slipping hazards. A sturdy and flat surface should be used for the experiments to keep materials from falling or creating unintentional movement.

Also, obey the proper handling rules for all materials and instruments that are used. Be careful with the application of force because too much pressure might break the equipment or cause sudden and uncontrolled movements. Make sure that all safety measures indicated in the experiment manual are followed strictly, and do not hesitate to ask your instructor or supervisor for help if you need clarification.

Key Equipment Used in the Lab

Types of Surfaces for Testing

When investigating the coefficient of static friction, using a variety of surfaces ensures comprehensive and reliable data. Some common types of surfaces and their typical characteristics include:

| Surface Type | Characteristics | Coefficient Range |

|---|---|---|

| Wood | Wood is a versatile surface, often used in friction experiments due to its moderate roughness. Unfinished wood creates significant friction, while polished wood has reduced friction. | 0.2 – 0.6 |

| Metal | Metal surfaces, such as aluminum or steel, vary in frictional properties depending on their finish. Polished steel provides less friction, while rusted or rough steel presents higher friction levels. | 0.15 – 0.3 |

| Glass | Glass is a smooth surface with low friction, making it an ideal material for comparing results with rougher textures. | 0.1 – 0.3 |

| Rubber | Rubber offers high friction properties. This surface is used to simulate conditions such as road friction with tires or grip-related scenarios. | > 1.0 |

| Tile (ceramic) | Tiles have a wide range of frictional values, from smooth glazed tiles (low coefficients) to textured tiles (higher coefficients), depending on their designs and finishes. | 0.1 – 0.8 |

| Plastic (e.g., acrylic or PVC) | Plastic surfaces provide intermediate friction levels that can vary widely based on the type of plastic and its texture. Smooth plastic usually has moderate coefficients. | 0.2 – 0.4 |

Instruments for Measuring Force

The interaction between objects is often measured by devices that are specifically designed to quantify this interaction. Among the most prominent force-measuring instruments, the following are listed:

- Spring Scales: These instruments utilize Hooke’s Law, which asserts that the force applied to a spring is directly proportional to its extension as long as the spring is not subjected to over-stretching. The use of spring scales is popular in various industries for measuring weight and tension.

- Force Gauges: A force gauge is an instrument that can indicate force in both tension and compression. They are widely used in industries and laboratories for tasks such as testing material strength, checking safety standards, and assessing mechanical parts. Depending on the required precision, they can be either digital or mechanical.

- Load Cells: Load cells are very accurate sensors that transform force into an electrical signal. Their use is widespread in areas where accuracy is paramount, such as weighing scales, industrial presses, and engineering. Load cells are capable of providing consistent and trustworthy readings across a wide range of forces.

This assortment of instruments makes it possible to measure forces in different fields with high precision and efficiency, from scientific research to daily practical uses, thus achieving accuracy and reliability in each of the domains.

Calibration of Equipment

Calibration of equipment is a necessary step in the process of ascertaining the precision of a measuring instrument by comparing it to a standard that is already known. This is a process that cannot be avoided in contemporary manufacturing, research, and engineering as it provides the users with the assurance of getting the same results every time out of the same piece of equipment input. Calibration done correctly serves the purpose of the equipment to operate at its defined limits and thus, gives reliable results.

Calibrating the equipment properly, the procedure usually consists of the use of a standard or a tool that has been certified or verified with a measurement that is known. The instrument is evaluated in comparison to this standard, and if any difference is found adjustments are made. Calibration done at regular intervals eliminates the possibility of errors caused by the instrument losing its accuracy due to incessant use, the surrounding conditions, or being worn out; thus, it keeps the guarantee of results being precise for a longer period of time.

It is advisable to set up a calibration routine based on how often the equipment is used, the condition of the place where it resides, and the degree of precision needed. Calibration not being done can result in the same machine giving different readings, more time lost on waiting for the machine to be repaired, and even some safety hazards being created. Calibration done the right way can help the industry retain the quality and effectiveness of its tools and equipment.

Data Analysis Techniques

Collecting and Recording Data

The act of collecting and recording data is typically the very first step in the whole data analysis process, which is no less than a critical phase. It is the case of thoroughly gathering credible data from the sources and making detailed notes in a way that helps to avoid getting inaccurate and inconsistent results. Some of the main things to take into consideration at this stage are clarifying the aim of the collection of data, picking the measurables, and deciding on the methods like surveys, observations, or automated systems. Good planning guarantees that the data to be processed is relevant and of sufficient volume.

Recording the data accurately has the same significance as collecting it in terms of making it usable and organized. One of the very effective methods of this is adopting one of the standard formats like spreadsheets, databases, or certain data collection tools. Proper variable labeling and a neat dataset prevent the occurrence of errors and allow for smoother analyses in the future. Moreover, following ethical rules like keeping sensitive information safe and getting consent from participants are all very important during data collection and recording.

Organizing and storing data in an orderly manner, companies can not only guarantee the data’s integrity but also make it available for stakeholders and analysis with no time constraints. Collecting and recording data is the strong foundation that applications of advanced data analysis techniques can build on which in turn leads to better and more informed decision-making processes driving the whole organization forward.

