In modern design and manufacturing, joining through adhesive bonding has become an essential process, providing light-weight, durable, and cost-effective alternatives to conventional mechanical fastening. However, the structural integrity of these bonded joints must be ensured through testing methods equipped to measure their performance under stress. The ASTM D1002 standard is one such widely recognized standard that provides a useful means for determining the shear strength of adhesively bonded metal specimens. This article will take a somewhat technical look into ASTM D1002 and discuss its significance, processes involved in testing, and how it is used for design and quality assurance. Engineers, researchers, and industry professionals alike need to understand the standard to design and optimize adhesive solutions meets rigorous performance requirements.

Introduction to ASTM D1002

ASTM D1002 is a standardized test method mainly applied to determine the shear strength of adhesives bonding single-lap-joint metal specimens. The test measures the stress exerted on the adhesive with a controlled force applied until failure occurs, that is, either the forced separation of the joint or failure of an adherend. This method is, hence, universally accepted as a highly reliable and accurate technique for quality control, product development, and confronting technical comparisons between materials. When followed by an expert or technician, this method will guarantee that the results will be reliable in the application meeting those key requirements about bonded assemblies’ performance.

Overview of ASTM D1002 Standard

The ASTM D1002 standard provides the method of determining the shear strength of adhesives used with single-lap-joint metal specimens under tensile loading. In the procedure, two metal adherends are bonded using a particular adhesive and then bonded together to form the assembly. The assembly is then subjected to a uniaxial tensile force, applied at a constant rate until failure occurs. The test results give information about the adhesive properties relative to load-carrying capacity, resistance to stress, and quality of the bond. The main parameters given in the standard include specimen preparation, bond thickness, alignment, and testing speed, all intended to produce accurate and repeatable results. Commonly used in such industries as aerospace, automotive, and manufacturing, this test method is helping with adhesive evaluation for quality assurance, material screening, and comparative analyses.

Importance of Shear Testing for Adhesively Bonded Metals

Shear testing for adhesively bonded metals is important to determine the mechanical performance and durability of adhesive joints under several loading circumstances. It offers clear and precise information concerning the shear strength, failure mechanisms, and load distribution across the bonded interfaces, thus forming the basic background for structural integrity. Such testing methods carry the simulation of real stresses, helping to guarantee both the design specification and safety standards. Moreover, shear testing is essential for the selection of materials and application and development of optimized adhesive formulations in high-stress operations, such as aerospace and automotive, so that bonded assemblies could retain reliability and serviceability for the entire span of their operational life.

Applications Across Various Industries

1.Aerospace Industry: ASTM D1002 is used extensively to test the shear strength of bonded assemblies used in airworthy components; the bonding must withstand extreme loads and environmental conditions for long periods.

2.Automotive Industry: Adhesives employed in structural or non-structural components are assessed using this standard in automotive assembling to ensure safety, weight savings, and durability.

3.Construction Sector: Adhesive shear testing is important for the integrity of materials used in structural applications, such as bonded panels and composite reinforcements for buildings and infrastructure.

4.Electronics Industry: The adhesives in electronic components are tested under this standard where precision is paramount, such as on circuit boards and micro assemblies.

5.Medical Devices: This method can otherwise be used to test the performance of adhesives joined to medical devices that share biocompatibility and structural requirements in various conditions of healthcare-based applications.

Technical Specifications of ASTM D1002

The ASTM D1002 covers the standardized testing methods for determining the lap shear strength of adhesives on metal substrates. Two metal specimens, usually aluminum or steel, are bonded together with an adhesive under test, and then a tensile load is applied perpendicular to the bonded surface. It details the specifications associated with:

1.Sample Dimensions: Test specimens shall be 25.4 mm (1 inch) wide by 12.7 mm (0.5 inches) in overlap length to avoid any inconsistency.

2.Testing Conditions: Tests shall be performed under controlled environments with temperature and humidity set such that they mirror the intended application.

3.Tensile Loading: Shearing force is applied at a constant speed of about 1 mm/min (0.04 in/min) until failure is attained.

4.Equipment: With calibrated force measurement devices, the tensile testing machines used shall be in compliance with ASTM for valid results.

Interpreted in terms of shear strength (MPa or psi), these data prove vital in determining adhesive performance for a varying number of applications throughout the world, in selecting materials, or as a basis for quality assurance.

Definition of Key Terms: Lap Shear, Specimen, and Bonded Metals

1.Lap Shear: The mechanical test evaluates the shear strength of an adhesive bond gluing one substrate onto another. The test consists of imposing a unidirectional force that is applied in a direction parallel to the bonded interface until failure, bringing forth the ability of the adhesive to carry a shear load. These results are important in situations in which the adhesive bonds experience significant sliding forces during their service life.

