The universal testing machine (UTM) is a marvel of modern technology that stands unrivaled in its ability to assess a wide array of mechanical attributes of a material. From interdisciplinary material science to engineering industries, this single device serves multiple functions, streamlining workflows with its capabilities in tensile and compressive tests. What, however, makes it “universal” and sets it apart from other testing machines? In what follows, we will look into the multifunctionality of UTMs, including their operating mechanisms, the diverse range of tests enabled, and their importance in several industries for innovation and quality control. Whether you are well-acquainted with these fields or interested in methodologies of testing, you will learn what makes this device truly universal in function and application.

What is a Universal Testing Machine (UTM)?

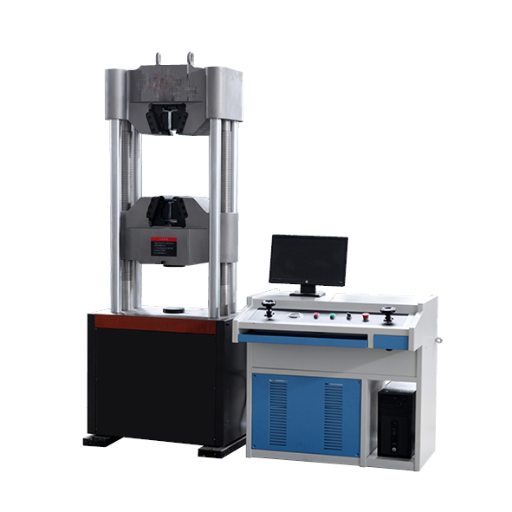

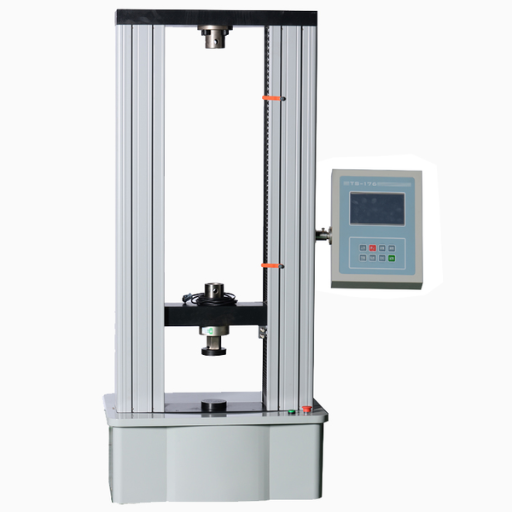

A universal testing machine (UTM) provides great versatility of use from the construction of different materials to testing their mechanical strength. The device, UTM, is capable of performing numerous tests such as tension, compression, and bending with multi-directional loading and simultaneously measures all of them. It is constructed with vital pieces such as a load frame and a force transducer, which enable it to apply precise measurement of forces and record data accurately on all pertinent measures. The device is widely used across sectors in manufacturing and construction for the purposes of quality aid ensuring and material development.

Definition and purpose of UTM

With a UTM, it is possible to measure yield strength, tensile strength along with other important factors in engineering to enable complete analysis on materials. The system is popular in the industry as it verifies whether a material meets the expectation for performance quantitative accuracy of tuned and tested materials in cross-section under in-depth x-ray sources. Equally important, precision becomes critical and modern UTMs help facilitate the industry. Increased ease comes as they UTMs / testing machines as they come equipped with advanced digital systems boosting data process efficiency and accuracy while improving characterization of the concerned material.

How does a UTM work?

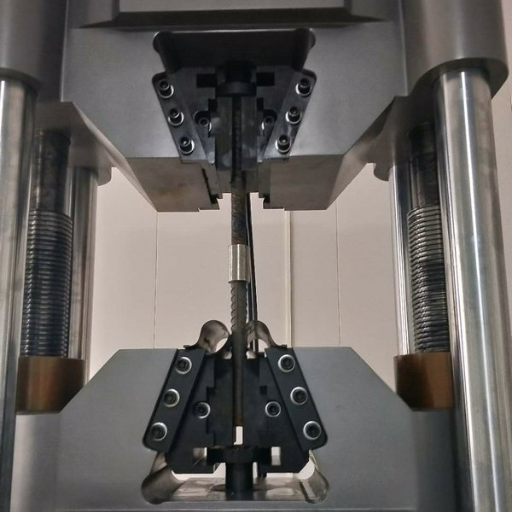

A Universal Testing Machine (UTM) functions by applying predetermined forces on a material sample, measuring the sample’s mechanical attributes. A UTM system is made of core parts such as a load frame, load cell, crosshead, grips or fixtures, and a control system. Each component has a specific purpose; the load frame need provides a stable structure for testing while the load cell detects the force applied, the crosshead moves either upward or downward (type of test), and grips or fixtures hold the specimen in place.

