Polymers have become very important materials for various industries including automobile manufacturing, medical devices, and so on. To know their performance and durability for a specific application, it is necessary to know their mechanical properties like tensile strength and compression force resistance. This blog post is going to be about tensile and compression testing in a polymer testing laboratory. The aim will be to understand the tests, their significance, and the material behavior under stress that has been brought out by the tests. If you belong to any of the categories—researcher, engineer, or industry professional—you will come to know the role of these tests in the development of safer and more efficient products to a great extent. Do not miss out on exciting revelations in the very niche area of polymer mechanics!

Introduction to Polymer Testing

What is Polymer Testing?

The term polymer testing signifies the process of assessing the polymeric materials in order to know the properties, performance and possible applications. Through these tests, it is possible to find out how the polymers will act and react to such as mechanical stress, high temperatures and interaction with the environment. The detailed and analyzed results will provide determinations on strength, durability, flexibility and chemical resistance, which will be the main factors in making sure that the material is fit for the purpose.

Commonly, the testing process will cover a variety of standardized methods along with the laboratory measurements of properties like tensile strength, hardness, and so on. By way of example, mechanical tests consisting of tension or compression tests look at the polymers’ behavior concerning the applied forces, while thermal tests gauge the material’s performance at extreme temperatures. Other evaluations are included, such as chemical resistance tests that determine how well a polymer will withstand specific chemicals, and weathering tests that assess the material’s durability under prolonged exposure to environmental factors.

Polymer testing becomes no longer an option but a necessity for the automotive, aerospace, medical devices, and packaging industries. The poor material performance will be a direct cause of failure in the aforementioned areas. Thus, potential weak spots can be determined through these tests and they can also be a means of verifying compliance with industry standards. Consequently, these tests are crucial for bettering the production process, making trustworthy products, and facilitating innovations in material science. Accurate testing ensures that polymers can meet the expectations of contemporary applications while also being durable.

Importance of Polymer Testing in Industry

Polymer testing is vital to the quality, safety, and performance of materials used in different industries and thus takes an active part in their detection. Confirming the physical, chemical, and mechanical properties of polymers, manufacturers are in a position to ensure that their products are compliant with the crucial industry standards and regulations. This, in turn, assures the dependability of the end products and their capacity to perform as expected under specified conditions.

Polymer testing also plays an important role in risk management, for instance, it helps to eliminate the risks associated with product failures or safety dangers which could consequently lead to expensive recalls or lawsuits. During the test, potential weaknesses are identified at an early stage of production so that manufacturers can solve the problems before the products are put on the market. This is not only time and cost saving but also builds consumer and stakeholder confidence through the provision of continuous and reliable results.

Moreover, polymer testing is a main driver of innovation and sustainability. By performing and combining the testing of new materials, technology, and in-house capabilities, manufacturers can create the next generation of polymers that will present the market with new properties. Besides, durability and environmental impact assessment can be done by proposing less harmful and more sustainable products. The testing methods are just one example of how the industries can innovate in material science while meeting the environmental and performance criteria.

Overview of Test Methods

The methods of testing in polymers and material sciences are essential for durability, environmental impact, and the functionality assessment of the materials under different conditions. These methods are rapidly changing, by using the latest technology, to get better accuracy and faster results. The main categories of test methods are mechanical testing, thermal analysis, chemical resistance evaluation, and environmental impact testing.

Mechanical Testing

The mechanical testing is the process of the properties such as tensile strength, elasticity, and impact resistance. The instruments such as universal testing machines (UTMs) and dynamic mechanical analyzers (DMAs) enable the precise measurement of stress-strain responses according to the latest advancements. For instance, UTMs can measure forces as low as 0.5 N now, thus allowing micro-scale materials testing and ensuring reliability in both automotive and aerospace applications.

Thermal Analysis

Thermal analysis studies and measures how polymers change physically and chemically with temperature changes, concentrating on properties such as glass transition temperature (Tg) and melting points. Amongst the techniques that Differential Scanning Calorimetry (DSC) and Thermogravimetric Analysis (TGA) are most widely used. The modern-day DSC instruments which can handle data resolution up to 0.01°C/min grant very precise access to thermal properties and facilitate the production of heat-resistant materials for extremely hot environments.

Chemical Resistance Testing

Chemical resistance testing is a must-have for applications in manufacturing, health care, and packaging. Immersion testing together with advanced spectroscopy methods (e.g., FTIR and Raman spectroscopy) provides a comprehensive analysis of material degradation due to exposure to different chemicals.

