ASTM D3574 is widely regarded as the industry standard testing procedure to assess performance and durability of flexible cellular urethane foams. The scope of this detailed testing procedure encompasses a series of tests designed to ascertain and measure the physical and mechanical properties of foam materials used in applications as varied as furniture and automotive seating to bedding and packaging. A thorough understanding of ASTM D3574 is required by manufacturers, quality control, and engineers who wish to certify that their products perform as intended with respect to reliability and functional efficacy.

In this article, the reader will journey into the purpose, methods, and significance of the ASTM D3574 testing program. After this extended discourse, one will be well-acquainted with the construction and amelioration of foam materials as governed by these standardized tests. Whether you are a novice in the testing of foams or speckled for advanced insights, this article is guaranteed to furnish you with information that will assist you in making the best choices for material selection and performance assessment.

Introduction to ASTM D3574

ASTM D3574 is a standard test method for determining the physical properties of flexible polyurethane foams. The test method comprises a series of tests that are presented to measure key performance characteristics such as indentation force deflection (IFD), tensile strength, tear resistance, and compression set. These tests must be conducted to assess the ability of the foam in terms of weathering, comfort, and a definite application with assurance of quality and worth workmanship in furniture, automobile, and bedding industries. ASTM D3574 forms the benchmark for manufacturers and researchers to get the mater performance tests done with a repeatable accuracy.

What is ASTM D3574?

ASTM D3574 is a set of standardized procedures approved by ASTM International to determine the physical properties of materials categorized as flexible cellular materials, such as polyurethane foams. The standard provides a full series of testing methods to measure density, resilience, indentation force deflection (IFD), tear strength, tensile strength, and compression set. The ASTM D3574 has been in use for decades to provide the foam manufacturer with a mechanism of assuring most consistent quality of foam engineered for a specific application.

Testing of materials is extremely important to industries which utilize these foam materials as cushioning and support in automotive, furniture, and bedding. The ASTM D3574 testing standards enable an effective evaluation of the performance of materials in different products and brands, allowing them to provide for durability and user satisfaction, and meeting the safety and regulatory stipulations. By this standard method, companies can establish standards in manufacturing to enhance foam performance both for consumer as well as commercial application.

Importance of ASTM D3574 in the Foam Industry

ASTM D3574 standardizes test codes for the physical properties of flexible polyurathane foam, allowing producers to manufacture products conforming to clear performance standards. The principal benefit derived from the standardization of ASTM D3574 is the promise that foams are consistent with respect to properties such as tensile strength, elongation, indentation force deflection (IFD), or tear resistance. This testing ensures high quality so that materials may find applications in furniture, automotive seating, and medical cushioning, among others.

This standard also enables ASTM D3574 to enhance manufacturing efficiency through providing a clear test concept for assessing foam performance under standardized conditions. This guarantees that the products upon delivery are reliable and can be conveniently compared between suppliers, a very important aspect towards making procurement decisions. Enforcement of standard will also guarantee that products meet regulatory and safety requirements in order that the products might be sold to the international market.

Overview of Flexible Cellular Urethane Foams

Flexible cellular urethane foams comprise a very important class of polymeric materials characterized by their lightweight, highly resilient structure. They are formed as a result of the reaction between polyols and isocyanates to form an open-cell structure, which provides cushioning, energy absorption, and thermal insulation. Flexible urethane foams find use in several industries, including the automotive industry, furniture, medical device manufacturing, and packaging, with each type being molded uniquely for specific applications. They have good aging characteristics, compressive strength, and resistance against normal wear and tear, while at the same time offering shock absorption. Improved formulations now enable even better performance, with the ability to fine-tune density, firmness, and other mechanical properties to meet the requirements of specific applications. Furthermore, environmental concerns have promoted the formulation of environmentally friendly foams with lower emissions, making them compliant with worldwide regulatory standards.

