Compression testing plays a critical role in determining the behavior and performance of materials under compressive loads, making it a cornerstone of material science and engineering applications. Among the most widely recognized frameworks for conducting accurate and standardized compression tests are ASTM D695 and ASTM E9. These standards offer detailed methodologies for evaluating materials ranging from rigid plastics to metals, ensuring consistency and reliability in test results across industries. This article aims to provide a comprehensive exploration of these ASTM standards, shedding light on their applications, methodologies, and key differences. Whether you are an engineer, researcher, or quality control professional, understanding these standards is essential for making informed decisions about material suitability and performance. Read on to discover how mastering ASTM D695 and ASTM E9 can streamline your testing processes and enhance material evaluations.

What is ASTM D695 and its Importance in Compression Testing?

ASTM D695 is a standard test method for determining the compressive properties of rigid plastics. It is widely used to evaluate materials under compressive loads, providing key data points such as compressive strength, modulus, and strain. These properties are critical for assessing a material’s performance in applications where it will experience compressive forces. The test follows a controlled procedure to ensure consistent and accurate results, making it an essential standard for material selection and quality assurance in various industries.

Overview of ASTM D695 Standard

Key Specifications of the ASTM D695 Standard

The ASTM D695 standard outlines the testing methodology for determining the compressive properties of rigid plastics. It specifies the precise parameters for specimen preparation, test setup, and execution to ensure repeatable and accurate results. The standard defines acceptable specimen dimensions, typically cylindrical or rectangular in shape, and describes the loading rates to be applied. Testing is performed using a universal testing machine, which compresses the specimen at a constant rate until failure or a predefined strain limit is reached. Key metrics obtained include compressive strength, compressive modulus, and percent strain at failure. These metrics are vital for materials designed to endure compressive forces, aiding industries in selecting appropriate materials for structural, mechanical, and thermal applications.

By following ASTM D695 guidelines, manufacturers and engineers can validate material performance under compressive loads, ensuring compliance with quality and safety standards.

Applications of ASTM D695 in Testing Rigid Plastics

- Material Selection: ASTM D695 is utilized to evaluate the compressive properties of rigid plastics, enabling industries to select materials suited to specific structural and mechanical demands.

- Quality Control: Manufacturers use this standard to ensure that materials meet predefined performance criteria and comply with industry regulations.

- Product Design and Development: Engineers apply ASTM D695 testing results to refine product designs, optimizing materials for durability and strength under compressive loads.

- Failure Analysis: The standard provides critical data for identifying the failure behavior of rigid plastics, aiding in troubleshooting and improving material formulations.

- Performance Validation: Under ASTM D695, the validated results help confirm that rigid plastics can endure expected stress and load conditions in real-world applications.

- Comparative Analysis: This standard facilitates comparisons between different materials, offering valuable insights for selecting the ideal option for specialized applications in construction, aerospace, automotive, and packaging industries.

Significance of Compressive Properties in Rigid Plastics

The compressive properties of rigid plastics are crucial for assessing how these materials behave under mechanical loads in diverse applications. Key technical parameters that define these properties include:

- Compressive Strength: This represents the maximum compressive stress a material can withstand before failure, typically measured in megapascals (MPa). For rigid plastics, compressive strength often ranges from 20 MPa to 150 MPa depending on the formulation.

- Modulus of Elasticity in Compression: This measures the material’s stiffness under compressive stress and is expressed in MPa or GPa. Rigid plastics may exhibit values between 1 GPa to 4 GPa.

- Compressive Strain: Evaluated as the deformation of the material under load, this parameter is typically expressed as a percentage, providing insights into ductility and elasticity.

Understanding these parameters ensures material performance aligns with anticipated stress scenarios in structural or load-bearing applications. Accurate characterization of compressive properties enables engineers to select materials that optimize strength, durability, and safety.

How to Conduct a Compression Test Using ASTM D695?

