Adhesives have certainly proved to be critical in numerous industries, from construction, automotive, packaging, and consumer goods. However, the question arises: Can we really assure that any adhesive will work satisfactorily in varying conditions or provide enough strength for its intended application? This article is on adhesives testing methods and beauty and instances of evaluating performance, strength, and durability. Whether you are a manufacturer seeking assured product quality or simply curious about the science behind adhesive development, this guide has something significant to share about the testing behind adhesive advancements. Stay around and let’s unravel those processes of how adhesives face tests for tough modern-day applications.

Introduction to Adhesive Testing

Importance of Adhesive Testing

Adhesive testing is crucial in measuring the performance of an adhesive and its application under various circumstances. The adhesive has to do its job under different conditions, like temperature variations, levels of stress, and exposure to environmental factors, such as moisture or solar radiation. Thorough testing could help manufacturers identify weaknesses in adhesives and improve them to meet industry standards or application requirements.

Another important reason for adhesive testing revolves around safety and compliance. Adhesives used in aerospace, automotive, construction, and even healthcare must conform to stringent regulatory standards to make sure they do not jeopardize the safety of the end product. Testing measures adhesives for their very performance, such as whether they can hold structural integrity, prevent damage, or conform to legal or environmental standards. Particularly when failure could cause harm or loss of material in an application, such testing is crucial.

And lastly, adhesive testing aids in fostering innovation and the development of new products. Based on adhesive behavior in different conditions, manufacturers develop advanced formulations for new materials and difficult-to-adhere-to applications. This enables more efficient and durable adhesive solutions and promotes confidence amongst consumers and industries relying on these technologies.

Overview of Adhesive Test Methods

Adhesive testing methods provide evaluation of the performance, durability, and reliability of adhesives under certain conditions. The tests ascertain the suitability of an adhesive with regard to specific applications for safety, quality, and function. The major types of test methods involve bond strength, shear resistance, and environmental resistance.

Peeling is one of the most popular tests. It measures the force necessary to pull apart two bonded materials by peeling one away from the other. It measures an adhesive’s ability to bond to a variety of surfaces and is usually applied for applications requiring some amount of flexibility and intermediate levels of adhesion. Tensile and shear tests also measure strength between two substrates under tension and shear forces-who may be representatives of real-world stresses that bonded materials may encounter.

Other methods like environmental durability testing, evaluate the behavior of adhesives under critical operating conditions such as high temperatures, chemical fumes, and heavy humidity. Such tests stand as a guarantee that the adhesive properties remain unchanged with time and in challenging environments. Ideally, having all of these methods would certify the reliability of adhesives for different applications-from industrial up to consumer.

Key Terminology in Adhesive Testing

Some key terms must be understood in interpreting adhesive test results and their proper application.

- Adhesive Bond Strength: The force by which an adhesive is used to separate two substrates. It is typically measured as tensile forces, shear forces, or peel forces, and it is a measure of how well the adhesive is holding materials together in certain conditions.

- Cohesion and Adhesion: Cohesion is the internal strength of the adhesive material itself, while adhesion is the ability of the adhesive to hold onto surface substrates. Both the adhesive and cohesion properties of an adhesive are evaluated in different methods for the qualification of their effectiveness.

- Substrate Surface Energy: A name to describe the energy characteristics of the surface of a material that influence adhesive capacity to bond to it. The ability to bond generally improves with greater surface energy, whereas a low-energy surface often requires surface treatments to optimize bonding.

By getting to know the terms, you can understand adhesive performance and make informed decisions in industrial or consumer applications.

Types of Adhesive Test Methods

Peel Test Method

The peel test method looks into the force necessary to separate two materials bonded together by pulling them apart at a controlled angle, either 90° or 180°. It is used mainly to test tape, films, coatings, and laminates. It is a consistent method of measuring the adhesive force under certain conditions.

During testing, one material is rigidly held while the other one is peeled away with force applied at a constant rate. The peel strength is measured by the force required to hold the materials from being reattached to each other for a predetermined distance. The profile value defines the uniformity of the adhesive and bond integrity during stress applied to it.