Test Methods in ASTM D3574

ASTM D3574 consists of numerous standardized test methods for determining the physical characteristics of flexible cellular materials, such as polyurethane foams. These tests cover various performance parameters concerning density, tensile strength, elongation, compression force deflection, and resilience. Selected methods include:

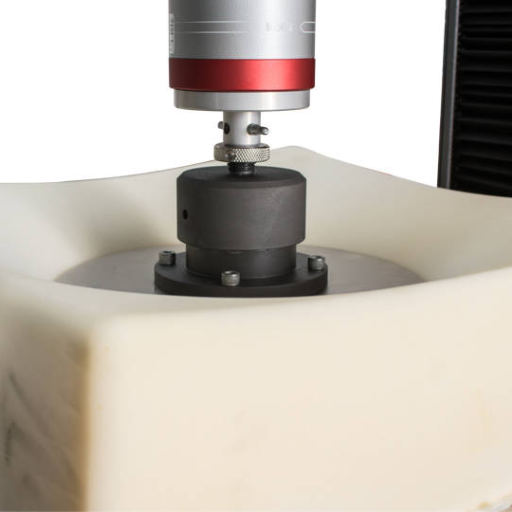

1.Test A: Indentation Force Deflection (IFD): This measures the force required to press a foam specimen to a certain percentage of its original thickness, providing indications of firmness and its ability to carry loads.

2.Test B: Compression Set: It determines the permanent deformation of a foam after being compressed under specified conditions and is very important in delineating long-term performance.

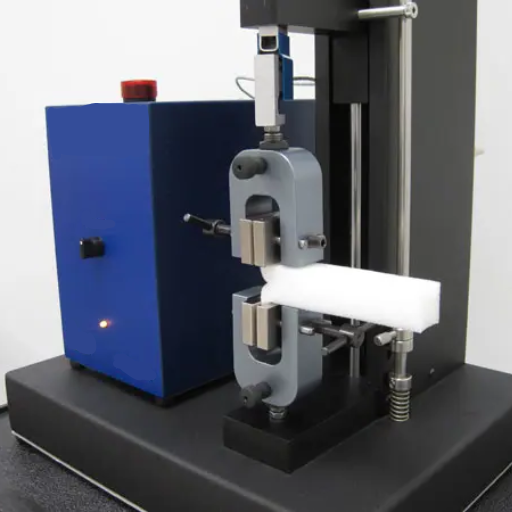

3.Test C: Tensile Strength and Elongation: It measures resistance to tension and the degree of elongation just prior to rupture, giving an indication of flexibility and cohesiveness.

4.Test D: Tear Resistance: It measures the force required to propagate a tear, showing the resistance of foam to mechanical damage.

5.Test E: Resilience/Impact Resilience: It measures the capacity for a foam to rebounce to its previous shape and to absorb shock energy during impact.

Together these methods offer a dependable way of comparing various formulations of foam and to ascertain that the foam meets all set performance criteria at the industrial level.

Standard Test Methods for Flexible Cellular Materials

Flexible cellular materials, which find applications from cushions to automotive components, should go through testing for their ability to perform, durability, and standard industrial conformance. Some of the commonly applied test methods, aligned with respective highest industry standards, are as follows:

1.Compression Set Testing (ASTM D3574-08) – This test measures the capability of the material to regain its thickness after being compressed for some specified time under controlled conditions. It treats shape retention and function so as to infer reliability in the long run.

2.Tensile Strength Testing (ASTM D3574-03) – It identifies the maximum stress the material may resist until fracture when tension is applied. It gives insight into mechanical strength and structural integrity, especially in applications where continuous stress is present.

3.Density Testing (ASTM D3574-17) – It determines the weight of foam per unit volume, which in turn affects load-bearing capability and comfort properties. Knowing the accurate density of foam guarantees the proper performance of each application in manufacturing.

4.Tear Resistance Testing (ISO 8067) – It determines the force that propagates a tear in the material, giving an insight into the material’s resistance to mechanical damage and wear suffered during use.