Procedure for Conducting a Compression Test Using ASTM D695

- Sample Preparation

Prepare the test specimen according to the dimensions specified in ASTM D695. Ensure the surfaces are flat, parallel, and free from defects to maintain accuracy during the test.

- Equipment Calibration

Ensure the testing machine is calibrated as per the standard. Utilize compression platens capable of maintaining alignment to prevent off-axis loading.

- Test Setup

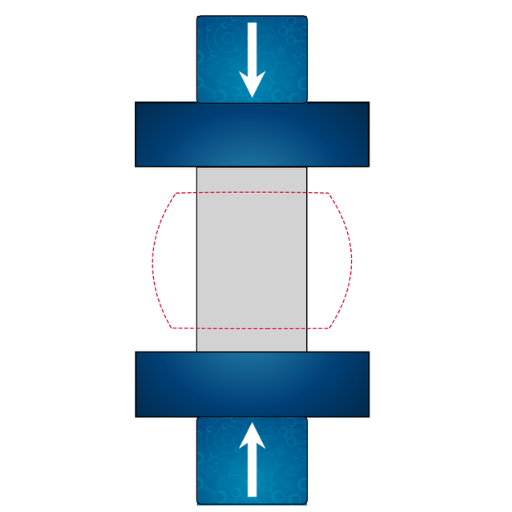

Place the specimen between the compression platens. Ensure proper alignment to distribute the load evenly across the specimen. Attach strain-measuring devices, if required, to record deformation.

- Loading Parameters

Apply the compressive force at the rate specified in the standard. Typically, a constant crosshead speed is used to ensure uniform application of load.

- Data Collection

Record the force and deformation continuously throughout the test. Identify the maximum load capacity and corresponding strain values.

- Analysis

Calculate compressive strength, modulus, and strain at failure using the recorded data. Verify results against desired material performance criteria.

Adherence to ASTM D695 ensures reliable and repeatable results, establishing the foundational data required for material selection and structural design.

Preparation of Test Specimen

To prepare the test specimen, I will ensure it adheres strictly to the dimensions and specifications outlined in ASTM D695. First, I will select a uniform, defect-free material and machine it into the required cylindrical or rectangular geometry, maintaining precise tolerances to minimize deviations. The ends of the specimen will be polished to ensure parallel surfaces, which is critical for consistent load distribution during testing. Additionally, I will measure and document the exact dimensions of each specimen to support accurate calculations of compressive strength and strain. Proper preparation is essential to achieve reproducible and valid results in accordance with established standards.

Setting Up the Universal Testing Machine

To set up the Universal Testing Machine (UTM), I will begin by calibrating the machine to ensure accurate force and displacement measurements. I will select and install the appropriate load cell and fixtures based on the type and size of the specimen being tested, ensuring proper alignment to avoid uneven loading. Once the specimen is securely positioned in the grips or compression platens, I will configure the testing parameters using the machine’s control software, including load rate, strain rate, and any specific test protocols required. A preliminary check will be conducted to confirm the system’s readiness before initiating the test. This meticulous setup ensures compliance with ASTM and ISO standards for mechanical testing.

Executing the Compression Test Method

The compression test commences by applying a gradually increasing load to the prepared specimen at the pre-configured rate, as defined in the control software. During the test, data such as force, displacement, and strain are recorded in real-time for precise analysis. The process allows engineers to determine critical material properties, including yield strength, maximum compressive strength, modulus of elasticity, and failure deformation. Throughout the experiment, the system ensures consistent load application to prevent anomalous data.

Upon reaching the specimen’s failure point or the predefined displacement limit, the system automatically terminates the test. Post-testing, the collected data is analyzed to generate stress-strain curves, which provide insights into the material’s performance under specified conditions. This process is essential for validating material suitability in applications like structural components, ensuring compliance with stringent design and safety regulations. Proper execution and documentation maintain adherence to ASTM and ISO standards while delivering reliable and reproducible results.

