Tensile strength testing ranks as one of the most critical procedures, as it determines the performance and reliability of a bonding material under stress, with thousands of products being constructed or manufactured at any given time using adhesives. In the construction industry, vehicles are built and assembled; in the electronics industry, various adhesives must meet geographical standards concerning tensile forces so that the products are safe, durable, and of a high standard. The article will discuss the basics of tensile strength testing, its application in assessing adhesive performance, and the factors that affect test results. With any luck, by the conclusion, one will comprehend how this process can lead to the formation of strong and dependable bonds in various applications and will, therefore, gain some insight into how to further improve the strategies for selecting and applying adhesives.

Introduction to Adhesives and Tensile Strength

An adhesive plays a crucial role in joining materials by creating durable bonds that can withstand various degrees of force and stress. The term tensile strength refers to the capability of an adhesive to resist forces of pulling or stretching before it fails, thereby providing a direct estimate of its behavior under stress. This parameter is of prime importance in applications where adhesives are required to bear mechanical loads and thus maintain their integrity over time. Tensile testing primarily evaluates strength under defined conditions, allowing for the collection of numerical data that can be used to compare different adhesive products and their suitability for specific tasks. Thus, with knowledge of tensile strength, manufacturers and users can specify the right shape to achieve the desirable bonding efficiency.

What is Adhesion?

Adhesion refers to the molecular or physical attraction between two different materials, which causes them to cling together at their interface. This phenomenon is based upon various forces between different materials, such as Van der Waals attraction, electrostatic charges, mechanical interlocking, and sometimes even chemical bonding. The strength of adhesion varies with the surface energy of the two materials involved in the adhesion process, as well as with respect to surface roughness or smoothness, and environmental conditions such as temperature and humidity.

In today’s advanced techniques, surface treatments are considered vitally crucial for maximizing adhesion. Methods of treatment include plasma cleaning, surface priming, and the use of adhesion promoters. Thus, the better the preparation of substrates, the stronger and more durable the bonds will be, especially considering the applications of adhesion in aerospace, automotive, and consumer electronics, where the high-quality application of adhesion will be of merit regarding the functionality and safety of the final product. Hence, a sound scientific understanding of adhesion allows engineers and manufacturers to produce reliable and consistent outcomes in bonding applications.

Importance of Tensile Strength in Adhesive Bonds

The tensile strength of an adhesive bond is the maximum stress an adhesive joint can withstand while being stretched or pulled until it eventually fails. It is a crucial parameter for determining the usefulness and reliability of an adhesive product in various applications. High tensile strength is essential to bind two materials together so that they can resist external forces, mechanical stress, and adverse environmental conditions such as temperature and humidity.

The Aerospace and Automotive sectors use adhesives that meet the exact tensile strength requirements for their bonds, ensuring performance and safety in harsh environments. The choice of adhesive for any given application, relative to its tensile strength, depends on factors such as the substrate material, substrate surface preparation, and anticipated operational loads. High tensile strength may reduce the chance of failure of the user materials, whereas the lower strength deleteriously affects the aging and performance of the assemblies with severe tolerance.

Key Terms Defined: Adhesive, Bond, and Strength Tests

Adhesive

An adhesive is a substance that binds two surfaces together. Modern adhesives are designed for specific applications and are characterized by their tensile strength, shear strength, environmental resistance, and other parameters, which ensure a durable bond under the conditions of use.

Bond

The bond is the status of adhesion or attachment attained when an adhesive holds two surfaces together. Such attachment depends upon the formulation of the adhesive, surface preparation, ambient conditions, and method of application. If the bond is strong, the attachment will ensure the stability and durability of the whole assembly.

Strength Tests

Strength Tests are aimed at establishing, under controlled conditions, that adhesives are operating correctly and are reliable under different stress situations. These tests include tensile strength measurements, peel tests, and shear tests, among others, and provide vital information regarding the adhesive’s ability to perform in operational situations. These data will then be used by engineers when selecting adhesives to meet specific structural and mechanical requirements.

