Strength and durability have always been necessities in engineering and product sciences, and tensile testing is one such prominent method for studying these properties. At the heart of these tests lies the Universal Testing Machine (UTM), a multipurpose and vital tool, which is also used to test tensile strength, elongation, and the final breaking point of different materials. In this article, we shall try to give you a fair idea of how tensile testing is actually carried out, how the UTM works in the process, and how important it is for material quality and reliability. Whether you are a student, an engineer, or even an inquisitive reader interested in material testing, this article will help you in grasping this most-commonly used testing method in greater detail. Keep reading to uncover the working principles, applications, and theories behind tensile testing with a Universal Testing Machine.

Introduction to Universal Testing Machines

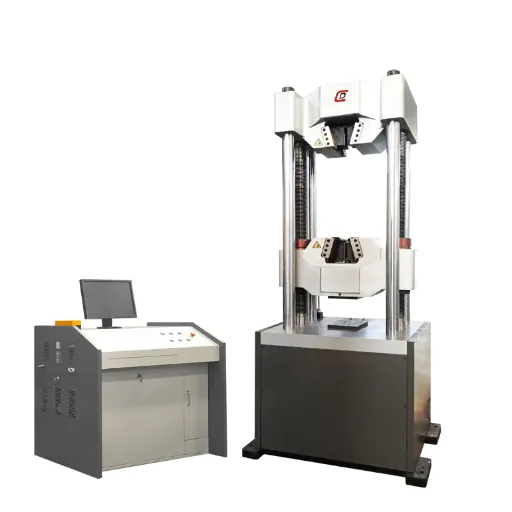

What is a Universal Testing Machine?

A Universal Testing Machine (UTM) is any and all instruments used to determine the mechanical properties of materials and components. It applies load on the specimen and records the specimen’s response against the applied load. Test parameters such as tensile strength, compressive strength, elasticity, and ductility are analyzed. UTMs are essential for checking whether materials conform to certain standards and specifications, having practical application in construction, manufacturing sectors, and laboratories.

A UTM has its characteristics comprising two sections: the load frame and the control system. It allows the load frame to hold the specimen securely while the force gets applied to the specimen for tension, compression, bending, or shear. The control system, which is commonly computer software-controlled, controls the loading process very precisely, and simultaneously registers all important data such as force, displacement, and stress-strain behavior. Hence, it provides industries with an opportunity for accurate and reproducible testing on a huge number of materials, namely metals, polymers, and ceramics.

Another essential benefit offered by the Universal Testing Machine is its versatility. By using various fixtures and accessories, this testing machine can be readily adapted to any number of testing conditions, specimen geometries, or special requirements. The information generated is vital for interpreting the performance of the material in the application under consideration and is directly used in improving product design, ensuring safety, and optimizing manufacturing processes.

Importance of Material Testing

Material testing is highly imperative for ensuring various materials can meet the requirements of different industries with regard to reliability, performance, and, most importantly, safety. The universal testing machine is thus an instrument of utmost importance in the realm of materials testing as it analyses mechanical properties of the material, such as tensile strength, compressive strength, or elasticity. These properties are of fundamental importance, since they serve as tools by which one can predict how a given material might behave under particular circumstances or stresses.

One of the most significant benefits of material testing with the UTM lies in the fact that it helps create working conditions like those of the real world to test whether the material is fit for its intended purpose. This is important when considering instances such as construction, aerospace, automotive, and medical fields, where the failure of a material can have serious consequences for the designing engineer. Material selection therefore has to be determined on the basis of the data collected from the tests, never compromising on safety or efficiency.

Besides that, material testing also helps the quality of products during the manufacture. Manufacturers will be able to make sure that all the materials being used do not contain any defects due to some regular UTM testing carried out in the working environment. This prevents the failure of the product and also reduces the cost due to wastages and reworks resulting from the defective stocks. In essence, it is Universal Testing Machine which fosters an environment of innovation as well as reliability extended to the designing and application of materials.

Applications of UTM in Various Industries

Construction Industry

The construction industry is the largest user of UTMs, considering their test of strength on materials like concrete, steel, and composites. This is made to ensure that structures built are of materials bearing suitable levels of stress and hence safer choices to live on.