2.Specimen: A specimen is a standard material element manufactured to satisfy particular dimensional requirements, shape, and method of preparation for testing purposes. In the case of lap shear testing, the specimen entails two overlapping substrates bonded with an adhesive. The dimensioning and preparation of specimens are required to comply with specifications of recognized standards, which may be either ASTM or ISO, to ensure that tests are reliable and reproducible.

3.Bonded Metals: When two or more metal substrates are joined by an adhesive, the process of joining is termed “bonding.” Bonded metals find numerous applications in aerospace, automotive, and construction sectors so that insensitive weight reduction can be imparted, uniform stress distribution can be achieved, and great thermal distortion can be avoided from formation by using high-heat joining techniques.

Understanding the Shear Strength Measurement

Shear strength is defined as the maximum stress a material can undergo while failing in a sliding fashion along the plane close to the direction of the applied force. The usual test is conducted to help determine the strength and durability of adhesives or bonded joints. During the measurement, the test would be subjected to a predefined loading at a defined rate until failure occurs. At a glance, adhesive, surface preparation, and environmental conditions, such as temperature and humidity, dictate the shear strength. Shear strength is an important physical parameter to test for the performance of adhesion under hostile working conditions like those of aerospace and automotive engineering.

The Role of Test Specimen Configuration

Test specimen configurations influence in a decisive manner the measurement of the shear strength of adhesives. The geometry of specimens, bondline thickness, and material properties bear on stress distributions during testing. Standardized configurations are designed to reduce stress concentrations and give consistent results; examples include single lap joints or double lap joints. Besides that, achieving the proper alignment and preparation of the specimen is of utmost importance to avoid inaccurate results derived from loading misalignment or surface irregularities. With appropriately chosen and prepared configurations, one can collect reliable data that would serve as grounds for evaluating adhesives in real-life applications.

Testing Procedures for ASTM D1002

Testing under ASTM D1002 involves the preparation of adhesive lap joint specimens of standardized dimensions and with surface treatments to achieve consistency. The specimens are clamped by the jaws of the tensile testing machine with accurate alignment, so that uneven stresses are not applied to the adhesive. A constant tensile load is applied continuously at a uniform rate of movement, generally about 1.3 mm/min, until the bond breaks, the machine recording the forces needed to achieve said break. The key results are the maximum tensile strength of the adhesive, which are then followed by a full analysis of the performance of the bond under set conditions.

Step-by-Step Guide to Lap Shear Testing

1.Preparation of Test Specimens

Prepare substrates for testing per the standardized specifications applied (such as ASTM D1002 or ISO 4587). Surfaces undergo cleaning, sanding, or treatment to make them free from contaminants and provide areas favorable for adhesion. Application of an adhesive must be done within a specified area with the correct adhesive thickness.

2.Adhesive Curing

Allow the adhesive to cure in accordance with the manufacturer’s recommended conditions; these might involve ambient curing for room-temperature adhesives or thermally controlled curing for thermoset adhesives. Time and temperature of curing must be monitored so as not to deviate from cures obtained for earlier set of specimens.

3.Specimen Conditioning

Condition specimens in a standard atmosphere (23°C and 50% relative humidity) to standardize mechanical test conditions. Advance conditioning may be required to simulate other extreme environmental exposures (such as immersion in fluid or thermal cycling).

