For comprehending the mechanical properties of metallic substances, ASTM E9 is still a significant standard for researchers, engineers, and manufacturers. The guideline delineates a precise framework for performing compression tests at room temperature, which provides major inputs regarding the material’s behavior under compressive forces. By the way, ASTM E9 is the one that guarantees the strength testing of alloys used in critical infrastructural areas or the assessment of the longevity of parts for sophisticated machinery by providing uniformity and trustworthiness in your testing process. The article will go through the basic notions of compression testing, the necessity of adhering to ASTM E9, and the standard’s usefulness in different fields. Ultimately, you will be given a transparent insight into the reason for this test being vital for the performance and quality assurance of metallic materials. Get ready to see how exact testing can break new ground in material science and engineering!

Introduction to ASTM E9

What is ASTM E9?

ASTM E9 is a standard developed by ASTM International that specifies the procedures for the compression testing of metallic materials. This standard covers the different factors that influence the results of compressive tests, namely: procedure, equipment, and environment, in detail. By following these standards, engineers and researchers will be able to produce data that is both accurate and reproducible, thus guaranteeing trustworthy assessments of the material.

ASTM E9’s main objective is to assess the behavior of a material upon application of compressive forces. The specific properties to be tested are deformation, yield strength, and ultimate strength. This information is vital for materials’ applications that will be subjected to compressive forces, such as structural components, load-bearing systems, and manufacturing processes. Moreover, ASTM E9 provides testing procedures suitable for preventing inconsistencies due to wrong test setups and thus ensuring the production of reliable results.

ASTM E9 must be followed as this will assist the industries in maintaining their quality standards and in guaranteeing the safety of their products. The standard does not only advocates for standard testing practices but also plays a role in the comparison of materials and their qualification for particular applications. The standard’s significance in the field of materials science indicates the necessity for accuracy in testing and sticking to the accepted guidelines.

The Importance of Compression Testing

Testing under compression is a decisive test for materials’ mechanical characteristics under compressive loads. It indicates the way the material is going to act when the forces that try to reduce its size or its deformation are applied. This kind of testing offers a lot of useful data like compressive strength, yield strength, and deformation behavior that are necessary for the material’s suitability assessment for specific applications. The knowledge of these properties guarantees that the engineers and manufacturers will be able to design products with good performance and longevity.

The main advantage of compression testing is that it helps the industry to discover the limits of the materials. It is ensured that the materials will not fail in their practical loads during the lifetime of the product. For instance, in the case of construction, the testing of compression is very crucial for determining the strength of concrete and metals that are used for building and infrastructure. In the same way, for the packaging industry, it is very useful in determining the endurance of materials under stacking or shipping conditions. Thus, the selection and application of materials will be much safer and efficient, with the risks involved in the process and the reliability of the materials being improved.

In addition, compression testing plays a role in quality control and adherence to the set standards. By following the standardized testing methods, the different industries can assure that the performance of the materials is consistent throughout the different batches. This is especially true in cases where safety and reliability are of utmost importance, like in the manufacturing of aerospace, automotive, and medical equipment. Compression testing does not only confirms the specifications of the materials but also assures that the products are in compliance with the regulations, thus, creating trust and reliance on both manufacturers and consumers.

Scope of the Standard

The ASTM E9 standard has been approved by ASTM International as a method for testing metallic materials in compression at room temperature to characterize their behavior when applied with compressive forces. By means of the standard, the main mechanical properties of the materials like yield strength, ultimate compressive strength, and modulus of elasticity, are determined. It is a standard that applies to many industries where the performance of materials under compression is a matter of great concern, such as aerospace, automotive, construction, and medical fields.

The specifications that the ASTM E9 test method provides are for specimen preparation, test equipment, and test procedures to maintain the accuracy and reproducibility of results. It also specifies the nature of the specimens, which have to be of uniform cross-section, and surface defects are not allowed. The standard also says that proper machine alignment during the test is crucial in order not to introduce bending stresses that could lead to distorted results. The data that come out from the ASTM E9 tests are very important for quality assurance, material selection, and even the development of new alloys that are specifically designed to meet the strict performance criteria.

Via its accurate methodology, ASTM E9 gives the manufacturers and engineers the trustworthy data they require to fulfill the regulatory and safety requirements and thus, make sure that the materials are up for the mechanical challenges of their intended applications. Its wide range of applicability to different types of metallic materials is a clear indication of its significance in the continuous advancement of innovation and the maintenance of industry standards worldwide.