Peel tests are an imperative stage for quality control and product development so adhesives meet the standards of performance required for their intended application. This type of test is therefore used in those industries industries including automotive, electronics, packaging-where strong and durable adhesive bonds are paramount for their product functioning and reliability.

Shear Strength Testing

Shear strength testing enables us to see how an adhesive or a bonded joint holds up against parallel forces along the bond line. This test measures how the adhesive will perform when lateral stresses exist; that is, the adhesive needs to ensure that the materials it bonds to will remain bonded even under such stresses while testifying to the structural integrity of the product. The results gained provide important information about whether a product will withstand the operational loads it may experience during use.

The procedural testing of shear strength entails applying a controlled force acting parallel to the interface until failure occurs, thereby exceeding the load, between bonded substrates under adhesive. The greatest maximum force-based deviation occurring at the set failure time is used to calculate the shear strength. In harmony with this, testing standards and methodologies, such as those laid down by ASTM or ISO, ensure that such tests bear reliable data, so the data derived are comparable in different applications.

The aerospace, construction, and manufacturing industries need to shear-test adhesives in order to ensure safety and the performance of the product. For example, in the aerospace industry, adhesive bonds are required to resist extreme lateral stresses during flight, whilst the construction materials must withstand environmental pressures. These rigorous tests essentially ensure that the adhesive solutions satisfy the quality and compliance standards set forth before release on the market.

Tensile Strength Testing

Tensile strength testing describes setting an adhesive bond to maximum tensile force, thereafter to breaking. Therefore, the method may focus on testing the durability and reliability of adhesives when subjected to force in an attempt to pull apart the material in opposite directions. Such tensile tests are of the utmost importance in determining whether an adhesive is capable of handling high-strength applications.

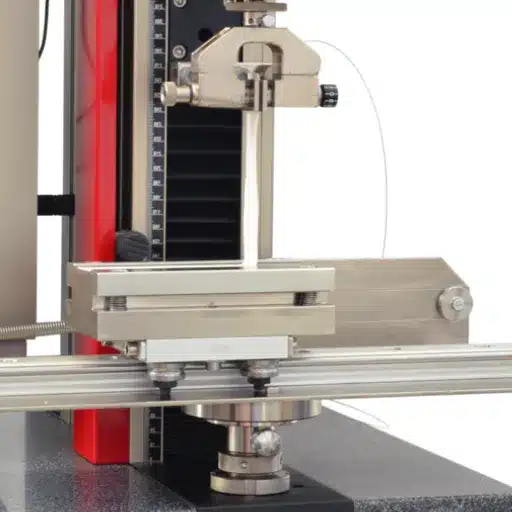

Usually, in the case of tensile strength tests, the test specimens, often consisting of two bonded substrates, are mounted in the grips of a tensile testing machine. A steadily increasing force is applied to these materials by the machine until bond failure and ultimate failed strength data may be recorded. The results yield data on the force at maximum load of the adhesive, some load-extension characteristics, and several important parameters for application in the automotive and aerospace industries constitute some of the most important instances.

During testing on tensile strength, manufacturers can check to see if their adhesives meet the requisite standards of performance and even safety. The data can now be used to instruct a particular adhesive material to the right application, hence minimizing the possibility of product failure and leading to the general reliability thereof.

Evaluating Adhesion in Adhesives

Factors Affecting Adhesion

Diverse factors influence the strengths and effectiveness of adhesives that determine their suitability for various applications. Below are some of the most important factors affecting adhesion:

- Surface Preparation: Maximizing adhesion can only be attained with proper preparation of the surface itself. Contaminants such as dust, grease, or moisture may present themselves against the bonding force. Studies state that around 40% increase in adhesive strength can be obtained by preparing the surface. Surface treatment includes sandblasting, cleaning with solvent, and mechanical roughening, to name a few.

- Surface Energy: The surface energy of the substrate is very important for the adhesive molecules to interact with it. Metals with high-energy surfaces are more attractive for adhesion; on the other hand, plastic surfaces with low surface energy need to be treated in order to bond with good adhesion. For example, plasma treatment can improve the wettability of low-energy plastic surfaces by about 50%.