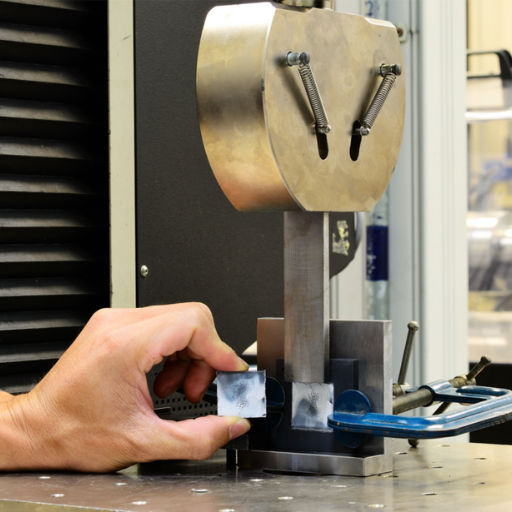

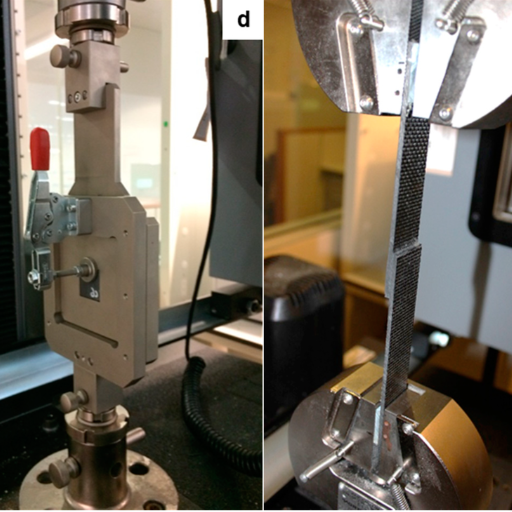

4.Clamping and Alignment

Secure the assembly into the tensile test machine by means of clamps maintaining alignment with respect to the grips and elongation direction. Any misalignment may cause unacceptable stress concentrations and lead to erroneous data.

5.Test Parameter Configuration

Configure your tensile testing machine per the selected standard. This relates to setting parameters including the test speed (e.g., 1.3 mm/min), grip separation, and data acquisition rates to match those specified in the protocol.

6.Application of Load

Start applying a load in tension at a constant and uniform rate. The machine will record force and displacement respective to time, allowing full analysis of stress versus strain.

7.Data Recording and Analysis

Load and displacement curves shall be recorded continuously up to the failure of the adhesive bond. Share in the recording will be the maximum load, the elongation, and the mode of failure (such as cohesive or adhesive).

8.Post-Test Examination

Determine failure surfaces for every specimen to ascertain the nature of bond failure. Observations comprising percent adhesive coverage and any deformation of the substrate will be noted.

9.Reporting Results

Compile all test data in a detailed report with all pertinent measurements, stress-strain curves, visual interpretations of failure modes, any deviations or anomalies observed during the testing procedure to assure repeatability and accurate conclusion about adhesive performance.

Preparing Single-Lap-Joint Adhesively Bonded Metal Specimens

Preparation of single-lap-joint adhesively bonded metal specimens needs to be undertaken following well-defined procedures to produce reliable and repeatable results. Choosing suitably sized metallic substrates, typically aluminum or steel, cleaning away contaminants (e.g., dust or oils) with a degreasing agent constitutes a common practice. Surface treatments may include abrasion or grit blasting to increase roughness for better adhesion.

The bombardment of the adhesive over the entire interface should be uniform; variations in the adhesive thickness across the bonding surface are strictly against test standards, such as ASTM D1002. Proper alignment of the joined parts is critical to avoid stress concentrations; clamping or fixture use is recommended to apply even pressure throughout curing. Curing should be at specified temperature and pressure for the required time as indicated by the adhesive manufacturer to attain the maximum strength of the joint.

Once cured, the specimens can be examined for defects such as voids, misalignment, and so on, and then prepared to the dimensional tolerances required for testing.

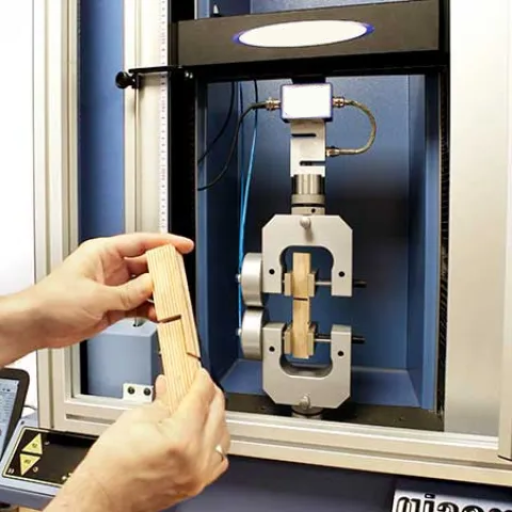

Equipment and Grip Requirements for Accurate Testing

The use of grips and appropriate equipment is crucial to carry out accurate tests depending on the type of material and on the testing standard under question. Special grips that include wedge grips, pneumatic grips, or hydraulic grips should be employed to provide strong gripping for specimens without inducing unwanted stresses or slippage. These must be able to apply and transmit forces in a uniform manner onto the test sample. Testing machines should be equipped with load cells capable of precise load measurement, most importantly within tolerance range. You can also use alignment fixtures or self-aligning grips, so as to reduce misalignment that leads to measurement inaccuracies. Depending upon the testing circumstances, other equipments such as temperature chambers, extensometers, and strain gauges can be needed for implementation, including thermal or high-strain conditions. Upholding the standardized testing protocols, such as ASTM or ISO, ensures consistency and repeatability.