The UTM applies force stepwise which is monitored continuously by the load cell and displacement transducers. Data regarding stress, strain, elongation, and fracture limits is gathered. Current generation UTMs come with sophisticated software that captures and processes data during the test and instantly provides information on material properties like strength, elasticity, and deformation. Such precise measurements allow material evaluation for comparison with standards set by industries and regulatory bodies.

What Types of Tests Can a UTM Perform?

A Universal Testing Machine (UTM) can carry out a range of individual tests to evaluate the distinct mechanical characteristics of different materials. The most important tests are:

- Tensile Test: Dipangkat Sampel analyzing response for Tensile stretching South uniaxial stretch pada tayangan tensile, evaluating properties such as strongbend, yield, cumulatively combust, and elongationing.

- Compression Test: Researching behavior of materials under Compression load, estimating with compressive strength and having some deformation characteristics.

- Flexural Test: Used to measure brittle materials like ceramics or composites, put into the sphere to undergo marked bends.

- Shear Test: Uses a force which is parallel to the surface of the specimen applying so as to measure the specimen’s shear strength.

- Hardness Test (if equipped): Measures wear resistance as surface hardness checks are made.

- Peel, Tear, and Adhesion Tests: Used for layered structures to test the strength of the bonds between the layers.

All these tests help to accurately and reliably characterize materials to meet industrial needs and design specifications.

Understanding tensile testing and Its Importance

Materials Science and Engineering, as an applied field of science concentrates on the analysis and design of new materials, starts with testing their response to uniaxial stretching, an essential procedure for tensile testing. Through controlled specimen loading, its critical properties i.e., tensile strength, elongation, and Young’s modulus are obtained. To interpret these parameters, tensile strength indicates stress limit up to which a material exhibits an isometric expansion without fracturing. Elongation at break gauges ductility which is essential in many applications where flexibility is required. Young’s Modulus which is calculated from the initial linear part of the stress-strain curve gives material stiffness and elasticity.

This exam is vital for quality assurance, selection of components, and investigating failures in automotive, aerospace, and construction industries. Advancements for extensometric devices used in tensile testing, like automated extensometers and real time digital analysis, enhance efficiency. These improvements increase productivity while meeting strict requirements, thus rigorous tensile testing is essential in refining the design and engineering strategies of materials.

How to Conduct a Compression Test?

Compression testing is particularly important for any compressive load applications requiring structural efficiency because it analyzes how materials act when subjected to compressive forces. The process starts with specimen preparation which is ensuring that the material sample is standardized to certain dimensions and shapes that are cylindrical or cuboidal per ASTM or ISO standards. Avoiding bending stresses is crucial for flesshing accuracy and thus aligning the specimen in the testing machine is extremely important.

Typically, the test device is a UTM (Universal Testing Machine) with compression platens for applying force incrementally to predefined values of displacement, applying force incrementally or at a predefined rate of displacement. More advanced UTMs that have load cells as well as displacement transducers can measure the compressive load and the deformation with precision. Some important parameters such as yield strength, ultimate compressive strength, and modulus of elasticity are found from the force-deformation curve which the software generates during the test in real-time.

As with most physical tests, the material’s environmental baseline, like temperature and humidity, may have an impact on the UTM’s performance. Therefore, these parameters may be controlled within operational ranges or simulated within dedicated testing chambers. After the tests are completed, further refinement includes the evaluation of the so-called ‘failure’ modes, buckling tendencies, and even elasticity limits, as well as the interpretation of the relevant data. The derived characterization provides crucial insights that define the implications of safety, performance, and operational compliance against the material’s engineering acceptability.