Environmental Impact Testing

In an eco-friendly approach, environmental impact testing is indispensable in the case of new biopolymer development. Life Cycle Assessment (LCA) tools, which are now connected with AI and big data analysis, allow manufacturers to simulate the environmental impacts of a material throughout its life span. For example, LCA software can now estimate a 15-20% reduction in carbon emissions by switching from conventional polymers to bio-based ones as depicted in contemporary studies.

The advanced testing methods not only secure performance and compliance with the standards but also become essential in the continuous process of creating opportunities for sustainability and innovation in the material sciences.

Tensile Testing of Polymers

Understanding the Tensile Test

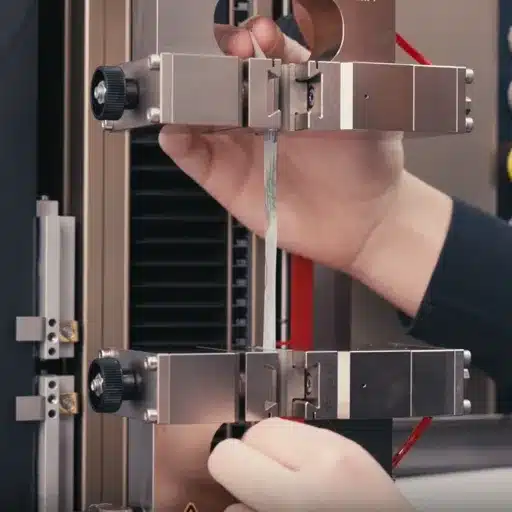

Tensile testing is an essential technique to determine the mechanical properties of polymers, especially their strength and flexibility. The test pertains to a sample under a uniaxial force and then breaking it, which gives the parameters like tensile strength, elongation, and Young’s modulus. These properties are the indicators of a material’s stress performance in actual applications.

The test procedure starts with attaching the polymer sample to a tensile-testing apparatus. The machine pulls the sample slowly up to a predetermined rate, and at the same time, sensors record the force applied and the extension measured. The data from this process is plotted in a graph, known as the stress-strain curve, that gives a pictorial representation of the interaction between the material’s stress (force/unit area) and strain (deformation). Important points on this curve, like yield strength and ultimate tensile strength, show the material’s ability to endure stress without going through deformations or total failure.

Tensile testing remains a very important tool in polymer performance assessment for such sectors as construction, automotive, or packaging. Through mechanical properties knowledge, manufacturers can determine the material’s fitness for particular applications, facilitate product development, and support the environment by introducing alternatives to conventional materials. This meticulous examination not only propels the evolution of polymer technologies but also highlights tensile testing as a pivotal factor in the scientific revolution of materials.

Key Parameters in Tensile Testing

Tensile testing is characterized by a number of crucial parameters that have a direct effect on the precision and trustworthiness of the results. Among these parameters, stress, strain, ultimate tensile strength (UTS), yield strength, and elongation at break, the latter is the most important.

| Parameter | Description | Example Values |

|---|---|---|

| Stress and Strain | Stress is the applied force divided by the area of the material, while strain is the extension or change in length that a material experiences as a result of stress. The stress-strain curve is a very important tool for understanding the material’s behavior. | HDPE: 20-30 MPa |

| Ultimate Tensile Strength (UTS) | UTS is the term used to describe the maximal stress that a material is capable of withstanding without breaking. | Aluminum alloys: 300-500 MPa Carbon fiber-reinforced plastics: >600 MPa |

| Yield Strength | Yield strength marks the stress level where a material starts to undergo plastic deformation, which means the material will not go back to its initial shape after the load is taken off. | Low-carbon steel: ~250 MPa |

| Elongation at Break | This feature shows the number of fractures that a material can endure by saying how much its length will increase as a percentage of the original length before the fracture occurs. | Natural rubber: up to 700% Ceramic materials: <1% |

| Young’s Modulus | Young’s modulus, sometimes referred to as the elastic modulus, is the value of a material’s rigidity or its ability to resist elastic deformation. | Titanium: ~120 GPa |

Note: Modern tensile testing methods and equipment have made it possible to obtain very precise measurements even for materials that were previously regarded as difficult to test. Precision can be at the level of industries requiring very tight tolerances where modern machines with high-resolution load cells and extensometers are used. For example, automated tensile testing systems with real-time data analysis capabilities are being used to enhance material performance and safety requirements in aerospace and automotive applications.