Insights into ASTM E9 for Compression Testing of Metallic Materials

Key Considerations for ASTM E9 Compliance

ASTM E9 specifies standardized procedures for the compression testing of metallic materials, particularly focusing on determining properties such as compressive strength, modulus of elasticity, and yield behavior. To comply with ASTM E9, it is critical to use properly machined specimens with flat, parallel ends to minimize misalignment and ensure uniform distribution of load during testing. The testing machine must be calibrated and capable of providing precise load and displacement measurements, as per ASTM E4 standards.

Fixtures used during compression testing should remain rigid under test conditions to prevent inaccuracies caused by deformation or misalignment. Additionally, data acquisition systems must accurately capture stress-strain relationships to allow for meaningful analysis of material performance. Adherence to ASTM E9 ensures evaluation accuracy, reproducibility, and reliable assessments for structural and engineering applications.

Purpose of ASTM E9 in Testing Metallic Materials at Room Temperature

- Ensures standardized procedures for conducting compression tests on metallic materials at room temperature.

- Promotes consistency and reproducibility in evaluating material performance under compressive loads.

- Provides guidelines for specimen preparation, test equipment, and alignment to prevent inaccuracies.

- Facilitates accurate determination of mechanical properties such as yield strength, modulus of elasticity, and compressive strength.

- Enables comparison of test results across laboratories and industries by adhering to a universally recognized standard.

- Supports the development and validation of materials for structural and engineering applications through reliable testing methodologies.

Comparison between ASTM E9 and ASTM D695

ASTM E9 and ASTM D695 primarily differ in their application scope, material focus, and testing specifications for compression tests.

|

Key Point |

ASTM E9 |

ASTM D695 |

|---|---|---|

|

Material Focus |

Metals |

Plastics |

|

Application |

Structural |

Non-structural |

|

Specimens |

Cylinders/Prisms |

Prism/Rod |

|

Load Type |

Axial Load |

Axial Load |

|

Temp. Testing |

Optional |

Limited |

|

Accuracy |

High Precision |

Moderate |

|

Standard Scope |

Engineering |

General |

|

Strain Measure |

Extensometers |

Displacement |

|

Failure Mode |

Yield Criteria |

Compressive |

What Equipment is Essential for Compression Testing?

Compression testing requires specialized equipment designed to accurately apply and measure compressive forces on a material. The following are the essential components:

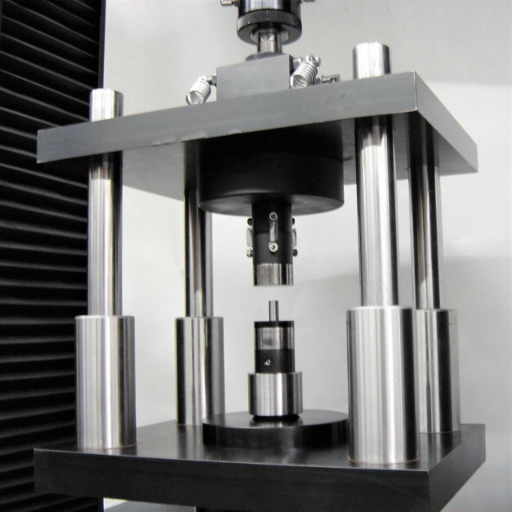

- Universal Testing Machine (UTM): This is the primary piece of equipment for applying controlled compressive loads. It features calibrated sensors for precise force and displacement measurements.