5.Resilience/Impact Resilience Testing (ASTM D3574-H) – It determines the capacity of foam to recover from being deformed and impact loading in a dynamic manner, thereby upholding its relevance to high impact yet cushioned applications such as automotive interiors.

The tests mentioned above are intended for thorough evaluation of flexible cellular materials to determine their quality, durability, and application-related functionality.

Detailed Examination of Tear Tests

The tear tests are used to determine and analyze tear resistance properties of flexible cellular materials under particular conditions. Tear resistance may be usually determined in a tensile testing machine that conforms to ASTM D624, which measures the force to propagate a tear in a standard specimen geometry. Therefore, these values can be used to evaluate material durability specifically when the product is subject to mechanical stresses or is flexed repeatedly. A material may be given its tear resistance by means of density, the cell structure, and formulation. Tear testing delivers directional strength variation data within a material so that weaknesses may be located and altered for better material performance in demanding environments.

Energy Loss Testing Procedures

This method of energy loss testing investigates the retention or dissipation of energy within a material under applied stress. In performing this test, we usually employ dynamic mechanical analysis (DMA) or other methods to measure such material properties as damping behavior and energy dissipation. These tests seek to tell just how resilient a material may be and what factors contribute to energy absorption or energy loss, such as internal friction, viscoelastic characteristics, and structure features. These test results thus guide us in tailoring material formulations for use in situations where energy efficiency and service life of material matter.

Applications of ASTM D3574 in Various Industries

1. Automotive Industry

ASTM D3574 has extensive use in the testing of foams for seating, insulation, and interior parts for automotive use. The tests are designed to demonstrate durability, comfort, and safety standards while maintaining weight and energy absorption characteristics important for vehicle performance.

2. Furniture and Bedding

A foam material is tested under ASTM D3574 by manufacturers of furniture and bedding for conformity with criteria for comfort, support, and durability. This standard is aimed at optimizing the performance of foams in mattresses, sofas, and chairs to meet consumer expectations and industry standards.

3. Packaging

In packaging, this standard would be employed to evaluate the protective properties of foam materials used in cushioning delicate articles during storage and transport. Compression set and resilience are the parameters that would be tested to ensure the foams serve as adequate shock absorbers.

4. Aerospace and Defense

The aerospace and defense industries employ ASTM D3574 to test their foams used in applications for seating, insulation, and protective equipment, ensuring the materials perform satisfactorily when exposed to extreme stress and environmental conditions.

Use in Furniture Manufacturing

ASTM D3574 remains relevant for the furniture industry, wherein quality performance and durability tests of flexible polyurethane foam for cushions, mattresses, and upholstered furniture are conducted. Methods to test such properties as indentation force deflection (IFD), tear resistance, and durability from repeated stress and compression set are addressed. The tests ensure that the foams are of the right degree of comfort, support, and longevity to meet consumer expectations as well as regulatory requirements for quality and safety. Manufacturers, by conforming to ASTM D3574, are able to ensure consistency of performance of their product, which in turn is helpful in design and optimization of the material.

Significance in Automotive Seating

ASTM D3574 plays a critical role in automotive seating with reductions on standardized methods for testing polyurethane foam, which is used in the seat cushion. It demands that the foams meet specifications in properties required of comfort, durability, and safety in an automotive application. In following ASTM D3574, manufacturers consider some key properties to sitiong quality, with respect to IFD and compression set, whereas enhancement of passenger satisfaction is an additional benefit. Also following this standard ensure that industry regulations are adhered to, which assist in the optimization of the seat design for long-term reliability and good performance.

Role in Mattress Production

ASTM D3574 remains relevant for mattress-making applications in which performance and durability tests are very deeply considered. By application of this Standard, I can go and test essential foam properties such as indentation force deflection (IFD), density, and compression set, among others, so as to rate support, comfort, and durability of potential mattresses that meet consumer satisfaction and regulatory requirements. Also, application of ASTM D3574 enables materials and design optimization for better pressure distribution and resilience, culminating in better sleep and reliable mattresses.