Overview of ASTM Standard Test Methods

ASTM standard test methods provide unanimously accepted testing procedures to assess the performance, consistency, and reliability of adhesives when used in different applications. Some of these methods include ASTM D1002 for lap shear strength, ASTM D3163 for plastics bonded with adhesives, and ASTM D1876 for peel resistance testing. Testing conducted under these strictly defined conditions enables engineers to obtain accurate and reproducible results, which can be accurately compared with and validated against adhesive properties under the intended operational conditions.

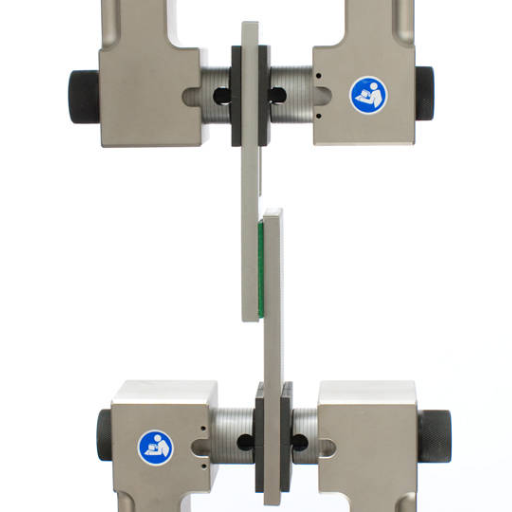

ASTM D897: Standard Test Method for Tensile Properties

ASTM D897 covers the determination of the tensile properties of adhesives using butt-joined specimens. This test method evaluates the strength of adhesive bonds under tensile stress. Specimens are prepared in a controlled environment to ensure uniformity of results. The adhesive is to be applied uniformly in a manner that allows for proper bonding; cure conditions must satisfy the manufacturer’s recommendations for accurate results.

The specimen is put under tensile loading in a universal testing machine until bond failure occurs. Important information obtained from the test is the maximum tensile strength and mode of failure (i.e., adhesive, cohesive, or substrate failure). These results serve as a reference for comparing how an adhesive reacts to tensile forces, which aids in selecting materials and potentially modifying the adhesive to suit the application better.

Other Relevant ASTM Standards for Adhesive Testing

Several ASTM standards cover adhesive testing under varying conditions:

- ASTM D1002 – It deals with lap shear testing of metal-to-metal bonded assemblies, relating to shear strength and performance of the adhesive.

- ASTM D3163 – Relates to testing of single-lap-joint bonded plastic specimens in tensile loading to determine adhesive strength and failure characteristics associated particularly with plastic substrates.

- ASTM D903 – Employed for the measurement of peel or stripping strength of adhesive bonds, it is crucial for durability evaluation in applications where peel resistance is required.

Each of the above standards is focused on different types of testing, ensuring that adhesives meet their stringent operating and application requirements.

Benefits of Following Standard Test Methods

- Quality Assurance – Reliability in performance of adhesives is ensured by following standardized tests, which contribute to minimizing variation and enhancing the final product quality.

- Comparative Analysis – Using the same standards allows adhesives to be compared against other materials or manufacturers, and to further select which best suit an application.

- Regulatory Compliance – Adherence to regulations specifying standards is necessary in processes across many industries, guaranteeing the safety and legal aspects of product development and use.

- Better Strength and Performance – Recognizing and improving longer-lasting top-performing formulations under stress is reasoned by testing adhesives under controlled conditions.

- Cost-Effectiveness – Cost in recalls for defective adhesives, repairs, or replacements can be reduced, should such cases be knowingly detected earlier through uthe se of standardized methods.