By scrutinizing these key parameters, the manufacturers and researchers can customize the materials for the particular use, thus ensuring both the performance and the sustainability.

ISO Standards for Tensile Testing

The ISO standards for tensile testing laid down the foundations of the testing methods and procedures that all industries could equally rely on for correct and trustworthy material evaluation. The standard ISO 6892, which is one of the most widely accepted ones, defines the testing method for metallic materials subjected to a uniaxial tensile load. This standard gives the test procedure, specimen dimensions, strain rate control, and reporting of data to get precise and repeatable results. Using ISO 6892, the producers and researchers can assess the properties of the materials like tensile strength, yield strength, and elongation accurately.

The other standard that could be applied is ISO 527, which highlights the tensile properties of plastics. It offers a comprehensive plan for the evaluation of the mechanical characteristics of plastic materials under tension, thus securing uniformity in testing. The properties of plastics determined by these specifications, such as tensile modulus and stress at break, are vital for product design and safety assessment. ISO 527 serves industries like packaging and construction where polymers have to meet certain performance requirements, and the like, especially.

The ISO standards are an important part of the process of material testing because they have developed a common ground that is used worldwide which will ease the material testing for global trade and innovation. They allow for a systematic comparison of materials regardless of their location in the world and at the same time maintain the credibility and reliability of the test results. Following these standards leads to the establishment of trust and confidence between the different parties involved, thus engineering, construction, and manufacturing industries gradual progress.

Compression Testing of Polymers

Overview of Compression Testing

Compression testing is a primary process that is employed to determine the mechanical properties of the polymer materials that are load-affected in a compressive mode. One of the main aims of the test is to gauge the behavior of the polymers against the forces that are trying to either make them smaller or distort their structure. Such a method can detect the material properties of compressive strength, modulus, and deformation behavior which along with being critical for testing the material’s fitness for a certain application, are also the ones most frequently required in the industry.

The testing is done by doing a compression test, where there is put the specimen of the polymer material is placed in a compression testing machine, which is capable of applying a steady increase of compressive force. Meanwhile, the specimen is observed and the behavior is recorded with a camera. The recording and the observation will be mainly connected to how much stress and strain the specimen can take until it fails or a certain limit is reached. The observations made during this process will give data about the elasticity, ductility, and overall performance of the material subjected to load and it will also ensure that the material is fit for use according to the standards required.

Without compression testing it is impossible to think of the polymer applications in the industries where the material is used as load-bearing or structural like constructions, automotive, and packaging. By going through the process of identifying the mechanical limits of a certain material, manufacturers can guarantee the safety, reliability, and efficiency of their products. The other advantage of the standardized process is that it enables the comparison of various materials which consequently leads to the development of innovative materials and improvement of material design.

Loading Techniques in Compression Tests

The process of a compressive strength test is simply the application of force on a material to determine its resistance to compressive loads. The loading methods adopted during the compression tests are very important for getting accurate and reliable results. Here are the main techniques used in this process:

1 Axial Loading

Applying axial loading guarantees that the compressive force is exerted uniformly along the axis of the specimen being tested. This technique not only reduces sagging or non-uniformity in the stress distribution but also helps in getting an exact reading of the material’s compressive properties. It is done by using accurately aligned load frames and compression platens.

2 Incremental Loading

Incremental loading is a technique where compressive force is applied in gradual steps because it is a controlled way of applying force. This technique allows studying the material at different load levels; thus it is possible to detect the point of elastic deformation, yield strength, and ultimate compressive strength.

3 Continuous Loading

Continuous loading not only applies force at a constant rate but also does so without any interruption until the material fails or reaches its limit. This method is frequently employed to ascertain the ultimate compressive strength of the material and the flow-like behavior of the material when subjected to continuous pressure.

These methods enable engineers and researchers to obtain a very precise evaluation of the mechanical properties of the materials in question and consequently the application of the results in areas like construction, automotive manufacturing, and product design.