Understanding Compression Testing of Metallic Materials

Definition and Purpose

Compression testing of metallic materials is a testing technique that reveals three things: the solo behavior of the material under an applied compressive force, its strength, and its mechanical properties. The test is intended to find out the material’s reaction to such conditions as squeezing, crushing or compression. This is very important for those applications where metallic parts are to be exposed to compressive loads without breaking or deforming beyond the usual limits.

In this process, the applicator steadily increases the compressive force on the material sample till it yields, breaks, or is deformed a certain amount. The compressive strength, elastic limit and deformability are the parameters that the process measures. The outcome of these tests is also useful in providing data to engineers and researchers, who assess the material’s fitness for a wide range of industrial applications, by means of its compliance with safety and performance standards under stresses of compression.

The major benefit of compression testing is that it gives the necessary data for designing various components like, for instance, structural supports, fasteners, or pressure vessels. Thus it is to be ensured that the materials can withstand the mechanical demands under real-world conditions with a good margin of safety. Ultimately, this test facilitates the creation of metals that are strong, dependable, and capable of high performance in less demanding situations. Furthermore, it spans the industries of construction, aerospace, and automobile engineering etc.

Types of Metallic Materials Tested

Metallic materials of various kinds are tested in different industries to confirm that they possess the required characteristics like strength, durability, and being reliable. Steel and aluminum are two of the most commonly tested metals; both are versatile and have a wide variety of applications. Steel, which encompasses both carbon and alloy variants, is often put through the tests due to its high tensile strength and suitability for the construction of different structures. The metal aluminum, which has the property of being light in weight and also being resistant to corrosion, is often subjected to testing in different industries such as aerospace, construction, and transportation.

Copper is one of the metals that are regularly tested alongside its alloys like brass and bronze, which are appreciated for their ability to conduct electricity, be easily shaped, and resist corrosion. These metals are commonly used in electrical systems, plumbing, and manufacturing. Just the same, titanium which stands to be one of the most tested materials is in the limelight of the aerospace and medical industries due to its great strength-to-weight ratio, biocompatibility, and ability to survive in harsh conditions.

Another point to note is that less available but essential metals like nickel, magnesium, and zinc are also under testing. Nickel and its alloys will, therefore, be the subject of tests where high-temperature conditions prevail, like in jet engines or industrial furnaces, while magnesium will be tested as a lightweight structural component suitable in the automotive and aerospace industries. Zinc is initially intended for galvanization, through testing its ability to protect other metals against corrosion is ensured. A wide variety of metallic materials exist, and their testing serves as a reminder of the critical role rigorous testing processes play that are specifically tailored to the requirements of each industry.

Applications of Compression Testing

Testing for compression is considered as a prerequisite in different industries to get the proper understanding of the mechanical property of a material when subjected to compressive loads. The tests done through compression also guarantee that the materials will be able to (forces) applied without the risk of performance (in terms of quality) and safety standards being breached. The highlighting points of compression testing can be observed in the following applications:

Construction Industry

Measuring the strength of materials like concrete, cement, bricks, and stones is one of the main purposes of compression testing. For instance, the testing of concrete is necessary to know whether heavy loads, like those of the building itself, are being supported or not. Furthermore, for the residential area, concrete has a compressive strength of about 3,000 to 7,000 psi; however, performance concrete, becoming increasingly popular in construction for bridges and high-rise buildings, may even go beyond 10,000 psi.

Automotive Industry

Testing is done to check how well different components manage to endure (and resist) compressive forces during collisions, besides, crash-resistant materials are included, engine blocks, and suspension systems, etc. The modern-day automobile industry is focusing on using advanced lightweight materials like carbon fiber composites and magnesium alloys has made the compression testing very strict.

Aerospace Industry

Different aircraft components suffer a lot of compressive stress during takeoff, landing, and flight. Some of the components include wings, fuselage structures, and landing gear. The so-called disintegration testing of titanium alloys and high-strength aluminum composites is done under stringent conditions to ensure that they can stand up to fatigue and safety requirements.