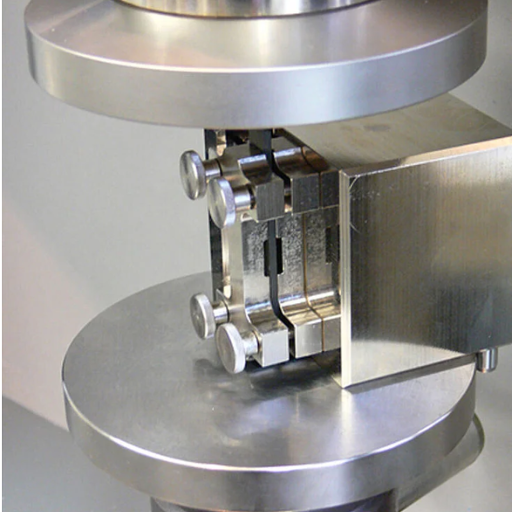

- Compression Platens: These are flat, rigid surfaces that distribute the compressive load uniformly across the specimen. High-quality platens ensure minimal deformation during testing.

- Fixtures and Alignment Tools: Proper fixtures and alignment systems maintain the specimen’s stability and prevent uneven loading, which could introduce errors.

- Strain Gauges or Extensometers: These devices are used to measure strain and deformation in the specimen, enabling accurate calculation of modulus and other material properties.

- Data Acquisition System: This system collects and processes data from sensors and transducers, allowing for detailed analysis of stress-strain behavior.

Proper calibration and maintenance of this equipment are critical to ensure reliable and reproducible results in compression testing scenarios.

Role of Compression Platens and Fixtures

Compression platens and fixtures play an integral role in ensuring accurate and consistent results in compression testing. Their primary functions include:

- Uniform Load Distribution: Compression platens ensure that the applied force is uniformly distributed across the test specimen, minimizing uneven stresses that could affect the accuracy of the results.

- Alignment of the Specimen: Properly designed fixtures maintain the alignment of the specimen during testing, reducing the likelihood of bending or off-axis compression forces.

- Surface Contact Optimization: Platens are often designed with highly precise, flat surfaces to maximize contact with the specimen and reduce localized stress concentrations.

- Accommodation of Various Specimens: Fixtures and platens are versatile, enabling testing of diverse specimen geometries and dimensions, ranging from cylindrical to non-standard shapes.

- Prevention of Material Slippage: Many fixtures incorporate textured or specialized surface treatments to prevent specimen slippage during compression loading.

- Facilitation of Repeatable Testing Conditions: By standardizing the way force is applied and distributed, platens and fixtures ensure test conditions can be replicated accurately across multiple tests.

Their design and quality directly influence the reliability and validity of the stress-strain data collected during compression testing, making them essential components of any testing setup.

Importance of Universal Testing Machines

Universal Testing Machines (UTMs) are critical in material science and tensile testing due to their versatility, precision, and reliability. These machines are designed to perform fundamental mechanical tests such as tension, compression, bending, and shear, ensuring comprehensive material characterization. By accommodating a wide range of specimens and materials, UTMs enable manufacturers and researchers to evaluate properties like tensile strength, elongation, and modulus of elasticity under controlled conditions.

The controlled environment provided by UTMs allows for highly accurate and repeatable testing, making them indispensable for quality assurance, product development, and compliance with industry standards like ASTM and ISO. Furthermore, their modular design, often featuring interchangeable load cells, grips, and fixtures, extends their functionality across diverse applications, including pharmaceuticals, aerospace, automotive, and construction. This adaptability, combined with advanced software for data acquisition and analysis, empowers engineers to generate detailed material profiles that underpin informed design and production decisions.

Ensuring Accurate Compressive Load and Yield Strength Measurements

Ensuring accurate compressive load and yield strength measurements involves a meticulous approach rooted in precision and consistency. I rely on calibrated testing machines compliant with international standards such as ASTM or ISO to guarantee reliable results. Before testing, I ensure that samples are prepared to exact specifications, including uniform geometry and surface finish, to minimize inconsistencies. The use of advanced software for real-time data acquisition allows me to analyze stress-strain behavior with high precision, identifying critical points such as the material’s yield strength or ultimate compressive load. By strictly following these protocols, I can confidently produce reproducible and accurate material performance data essential for engineering analysis and decision-making.