Factors Affecting Compression Results

Compression testing results can be affected by various factors such as the material characteristics, environment, and methodology used. Moreover, the accuracy of the compression testing machine can also affect the results. To achieve results that are both accurate and reliable, it is important to understand these factors.

| Factor | Impact on Results | Example Data |

|---|---|---|

| Material Composition | The characteristics of the material, including its density, elasticity, and microstructure, are the major factors that influence the outcome of the compression test. | Stainless steel: ~520 MPa Aluminum: 90-250 MPa |

| Sample Geometry and Size | The geometry and size of the sample can significantly influence the test results. Height-to-diameter ratios should be consistent to avoid stress distribution issues. | Optimal ratio: 1.5-2.5 |

| Temperature and Humidity | Environmental factors affect material behavior, particularly for plastics and composites where temperature increases can significantly reduce compressive strength. | PVC at room temp: ~50 MPa PVC at 100°C: <30 MPa |

| Loading Speed (Strain Rate) | The rate at which the compressive force is applied determines the behavior of most materials during the tests. Quick strain rates can show increased strength in metals. | Standardization required for consistency |

| Testing Machine Calibration | The reliability of compression tests depends on the efficiency of the testing apparatus. Regular calibration ensures precise measurements. | Modern systems: ±0.1% precision |

| Surface Preparation | Proper surface treatment is necessary to avoid stress concentration or uneven load distribution. Surfaces should be smooth, clean, and defect-free. | Critical for accurate measurements |

Industry Standards: Researchers and engineers apply the same testing standards like ASTM E9 for metals and ASTM D695 for plastics, thus securing the sameness of the compression tests across the various industries. The consideration of these factors can lead to an optimization of the results and a better understanding of the material’s response to compressive loads.

Advanced Testing Techniques

Hardness Testing Methods

The hardness test is the measurement of a material’s ability to withstand deformation, usually by indentation. This characteristic of material plays an important role in deciding the material’s application in the area of manufacture, i.e. in cases where the material will be subjected to heavy loads or in cases where the material is to be the wear-resistant one. The main hardness testing methods are Brinell, Rockwell, and Vickers, with each method having its own specificities regarding the type of materials and the purpose for which they are going to be used.

Brinell Test

A steel or a tungsten carbide ball indenter first applies a predetermined load upon the surface of the material, and then the diameter of the indentation made is measured. The method works pretty well with the softer metals and the materials with coarse structures since it yields a bigger area average hardness value. This, however, is particularly helpful with castings for the materials’ quality is defined greatly by the casting process.

Rockwell Method

The Rockwell method provides more accurate results because it applies smaller indenters and measures the depth of the indentation made. This test can be performed on metals and alloys of all hardness levels, as it provides fast and repeatable results.

Vickers Test

The Vickers test employs a diamond-shaped indenter and hence is capable of measuring microhardness is why it is used for small or thin materials and coatings. These methods, taken together, offer a holistic approach to hardness testing that will suit a very large variety of industries and applications.

Thermogravimetric Analysis (TGA)

Thermogravimetric Analysis (TGA) is a method that is utilized to evaluate alterations in the weight of a sample as a function of both temperature and time under a predetermined atmosphere. This process unveils important details regarding the thermal stability and the material’s composition. TGA facilitates the recognition of events like destruction, oxidation, and evaporation of the non-volatile materials through the weight loss of the heating sample.

Thermogravimetric Analysis (TGA) is an indispensable method for the analysis of thermal stability among materials like polymers, composites, and so on and it is defined as the maximum temperature at which a material starts to lose its performance. Thus, TGA is even more potent for industries that use high-quality materials, which can handle the scorching temperatures. The process of TGA is also beneficial in the treatment of moisture, purity testing of the substances, and exploring the decomposition patterns.

Thermogravimetric Analysis (TGA) is an indispensable technique that finds its way in industrial research and development such as pharmaceuticals, polymers, and energy storage. The feature to evaluate the behavior of the materials when subjected to high temperatures makes TGA a powerful tool in the areas of quality control and material characterization. In fact, the accuracy and reliability that TGA provides empower scientists as well as engineers to enhance materials for varied applications and realize their performance in actual conditions.

Melt Flow Index (MFI) and Its Importance

The Melt Flow Index (MFI) is the primary numerical that discloses the flowability of thermoplastic polymers. It portrays the speed of flow through the prescribed die under the regulated temperature and pressure conditions for a certain quantity of the polymer. It is the melt flow indexer that typically operates the test and the outcome is illustrated as a weight in grams of the material extruded every 10 minutes. MFI is a very significant factor when it comes to judging the processing characteristics of polymers in use like injection molding and extrusion.

Key Benefits of MFI Testing

- Material Selection: The knowledge of MFI of a polymer is of utmost importance for the decision related to its eligibility for a specific manufacturing process.

- Flow Properties: An MFI value that is higher implies that the material has a good flow property and hence is suitable in creating thin-walled or complex-shaped products.