- Temperature and Environmental Conditions: Temperature variations and environmental exposure can adversely affect adhesion. High temperatures tend to soften adhesives and degrade their performance. On the other hand, when exposed to intense UV light for a long period, adhesives might slowly degrade. In fact, adhesives developed with UV resistance can maintain about 90% of their original bonding strength even after 500 hours of UV testing.

- Compatibility of Materials: Adhesive and substrate materials must be compatible. Some adhesives work better on porous surfaces such as wood, while others behave wonderfully on non-porous substrates like glass and metal. Epoxy adhesives, for example, have been found to shearing strength of 5,000 psi on metals, showing that it excel at these applications.

- Surface Preparation and Application Technique: Concerning bonding, the right methods are crucial to avoid bubble entrapment in the adhesive film or an uneven distribution of the film, resulting in poor contact of the adhesive with the substrate. Automated application processes such as robot-aided adhesive dispensing give adhesives the precision and consistency they require to show their best strength.

- Curing Process: Curing time generally affects the strength of any bond, i.e., whether humidity or curing temperature may gradually destroy a weak bond. Advanced adhesives that cure in ambient atmospheric conditions usually possess approximately an 80% cure within 24 hours, thereby sometimes especially aiding in factory setups.

By understanding all these subtle issues involved, manufacturers can better decide upon their choices of adhesives and methods of applying the adhesive to reduce product failures while enhancing product performance and durability.

Adhesive Strength Measurement Techniques

The need for determining adhesive strength demands the usage of several worldwide methods, depending on the characteristics that must be tested for reliability, making the results precise to a considerable extent. These methods basically check for the strength of the bond between two substrates and establish how adhesives behave under certain conditions. The most commonly employed methods include tensile, shear, and peel tests is, depending on the application and the requirements.

The tensile force checks for the ability to resist a force that tends to separate two joined varieties from each other in a perpendicular manner. Equal forces are applied to the two substrates in order to ascertain the amount of tensile force the adhesive bond can withstand before it finally gives way; hence this is a method through which one can know how well an adhesive can resist being pulled apart in those applications where perpendicular forces are usually of concern.

Shear strength tests measure the resistance of the adhesive bond against forces applied parallel to it. This simulates real-life conditions of sliding or shifting lateral stresses, especially so in automotive or construction applications. Peel tests complete these types of evaluation with considerations for forces required to peel bonded materials therefrom at an angle, mostly dealing with flexible or thin substrates. Hence, these methods together give a complete inspection process for adhesive performance, thus assisting manufacturers in selecting the right adhesive for their needs.

Adhesion Testing Standards (ASTM)

The ASTM serves to ensure uniform and dependable ways of testing the bonding strength between two materials. These specifications lay out directions for the way adhesives should be tested under many conditions so that industries can maintain standards of quality and safety in their products. The tests commonly applied are tensile, shear, and peel, each verifying the adhesive’s performance against different forces and conditions for a defined time period.

A very important standard is ASTM D1002, the typical lap shear test for adhesives, which determines the capacity of a bond to resist shear stresses commonly present in mechanical or structural applications. Another well-known test is the peel test as specified in ASTM D903, which evaluates the bond strength between flexible adherends. This test is crucial for laminated or layered materials where the force required for separation must be controlled.

Using ASTM standards, manufacturers could maintain their product performance at a robust level checked with industry benchmarks given real-world parameters. These standardized testing methods are good for quality control, as they help create consistency and trust in consumers and stakeholders.

Performance Testing of Adhesives

Durability testing for adhesive bonds is crucial in determining whether or not an adhesive can remain free from environmental and mechanical stresses with time. This testing subjects the bond to real-world conditions such as changes in temperature, humidity, or chemical exposure to determine the bond’s ability to maintain strength and reliability over time. By simulating such conditions, manufacturers can make sure that a bond will perform well in a given application for the long haul.

The most common ways of performing durability tests are cyclic aging, where the temperature alternates from high to low, with exposure to humidity likely simulating outdoor or industrial conditions. Under such conditions, tensile and shear tests measure the strength of an adhesive after it has been kept under stress for some time. This ensures adhesive bonding is fit for safety and strength in real-world arduous conditions.