Automotive Industry

UTMs find heavy applications in the automobile industry for testing the mechanical properties of parts consisting of metals, plastics, and rubber. Materials are studied to determine how well they undergo a state depending on tension, compression, or bending so as to meet standards that ensure the safety and performance of vehicles.

Aerospace & Manufacturing

Likewise, UTMs play a huge role in aerospace and manufacturing, where precision and reliability matter the most. They test materials and components exposed to extreme pressure or environmental conditions, so they can meet the higher quality standards. In that way, UTMs form vital instruments behind design verification, process optimization, and the guarantee of product reliability.

Understanding Tensile Testing

What is Tensile Testing?

Tensile testing is a mechanical test used to measure the ability of materials to withstand forces of tension. Uniaxial force is applied to a test specimen until rupture; this test measures how a material reacts to being stressed and strained. This testing yields important data such as tensile strength, yield strength, elongation, and Young’s modulus that help define the overall performance of the material under tension.

The whole method is quite simple and very informative. First, a specimen, usually in a standard size, is mounted in a Universal Testing Machine (UTM). The machine applies force at a slow pace along the specimen’s length, stretching it to the point of failure. The UTM, during this process, gathers the necessary data about force and deformation, plotting the results on a stress-strain curve to show the material’s behavior during the test.

Tensile testing is an essential activity in a variety of industries as this procedure assures materials’ ability to meet safety and performance standards. For instance, testing is done for materials in construction, automotive, and aerospace to make sure materials can withstand operational stresses. With tensile testing, manufacturers stop material failures, improve production processes, and design better products.

How Tensile Tests are Performed

Step-by-Step Process:

- Fit the test specimen between the grips of the testing machine

- Ensure proper alignment to prevent slippage during testing

- Apply force at a pre-set speed through the UTM

- Record measurements of force, elongation, and deformation

- Continue until specimen breaks or reaches failure point

- Generate report with graphical and numerical data

Tensile tests are carried out using a universal testing machine, which is a very versatile piece of equipment for measuring the mechanical properties of materials under tension. The procedure begins by fitting the test specimen, usually in the form of a standard bar, between the grips of the testing machine and ensuring alignment so that the material will not slip during the test. The grips of the machine clamp onto the material firmly, and a force is applied onto it.

The universal testing machine pulls on the specimen at a pre-set speed. This designed stretching creates stress on the specimen to maintain uniformity so that measurements can be taken at different points. Measurement data on parameters like force, elongation, and total deformation are recorded by the UTM while testing. These data lead to the assessment of the tensile strength, yield stress, and ductility of the material.

After the specimen breaks or attains a pre-selected failure point, the test is finished. The UTM then produces a report in the form of graphical and numerical data. These analyses are then used to ascertain if the material meets a particular standard of performance or to facilitate decision-making in the selection of materials or design modifications in engineering and manufacture.

Significance of Tensile Strength Measurements

Tensile strength determination is a pivotal matter in ascertaining the limitations and capabilities of materials used in various industries. If engineers and manufacturers were to decide on the ability of a particular material to behave reliably and safely in structural and mechanical application, such would be on the dependent basis of tensile strength; this helps guarantee product and system integrity so that any failure leading to an expensive loss or hazard can be averted.

The data that arises from tensile testing on a Universal Testing Machine (UTM) facilitates the selection of the right kind of material for any particular application. For instance, in the design of critical lightweight components for construction, aerospace, and automotive applications, tensile strength values are used to select materials that withstand the expected load and stresses. This will allow them to optimize performance and durability and minimize the risk of over-engineering or under-engineering.

In addition, international tensile strength levels may be used as standards to certify that materials require measurements to fulfill their standards before manufacturers commence production. Besides the assurance of quality, it also builds trust from consumers and limits possible litigations. Hence, tensile testing is crucial in material efficiency, design optimization, and conformation to safety and performance standards.