- Material Strength: A lower MFI means more viscosity is involved, thus the material is stronger and more durable.

- Process Optimization: Manufacturers use MFI data to their advantage for setting the processing conditions at the most optimal situation which is both cost-effective and guarantees quality of the output.

MFI also acts as a monitoring tool for the materials. MFI fluctuations might point out the changes in polymer mixture, molecular weight or working conditions, which may eventually lead to a change in the performance of the finished product. The manufacturers will therefore be able to identify and rectify the problem and this will enhance the quality control and reliability of the production at the end. Thus, the MFI becomes a basic parameter in the plastic sector for ensuring both efficiency and product integrity.

Applications of Polymer Testing Services

Industry Applications of Tensile and Compression Testing

The use of tensile and compression testing in the industry is not just limited to the determination of material’s mechanical properties but also serves to prevent the failure of a product at an early stage, which is costly in terms of time and money. Apart from that, the information given from these tests helps the manufacturers to choose the right materials, design products, and even come up with new ones.

Applications in Different Industrial Fields

🚗 Automotive Sector

The implementation of tensile and compression tests is a top priority in the production of lightweight yet resilient parts for cars. To illustrate, high-strength steels with a tensile strength of more than 1200 MPa are already in the market as a part of techniques aimed at increasing the mileage per liter of fuel consumed without damaging the safety aspect of the car.

🏗️ Construction Sector

These tests, worth the money, take the utmost care in revealing the actual strength and load-bearing limit of concrete, steel, and composites, and thus the integrity of these materials is maintained. Sometimes structural-grade concrete is found to be capable of withstanding compressive stresses in the range of 2500-4000 psi, and this is confirmed by compression testing which is a prerequisite for compliance with building codes.

✈️ Aerospace Sector

Modern high-performance materials used for the manufacture of aircraft and spacecraft components can be subjected to very rigorous testing conditions. For instance, aerospace-grade titanium alloys can be seen to have tensile strengths in excess of 1000 MPa, which guarantees their reliability in extreme environments.

🏥 Medical Sector

The area of Implants and medical devices production requires that not only materials be of high strength but also be human body-friendly. Compression and Tensile tests serve in that regard by deciding on the strength and flexibility of bone screws or plates implants considering the stresses of the body.

📦 Packaging Sector

Compression testing is of great importance in the performance evaluation of materials employed for packaging so that they are confirmed to withstand the stacking and transportation loads. The edge crush test on corrugated boxes, for example, is a common practice, wherein their compression resistance is rated in pounds per inch (lbs/in), which is a measure of the box’s strength.

The combination of these tests along with the constant growth of new ideas and innovations in the field, turns out to be a determining factor for the progress in the different industries, allowing the production of the highest quality and safest materials and products.

Quality Control and Assurance in Polymer Manufacturing

Quality control and assurance in polymer manufacturing are key to making sure that the end products have the necessary qualities regarding performance, safety, and dependability. The aforementioned processes are very tightly interwoven with monitoring the production stages from the selection of raw materials to the final product. Polymers are subjected to different tests such as tensile strength assessments, impact resistance tests, and thermal stability evaluations so that it is realized that they can actually be used in those applications. Continuous monitoring allows the manufacturers to detect the defects at an early stage and thus keep the production uniform.

In order to maintain high quality, adherence to the regulatory guidelines and industry standards is necessary. Many organizations strictly implement the protocols developed by the regulatory agencies, e.g., ASTM International, or ISO. Thus, by conforming to such universally accepted standards, manufacturers not only get a certification that their products are safe and have a minimal environmental impact but also create a bond of trust with the consumers and clients who depend on the availability of reliable materials with excellent performance.

Despite this being a technical area, the introduction of new technologies is another important factor. Automated testing systems and real-time monitoring systems are some of the techniques used in the quality control of the production process which have higher accuracy and efficiency than the manual quality control methods. Also, humans are prone to making mistakes; hence, technology helps to detect issues rapidly before they become major ones. Further, the continuous training sessions for quality control staff are also of great importance since they provide the workers with the necessary skills to cope with the changing standards and technologies. Thus, these measures combined assure that polymer manufacturing remains an industry characterized by both reliability and technological innovation.