The tests are in tight alignment with what is described in ASTM and ISO standards. Upon following these standards, a manufacturer is assured of getting accurate and comparable test results for different products and in different industries. Regardless of whether the tests are performed in a laboratory or at the manufacturing site, durability testing assures that the adhesive product will perform well during its intended lifetime. It is in this manner that durability testing qualifies as a major area of product development and quality assurance.

Environmental Effects on Adhesive Performance

Environmental differences, including temperature fluctuations, humidity levels, exposure to UV radiation, and other chemical agents, have a key role in affecting an adhesive’s bonding effectiveness and desired duration of usage. For example, under increased temperatures, adhesives may soften, hence losing bonding strength; under freezing temperatures, adhesives may get brittle and thus cause a bond to fail. Certain adhesives may also weaken when humidity encourages reactions to a chemical process in the adhesive or moisture absorption that interferes with adhesion.

Another challenge is UV radiation since adhesives are degraded after prolonged exposure to the sun. This degradation, which is sometimes called photodegradation, occurs because the UV rays break down the molecular structure of the adhesive, leaving behind a weaker bond, or in some cases, total failure. For outdoor applications, therefore, adhesives should be selected with UV resistance in mind or protected from direct sunlight.

In addition to that, chemical exposure can deteriorate adhesives in an environment where they may come in contact with oils, solvents, or other corrosive agents. Such chemicals can bring about the dissolution or decomposition of the adhesive components. Hence, for ultimate performance, the adhesives have to be tested considering these specific environmental conditions in which they are to be utilized and must be wisely selected for such conditions. This ensures that the adhesive can withstand the environmental conditions to which it will be exposed.

Emerging Technologies in Adhesive Testing

Innovations in Adhesive Testing Equipment

There has been an increased emphasis, in recent years, on precision, efficiency, and versatility with regard to enhancements in the adhesive testing equipment. One critical innovation pertains to the adoption of automated testing systems capable of running multiple tests simultaneously. This allows faster data collection and analysis and hence significantly reduces the time needed for adhesive evaluation vis-a-vis tensile strength, shear strength, peel resistance, or comparison among various parameters. Further, industries requiring high-throughput testing benefit the most from automated systems.

Then there is the development of environmental simulation chambers within testing equipment. These chambers simulate situations very much in the real world-from temperature extremes, humidity, to exposure to UV light. That means the testing tool will check accurately for adhesive performance and durability under particular environmental situations. This feature is essential because reliability is assured in aerospace, automobile, and construction work, where adhesives are exposed daily to adverse situations.

Furthermore, transformations on the interpretation of test results in the fields of digital technologies-detailing connectivity and data analysis software-have somehow transpired. Most modern glue-testing machines nowadays may be bought with digital sensors integrated with the cloud, which allows for real-time monitoring and remote access to test data. These digital capabilities have increased traceability and allowed for a more quantifiable decision-making process in different industries, ensuring the capability of the glue to perform best in a particular use.

Advanced Adhesive Testing Methods

There are numerous modern adhesive testing methods. These techniques assess an adhesive’s strength, durability, or compatibility for a serious type of application. Tensile testing, the simplest test to understand, assesses the adhesive’s ability to resist forces that tend to pull it apart. It provides data on ultimate strength and elongation to make sure the adhesive meets its functional requirements.

Peel testing is another advanced technique. This examines the strength of the adhesive bond when subjected to forces that tend to peel the layers apart, thereby simulating stresses encountered in actual applications. The peel test is particularly important to the packaging and electronics industries, in which precision bonding strength is crucial.

Thus, environmental aging tests simulate any of the peculiarities of temperature, humidity, or chemical exposure to assess the long-term performance of adhesives. If an adhesive stays in a controlled environment for a certain period during testing, industries can predict its behavior for an extended time, ensuring its use is safe and reliable. In combination, these tests allow manufacturers and industries to pick adhesives that have proven records of meeting high-performance standards.

Future Trends in Adhesive Testing

Advancements in the field of adhesive testing parallel the growing emphasis on sustainability and the requirement for environmentally friendly adhesives. Testing practices increasingly take into consideration the possibilities of adhesives based on bio- or recyclable matter. Such tests are developed to ensure that sustainable adhesives perform and endure identically to conventional adhesives, propelling the reduction of environmental impact all over the globe.