Components of a Universal Testing Machine

Key Components Overview

A universal testing machine is a multipurpose instrument used to determine the mechanical properties of materials subjected to various forces. The principal components work in unison with precision to carry out tensile, compression, and other material testing methods.

| Component | Function |

|---|---|

| Load Frame | Forms the structural body of a UTM consisting of two crossheads supported by columns. The upper crosshead is usually fixed; however, the lower crosshead may move to induce tension or compression forces during a test. The rugged load frame construction gave great stability and accuracy during an operation. |

| Load Cell | Measures the load or force being applied on the material under test. The load cell develops a signal when force acts on it. This signal is converted into an electrical signal that varies in amplitude and is electronically amplified, converted into a digital reading, and displayed on an indicator. |

| Actuator/Drive Mechanism | Provides the relative movement of the crosshead under test. In this way, hydraulic or electromechanical means may be provided for the application of a force and displacement in a smooth and controlled way. |

| Controller & Software Interface | Coordinates the UTM operation and data acquisition. Through the interface of the controller, operators manipulate testing parameters, such as rate of load and displacement. The software processes and stores test results for further analysis. |

| Grips and Fixtures | Fix the specimen in place during testing. The type of grips different from each other depending on the material and test type so that proper alignment and no slippage occur during force application. |

Together, the above-listed components enable a universal testing machine to perform various tests, yielding essential data for material analysis, quality assurance, and manufacturer conformity.

Load Cells and Their Function

The load cell is an indispensable part of the universal testing machines, chiefly because it must measure forces applied to it during a test. Load cells function by converting mechanical force into an electrical signal; the magnitude of the electrical signal corresponds exactly to the load applied. Any uncertainty in the force measurement leads to another source of error in the test and thus will reduce the reliability and consistency of the results.

The load cell works on strain gauges, which are the sensitive elements capable of picking up changes in deformation of the material when loaded. Upon the application of force on the load cell, those strain gauges are deformed slightly, causing changes in electrical resistance. The change in resistance is then used by the measurer to calculate and display the force. It is this precise measurement that makes load cells suitable to be used for tests where very high accuracy is required.

Load cells are also designed to accept a multitude of testing capacities so as to be compatible with different types of specimens. Either metals, polymers, or other materials are tested, the load cell can provide the versatility required in handling a wide range of loadings. With the help of this proven force-measuring device, the load cell plays a vital role in making data produced by the universal testing machine useful for material characterization and engineering analysis.

Hydraulic vs. Electromechanical UTMs

Hydraulic UTMs

- Use hydraulic pressure to exert force

- Perfect for high-load testing

- Ideal for structural testing

- Great force application with stability

- Suitable for metals and structural materials

- Cost-effective for heavy-duty applications

Electromechanical UTMs

- Utilize electric motors to create force

- Precise control of speed and load

- Good for low-force applications

- Suitable for polymers, textiles, composites

- Versatile for various test types

- Preferred for precision and versatility

The hydraulic and electromechanical universal testing machines differ basically for operation and application. Hydraulic UTMs work using hydraulic pressure to exert force, which is perfect for testing materials at very high loads. They are generally employed for structural testing since they can apply great force with stability. These machines are potent, sturdy, and suitable mainly for metals and other structural materials.

Electromechanical-type machines utilize electric motors to create force; hence they can precisely control speed and load application. This makes them a good choice for applications requiring accuracy, especially at the low-force end or with less rigid specimens, such as polymers, textiles, and composites. They are versatile machines that allow a broader range of test types, including tensile, compression, and flexural testing.

The choice, therefore, between hydraulic-type and electromechanical-type UTMs is very much dependent on the test requirement. For high-capacity testing, hydraulic systems would be advantageous because of their cheapness in heavy-duty applications, whereas the electromechanical systems are preferred for precision and versatility over various material categories. It is essential for one to understand the actual requirements of their testing scenario to decide correctly on the kind of UTM to use.

Types of Tests Performed on a Universal Testing Machine

Tensile Tests

Tensile testing is, no doubt, one of the most commonly performed mechanical tests in a Universal Testing Machine (UTM). The test measures the capacity of a given material to resist forces attempting to pull it apart. It essentially aims at determining the tensile strength, elongation, modulus of elasticity, and yield strength of the specimen. By pulling out a material to failure, engineers and researchers can judge them for their applications in real life.

When the test begins, the material specimen is secured within the grips of the UTM and tension is applied at either a constant or programmed rate of load. The output of this test is graphically plotted as a stress-strain curve which portrays the behavior of the material when subjected to a load. Metals, plastics, composites, and textiles are the kinds of materials subjected to the test to ascertain compliance with certain requirements and safety standards.