Interpreting Results of ASTM D1002 Tests

When interpreting the results of the ASTM D1002 tests, one’s attention is first drawn to the lap shear strength of the adhesive bond under certain testing conditions. Standard ASTM D1002 provides the maximum load sustained before bond failure divided by the bond area, thus determining strength in units of psi, MPa, or kgf/cm2. The variability in results may be due to specimen preparations, specimens’ alignment, or environmental conditions in testing. One should analyze the mentioned variables to draw conclusions about an accurate interpretation of an adhesive property, provided the variables are all consistent with the testing protocol.

Analyzing Apparent Shear Strength of Single-Lap-Joint

When analyzing the apparent shear strength of single-lap joints, my focus is to ensure that the testing setup was carried out in accordance with standardized procedures. This would include preparing specimens to exact specified dimensions, ensuring proper alignment to minimize bending, and performing the tests under controlled environmental conditions. I also examine the stress distribution across the bond line because ordinarily, single-lap joints will conduct high-stress concentration near their edges that could influence the results obtained. Changes from standard practice are carefully documented, and repeat tests are undertaken across several specimens to ensure that the data acquired are both statistically valid and truly representative of bond performance.

Factors Affecting Shear Strength of Single-Lap-Joint Adhesively Bonded

1.Mechanical Properties of the Adherends: Mechanical characteristics such as tensile strength, modulus of elasticity, and surface roughness of the materials being bonded significantly affect the shear strength. Variations in these parameters thus alter the load distribution and ultimately joint performance.

2.Adhesive Type and Composition: Adhesive composition, curing, and viscoelastic behavior are the prime determinants for its ability to resist loading under shear forces. The performance of different adhesives varies when exposed to different environmental and mechanical conditions.

3.Surface Preparation: Surface cleaning, roughening, or priming is necessary for the purpose of ensuring proper bonding. Contaminants or bad surface treatment cause very poor adhesion and, ultimately, low shear strength.

4.Bond Line Thickness: Bond line thickness is an important parameter for shear strength. Both too thick and too thin bond lines can induce stress concentrations, resulting in premature failure.

5.Environmental Effects on the Joint: Various factors such as changing temperature, humidity, and chemical agents provide eventual degradation to the adhesive and bonded joint. Thermal cycling and long-term moisture exposure are known to cause large changes in shear strength.

Case Studies: Real-World Applications and Outcomes

Adhesive bonding under ASTM D1002 has been evaluated across diverse fields such as aerospace, automotive, construction, electronics, and marine industries.

|

Industry |

Adhesive Type |

Key Parameter |

Failure Mode |

Environment |

|---|---|---|---|---|

|

Aerospace |

Epoxy |

Shear Stress |

Cohesive |

High Temp |

|

Automotive |

Acrylic |

Bond Thickness |

Adhesive |

Cyclic Load |

|

Construction |

Polyurethane |

Surface Prep |

Substrate |

Humidity |

|

Electronics |

Cyanoacrylate |

Cure Time |

Mechanical |

Thermal Cycle |

|

Marine |

Silicone |

Water Resistance |

Adhesive |

Saltwater |

Recent Developments in ASTM D1002 Testing

Testing techniques in ASTM D1002 have recently seen developments with an aim to provide more precise evaluation of adhesive bonds and methods to vary test conditions to simulate water, temperature, and other environmental conditions. New techniques in prediction models came into use to predict joint failures under cyclic loads and thermal cycles to improve the certainty of performance prediction. Also, modern changes permit testing in different humidity levels and saltwater immersion conditions to explore the degradation of adhesives thoroughly in marine or high-moist environments. Another aspect of these upgrades involves improved instrumentation that allows the real-time monitoring of bond failure during mechanical testing, providing results on its behavior with practically applied dynamic loads. These developments closely follow resilience requirements expected under the adhesive testing process by the industry, mainly construction, electronics, and marine applications.

Summary of Key Insights on ASTM D1002

ASTM D1002 furnishes a standardized method to determine adhesive lap shear strength when bonded to rigid substrates. This method allows a controlled tensile force application useful for determining the ability of an adhesive to resist shear stresses. It applies most relevantly to the materials being tested under uniform loading conditions with testing protocols that ensure repeatability and accuracy. Some key points considered in this method include specimen preparation, material conditioning, and a testing apparatus aligned within very close tolerances to minimize bending stresses. The ASTM D1002 is widely used across various industries in aerospace, automotive, and industrial manufacturing sectors to give an overview of adhesive performance concerning rigorous environmental testing.