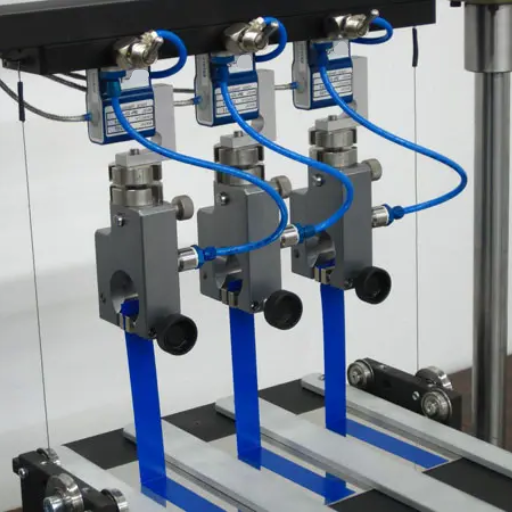

Tensile Strength Testing Process

The tensile strength tests require several vital stages to guarantee accurate and reproducible results. After preparing the adhesive sample according to all standard dimensions to ensure consistency among the tests, it is placed in a tensile testing machine, where a uniaxial force is exerted until adhesive failure occurs. Data relating to maximum force, elongation, and stress at the breaking point are measured. Test conditions represent temperature, humidity, and loading speed, conditions that are set to replicate the test situation in the field and ensure repeatability. With the data provided, adhesive manufacturers can assess an adhesive’s structural integrity, flexibility, and suitability for specific applications.

Preparation of Adhesive Samples

Sample preparation of adhesives for testing involves executing precise and standardized procedures that ensure testing results are accurate and reproducible. At first, substrates are selected and cleaned thoroughly to eliminate any contaminants that could interfere with the process, which could be grease, dust, or oil. Cleaning may involve degreasing with solvents or cleaning agents, followed by drying. Then, about the required thickness and curing conditions specified by the manufacturer, the adhesive is applied evenly. This would allow for curing such as air drying, heat curing, or curing under certain environmental conditions (e.g., UV light). After curing, the samples are cut and shaped in accordance with the standards listed in the test methods, such as ASTM or ISO, which ensures uniformity in all specimens before testing.

Conducting the Tensile Strength Test

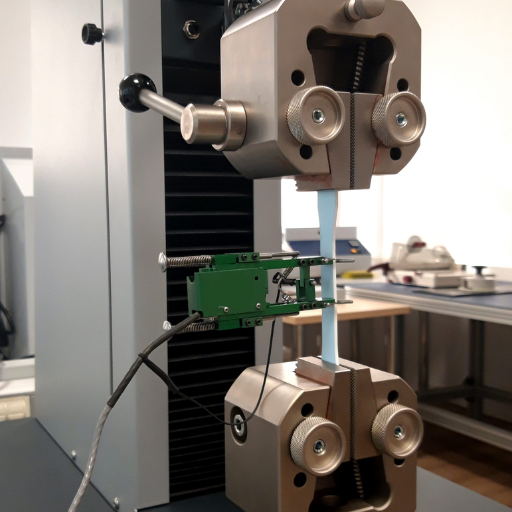

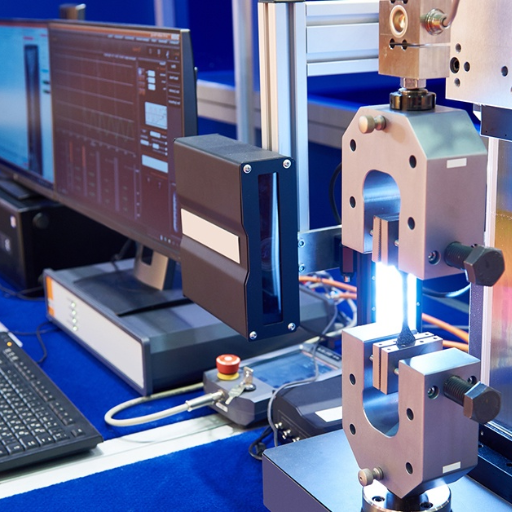

Tensile strength tests were performed to find out the maximum stress that a material can sustain while being stretched or pulled before failure. Typically, during testing, the prepared sample is clamped between the clamping mechanism of the Universal Testing Machine, with maximum grip strength applied to ensure that the sample does not slip during testing. Then, a tensile force is applied in a controlled manner and gradually increased to the specimen, recording the responses to stress and strain in real-time.

Parameters relevant to material performance when subjected to load include yield strength, ultimate tensile strength, and elongation at break. The data obtained is detailed enough to provide information for material selection, quality control, and structural design applications. Tests are performed according to standard test methods, such as ASTM E8/E8M or ISO 6892, to ensure reproducible results that meet industry standards.