Understanding the Modulus and Compressive Strength in Testing

Modulus of Elasticity

The modulus of elasticity, often referred to as Young’s modulus, is a measure of a material’s stiffness or rigidity under elastic deformation. It is calculated as the ratio of stress (force per unit area) to strain (relative deformation) within the material’s elastic limit, where deformation is reversible. Higher modulus values indicate stiffer materials that deform less when subjected to the same stress level. This property is critical in predicting how materials will behave under loads and is determined through precise stress-strain curve analysis during testing.

Compressive Strength

Compressive strength is the maximum compressive stress a material can withstand before failure. Testing for compressive strength involves subjecting a specimen to a gradually increasing load until it fractures or deforms permanently. This value helps engineers evaluate a material’s ability to sustain axial loads without buckling or cracking, which is vital for applications such as structural elements. Compressive strength is typically reported as the peak stress observed during the test and directly influences material selection in engineering design.

Defining Compressive Strength and Its Measurement

Factors Influencing Compressive Strength and Advanced Measurement Techniques

Compressive strength is influenced by several factors, including material composition, specimen geometry, and environmental conditions during testing. For instance, concrete’s compressive strength is significantly affected by its water-to-cement ratio, aggregate characteristics, and curing conditions. Advances in testing methodologies now provide more accurate and granular data on material behavior under stress. Using non-destructive techniques, such as ultrasonic pulse velocity testing or rebound hammer methods, engineers can assess compressive strength without damaging the specimen. Furthermore, innovative digital tools and machine learning algorithms, integrated with data from sources like Google’s search trends and aggregated experimental results, are employed to predict compressive strength with high reliability. These advancements improve design precision and contribute to the optimization of material performance in practical applications.

Calculating Modulus During a Compression Test

The modulus of elasticity, often referred to as the elastic modulus, measures a material’s ability to resist deformation under stress and is a critical parameter in compression testing. To calculate the modulus, the stress-strain relationship is analyzed during the linear elastic portion of a material’s deformation. Stress is derived by dividing the applied load by the cross-sectional area of the specimen, while strain is obtained by dividing the change in length by the original length.

Using the formula E = σ / ε, where E is the modulus of elasticity, σ is stress, and ε is strain, engineers evaluate the slope of the initial linear region of the stress-strain curve. Accurate measurements require precise equipment and calibration to minimize errors caused by uneven loading or material anisotropy. Tools like extensometers are commonly utilized to ensure high-fidelity strain measurements during testing, thereby enhancing the reliability of the calculated modulus.

Interpreting the Stress-Strain Curve

The stress-strain curve is a critical analytical tool in material science and engineering, providing detailed insights into a material’s mechanical behavior under applied loads. It characteristically comprises several distinct regions, each offering valuable information about material properties.

- Elastic Region: This portion of the curve exhibits a linear relationship between stress (σ) and strain (ε), defined by Hooke’s Law, where σ = Eε. The slope of this region is the modulus of elasticity (E), reflecting the material’s stiffness. Any deformation within this region is reversible, making it vital for applications where structural integrity must be maintained under minimal loads.

- Yield Point: The onset of the yield point marks the transition from elastic to plastic deformation. Materials demonstrate a yield strength (σy), indicating the maximum stress that can be endured before permanent deformation occurs. Modern studies suggest that enhanced manufacturing techniques, such as heat treatment or alloying, can significantly impact σy, tailoring materials for specific industrial needs.

- Plastic Region: Following yielding, the material undergoes plastic deformation, where stress increases non-linearly with strain. During this phase, dislocations within the crystal lattice increase, and work hardening may occur, slightly raising the stress capacity before failure.

- Ultimate Tensile Strength (UTS): Representing the peak of the stress-strain curve, UTS defines the maximum load a material can bear. For instance, advanced high-strength steels (AHSS) have demonstrated UTS values exceeding 1,000 MPa, making them ideal for critical automotive and aerospace applications.