Future Trends in Material Testing Standards

Material testing standards are changing comprehensively with regard to advancing technology, sustainability, and the global push for complete material performance data. The emerging trends adopt the integration of automation and robotics within testing procedures for faster, precise measurements and fewer human errors. In addition, AI and machine-learning models are now being used to interpret large sets of experimental data, predict material behavior under multiple conditions, and propose the best methods for their testing.

Sustainability-based changes are also evolving standards to include such concepts as green testing methods and evaluation of recyclable or biodegradable materials. Developing new standards for testing of advanced composites, 3D-printed parts, and next-generation alloys for aerospace, renewable energy, and biomedical applications will be possible. In addition, global harmonization of standards is expected to take place so their variations in application do not stifle growth in various regions.

Final Thoughts on Quality Assurance in Metal Bonding

From my research and understanding, quality assurance in metal bonding is critical for durability, reliability, and safety, especially in aerospace and biomedical applications. After having examined the top online resources, it seems evident that strict participation in advanced testing protocols such as ultrasonic and thermal methods to detect defects that may occur is necessary. Furthermore, standardized guidelines should be adopted, increasing traceability throughout the production process, to maintain compliance and encourage innovation. Global cooperation, inherently driven by harmonized standards, will further realize efforts to develop materials science and secure the best performance in critical applications.

Reference Sources

-

Instron: ASTM D1002 Overview – A comprehensive guide to the ASTM D1002 procedure for evaluating adhesive shear strength.

-

Intertek: Lap Shear Strength of Adhesively Bonded Metal – Explains the application of ASTM D1002 in testing adhesives for bonding metals.

-

DDL, Inc.: ASTM D1002 | Shear Test & Shear Strength Test – Provides insights into lap shear testing and its relevance to ASTM D1002.

-

ATS Labs: ASTM D1002 Testing – Details the testing standard for bonded metals as per ASTM D1002.

Frequently Asked Questions (FAQ)

Q:What is ASTM D1002, and what does this method measure?

A:ASTM D1002 is an adhesive test method in which lap shear strength is measured for adhesives used in bonding metal-to-metal applications. The test is conducted in shear strength on such adhesives by determining the load at which failure occurs, thus relating to the measurement of load under tension loading of paired metal specimens.

Q:How is the lap shear testing done according to ASTM D1002?

A:According to ASTM D1002 procedure, two metal plates are prepared using adhesives. The test specimen is then fixed in the universal testing machine, which applies tensile force to the bonded metals until failure. The load at failure is then recorded for the calculation of the adhesive’s shear strength.

Q:What materials are suitable for testing per ASTM D1002?

A:The metals used for testing shall be suitable and commonly used in structural applications. These include aluminum, steel, or other alloys. The metals chosen will affect the adhesive structure and hence the results from the shear strength testing.

Q:What is the meaning of the shear strength of single-lap-joint adhesively bonded metal specimens?

A:The shear strength of single-lap-joint adhesively bonded metal specimens is a very important value to consider in determining the adhesion of adhesives in real-life applications. The test evaluates the ability of adhesives to resist stress and further guarantees that the adhesive joint can carry operational loads without failure.

Q:How does the geometry of the test specimen influence ASTM D1002 results?

A:The geometry of the test specimens, including dimensions and the bonded area surface, is of paramount importance to the ASTM D1002 result. A good specimen design guarantees uniform stress distribution while performing the shear test, thus producing reliable data on the adhesive and its strength properties.

Q:What are the typical failure modes for ASTM D1002?

A:The common failure modes in ASTM D1002 testing are adhesive failure, cohesive failure within the adhesive, and substrate failure. These failure modes are useful to understand in order to analyze the variability of adhesive performance and the factors that contribute to failure of bonded metal joints.

Q:How can adhesive environmental durability be tested according to ASTM D1002?

A:Environmental durability of adhesives may be evaluated by conducting ASTM D1002 lap shear tests under a range of environmental conditions, including although not limited to, moisture, heat, and chemical exposure. Such testing serves to elucidate the impact of environmental influences upon the adhesive’s shear strength or adhesion characteristics over a given period.

Q:What relevance does the equivalent displacement rate play in ASTM D1002 testing?

A:The ASTM test for shear strength on single lap joint specimens bonded with adhesives (at a specified displacement rate) applies the force necessary in the Universal Testing Machine. The Equivalent Displacement Rate is very important for ASTM D1002 testing.

Q:How does the ASTM D1002 test method relate to other adhesive test methods?

A:The ASTM D1002 test method is basically comparative, allowing the relative strengths among adhesives and can be related to other test standards such as ASTM D5868 and ASTM D3163, which function to determine adhesive performance with respect to environmental durability and adhesive strength in varying configurations.