Overview of flexural tests Using a UTM

Flexural testing is important to assess the bending strength and deformation characteristics of a material. A universal testing machine (UTM) tests these properties. In most cases, a specimen with a rectangular cross section is placed over two support points and a concentered load is applied either at the midpoint or at two distant equal points from the center based on the test configuration (three-point or four-point bending). During the test, the UTM flexibly applies force and records the load, displacement, and deflection of the specimen.

During the test, the bending stress is calculated using the formula:

σ = (3FL) / (2bd²) for three-point bending

Where:

- σ = bending stress (in Pascals)

- F = applied force (in Newtons)

- L = length of the supported span (in meters)

- b = width of the specimen (in meters)

- d = depth of the specimen (in meters)

Flexural strength as a specific engineering metric is the maximum stress a material can bear before fracture occurs, while the load-deflection curve reveals attributes of ductility and stiffness. Advanced data acquisition systems on the UTM allow for proper record keeping and analysis guaranteeing accuracy and reproducibility. This is a widespread construction, automotive, and aerospace test for evaluating metals, polymers, composites, and ceramics. Engineers perform bending load tests to understand the mechanical behavior and certify that design and safety requirements are met.

Why is it called Universal?

In contrast to the simplicity of other types of material testers, The Universal Testing Machine (UTM) does have some more versatility – hence the title “universal”. It can conduct tension, compression, bending, and even shear tests on an array of materials which include metals, plastics, composites, and ceramics. Because of this level of adaptability, the UTM is relevant to a plethora of industries and applications and fulfills different testing needs with one machine.

Characteristics that make it called universal

- Wide Testing Range: The UTM can evaluate materials with very low forces, such as delicate specimens, up to extremely high forces needed to evaluate robust materials. This capability is advantageous in different industries with varying material needs.

- Multiple Test Configurations: The machine is capable of performing different kinds of mechanical tests which include tensile strength, compressive strength, flexural modulus and shearing, employing interchangeable fixtures and grips. The modular nature of machines permits precise personalization which is advantageous for particular test requirements.

- Material Diversity: With the growing use of metals, polymers, elastomers, ceramics, composites and even biomaterials, a UTM not only caters thorough scientific tests but also meets industrial and research needs.

- Precise Data Acquisition: Trustworthy outcomes are generated when high precision testing and measuring systems are used. Advanced load cells and extensometers measuring stress, strain and elongation delivers data with high fidelity.

- Automation and Software Integration: Tested UTMs with advanced control software are able to automate the testing phases, prepare automated reports, and run tests with integrated tools which provide deeper insights. This device lowers overall soft-error rates alongside human error.

These attributes highlight the unmatched adaptability and accuracy of the versatility and precision UTM is unrivaled in UTM’s universal status in material testing.

Comparison with Other Testing Machines

|

Testing Machine |

Key Features |

Primary Applications |

Advantages |

Limitations |

|---|---|---|---|---|

|

Universal Testing Machine |

Tensile, compression, and flexural testing |

Metals, plastics, composites |

High precision, versatile, automated |

High cost, requires setup expertise |

|

Impact Testing Machine |

Measures material toughness |

Metals, polymers |

Simple operation, quick results |

Limited to impact strength testing |

|

Hardness Tester |

Hardness evaluation via penetration resistance |

Metals, ceramics |

Precise hardness evaluation |

Limited to surface properties |

|

Creep Testing Machine |

Measures deformation over time under stress |

Polymers, metals |

Suitable for long-term testing |

Time-consuming assessments |

|

Fatigue Testing Machine |

Analyzes failure under cyclical loading |

Automotive, aerospace materials |

Simulates real-world cyclic stress |

Complex setup, specialized operation |

|

Torsion Testing Machine |

Tests material resistance to twisting forces |

Wires, shafts, fasteners |

Dedicated torsional property testing |

Limited to torsion-related parameters |

|

Dynamic Testing Machine |

Evaluates materials under dynamic conditions |

High-speed components, elastomers |

Measures under real-time stress |

Requires advanced calibration |

|

Shear Testing Machine |

Measures material response to shear forces |

Adhesives, fasteners |

Accurate shear force assessments |

Limited to shear-specific properties |

|

Compression Tester |

Focused on compression strength analysis |

Concretes, ceramics, foams |

Robust compression analysis |

Inefficient for tensile properties |

Applications in Various Industries

Across various sectors, material testing machines are essential as they determine the integrity of the product, ensure it meets material standards, and function optimally within given conditions. Below is a detailed breakdown of their applications:

- Construction Industry

In construction, material testing machines are used to analyze the performance of structural materials. Concrete, steel, and composite materials undergo rigorous evaluation through compression testing. For example, the concrete used for building construction undergoes compression tests to certify that it meets load stresses. This complies with the ASTM C39 standard for compressive strength.