Case Studies: Successful Polymer Testing Implementations

Real-World Success Stories

1 Improving Durability in Automotive Applications

The first case that we can mention is the one where polymers were tested for the automotive industry as a means to make the components more durable and to perform better under extreme conditions. The intervention of advanced thermal and mechanical testing shed light on the very particular polymer blends that would able to give not only the conductivity to the heat but also the stress resistance. This enabled the company to make components that had a much longer lifespan, thus cutting down the maintenance costs and, more importantly, making the whole operation safer for the customers.

2 Enhancing Medical Device Reliability

The second success story is from the healthcare area where the polymer testing was done very carefully and the results ensured that the materials used for the medical devices were reliable. The process was such that it required extensive biocompatibility and chemical resistance testing that needed to be done in compliance with very strict regulatory standards. The outcome of this allowed the manufacturers to bring in safer and more effective devices thus winning the patient’s trust and keeping them in line with the global health guidelines.

3 Advancing Recyclable Packaging Materials

Last but not least, we have the packaging industry as a topic of the last example, where polymer testing played a significant role in developing environmentally friendly, recyclable materials that were still capable of being as durable and functional as the non-environmentally friendly ones. In the area of product development, the researchers worked on the barrier properties and environmental resistance and were eventually able to make polymers that met the consumers’ demand for green options. These new products not only decreased landfill waste but also supported the circular economy initiatives without compromising the quality of the product.

Frequently Asked Questions (FAQ)

❓ What is a test bar polymer?

Test bar polymer is a model made of a polymer material that has been subject to certain conditions and is a standardized specimen used to assess the mechanical properties of polymers. Bars of this kind are usually made with specific dimensions that help test properties such as tensile strength.

📏 What are the standard dimensions for a test bar polymer?

Test bar polymer standard dimensions come in different sizes but typical sizes include 1 mm, 4 mm thicknesses, and other selected measures to make sure the testing is consistent. The bars’ cross-section is planned so that it can best serve in evaluating various mechanical properties.

📊 How does thickness affect the behavior of polymers in tests?

The thickness of a test bar polymer has an important bearing on its mechanical behavior. Generally, stronger specimens have diverse tensile stress and deflection characteristics as to the weaker ones; thus, dynamic measurements and static testing may be influenced by the thickness.

🔬 What types of tests can be performed on a test bar polymer?

A lot of different tests can be carried out on a test bar polymer, such as tensile tests, flexural tests, and shear tests. These are the types of tests that are used to measure characteristics like the strength of the material, toughness, and also the effect of temperature and load variations on the material.

🌡️ What is the significance of the Vicat softening temperature in polymer testing?

The Vicat softening temperature is an important factor to consider when determining the application range of any given polymer. This temperature refers to the limit above which, at a given load, the polymer starts to lose its rigidity and hence it is among the most important aspects for the classification of various materials in terms of their use, especially in the case of high-speed and dynamic environments where the temperature is always fluctuating.

⚡ How do dynamic and static tests differ for the test bar polymer?

Dynamic tests give the tester an idea of how a test bar polymer would behave in real-world applications by simulating varying loads and changing conditions. Static tests, however, show what the material is capable of regarding its tensile stress and flexural strength by measuring its response to the application of a constant load.

🔗 What role do adhesives play in the performance of the test bar polymer?

Adhesives might be the major factors that determine the bonding strength that the polymer materials will exhibit in applications where test bar polymers are used. The interaction between adhesive and polymer can lead to changes in mechanical properties, which however, becomes important in the case of testing, especially in laminate structures.

🔍 Can X-ray or infrared techniques be applied in testing test bar polymer?

X-ray and infrared techniques are indeed applicable for the analysis of test bar polymer, as they are capable of revealing the internal structure and thermal properties of the material. These methods are of great help in assessing material quality and consistency, providing significant information about the material’s performance under various conditions.

References

-

Understanding Impact Testing Methods for Polymer Materials – A guide to impact testing methods like Izod and Charpy, which involve breaking a test bar to measure impact resistance.

-

ASTM D638 Type I Tensile Bar: A Comprehensive Guide – A detailed explanation of the ASTM D638 standard for evaluating the tensile properties of plastics.

-

Heat Deflection Temperature ASTM D648, ISO 75 – Information on heat deflection temperature testing, which measures how a standard test bar deflects under load at elevated temperatures.

-

ASTM D638: Tensile Properties of Plastics – A resource on determining tensile properties of plastics, including stress, strain, and modulus.

-

ASTM D7913M-14: Bond Strength of Fiber-Reinforced Polymer Bars – A standard for testing the bond strength of fiber-reinforced polymer composite bars to concrete using pullout testing.