The tensile test is one of the most important procedures in selecting a material and quality control. The results are used by engineers to design structures or products that will be able to withstand the expected stresses. From evaluating new construction materials to verifying manufacturing batch quality standards, the tensile test provides valuable information that steers product development and safety standards.

Compression Tests

Compression tests are the basic experiments carried out for studying the behavior of a material in compression. They determine how a material reacts when subjected to forces that aim to reduce its size, yield critical information concerning its strength, stability, and deformation characteristics. Engineers utilize this data to ensure that materials can be subjected to compressive forces during their application in buildings, bridges, or machine parts.

The compression test entails placing the specimen, usually a cylinder, cube, or prism, under increasing compressive load until the specimen fails or until some predetermined limit. Other results included are measures of load, compressive strength, yield stress, and modulus of elasticity of the material. These properties serve to explain the capacity of the material to resist crushing forces and deformation that does not cause collapse, which has significance during structural design and safety evaluation.

This method of testing has pertinent industrial applications well into construction and aerospace. For example, in civil engineering, compressive strength tests on concrete are essential in the design of load-bearing structures, especially columns and foundations. Conversely, in packing, compression tests ensure materials are designed for stack and transit pressures, thus guaranteeing material capability. These tests are of utmost importance in making reliability and durability claims about applications.

Flexural Tests

Flexural tests find utility in the measuring of the flexural strength and flexural rigidity of materials, in the presence of loads. The tests are especially pertinent to materials like concrete, ceramics, and composites, whereby they undergo forceful bending in practical applications. The results of the tests give answers to how the material can behave under a certain flexural stress, thereby guaranteeing structural integrity and safety.

Loading of the material in a certain well-defined environment is carried out, while the response of the material is monitored. However, usually, the specimen is held on simple supports at two points, and the load is either applied at a point in the center (third point flexure) or at two points equally spaced from the center (four-point flexure). Key parameters derived from the test, on how the material responds to stress, include the flexural strength or modulus of rupture and flexural modulus, which tell us about a material’s capacity to resist being bent or deformed and its tendency to undergo deformation and failure.

Flexural testing is valuable anywhere from construction all the way to manufacturing. For example, in construction, flexural testing data is used to aid in the design of beams, slabs, and other structural components. Similarly, in manufacturing, an understanding of how materials perform assists in determining appropriate materials for products designed to resist bending or impact forces so that they will be usable for an extended period and meet any safety criteria.

How a Universal Testing Machine Works

Working Principles of UTMs

Universal Testing Machines act on a material by applying an adjustable force and measuring how it sustains strength and other mechanical properties. The core principle is the tensile, compressive, or flexural action on the specimen and monitoring its reaction to such force. Hence an engineer/researcher evaluates the behavior of materials under given conditions and decides whether to meet any application.

Typically, in UTMs, a load frame is there for fixing the specimen, and a load cell measures the force applied to the material. Force application to specimens is generalized under the control of several sensors while software records above mentioned stress, strain, and deformation on the specimen interface. Essential properties of materials for various tests would include tensile efficiency, elongation, yield strength, ultimate strength, etc.

Specific process control guarantees accuracy and repeatability. With the help of advanced software, the UTMs automatically produce reports and graphs to elucidate the results. This feature gives consistent evaluation for testing different types of materials: metals, plastics, composites, and many more; which in turn, is the reason behind the UTMs being an essential factor in quality control and research areas in many industries.

Data Collection and Analysis

The Universal Testing Machine (UTM) collects data on force, elongation, and stress at specific time intervals throughout the process of testing. They are fitted with sensors and load cells that provide more accurate readings, which are critical to the consideration of mechanical properties of materials. The data is usually collected automatically for consistency and less chance of human error.

Upon collection of data, this information is then analyzed by advanced software programs to generate reports and graphs showing stress-strain curves, which depict the performance of the material during the test condition. This analysis leads an engineer and researcher to study some parameters like yield strength, ultimate tensile strength, and modulus of elasticity. The ability to identify trends and failure points aids with a better appreciation of the limits and real-world applications for the material.