- Automotive Industry

In automotive industries, tensile and impact testers are necessary for evaluating metals, polymers, and composites used in various automobile parts. It is essential to understand tensile strength to guarantee automobile safety measures, especially crashworthiness and fatigue testing for cyclic load durability.

- Aerospace Industry

Every industry is tested to the highest standards, especially the aerospace industry, due to the harsh operating environments of its materials. UTMs test lightweight alloys and composite materials to evaluate their tensile, compressive, and fatigue strengths to ensure compliance with FAA regulations and mitigate flight failure risks.

- Packaging Industry

Products are often subjected to tensile testing to check if the materials can withstand forces during shipping and handling. For instance, polyethylene and cardboard materials go through some form of tests concerning their elongation and tear strength. ISO compliance standards are also tested, for instance, ISO 527 for the tensile properties of plastics.

- Medical and Biomedical Industry

Materail testing machines are ncessary for evaluating the mechanical properties of biomaterials such as orthopedic implants and surgical tools. Ensuring flexibility, fatigue strength and impact resistance, guarantees reliable performance under various stresses experienced inside the human body.

This broad overview of applications serves as a reminder of the importance of material testing machines as they sustain quality control and technological development in any field. Every domain uses specialized methods of testing for safety, performance, and compliance with regulations.

What are the Components of a Universal Testing Machine?

The various components of a universal testing machine (UTM) are:

- Load Frame: This is the main part of the structure which houses and supports the machine during the test. The load frame consists of two vertical columns and a crosshead that is movable.

- Load Cell: This is a high-accuracy instrument capable of measuring the force or load on the specimen with tremendous precision.

- Crosshead: Movable parts that apply tension, compression or other forces to the specimen. Movable crossheads are often motorized for precise control.

- Grips/Fixtures: Equipment that hold the specimen under test while undergoing testing processes to hold it still. These vary with materials and could be designed for either tensile or compression testing.

- Drive System: The mechanism that translates the crosshead movement and is usually servo or hydraulic controlled. It grants constant and tunable application of force.

- Control System: Comprises peripheral devices and software managing operations of the machine, data measurement, and executing defined workflows including tests which are automated.

- Extensometer (Optional): Measures the specimen’s deformation during the test which is important for determining the accuracy of the specimen’s material properties.

- Data Acquisition System: A system which collects test information, processes it, and generates reports on force, displacement, strain, and stress.

These aspects operate simultaneously to allow for precision, trustworthiness, and uniformity in testing numerous materials and across diverse applications.

Load cell and measurement systems

Load cells are specialized types of transducers that are designed to capture minute changes in force or load applied during testing with great accuracy. They work on the principle of changing mechanical force into an electrical signal, which in the right conditions can be measured and analyzed. A load cell is made out of strain gauges glued onto a metallic structure which circuit undergoes deformation under load that changes its resistance. The change in resistance can then be measured as strain or stress which is directly proportional to the load thereby enabling precise measurement, collecting data, and information retrieval.

Integrated load measurement systems and measuring devices fitted with load cells automatically capture and process information as it is being tested. Signal conditioning, amplifiers, and even specialized computing systems that monitor stress, strain, and displacement are incorporated into more advanced systems. High precision calibration set for industry compliance and data certainty integrity improves these systems’ precision claiming reliability. Equipment for measurement and testing with modern load cells are designed to provide an increasing level of automation for the testing process accessible extensometers and other instruments to enhance performance material testing and provide accurate data.