Benefits of Adhering to ASTM D3574 Standards

ASTM D3574 requirements give the manufacturers-for example, the foam manufacturers-a well-developed working framework for the assessment of foam properties to maintain uniformity with respect to quality and performance of the finished goods. Following ASTM D3574 helps a company meet regulations, ensure better reliability of material, and enhance customer satisfaction through comfort and durability. Hence, by virtue of ASTM D3574, foams are compared at an industrial level to be precisely benchmarked and innovated in foam technology.

Ensuring Quality and Durability

Quality and durability are guaranteed for foam products when manufacturers impose stringent quality controls throughout the production processes. This involves testing things such as tensile strength, density, and compression resistance of the materials to ensure that they are produced according to stipulated standards. Furthermore, manufacturers assure product reliability and longevity using advanced manufacturing technologies, continuous monitoring, and accepting applicable industry certifications such as ISO standards. By doing this, they come out with foam products that serve the intent functionally and satisfy the regulating requirements effectively.

Impact on Product Reliability

Foam products operate on their reliability, a result of strict test methodologies and adherence to industry standards. Depending on high-quality manufacturing, a material shall perform consistently across intended applications. The testing of tensile strength and compression resilience should be regarded as fundamental in ensuring that the foam would withstand long periods under stress. The existence of ISO certifications and adherence to them ensures the operation of some level of quality control against decision-making, which leads to failures of materials. Where quality control systems are coupled with advanced monitoring methods in the production phase, varying inconsistencies would be caught at an early stage and never allowed to degenerate into the supply channels of finished goods. When done rightly, these things contribute to greater reliability concerning the foam products and their capacity to perform during their service life.

Enhancing Customer Satisfaction

In order to best increase customer satisfaction, one needs to pay attention to quality, responsiveness, and innovation. Profiling on consistent adherence to all set standards and practices of quality assurance well assuredly builds trust and loyalty for the customers. The other significant thing would be to communicate effectively and provide a support service that deals with challenges without reservation. Furthermore, the company must learn from customers and upgrade products while aligning them with today’s market requirements to enable the customer to feel valued. These factors together will assure the organization of customer retention for a long time.

Common Questions About Running ASTM D3574 Tests

1. What is ASTM D3574?

ASTM D3574 constitutes a standard test method for the physical property testing of materials classified as flexible cellular materials, such as urethane foams. It is composed of various specific testing methods, including compression, tensile,’tear resistance,’ and indentation force deflection tests, altogether serving as a measure of the materials in terms of their durability and performance.

2. Why should one conduct ASTM D3574 testing?

These testing methods are crucial in determining whether a material is capable of meeting the required standards in mechanical specification and performance for cushioning, insulation, or seating applications. Manufacturers look forward to quality products and meeting industry standards by ensuring that they have tested according to ASTM D3574.