Packaging Industry

The compression test is the main one to check the durability of ancillary materials comprising corrugated board, shipping containers, and plastic bottles. To illustrate, edge crush testing (ECT) for corrugated boxes is a measure of their strength in stacking, and a typical value for ECT of medium standard boxes is 32 pounds per inch.

Medical Devices

Indirect-to-product-test activities are taking place throughout the production of biomaterials and components, such as prosthetics, stents, and implants, where they have their safety is assured through means of testing. In this regard, the forces that are to be imposed on prosthetics, for instance, will be of a compressive nature and considerable in magnitude.

Energy Sector

The compression test remains the main determinant of the technical quality of materials that are used in wind turbines, pipelines, and oil drilling. One of the commonest ways of meeting this demand from the pipeline is through the testing equipment, which proves that the pipe can withstand the compressive forces created by the external pressure and the movement below the surface.

The perennially evolving nature of testing and their equipment, including computerized systems and elaborate data acquisition software, results in more accurate simulation of real-world conditions. Compression testing is still one of the indispensable tools that carry the message of material behavior under stress being crucial for safety and innovation across various industries.

Standard Test Methods of Compression

Overview of ASTM E9 Test Methods

The ASTM E9 test methods provide a clear standard for the performance of compressive tests on metals and other materials at ambient temperature. These methods will show the characteristics of materials under compressive stress and provide consistent and reliable data for research, development, and quality control applications. By using the ASTM E9 methods, scientists and engineers can determine the characteristics of the material such as compressive strength, yield point, and the flow of the material.

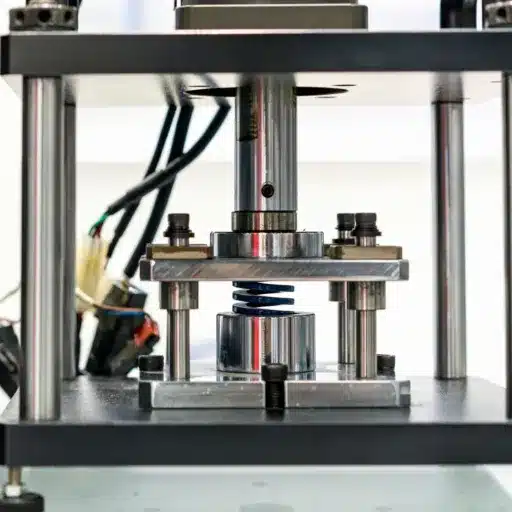

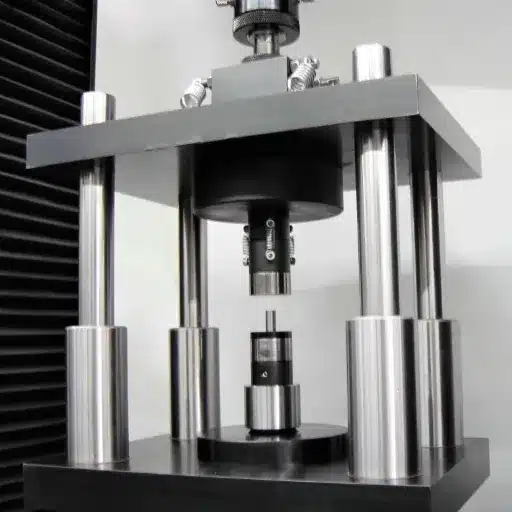

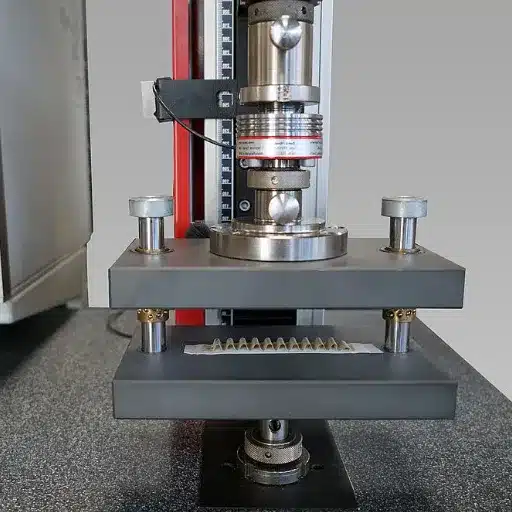

The test methods need the application of a compressive force to the metallic specimen by the use of standardized equipment. The specimen must be of the specified geometry, either cylindrical or rectangular to ensure accurate results. The compressive force and the amount of displacement are measured, and a stress-strain curve is generated, which reveals the mechanical behavior of the material under compression.