- Fracture Point: After reaching UTS, necking occurs, and the material’s cross-sectional area reduces until the fracture point. Understanding this region is essential for failure analysis to predict and prevent catastrophic structural breakdowns.

Current Data on Material Behavior

Recent industry data highlights notable examples of material performance. For instance:

- High-Performance Composites like carbon fiber-reinforced polymers exhibit excellent stiffness-to-weight ratios with a modulus of elasticity around 70–140 GPa, depending on the fiber orientation.

- Additively Manufactured (AM) Metals such as titanium showcase comparable tensile properties to conventionally processed metals; however, AM can result in anisotropic behavior, affecting the reliability of stress-strain predictions.

- Novel Alloys like superalloys used in jet engines reveal superior stress and temperature resistance, with UTS values often surpassing 1,400 MPa.

Numerous sectors now employ digital twins and finite element analysis (FEA) models to further interpret stress-strain behaviors under realistic conditions, culminating in optimized design and prolonged life cycles. This integration of experimental data and computational methods sets a foundational benchmark for advancing material engineering capabilities.

Reference Sources

- ASTM D695 Standard Test Method for Compressive Properties of Rigid Plastics – Official ASTM documentation.

- Instron: ASTM D695 Compression Testing Rigid Plastics – A detailed guide on ASTM D695 testing.

- ASTM E9 Standard Test Methods of Compression Testing of Metallic Materials – Official ASTM documentation for metallic materials.

- TestResources: ASTM E9 Compression Testing of Metallic Materials – Insights into ASTM E9 testing techniques.

- Top Compression Testing Machine in China

Frequently Asked Questions (FAQs)

Q: What is ASTM D695 and what does it cover?

A: ASTM D695 is a standard test method used to determine the compressive properties of rigid plastics. This standard describes the compression testing procedures for measuring the compressive strength, modulus, and deformation of plastics when subjected to a compressive force.

Q: What is the significance and use of ASTM E9 in materials testing?

A: ASTM E9 is significant in materials testing as it provides a standard for conducting compression tests on metallic materials. This test method describes the compression of metals and is used to determine their compressive properties, including compressive strength and deformation characteristics.

Q: How are test fixtures used in ASTM compression testing?

A: Test fixtures are used to securely hold specimens in place during compression testing according to ASTM standards. The fixtures ensure that the load is applied along the load axis and that the sample fails in compression without any additional torsion or bending.

Q: Is it the responsibility of the user to ensure safety during ASTM standard tests?

A: Yes, it is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to conducting ASTM tests.

Q: What is the process for conducting ASTM compression testing of metals?

A: Conducting ASTM compression testing of metals involves preparing the specimen, aligning it in a universal testing system, and applying compressive force according to ASTM E9 guidelines. The objective is to measure the metal’s ability to withstand compressive forces until it fails in compression by a shattering fracture or deformation.

Q: How is the compressive strength of cylindrical concrete specimens determined according to ASTM?

A: The compressive strength of cylindrical concrete specimens is determined by subjecting them to axial compressive forces in accordance with ASTM standards. This process evaluates the strength of cylindrical concrete and helps in assessing its load-bearing capacity.

Q: What should be considered when interpreting the results of this test method for compression testing?

A: When interpreting the results of this test method, it is important to consider the material properties, test conditions, and alignment of the load axis. Accurate interpretation requires understanding the significance and use of the test results in the context of material performance and application.

Q: Can you provide a quick question about running ASTM tests?

A: Certainly! A quick question might be: “What are the initial setup requirements for running ASTM compression tests on plastics?” To answer, ensure that the test fixture is properly aligned, the specimen is of correct dimensions, and the testing machine is calibrated according to ASTM standards.

Q: What types of materials can be tested using universal testing systems according to ASTM standards?

A: Universal testing systems can be used to test a wide range of materials, including metals, plastics, and concrete, according to ASTM standards. These systems are versatile and can perform various types of mechanical testing, including tension, compression, and bending.