Fixtures and grips used in testing

Grips and Fixtures are essential in keeping the test specimens in accurate positions for proper measurement. Temperature, Time, specimen shape, and material differences areFactors that need careful consideration during engineering of these components. Grips, Mechanical, Pneumatic, or Hydraulic, can all be used as they provide uniform, damage-free clamping forces. Also, some other special fixtures like bending jigs, compression platens, and thread grips are used for special tests such as flexural, compressive, and tensile testing. Many advanced fixtures are made of tempered steel or composite alloys since these materials have high strength and can withstand extreme forces which ensures reliability and repeatability over multiple test cycles. These advanced fixtures are further enhanced when integrated with digital alignment systems which improve accuracy and eliminate errors that may result from brute-force misalignment or uneven stress distribution during the testing process.

Hydraulic systems in UTM

The use of pump, valves and hydraulic cylinders working together allows for the Universal Testing Machines (UTM) to have absolute control over the load accuracy. Universal Testing Machines rely on the pressurized fluids for heightened accuracy and control. Advanced servo-hydraulic technology has been added to modern UTMs enabling highly accurate feedback on force applied.

The use of strain gauges and pressure sensors makes real time force assessment possible, ensuring that data integrity thresholds are met and deviations due to machinery performance are kept to a minimum. The use of low dispensing synthetic oils as hydraulic fluids has some benefits when it comes to loss of friction leading to reduced wear on the internal parts of the machines. These developments have led to an improvement in performance and allowed the hydraulic systems to become the first choice for the majority of high capacity materials testing.

How Does a UTM Contribute to Quality Control?

A UTM enhances quality control processes because it measures important material properties such as tensile strength, compressive strength, and elongation which helps in ensuring the material meets required standards of strength, durability, and performance benchmarks for an endurance test. UTMs also provide manufacturers with critical data to assess product reliability and compliance with industry specifications. These machines promote consistency in testing and results in reduced variability, so tested products behave as expected when deployed in real-life use. There is also the opportunity of early detection of material defects, reducing chances of failure in the end product and improving overall the quality of production.

Ensuring Material Standards with a universal testing machine

Universal testing machines (UTMs) are versatile in their scope of operation as they can conduct several tests on materials and systems. Universal machines conduct tensile, compressive and flexural tests to determine the yield strength, elongation and ultimate tensile strength of a material. Sophisticated software solutions have been incorporated in advanced UTMs to allow real time data acquisition and analysis. Accuracy and repeatability are further enhanced by adaptive load cells, multi-range force capacities, and high-resolution extensometers.

Moreover, UTMs can work with a wide range of materials including metals, polymers, composites and even ceramics which gives engineers the flexibility to create specific test setups for individual projects. Extreme operational conditions are easily simulated with automated cycling within temperature controlled chambers, programmable loading with set programs, and the application of overwhelming force. This feature enables fulfillment of stringent regulatory requirements and enhanced product safety and reliability in various industries like aerospace, automotive and construction.

Impact of UTM Testing on Product Reliability

The last several years have seen great improvements in Universal Testing Machines (UTM’s) accuracy and reliability of testing procedures with the incorporation of high-end technologies. Achieving precision in the measurement of mechanical properties, such as tensile strength, compressive strength, and material elasticity, is facilitated with modern UTMs’ real-time data processing and acquisition systems with high-resolution load cells and other sophisticated sensors. Such systems also have better software compatibility which allows industries to perform more detailed calculations and simplifies the compilation of reports. Moreover, these systems are capable of simulating dynamic loads and environmental conditions that incredibly resemble real-world scenarios and therefore greatly aid in understanding a product’s performance under stress.

What are the advantages of using a UTM?

1. Precision and Accuracy: Measurement attained from the UTMs are precise and accurate, which contributes to the integrity of material data and enhances trust in a material’s evaluation.

2. Versatility: UTMs are versatile as they can carry out numerous different tests such as tensile, compression, bending, and shear.

3. Efficiency: The integration of different functions into a single machine makes it possible to merge all tests into one sequentially, thus, shortening resource and time requirements.

4. Quality Assurance: UTMs are essential for identifying material properties, along with essential product safety and quality measures by detecting prospective weaknesses.

5. Data collection and Analysis: Evaluation and documentation of results is simplified through advanced analytical tools and digital outputs offered by UTMs.