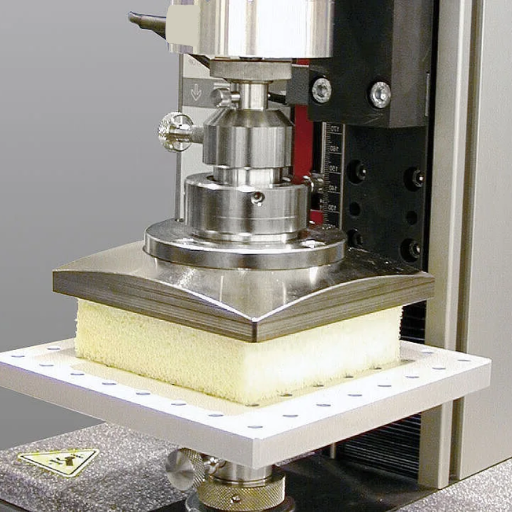

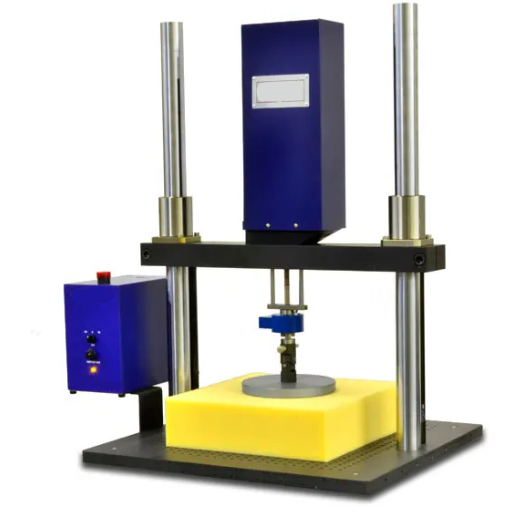

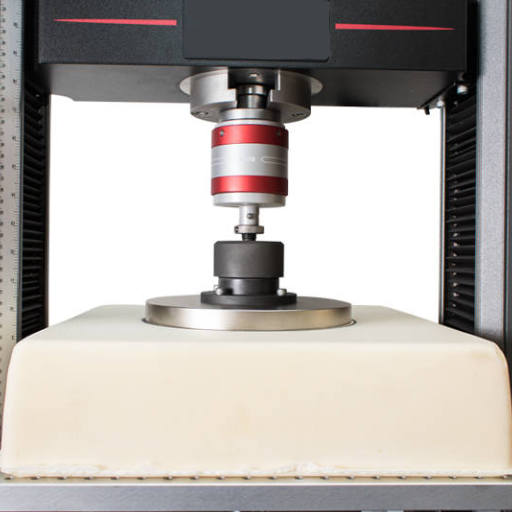

3. What test equipment is employed for ASTM-D3574 testing?

Typically, specialized equipment such as compression testing machines, tensile testing machines, and tear strength testing fixtures are used. All machines must comply with ASTM standards for accurate and consistent measurement or testing results.

4. How can test data from ASTM D3574 be analyzed?

Based on ASTM D3574, certain physical data concerning firmness, resilience, durability, and other such properties of the material are procured. A manufacturer uses the given data to indicate where and for what particular application certain materials need attention or improvement in a performance-based testing criterion.

Quick Questions About Running ASTM D3574

1. What are the main objectives of ASTM D3574?

The main objectives are to determine the physical properties of flexible polyurethane foams. These properties include indentation force deflection, tensile strength, tear resistance, and resilience, in order to ensure that the materials qualify for performance standards for a given application.

2. How is the testing done under ASTM D3574?

Testing is executed using standard procedures and instruments as being called for by ASTM. The test equipment may include a compression testing machine or tensile equipment. The material is subjected to mechanical operations that simulate real-life working conditions so that attributes of interest may be checked out.

3. Why is it important to follow ASTM specifications?

This is to assure that test results will be accurate, consistent, and reliable across all laboratories, thus providing manufacturers and end users with confidence in the performance and suitability of the material tested.

4. How should the test results of ASTM D3574 be interpreted?

The test results should be used to infer the firmness, mechanical strength, and resilience of the foam. On the basis of this data, manufacturers can decide whether the material meets design requirements or if it must be changed in order to achieve better quality.

Clarifying the Testing Process

ASTM D3574 includes several standardized procedures for assessing the properties of flexible cellular materials such as polyurethane foams. Some of the key tests include IFD, tensile strength, elongation, and tear resistance. These tests offer essential information on how the materials behave under compression forces, tensile forces, and tearing forces. The IFD test, for instance, checks the density or firmness of foams, finding the force required to compress the material to a specified percentage of its original thickness.

Test conditions are carefully controlled to ensure accuracy, with temperature and humidity cited as particular factors. Great care in sample preparation should be taken as alteration in sample size or shape may lead to significant differences in results. These results are then referred to industry or application-related standards to check for compliance. The interpretation of results in a logical manner then leads to alterations in foam manufacturing to meet given application considerations.