The ASTM E9 standards are accepted in the construction, aerospace, and automotive industries for material verification and checking the integrity of structures. By following these methods, uniformity in testing approaches is maintained, which reduces variations and facilitates easy comparison of results from different labs or projects. These methods are very significant in the process of making sure that the materials are capable of enduring the demands of their future uses.

Testing Procedures and Protocols

Curtailing the performance, reliability, and safety of Tracing the material remained a standard Testing Procedures and Protocols through the entire process. The procedures provide a common ground where every experiment can be equally accepted across the board of various industries and applications. The procedures have setup a range of conditions such as the testing environment, parameters, and finally the accurate documentation of results, to uphold the reliability and traceability.

Testing protocols one of the important aspects, is material testing, which measures properties like tensile strength, hardness, durability, and thermal resistance. These tests if properly conducted,d will ascertain if the material fits the specifications for its intended use. The testing standards which are usually provided by international bodies like ASTM and ISO, are followed through these processes, which make results valid and comparable no matter where the testing is done.

The compliance with these protocols is vital for the quality control and safety of the materials during production and utilization. If manufacturers and engineers use standardized testing practices, they will not only be able to detect potential flaws early in the process but also prevent material failures and optimize performance. The result of these methodologies is that the products will meet regulatory requirements while also being trusted for their reliability and effectiveness.

Calibration of Testing Equipment

Calibration of testing equipment is a step of critical importance towards the accuracy and reliability of the testing results. It involves measuring the values of a device and comparing them to a standard or known reference to identify any discrepancies. This procedure is necessary for consistency to be kept, especially in industries where accuracy is crucial, such as manufacturing, aerospace, and healthcare.

Hand in hand with proper calibration goes the reduction of measurement errors and the assurance that testing equipment will be in accordance with the established standards. Through regular calibration, the performance of the materials and products in their respective application is not only assured but also safety requirements met. More so, it indicates wear and tear on equipment, thereby giving rise to the possibility of timely maintenance or replacement which finally results in lower downtime and greater efficiency across the board.

The accomplishment of a successful calibration is such that organizations must stick to the standard methods and schedules as prescribed by regulatory bodies or industry norms. The keeping of regular records of calibration results is also a must in order to monitor performance over time and prove compliance in the event of audits. Calibration should be an area of focus for organizations as they not only keep the quality of their products up to par but also gain the trust of clients and stakeholders.

Room Temperature Considerations

Significance of Room Temperature in Testing

Room temperature is testing procedures’ most important factor since it has a direct effect on the accuracy, reliability, and consistency of the test results. A vast majority of the materials, devices, and systems can be very much influenced by temperature changes. Therefore, any deviations from the defined room temperature conditions can lead to a change in their behavior or performance. Room temperature, when kept stable, minimizes variations that could introduce errors during testing and thus ensures more reliable results.

The temperature consistency makes it possible to simulate the conditions of the market, where products and systems would most likely be used. In this way, the test environment is very close to the operational scenarios, which helps to understand how the materials or devices will perform in the conditions of the user’s typical use. Moreover, the prescribed temperature range has to be kept in order to ensure compliance with the international standards and regulatory requirements, which often impose certain environmental controls during the testing processes.

Room temperature considerations are also factors that help in the reproducibility of the testing procedures. Uniform temperature conditions under which the tests are conducted enable more effective comparison of the results, whether in terms of quality control, research purposes, or audits. Without such control, it becomes significantly more difficult to determine whether the changes in performance are attributable to the product’s defect or just to the inconsistency of the test environment. Therefore, stressing the need for room temperature management assures quality testing outcomes across different fields.

Effects of Temperature on Material Properties

Temperature significantly impacts the behavior and properties of materials, altering their structural integrity, mechanical performance, and overall functionality. When materials are exposed to fluctuating temperatures, their thermal expansion, melting points, and elasticity can change. For example, metals typically expand when heated and contract upon cooling, a property that engineers must carefully consider in designing structures like bridges or machinery.