Interpreting Test Results and Data Analysis

During the process of interpreting test results, my focus is on key mechanical properties, such as yield strength, ultimate tensile strength, and elongation at break. By these, I assess a material’s capability to resist stress and deformation in concrete situations. To provide results that comply with pre-established standards according to ASTM or ISO guidelines, I try to examine trends in data, including irregularities that might indicate an issue with production, inconsistencies in materials, or the necessity of modifying parameters in design. I never decide on test data alone, but always within the frame of the technical requirements that relate to the application of the material. This yields decisions regarding both the appropriateness and performance of the material, which are accurate and defensible.

Practical Applications of Adhesive Strength Tests

Adhesive strength tests find a host of varied yet practical applications across diverse sectors. They guarantee and enforce the durability and reliability of bonded components in products on the manufacturing side, including automotive parts, aerospace assemblies, and consumer electronics. As the construction industry uses its test standards to check the suitability of adhesives in structural materials, including panels, tiles, and sealants, for safety and code compliance, packaging tests ensure the adhesive seal is sufficient for preserving the product and its branding. By establishing consistency and performance within a set of parameters, these tests serve as quality assurance and development processes.

Adhesive Testing in Manufacturing Industries

Adhesive sufficiency testing is a vital testing in the manufacturing industries, signifying the durability and reliability of bonding materials. From search trends on Google and various industry reports, it has been observed that modernized formulations of adhesives have created a need for specialized testing capable of validating the performance of adhesives against various environmental and mechanical conditions. Similarly, aerospace manufacturing requires adhesive testing for verifying adhesives in resistance to extreme temperature and shearing stresses that maintain structural integrity in flight, while for the automobile industry, the tests ensure that the adhesives may withstand vibrations, shocks, and perhaps long-term contact with chemicals such as fuel or oil.

Such rigorous testing of adhesives improves operational safety and promotes sustainable manufacturing systems. In the wake of increased interest from consumers and regulators on the use of green materials, manufacturers are increasingly advertising bio-based or low-VOC adhesives. These formulations undergo exhaustive performance testing to ensure that their environmental merits do not compromise their bond strength and durability. These changes pave the way for adhesive testing to oversee both innovation and environmental stewardship in the sectors.

Importance of Adhesive Strength in Construction

Adhesive strength is paramount in construction, thus affecting the durability and safety of building structures. In my opinion, adhesives form a bond between materials such as wood, metal, and concrete, allowing them to resist stresses or changes caused by temperature variations or moisture absorption. A secure building has fewer chances of structural failures and therefore has increased longevity. Furthermore, these new adhesive technologies promote efficiencies as they replace mechanical fixing between various building substrates and materials.

Aerospace Applications and Material Durability

In aerospace applications, adhesives are paramount from the viewpoint of material durability and light structures. High-performance adhesives are used in the bonding of composite materials with metals and plastics to retain structural integrity within extreme high pressure, vibration, and temperature changes, conflicting further with uniform stress distribution across bonded surfaces to enhance their fatigue resistance and impact resistance, as the utmost concern of their longevity and safety of aircraft structures. Moreover, the adhesive would facilitate the reduction in mechanical fasteners, thereby significantly reducing the weight factor, which is a daunting challenge in contemporary aerospace engineering.

Factors Affecting Adhesive Strength

1. Surface Preparation

Surface preparation quality is crucial to achieving the desired adhesive strength. Dirt, greasy contaminants, or an oxide layer could drastically weaken bonding. Cleaning of surfaces, with adequate abrasion and priming, ensures optimal adhesion and long-term durability under operational stresses.

2. Environmental Conditions

Various environmental variables can drastically affect the performance of an adhesive. Such variables include temperature, moisture, and chemicals. Extreme temperatures cause thermal expansion/contraction, which may in turn degrade bond integrity. Instructors, therefore, must learn to differentiate adhesives based on their resistance properties suited to specific environmental conditions.