Challenges in Foam Testing and Solutions

Consistency or uniformity in test conditions is one of the top issues; just slight changes in temperature, humidity, or pressure will alter the results. I ensure that the test environments are very controlled and standardized according to industry recommendations to nullify this factor. Differences among foam samples form another problem that tends to give disparity in performance data; I very specifically prepare my samples and apply standard dimensions to all my test specimens. Another problematic scenario is the analysis of results for new or somewhat changed applications; to address this, I append consulting current benchmarks in the industry-use and apply sophisticated analytical tools to provide a more precise analysis for the respective use. Thus, through my intervention, I ensure that most obstacles are tackled and achieved reliable and repeatable testing results.

Reference Sources

-

ZwickRoell: ASTM D3574 Flexible Foam Testing – Provides an overview of the standard and its applications in evaluating physical and mechanical properties of flexible foams.

-

TestResources: ASTM D3574 Testing Equipment – Discusses the test standard and the variety of foam samples it applies to, including slab, bonded, and molded forms.

-

Instron: ASTM D3574 Testing Solutions – Details the 18 different mechanical tests included in ASTM D3574, such as compressive, tensile, and tear resistance tests.

-

ADMET: ASTM D3574 C Foam Force Deflection Testing – Focuses on specific sections of the standard, like compression force measurement.

-

Professional Testing: ASTM D3574 Flexible Material Test Overview – Offers a comprehensive overview of the 16 different foam tests outlined in the standard, covering elasticity, tensile strength, resilience, and more.

Frequently Asked Questions (FAQ)

Q:What is ASTM D3574?

A:ASTM D3574 is a set of standard test methods that determine the procedure for testing flexible cellular materials, mainly molded urethane foams. It provides how to test having a certain set of physical properties that foam specimens must fulfill for consistency in testing.

Q:How does ASTM D3574 describe the testing system?

A:The testing system outlined in ASTM D3574 comprises a number of test methods such as Test A, B1, C, and F for the evaluation of different properties of molded flexible cellular materials, with separate procedures for getting accurate results for a thorough evaluation of the foam’s characteristics.

Q:What are the key properties evaluated in ASTM D3574?

A:Some properties evaluated include density, compression resistance, and fatigue characteristics, and all of those properties are strongly determining the behavior of molded urethane foams toward various applications in life.

Q:What is the significance of the lower compression platen in ASTM D3574?

A:As for ASTM D3574, the lower compression platen of the testing equipment sets a measured force onto the foam specimen so that the response of the foam to compression can be measured. This is crucial for performance testing.

Q:How are the test methods applicable to molded flexible cellular materials?

A:As the test methods under ASTM D3574 are designed for molded flexible cellular materials, relevancy and utility of data are ensured. These standard methods are used in evaluating various properties of foams, hence applicable to various types of molded urethane foams.

Q:What is the procedure before conducting ASTM D3574?

A:Before conducting the ASTM D3574, the foam specimen must be prepared to comply with the specifications specified in the standard, i.e., ensuring that the sample is cut to the specified dimensions and that it is conditioned under the specified temperature and humidity conditions before testing for accurate results.

Q:What is involved in ASTM D3574 Test F?

A:ASTM D3574 Test F is a fatigue test that measures the capacity of molded urethane foams to resist repeated compressive deformation and hence the time of service of the foam.

Q:How do the test methods provide a standard for testing?

A:These test methods give a standard for testing by ensuring that the evaluation procedures and criteria used are uniform for molded urethane foams, so that the results obtained by these test methods can be compared between the different laboratories in which they may be employed or applied.

Q:Can ASTM D3574 be used for the testing of other types of foams?

A:While ASTM D3574 is essentially intended for molded flexible cellular materials, there might be test methods therein that can be applied to other types of foams, as long as the foams satisfy the criteria in the standard. One should therefore see the relevant ASTM publication to seek guidance on the suitability of the tests for any specific type of foam.