One key material to analyze in this context is steel. At room temperature, steel maintains a high level of strength and durability. However, as the temperature rises above 1,100°F (593°C), steel begins to lose roughly 50% of its strength, and at around 1,800°F (982°C), it can lose up to 90% of its strength. This is why temperature resistance is critical in industries like construction and manufacturing.

On the other hand, plastics display a very different response. Thermoplastic materials soften when heated, which can lead to deformation or loss of mechanical properties. The glass transition temperature (Tg) is a crucial threshold for polymers; for example, polycarbonate has a Tg of approximately 147°C (297°F), beyond which its rigidity diminishes.

Ceramics and other high-performance materials, however, often thrive under extreme thermal conditions. Advanced ceramic composites can withstand temperatures higher than 2,000°C and are thus used in aerospace applications, such as in heat shields for spacecraft.

Understanding temperature effects on materials is crucial for optimizing their performance in real-world applications. Regular testing at controlled temperatures allows researchers to gather reliable data, ensuring materials are well-suited for their intended environment and use cases.

Maintaining Temperature Control During Tests

Material testing processes demand accurate and dependable results, which can only be provided through effective temperature control. The most reliable way to attain this is by the use of noticeable temperature-chambers or furnaces in laboratories, able to provide steady and thorough conditions. These systems have great care taken in calibrating to give stable environments while minimizing fluctuations that can lead to the rejection of test results.

The use of strong sensors like thermocouples and resistance temperature detectors (RTDs) enables continuous temperature monitoring during the whole testing process. This rapid detection of any deviation ensures immediate corrective action. Also, deploying multiple sensors over different points of the test chamber, leads to even higher measurements, especially for those materials that are very much affected by thermal gradients.

Apart from that, keeping up with the documentation and following testing protocols, like ASTM standards, support further the temperature control in tests. Regular equipment performance checks and maintenance schedules ensure technology compliance and reliability. Thus, by the application of such techniques, researchers can assess material properties accurately and also determine their appropriateness for certain applications.

Historical Context and Evolution of ASTM E9

Development of ASTM Standards

Material testing has greatly profited from the establishment of ASTM E9 standards. The standards were set up by ASTM International, which was the original name of the American Society for Testing and Materials, to say nothing of the unification and precision in the evaluation of material properties under compression procedures. The compression testing regulation for metallic materials is specifically covered by ASTM E9, which gives direction on specimen preparation, testing apparatus, and the proper procedures that will produce results that are both repeatable and reliable.

The ASTM E9 standard over the years has been revised in tune with technological progress and new industry demands. It presently utilizes the state-of-the-art technologies, e.g., the latest methodologies and equipment specifications, to enhance the accuracy of the results and to be in line with the material science practices of today. The updates are vital because they allow the use of the latest materials and mechanical properties which are more common in modern engineering and construction, therefore, they are widely in demand.

With the global acceptance of ASTM E9, one can believe that there will be uniformity all over the world – in laboratories, industries, and even in the use of these materials. It is a public understanding of material performance data that the standard guarantees. It is very easy to compare test results accurately when researchers and engineers follow this standard, besides verifying the quality of materials and guiding the innovation of materials for specific environments or load conditions. The common framework all over the world highlights the necessity of common standards in the improvement of both research and practical uses in material sciences.

Key Revisions and Updates to ASTM E9

Recently, the revision of ASTM E9 hasbeen initiated to facilitate and promote the use of affective and consistent practices in the compression testing of metallic materials by means of new, more accurate and tighter guidelines. Such updates will open up a whole new world of accurate measurements and consistent tests all over the different laboratories and industries that use these standards. Deciding precisely what was meant by those very words, how to perform the respective activities, and determining the use of contemporary testing technologies and methodologies have all been the activities the standard has been going through while keeping its charms of lucidity and reliability intact.

Preparation of specimens is another area that has been significantly affected by the revision. The new specifications include very clear and comprehensive descriptions of the permissible specimen’s geometry and the finish on its surface, which factors in a large extent the lowering of variability in test results. The whole idea behind this is that since all the materials tested will be subjected to the same conditions, the results will be more easily compared and thus the standard’s trustworthiness will be restored.

A focus on environmental testing conditions was introduced lastly. The revised standard demands the correct handling and recording of ambient conditions e.g. temperature and humidity, in order for the material performance to be minimally influenced by the environment. These updates bring the standard closer to the current industry’s needs, thus recognizing the demand for reliable and reproducible data in material science applications.