Cost-effectiveness in quality assurance

Acquiring Universal Testing Machines (UTMs) increases cost efficiency by improving testing productivity. Modern UTMs integrate testing functions like tension, compression, and bending into one device which eliminates the need for several specialized machines. This integration makes the devices more cost-effective as the total equipment expenditure and space requirements in the testing laboratories are minimized. Moreover, modern UTMs lower manual labor, accelerating the pace of testing and decreasing costs. Advanced automation and the ability to program tests increases precision and repeatability, thereby minimizing errors and costs related to reworking faulty products. Moreover, the modular design of UTMs allows companies to dynamically underscale or overscale their operational testing capabilities, adapting to business demands with minimal capital reinvestment.

Enhanced data accuracy and reliability

Modern Universal Testing Machines (UTMs) are equipped with state-of-the-art data acquisition systems that improve accuracy and reliability in all testing procedures. Due to high-resolution sensors, as well as high-speed algorithms that process data in real-time, UTMs can obtain accurate measurements under different test conditions. In addition, these systems provide powerful software that performs trend analyses and generates reports while maintaining efficient data organization. Moreover, recon temperature control greatly reduces the effects of the environment. trim lag at stitching line, enable trim lag, trimming on set flow, unlink edit enables trim lag, trim removedensures precision and reproducibility in repeat tests. Much external cutting-edge software optimizes testing machines, making them reliable, making them work without issue, well, all modern universal testing machines. Engineers and researchers mitigate the influence of external factors, ensuring precision data is ready and correct, and testing machines can accurately measure and analyze data. This powerful conclusion, Data provided by hardware-advanced UTMs, enables a confident era of imagined recorded aid, accepting testing methods, and recon trim flow set.

Reference Sources

-

Micro Universal Testing Machine System for Material Property Measurement: This study introduces a micro UTM system designed for composite materials. It evaluates mechanical properties like tensile strength, yield strength, and elongation. The system uses a stepper motor and visual basics software for control, meeting UTM standard 1828.

-

Tensile Strength Testing of +45° Isotropic FRP Laminate on Different Universal Testing Machines: The study compared tensile strength results of fiberglass-reinforced polymer (FRP) laminates using different UTMs. The “MFL system, UPD-20” UTM provided the highest tensile strength and force.

Frequently Asked Questions (FAQs)

Q: Why is the universal testing machine called a universal testing machine?

A: The universal testing machine is called a universal testing machine because it is capable of performing various types of mechanical testing, including tensile and compression tests, making it a versatile tool in testing systems.

Q: What types of tests can be performed using a UTM machine?

A: A UTM machine can be used to test the tensile strength, compressive strength, and other mechanical properties of materials, which makes it essential in quality control and research.

Q: How does the UTM machine work?

A: The UTM machine works by applying a controlled force to a test specimen and measuring its response, allowing for accurate test results in evaluating the strength of materials.

Q: What is a tensile testing machine?

A: A tensile testing machine, also known as a universal tester, is a specific type of UTM machine used to test the tensile strength of materials by pulling them until they break.

Q: What is the role of an extensometer in UTM testing?

A: An extensometer is an accessory used with the UTM machine to measure the elongation of a test specimen during tensile testing, providing accurate data on the material’s deformation.

Q: Can the universal testing machine be used for different materials?

A: Yes, the universal testing machine is used to test a wide variety of materials, including metals, plastics, and composites, making it a fundamental piece of testing equipment across industries.

Q: What is the significance of test results obtained from a UTM machine?

A: The test results obtained from a UTM machine are significant as they provide crucial information on the mechanical properties of materials, which is vital for engineering applications and material selection.

Q: What are some common applications of a UTM machine?

A: Common applications of a UTM machine include quality control in manufacturing, research and development, and material certification processes, where understanding the strength and durability of materials is essential.

Q: What is a peel test, and how is it conducted using a universal testing machine?

A: A peel test is a type of test used to evaluate the adhesive strength of materials, and it can be conducted using a universal testing machine by applying a force to peel apart bonded materials.

Q: How do different machines affect the UTM machine’s working?

A: Different machines may have varying capabilities and specifications, which can affect the UTM machine’s working, including the maximum load, speed of testing, and the type of testing equipment used for specific applications.