What the automated system for data collection and analysis in UTMs achieves is merely upgrading the work of testing, along with the guarantee of reproducible results. This is the most necessary feature in fields such as aerospace, construction, manufacturing liquids: names where materials must be trustworthy. By making decisions on data collected using UTMs, an organization can shorten the scope during material selection, increase safety while using the product, and meet the standards of the industry in a fast manner.

Testing Standards and Compliance

Universal Testing Machines (UTMs) constitute an integral need to test approaches and comply with the standards in industry. By measuring and testing the mechanical properties of materials such as tensile strength, compression, and elongation, UTMs certify these properties with accurate test data computed as per strict international-standard codes such as ASTM, ISO, and EN. The materials are certified through these very data, which are then employed by aerospace, manufacturing, and construction applications having a high probability of failure in critical assemblies, thereby keeping the end user/consumer safe.

Key Benefits of Standardization:

- Ensures data comparability across laboratories and organizations

- Provides highly accurate systems of reference and data acquisition

- Enables compliance with regulations and industry codes

- Reduces risks in decision-making processes

Standardizing the tests, UTMs enable one to use the resultant data in comparison to any other laboratory or organization. Universal Testing Machines come with highly accurate systems of reference and data acquisition for recording exactly what is required. These are hence indispensable in case manufacturers and researchers aim at complying with regulations or meet the established parameters of an industry code within the shortest time.

UTMs also foster innovation by helping to confirm materials and designs. They permit a manufacturer to evolve new methods at the frontier of materials science and engineering while staying within the framework of industry guidelines. Because they provide trustworthy data, Universal Testing Machines contribute by lessening risks in decision-making to the improvement of present-day designs. Being integrated with testing and quality assurance, Universal Testing Machines assure safety and performance standards.

Frequently Asked Questions (FAQ)

Q: What is a universal testing machine?

A universal testing machine (UTM) is a multitasking testing system used to test materials for tensile and compressive strength. It can carry out almost every sort of test and comes with a range of grips and fixtures suitable for securing the test specimen.

Q: For what are tensile testing machines used?

These tensile testing machines are only designed to test tensile strength. The tensile force is applied to the test specimen until it fractures, so the testing can be used by the confining engineers to consider the tensile properties of the material for use in different applications.

Q: How does it operate?

A universal testing machine operates by applying a load through hydraulic or electromechanical transmission to a specimen in a controlled manner. The machine measures the force applied to the specimen and the corresponding deformation, thus allowing the correct test results for tensile and compressive strength to be determined.

Q: What is the difference between tensile and compressive testing?

Tensile testing applies a pulling force to a specimen to measure tensile strength, while compressive testing applies a pushing force to evaluate compressive strength of the material. Both these tests are important for material characterization regarding their mechanical properties.

Q: Name the components of a universal testing machine?

A few components of the universal testing machine are a materials test frame, a load cell, grips, and fixtures and testing software. These components work together to provide accurate measurements during the testing process.

Q: What are the standard test methods for universal testing systems?

Standard test methods of universal testing systems are ASTM E8 for tensile testing and ASTM D638 for plastics. These standards provide means on how to carry out tests so that the results obtained are consistent and reliable.

Q: What sort of materials are tested on UTM machines?

Materials tested on UTM machines are metals, plastics, composites, etc. due to its versatility; it has become a vital material testing tool in almost every industry, including manufacturing and construction.

Q: How are hydraulic universal testing machines different from electromechanical ones?

Hydraulic universal testing machines are powered by hydraulic forces so are appropriate for higher load tests, while electromechanical ones use an electric motor and screw to allow for a more precise control of load, but work in much lower capacity test applications.

Q: What is the role of an extensometer in testing?

The extensometer is used to measure elongation or deformation of the specimen during testing. This data is critical in understanding the behavior of materials under tensile or compressive loads, thereby facilitating a precise determination of the mechanical properties of the materials being tested.

References

Wikipedia – Universal Testing Machine

An overview of the machine’s uses, including tensile, compressive, flexural, and shear testing.

Aimil – What is Universal Testing Machine (UTM)

A detailed explanation of the UTM and its role in determining the mechanical properties of materials.

Instron – Introduction to Universal Testing Machines

A resource on the various tests performed by Instron universal testing machines, such as tensile and compression tests.

ZwickRoell – Universal Testing Machines for Static Applications

Information on the applications of universal testing machines for static material testing.