Impact on Industry Practices

By the updates to the standard, the industry practices are considerably affected because they improve the reliability and precision of the testing methods. The stricter regulations regarding the ambient conditions like temperature and humidity, have now obliged the companies to open up the cycle of investment in controlled environments so that they can obtain the same results all the time. This in turn has led to the manufacturers, researchers, and end-users who depend on accurate data to be the ultimate beneficiaries of the improved reproducibility in material performance evaluations.

To the manufacturers, the revised standard means a stronger quality control process. Following the more stringent testing procedures lowers the likelihood of product failures and raises consumer confidence. This is especially true for the sectors where materials have to comply with very high performance standards, such as construction, aerospace, and automotive. When companies manage to get their testing processes up to the updated regulations, they can better position themselves in the market.

Researchers and testing labs have also rise to power with these changes. The control of the environment more so than ever promotes accurate experimentation and the breakthroughs in material science. The accurate data is a wing to new ideas and is a catalyst for inter-sector cooperation. The standard ensures the consistency of testing procedures and thus, unifies the industry’s efforts and accelerates the world’s sharing of materials and technology.

Frequently Asked Questions (FAQ)

Q: What is ASTM E9?

A: ASTM E9 is considered the standard test method having the maximum use and application for metallic materials testing and is limited to compression testing at room temperature, and it also contains the deformations of the materials e.g. yield strength and compressive strength.

Q: What are the main objectives of ASTM E9?

A: The main objectives of ASTM E9 consist of providing standardized test methods for the characterization of compressive properties of metallic materials, the safety of applications involving compression, and data that engineers and designers can trust to be accurate.

Q: How does the compression test according to ASTM E9 work?

A: The compression test according to ASTM E9 procedure involves the application of a force that compresses a sample until it breaks or deforms. The stress-strain curve that results from this test is then examined to identify the properties of the material such as yield strength, compressive strength, and Young’s modulus.

Q: What types of materials can be tested using ASTM E9?

A: ASTM E9 can test a wide range of metallic materials that are characterized as ductile or brittle. It is very much applicable to the cases where the material could either fail by crushing or undergo a large compressive deformation during processes like forging and rolling.

Q: What is a stress-strain curve and why is it important in ASTM E9?

A: The stress-strain curve is a visual explanation of how the stress correlates with the strain during the conduct of a compression test, and is an important aspect in ASTM E9 because it allows the determination of mechanical properties of the material, including yield point, the modulus of elasticity and the ultimate strength.

Q: What equipment is required for conducting a compression test according to ASTM E9?

A: The testing apparatus has to meet ASTM E9 specifications which outline the necessary equipment used for conducting compression tests. This comprises of a universal testing machine with features for controlled application of compressive load and measuring the associated deformation.

Q: How does one ensure the accuracy of results when performing ASTM E9 tests?

A: To guarantee accuracy, it is a must for the ASTM E9 users to regularly calibrate their equipment and observe the testing conditions including specimen preparation and environmental factors; thus, keeping alignment of the specimen and applying load uniformly are also necessary for the desired results to be reliable.

Q: What safety considerations should be taken into account during ASTM E9 testing?

A: Among the safety measures during ASTM E9 testing is to make sure that the testing equipment is stable and that such equipment would not lead to accidents in case of failure, and secondly, the users should wear personal protective equipment that is suitable and also be knowledgeable about the hazards of the materials being tested.

Q: Can ASTM E9 test methods be applied to non-metallic materials?

A: ASTM E9 is strictly for metallic materials. If there is a need to test non-metallic materials, then different standards and test methods, respectively, would apply, as their mechanical behavior under compression may vary considerably from that of metals.

References

- ASTM Official Website: Standard Test Methods of Compression Testing of Metallic Materials (ASTM E9-09) – Provides details on apparatus, specimens, and procedures for axial-load compression testing.

- ASTM Store: ASTM E9 Standard – Offers the official standard document for purchase and reference.

- MTS Systems Corporation: ASTM E9: Compression Testing of Metallic Materials – Explains the application of ASTM E9 in determining mechanical material properties.

- ATS Labs: ASTM E9 Overview – Discusses the standard’s role in evaluating material properties like compression strength.

- ASTM Official Website: ASTM E9-19 Standard – Covers updated guidelines for axial-force compression testing of metallic materials.