3. Adhesive Selection

Adhesive selection is a crucial criterion in achieving the required sustainability and strength. Selection depends on the materials to be bonded, the loads expected on the bonding, and the environmental conditions. Typical variants of adhesives considered for application in bonding metals are epoxy, polyurethane, and cyanoacrylate.

4. Cure Time and Method

To achieve an optimum bonding strength, proper curing conditions must be adhered to. In cases of two-component adhesives, actual curing occurs through chemical reaction and can also be promoted by heat, UV light, or pressure in some cases. Following the specified cure time and method would ensure that the adhesive attains full strength and stability of the bond.

5. Load Type and Distribution

The type of load application and its distribution would affect the overall performance of the bond. The shear load constitutes a force well resisted by adhesives, while peel and cleavage tend to be the forces that may cause bond failure. Engineers, in turn, must account for these forces when designing to optimize adhesive use and longevity.

Influence of Adhesive Type: Epoxy vs. Acrylic Adhesives

Epoxy adhesives offer superior strength and chemical resistance, while acrylic adhesives provide faster curing times and greater flexibility for a wider range of surfaces.

| Parameter | Epoxy | Acrylic |

|---|---|---|

| Strength | High | Moderate |

| Flexibility | Low | High |

| Cure Speed | Slow | Fast |

| Surface Prep | Extensive | Minimal |

| Temp Resist | High | Moderate |

| Chemical Res | Strong | Moderate |

| Bond Types | Rigid | Flexible |

| Durability | Long-term | Medium |

| Cost | Higher | Lower |

Understanding Bond Failure and Shear Strength

Bond failure occurs when the adherence of an adhesive to a surface is compromised, thereby compromising its structural integrity. Comparatively, the causing factors could arise from anything involving a lack of proper surface preparation, wrong adhesive selection, environmental, or mechanical conditions; environmental conditions include temperature and moisture, while mechanical denotes any force that must be greater than what the adhesive can accommodate. Shear strength refers to the maximum stress in consequence of parallel forces being applied along the plane of adhesion. Furthermore, a good shear strength indicates a strong bond that withstands mechanical loads well before failure occurs.

More recent trends indicate that epoxy adhesives, due to their high shear strength and enhanced resistance to environmental influences, are the adhesives of choice in applications where long-term durability and structural integrity are of utmost importance, particularly in industrial and structural settings. However, this shows a significant difference from acrylic adhesives, which are best suited for open courses and require more consideration of flexibility and curing time, even when the application time and conditions are not entirely favorable. The selection ensures that the adhesive system can withstand the slightest chance of bond failure while maintaining the greatest possible shear strength relative to the application, loading conditions, and environmental demands.

Reference Sources

-

How do we test the mechanical strength of adhesives? – Explains tensile strength testing methods for adhesives, including the use of ASTM D638 standards.

-

Standard Test Method for Tensile Properties of Adhesive Bonds – Details the ASTM D897 standard for testing the tensile properties of adhesive bonds, particularly for metal-to-metal applications.

-

Testing the Tensile Properties of Adhesives – Describes the process of testing adhesive tensile properties using universal testing machines.

-

Adhesive Testing – Provides insights into various adhesive testing techniques, including tensile strength and other physical property analyses.

-

A Comprehensive Guide to Bond Strength – Offers an overview of tensile strength and its role in determining adhesive bond performance.

Frequently Asked Questions (FAQs)

What does the adhesive tensile strength test refer to?

How is ASTM D897 related to adhesive strength tests?

What factors concern the strength of an adhesive bond?

What is the importance of tensile strength data in adhesive testing?

Can surface treatment improve adhesive strength?

Surface treatment can indeed significantly improve adhesive strength. Common surface treatment methods include sanding, cleaning, and applying suitable primers. They help increase the surface energy and texture of the substrate, characteristics that promote mechanical interlocking and chemical adhesion, ultimately leading to strong adhesive bonds.

How do tensile strength tests differ from shear strength tests?

The tensile strength test measures the ability of an adhesive to resist forces that try to separate the bonded materials. In contrast, the shear strength test measures the performance of the adhesive against forces that try to displace the bonded materials against each other. Both tests are essential for understanding the strength characteristics exhibited by adhesive bonds in different applications.