Calculating the Coefficient of Static Friction

To determine the coefficient of static friction, one must first grasp the connection between the frictional force and the normal force exerted on an object. The coefficient of static friction is a unitless figure that denotes the proportion of the highest static frictional force to the normal force. This proportion plays a crucial role in determining the amount of frictional force that two surfaces can resist before they start to move.

Formula:

The coefficient of static friction (μs) is determined with the following formula:

μs = Fs / N

Where:

- Fs is the highest static frictional force which is the force needed to break the resistance and start moving.

- N is the normal force which is the force acting perpendicular to the surface of the object.

This calculation is very important in a wide variety of fields, such as engineering and physics, since it allows one to ascertain the interaction of different objects with surfaces under varying conditions. Knowledge of μs enables one to carry out the design optimization, safety assurance, and effective real-world problem-solving.

Interpreting the Results

The coefficient of static friction (μs) results must always be viewed in the light of the context giving them their utility. High values of μs denote large forces necessary to move the two surfaces apart, which is a crucial factor in braking systems, where stability is a desirable property, and in construction materials. On the other hand, a low μs shows that the surfaces can slide easily over one another, which may be considered a good thing in the case of lubricating machinery or creating more fluent material handling processes.

Precision in measurements and calculations is very important because even a slight mistake can have a very big impact on the practical use of the results. For instance, in engineering, a wrong calculation may lead to unsafe designs or reduced efficiency of systems. Regularly checking the methods used to determine μs is very important in order to get trustworthy results that are up to the required safety and performance standards.

Moreover, results should be taken under specific environmental and operating conditions, which they are meant to reflect. Surface roughness, material makeup, and environmental factors like heat or moisture can all have a say in how much the coefficient of static friction is. If we include these variables in our interpretation, the results give us more profound insights, and thus the overall effectiveness and accuracy of the applications in different fields are enhanced.

Frequently Asked Questions (FAQ)

Q: What is the coefficient of friction lab?

A: The coefficient of friction lab is an experimental arrangement that is constructed to quantify the coefficient of friction between dissimilar surfaces. Through the employment of assorted materials like cork and felt, the lab can be conducted by students to find out how the materials behave under various conditions.

Q: How do you measure the coefficient of static friction in a lab?

A: For the measurement of the coefficient of static friction, a block is usually positioned on a flat surface, and the force is gradually increased via a force sensor until the block starts sliding. The angle at which the block moves helps in the computation of static friction (µ) with tangent.

Q: What are some common lab activities related to the coefficient of friction?

A: Frictional force studies with dynamics carts are the most common lab activities. With the help of different materials and surface areas, students can find the effect of these factors on the coefficient of friction and thus acquire a deeper understanding of physics concepts.

Q: What role does velocity play in the coefficient of friction lab?

A: The velocity factor may lead to differences in the amount of kinetic friction that a moving body encounters. In a friction coefficient lab, for instance, the determination of the frictional variation with the different speeds of the cart moving across various surfaces can be obtained by measuring the cart speed.

Q: Why is the coefficient of friction important in education and research?

A: The coefficient of friction is a concept that is a priority in both the context of learning and scientific research. It is a tool that facilitates the acquisition of a basic understanding of the physics world by students and ultimately allows researchers to make better materials and surfaces for a variety of applications.

Q: Can you explain the significance of the diagram in a coefficient of friction lab experiment?

A: The diagram in a coefficient of friction lab experiment is a pictorial representation of the setup and the forces involved. It shows the interplay of the applied force, the experienced force of friction, and the inclination angle, thus helping the understanding of the physical laws that are being investigated.

Q: How does surface area affect the coefficient of friction?

A: In most cases, the coefficient of friction remains constant regardless of the area of surface; but the actual frictional force can still depend on the area of contact of the two surfaces. Students in lab experiments can use varying block sizes on the same surface to scrutinize these subtle differences.

Q: What materials are commonly used to demonstrate friction in the lab?

A: The frequently mentioned materials in a friction coefficient lab are cork, felt, and assorted plastics. The students are in a position to witness the differences in the frictional forces when doing experiments with different combinations of these materials.

Q: What is the process of conducting a coefficient of friction lab experiment?

A: The procedure consists of putting a dynamic cart on a surface, pushing it with a sensor, and slowly increasing the force until the cart starts sliding. The angle at which this occurs is then measured and based on the forces, the necessary calculations are performed to find the friction coefficient.

References

-

A Technique to Determine Friction at the Fingertips – A study presenting a reliable method to measure the coefficient of friction on fingertip skin.

(PDF) A Simple Lab Exercise to Determine the Coefficient of Static Friction – A detailed description of a straightforward physics lab exercise for determining static friction coefficients.

Kinetic Friction – The Physics Teacher – An experiment focused on measuring the coefficient of kinetic friction while exploring mechanics concepts.

Coefficients of Friction – Lab Experiments by PASCO – A lab using motion and force sensors to determine static and kinetic friction coefficients.

Friction Lab (PDF) – A comprehensive lab guide on friction, including methods to measure the coefficient of friction between surfaces.