Automation of these smart technologies is another key trend operating in adhesive testing. Sensor and AI technologies are deployed to create more precise and efficient conditions for testing. For instance, different commercially available environmental systems allow real-time feedback about the performance of an adhesive in response to different environmental stimuli, bypassing the rigorous time cycles of such testing. An intelligent system would thus be programmed to analyze large data sets gathered from tests and help make decisions in refining adhesive formulation or predicting trends of performance.

Finally, the growth of high-end simulation is enabling yet another revolution in adhesive performance testing. Computational modeling allows one to subject adhesives to a wide range of environmental conditions that are difficult to simulate in the laboratory, such as immense mechanical stress or harsh chemical exposure. Consequently, the development process is accelerated, improving the overall productivity of adhesive development; at the same time, environmental wastes are saved, thus promoting both economic and environmental. These trends tend to foster a more experimental, efficient, and conscientious chemical test methodology.

Frequently Asked Questions (FAQ)

Q: What is adhesive testing?

A: Adhesive testing is a broad term for testing the properties and applications of adhesives through standardized test methods and includes strength, viscosity, and durability testing. This helps to ensure that adhesives comply with given requirements for use in the various industries in which it is employed.

Q: What are the standard test methods used for adhesive testing?

A: Standard test methods for adhesive testing include tensile lap-shear strength, peel strength, and creep property. These help to determine the mechanical properties of adhesive bonds and how they perform under different loading conditions.

Q: How do you measure adhesive bond strength?

A: The strength of adhesive bonds is thus commonly measured through a standard test method for strength, of which lap shear tests constitute a common example. This tests the shear strength of single-lap-joint adhesively bonded assemblies to ascertain that they meet certain prescribed criteria for performance.

Q: What factors influence the viscosity of adhesives during testing?

A: The temperature, the chemical nature of the adhesive, and the presence of some fillers can influence the adhesive viscosity. The understanding of adhesives’ viscosity is important because it affects the way adhesives are put into place and the performance of adhesion bonds.

Q: Explain the importance of the apparent shear strength of single-lap-joint tests.

A: The apparent shear strength of single-lap-joint tests holds a unique position in governing the adhesive joint integrity. This test method helps in determining the ability of adhesives to resist shear forces on bonded assemblies, which is integral to their service life.

Q: How to Measure Lap-Shear Tensile Strength of Rigid-to-Rigid Bonded Assemblies?

A: Tensile lap shear strength is determined by standardized test methods in the shear mode produced by applying tensile loads. This test investigates the maximum load that the adhesive-bonded joint may bear before failure occurs.

Q: What are the other peel test roles for flexible-bonded-to-rigid test specimens?

A: The peel test for flexible-bonded-to-rigid test specimens measures the resistance of the adhesive to a peeling force. It is recommended for applications where flexible materials have been glued to rigid substrates, in order to ensure the adhesive will hold in stress.

Q: How could adhesive testing be another way to fix problems with adhesive quality?

A: Adhesive testing can analyze adhesive properties; therefore, manufacturers can define drawbacks and problems in quality. With the knowledge of performance metrics, engineers may refactor formulations or application methods to enhance adhesive performance.

Q: What is the standard specification for adhesives?

A: In general, a standard specification for adhesives defines the requirements and the performance criteria that adhesives must meet to be subject to a particular application. Standards specifications assure the dependability of adhesive bonding in various industries.

Q: What is the importance of testing for creep properties in adhesives?

A: Testing for creep properties is essential in understanding the behavior of an adhesive under equal load over time and, therefore, critical for applications where long-term stability and performance are needed so that adhesive bonds retain their strength and integrity under conditions of support.

References

-

Adhesive Testing by Intertek – A resource offering expert insights into adhesive performance testing across various industries.

Adhesive Testing Methods: Ensuring Reliable Bonding Solutions – A guide by Dymax on tailored adhesive testing methods for reliable bonding.

Adhesive Testing: How Important Is It? – A blog discussing the importance of adhesive testing for strength, reliability, and durability.

Test Methods for Coating Adhesion – A detailed explanation of quantitative adhesion tests, such as the pull-off test.

Adhesive Strength Tests: Common Methods & Analysis – An overview of common adhesive strength tests, including tensile, shear, and peel tests.